russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

Rob: I live on the Mississippi Gulf Coast. Same humidity. It happens. I have not had a huge problem with my rigging here in the house since we have central HVAC, but I have seen it happen in certain cases. . Sometimes, giving the line a decent stretch before using will help. Nothing too drastic, but a moderate stretch. Russ

-

Pat: Thanks. Little by little it is moving along. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Nice work. Congratulations on a beautiful completed model. Russ

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Welcome. That is a good kit. Glad to see you get back to it. Have fun. Russ

-

Not sure what kind of line you used. It may have needed a stretch prior to use. It may be that humidity might be part of the problem. Not sure what it is. However, the model as a whole is looking good. Russ

-

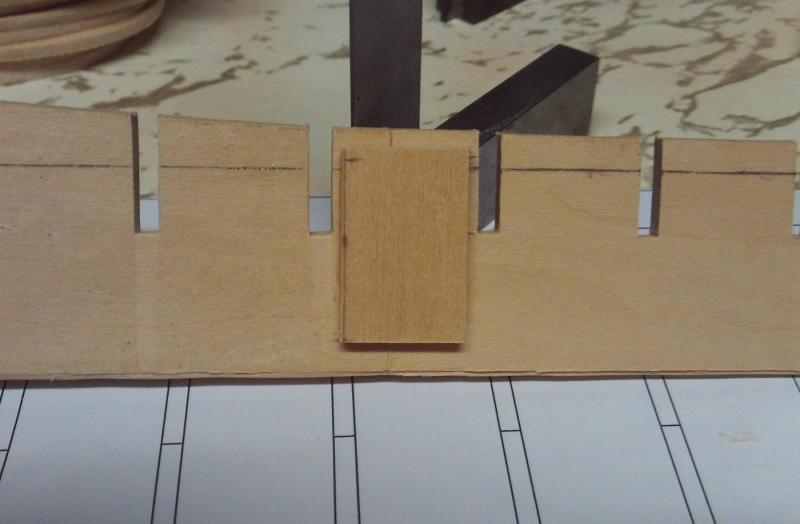

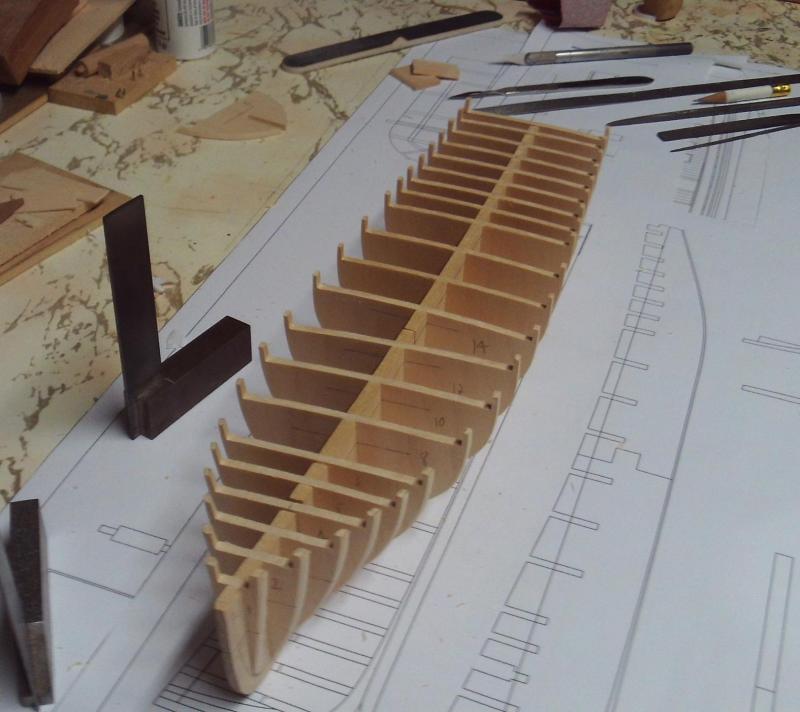

Some more progress. The two pieces of the profile former have been glued together and the reinforcing spline attached to one side. Once the keel, stem, and sternpost have been attached, the other side of the profile former will get a reinforcing piece as well. The stem has been shaped and glued on, and the deadwood and sternpost have been attached to the keel. The profile former is nice and straight so I am glad I made it in two pieces. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Down here, we used both terms in the late 19th and early 20th century. Barge schooners and scow schooners. Not sure if there was much if any difference though. I have records and photographs of several of our local scow schooners. One day I hope to model one of them. Russ

