russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

I use a number 2 pencil rubbed along the edge of the planks before they are installed. I place a penciled edge against a plain edge and the result is a thin line to represent caulking. It is not overdone, and has a decent scale appearance. You can see it in my current project where I just recently completed the deck planking. Russ

-

The Fair American was a real ship. The Annapolis model upon which the Model Shipways kit is based may or may not be that ship. As for the companionway, if you want to make a new one it will need to be up against the cabin bulkhead just like the existing door. The difference might be that the new door could be taller than the cabin bulkhead. On the real ship, the cabin deck was probably a bit lower than the main deck, sort of a half deck aft of the main deck. Thus you open that short door and step down into the cabin. There is not an absolute need for a larger door. Russ

-

Once you get the height of the bulwarks settled, your idea of planking both inside and outside will work. So long as the planking is not too thick, the width of the rail can cover it all and no one will be the wiser. Just remember that you still have the stanchions to deal with and their upper ends should come under the railing. Russ

-

Using a false deck

russ replied to Poppi's topic in Building, Framing, Planking and plating a ships hull and deck

I used a false deck on my current project and it made planking the deck much easier. Not strictly historically accurate, but easier. The two things you need to consider are 1. the thickness of the deck overall. If your deck is supposed to say 1/16" thick, then your false deck needs to be 1/32" thick and then the deck planking 1/32" thick. You do not want to raise the deck up too high. This will cause problems with the model's appearance. 2. the false deck material. You need something stable that will not crack or split on you. Plywood is a good choice. You can get plywood down to 1/64" thick, so there should not be a problem getting it. You can break the false deck into sections. It does not have to be laid as a single piece. Breaking it into sections will make it easier to fit. The seams do not have to be perfect either since you will plank over them. Hope this helps. Russ -

Pat: The new bowsprit looks good to my eye. The rigging line looks good as well. I cannot see any fuzz on the lines in the photos. Nice work. Russ

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Very well done. Congratulations on an excellent model. Russ

- 52 replies

-

- swift

- artesania latina

-

(and 2 more)

Tagged with:

-

Here is a photograph from the 1920s showing one type of chainplate arrangement for a local schooner. Note the cap over the edge of the rail. My deadeye strap will be greatly simplified for the current model, but in the future I plan to build a plank on frame version at 1/24 scale which will incorporate this kind of deadeye strap. Russ

-

Dave: Thanks very much for the suggestion, but mine have to be cut in from outside of the railing and then have the cap placed over the edge of the railing. That is a well known local method that shows in many old photos. I just need to be more careful in my use of the file. Nice work on your model, by the by. Russ

-

James Lees' The Masting and Rigging of English Ships of War 1625-1860 is a good reference for both mast making and rigging diameters. I have used it and Steel's Elements of Mastmaking, Sailmaking and Rigging. Steel has tables for various size ships in the back. Lees has several pages of proportions, all based off of the ship's max breadth.

-

Your capstan assembly looks very good. Very nice work indeed. Russ

- 601 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

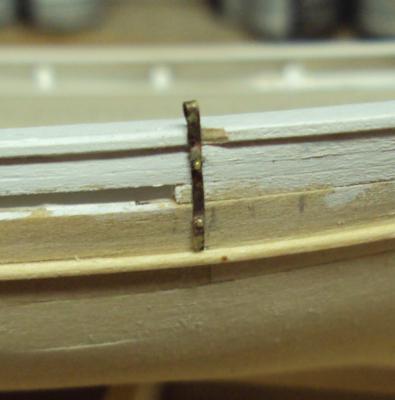

More progress tonight. Now that the deck is planked, the next thing will be the deadeyes and chainplates. My first pass at these was ... bad. Really bad. So, I decided to reengineer the chainplates a bit. Hopefully, this attempt will be better. The important issue is scale. The lower deadeyes and chainplates will all be painted white, but they need to appear in scale. That means everything has to be smaller than what I am used to working with. The chainplate is a simple strap with a loop soldered into its top end. However, there needs to be at least two fastenings for the strap into the hull. At this size and scale, that is a problem. The brass nails I have in stock are too large. So, I have made the strap with its loop and then drilled two holes in the strap into which two pieces of brass wire were soldered. The outer edges of each wire was trimmed and left just proud of the strap to appear like bolt heads. The wires go into the holes in the side of the hull. I will probably add a dab of CA to secure them. Even without glue, they are snug in their holes, but the CA should give some strength as well. Here are some pics. I still need to clean up the shape of the strap, but it should look okay once the hull is painted. There will be a wooden cap over the edge of the rail hiding that tear out along the edge of the rail. The strap is about 1/32" wide and the holes for the wires are .018" diameter. Questions and comments welcomed. Russ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.