-

Posts

225 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Angarfather

-

Hello Dimitris , Gianna is in German Hanna. Well, and thats my wifes name. Kindly Angarvater

- 67 replies

-

Thanks! @Sjors I think, that I will finish the Gianna in spring. Next time I have to made blocks. 120 pieces. That's not my favourite job. Kindly Angarfather

- 67 replies

-

Only the shrouds of the mizzenmast are rigged with deadeyes. The shrouds are served Kindly Angarfather

- 67 replies

-

Masts The masts of a pinco are made from one treestem. One peace. Non problem to make this on the turninglathe. The mastheads with the sheaveholes are quadrangle. This form can be sanded well on the millingmachine drilling and milling the sheaveholes. drilling in the holes for the fixingpoints of the cleats Foremast Mainmast Regards Hartmut

- 67 replies

-

Mayflower by SawdustDave - Finished

Angarfather replied to SawdustDave's topic in - Build logs for subjects built 1751 - 1800

Congratulation! What a nice idea, and what a perfect shop sign! Cheers Hartmut -

Thanks, Nils, Yes, gianna get's sails. Two sets. One latin, and one squaresails. Next week my wife will sew the sails. She is a perfect tailor herself, and I am very clumsy in needlework. Hartmut

- 67 replies

-

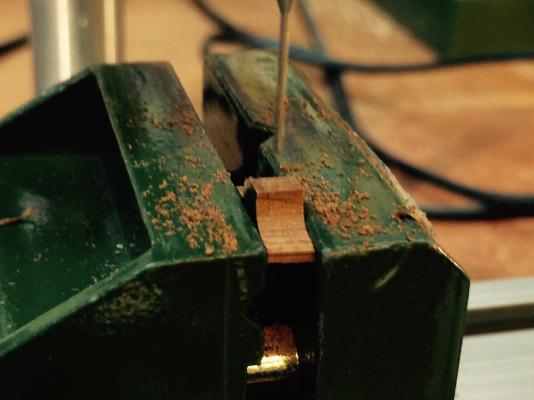

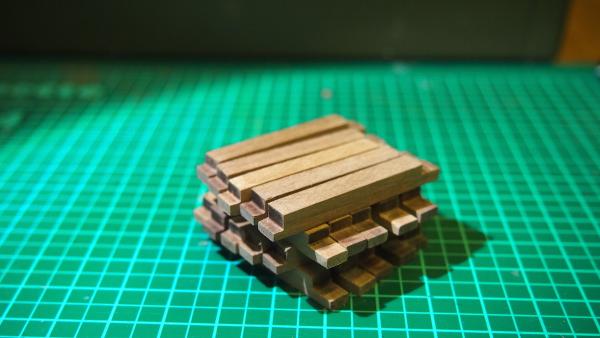

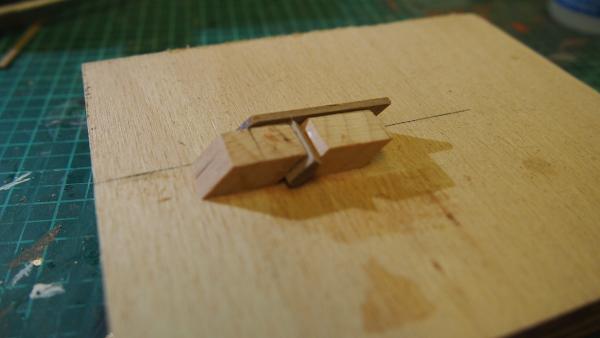

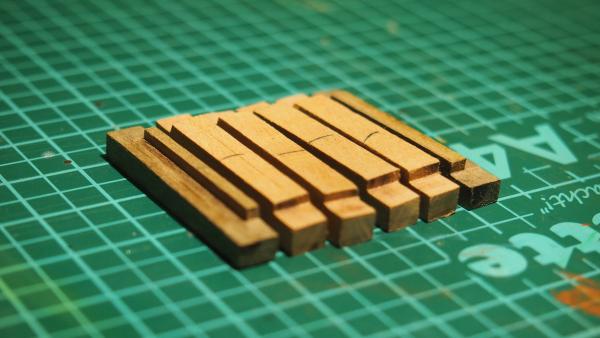

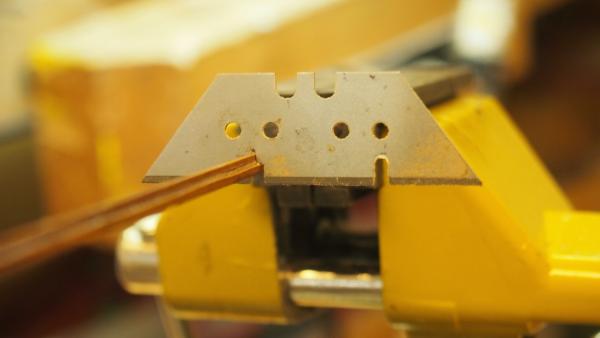

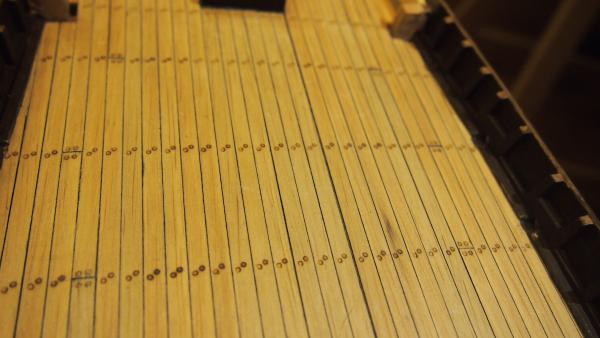

Thanks, John. I use distemper colours. These colors can be thined well. However, there are some small problems with the surface, as it is watercolor. I had to make nearly 50 cleats for this little ship. And that's may way to do this. First I have made a squarebar. Than milling the profile. Thats the result, a profilbar. Thereafter cutting with the circular saw I attach the cleats with glue and a nail in a centerhole. Drilling in the centerhole Now just grind a bit, and the first cleat is ready Angarfather