-

Bob: Your rigging is always so accurate and clean looking. I hope to be able to come close to your level of detail one day. Russ

-

Very nice effect. I look forward to seeing how it looks on the model. Russ

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

These are just awesome. The more I look, the more I like. Great colors, details, and appearance. Congratulations on a couple of fine finished scale models. Russ

-

Beautiful work. Great attention to scale and detail. The overall ambience is really good. Russ

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

Sometimes the eye can pick something out even when measurements tell us it is okay. If your hands and eyes tell you it is even, then go with that. Russ

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Looks pretty good so far. I think once you get the deck planked and a little progress on fittings etc, anything that is really bugging you will fall back into the perspective of the entire model and not be very obvious. Russ

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

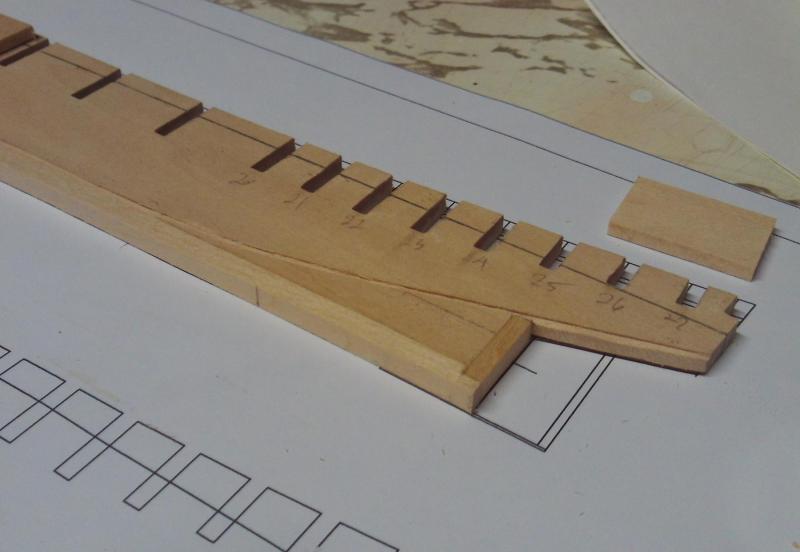

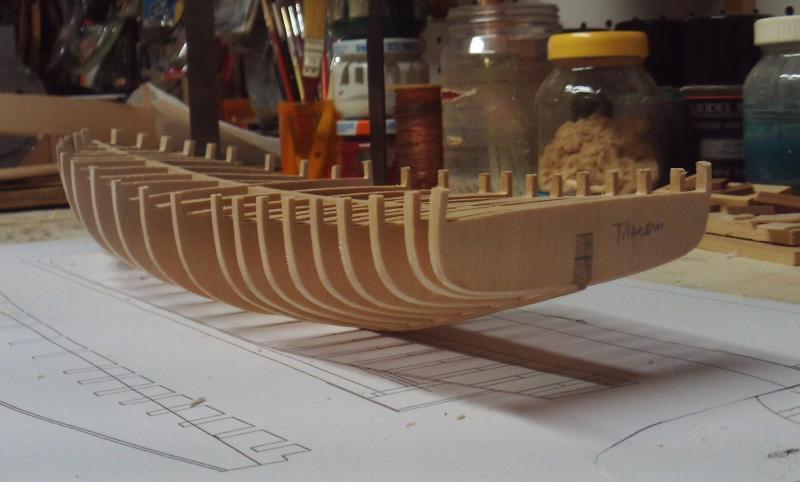

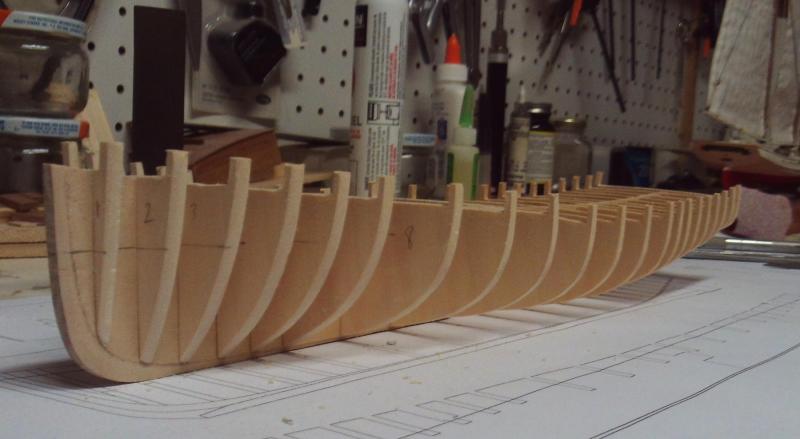

Popeye: Thanks. There are 28 bulkhead frames, including the transom. I had to keep telling myself to take it easy sanding the bevels. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

