russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

The masts look good. In that first photo, I almost thought you had the shrouds on the model instead of the drawing. Russ

- 127 replies

-

- model shipways

- syren

-

(and 1 more)

Tagged with:

-

I understand what you meant, however, the title of the thread might mislead those who are expecting to see an actual jig saw rather than a table saw. Russ

-

The stand looks good. I think the brass pedestals are the right call. The oak finished very well. Good work. Russ

- 127 replies

-

- model shipways

- syren

-

(and 1 more)

Tagged with:

-

Michael: That looks great. Very nice assembly. Russ

- 2,215 replies

-

If I understand correctly, you are not sure why scale is an issue? In a scale model, everything on the model, all the parts of the model, are as close as possible to the model's scale. If the model is 1.96 scale, that means that the entire model, parts and all, is 1/96 the size of the real ship. It would spoil the appearance of the model to have the hull be 1/96 scale, but the deck planks be wide enough for a 1/48 scale model. Or to have the windlass or the belaying pins at twice their size. The idea is that the deck planks, windlass belaying pins etc all should be at that same 1/96 scale as the rest of the model That is the short version of the importance of scale. I hope that helps. Russ

-

Yes, the owner of Model Expo is a member here. Check the Traders and Dealers forum and you will see him there as he posts about the latest sales all the time. Russ

-

Actually, this is a table saw. A jig saw is a hand held motorized saw to cut shapes. Russ

-

Pawl posts were very common. I agree with John that a post set in front of the windlass might be a better solution. Russ

- 2,215 replies

-

Harvey: Down here, what you describe would be a skeg with a shaft log. A skeg is the same as the regular deadwood, with the exception that the frames are mounted on the top of the skeg rather than fastened to its outer faces. See my current build. The skeg is a series of pieces built up just as deadwood would be built up. The difference is that it is outside of the hull rather than inside. Russ