John: Thanks. I once said I would never build anything that did not have sails. But the lines on some of these luggers are nice. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Pat: Thanks. Wait till she is planked. Glad to have you along for the ride. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

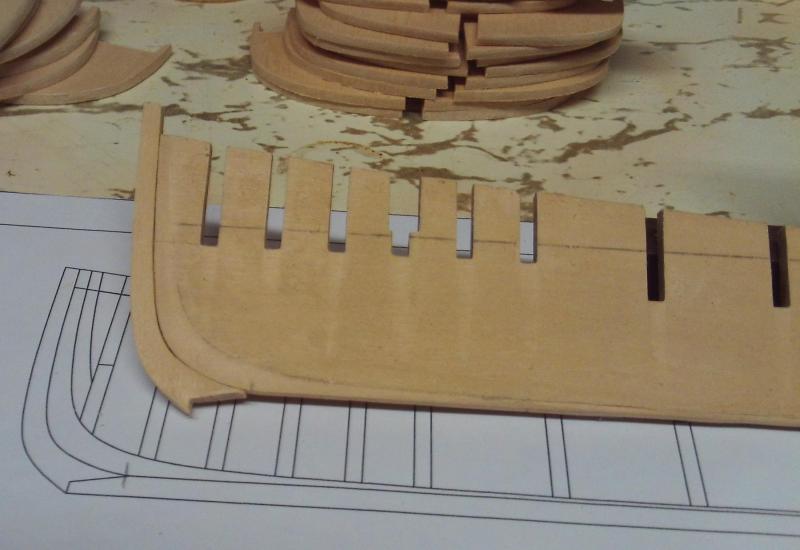

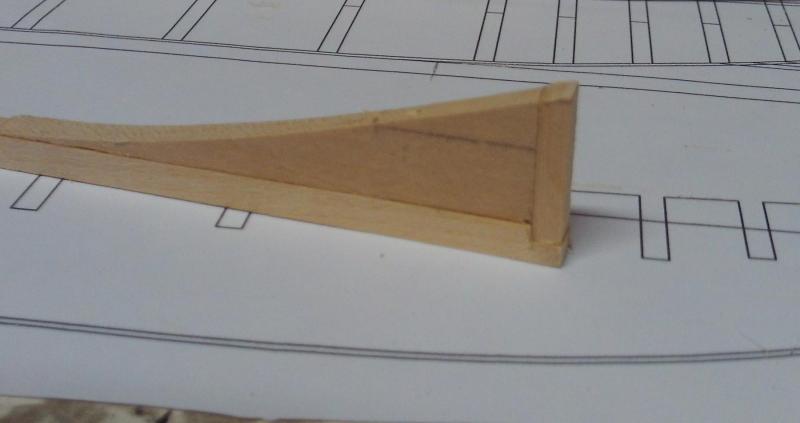

Marcus: Yes, she has very fine lines approaching the bow and very full from the midsection on back. Very typical of local boats. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Thanks. I am very pleased thus far. This makes me glad I went to the trouble to really fair the hull in the drafting process. There is nothing like an accurate plan to save time and trouble when building the model. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

She looks great. I really like the name plate. The model is its case is awesome. Congratulations again. Russ

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

The bulkhead frames have all been cut, sanded to shape, and fitted to the profile former. Nothing is glued yet. Everything is dry fitted at this point. So far everything looks good. The hull form is starting to come together. The components were cut on a scroll saw and then the shaping was done with files and sandpaper. So far there is about 20 hours of cutting and shaping for the entire framework of the hull. Still some work to go before I can open the glue bottle. Russ

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Walnut if not really a good choice. It tends to have an open, coarse grain pattern unsuitable for scale modeling. It can be brittle and difficult to manage in any case. I would recommend you get some basswood sheets from the local hobby or craft store. They are inexpensive and the they cut easily. You can paint or stain basswood. Staining basswood requires a pre stain conditioner or sanding sealer to ensure that the wood will absorb stain evenly. Painting basswood is not a problem, although water based paints will raise the grain and require some sanding and several thin coats to get a good finish. However, basswood will be a lot easier to deal with than walnut in my experience. Russ

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.