-

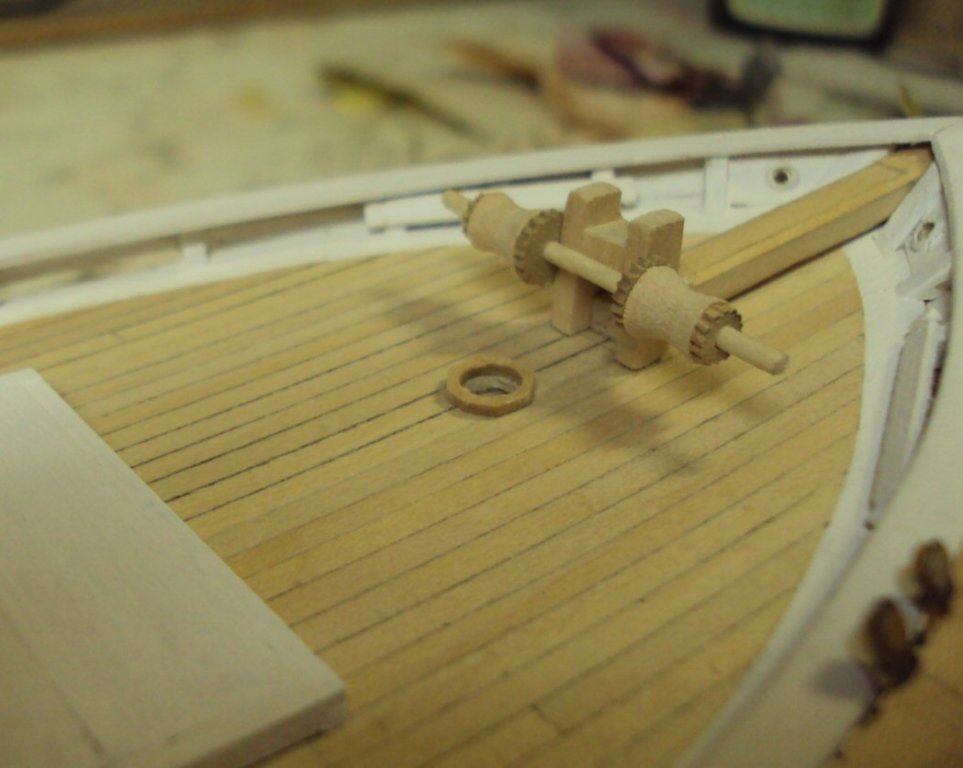

Druxey: Interesting question. I have two sources for what this should look like. One group of sources are contemporary photos of local schooners. There are very few that show enough of this sort of detail to even begin to guess what it looks like. The other source is Chapelle's field notes that are included in the second half of his American Fishing Schooners, 1825-1935. His detail drawings for the windlasses used by Grand Banks fishermen show a more complicated version of what was used down here. It has a purchase rim with teeth along its outer edge that engages the purchase arm that is operated from a lever attached to a single bitt. This is very much like what you would find on a mid 19th century merchant vessel. In this case, we have a set of teeth that are engaged by a simple iron pawl on either side of the bitts. What the rim with the teeth looks like I am not sure, but this will be hidden in between the warping head and the bitts. All you will see is the warping head and the teeth up against the bitts with the pawl engaging the teeth. That is all my sources show me so far. It may well be that the rim with the teeth for my schooner is much like that shown in Chapelle's drawings, but I have no way to know. If you have a drawing of the type of arrangement you are thinking of, I would be glad to see it. Russ

-

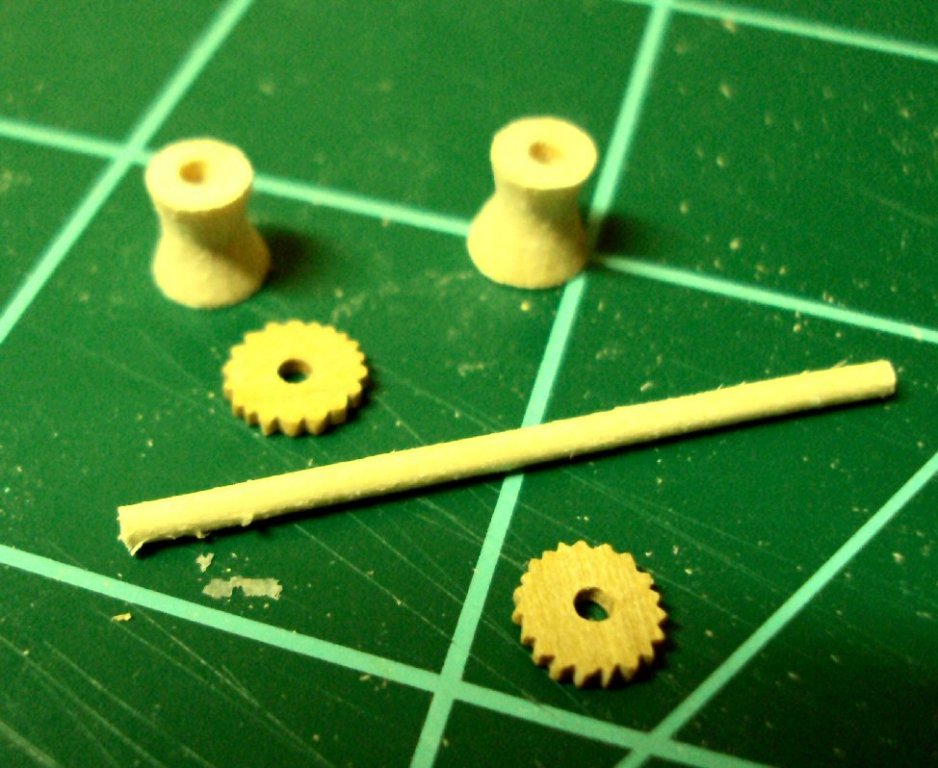

Here is a little more progress. I decided to break up the pace a bit and work on some deck furniture. Here is the windlass so far. It is a relatively simple assembly, compared with Grand Banks fishing schooners. Here is a photo of an actual windlass from the schooner Marie Foster circa 1920s. Questions and comments welcomed Russ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.