- 67 replies

-

Ahoy Sjors! I wish you a good and sucsessfull New Year. about rigging the cannons: now you know why I didn't build the Vic.:-) best regards Angarfather

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

- 67 replies

-

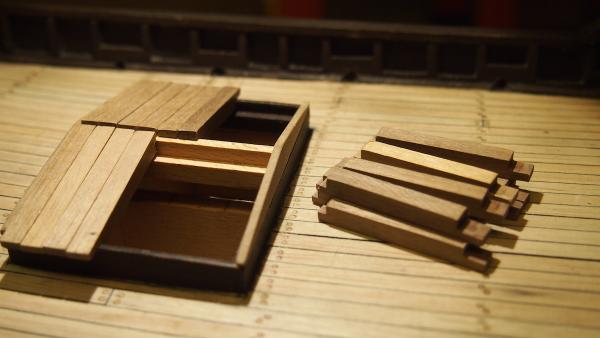

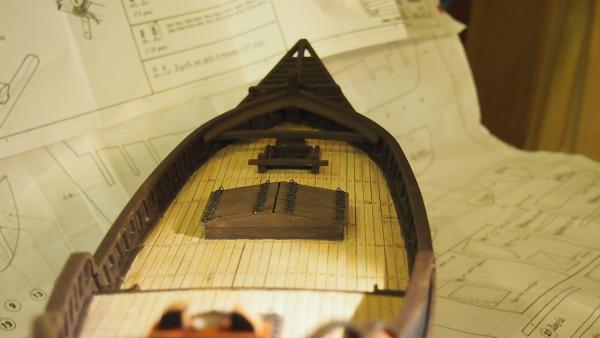

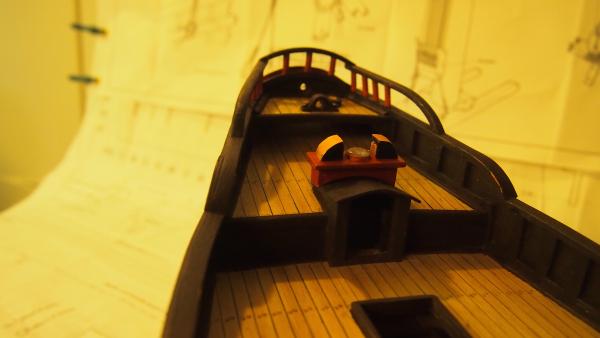

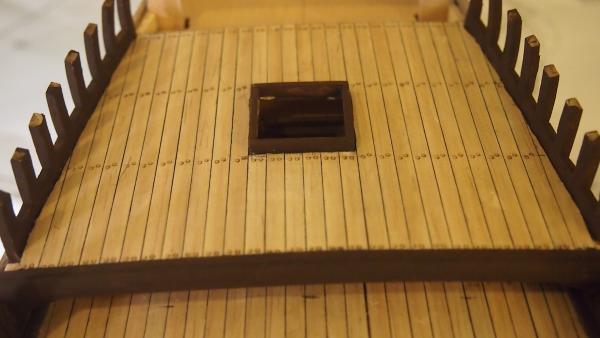

I have made the grips from 0,7mm black ironwire ( bindingwire from a floristshop). All together 12 pieces for the quaterdeckhatch and 40 for the cargohatch. The ready quarterdeck hatch. The cargo hatch on maindeck Milling the planks Ready A Happy New Year 2015 to all. Cheers! Hartmut

- 67 replies

-

Hi mates! thanks ! @: S.Coleman To show the nails I use this little device: two cutted hypodermic needles in the top of a soldering iron to burn in the covering of the nails. Kindly Hartmut

- 67 replies

-

Hi, one question. Is it ok to show how I make such little things like a ladder, or isn't it interesting? Things like this: There are 6 little laders on pincos deck. Every with only to stairs. I think it's more easy to make this parts with a jig. The laders in place Another new little piece. The kabinedoor This evening I thought how to make the cover of the hatchway on quarterdeck. The span width is only 1m /3,3". So I made the coverbeams like a roof. The way: the parts after milling the covering of the hatch. than sanding the "roofs" I think that will be ok Next step will be modelling the grasps - eybolds with rings - kindly Hartmut

- 67 replies

-

HMS Royal William by kay

Angarfather replied to kay's topic in - Build logs for subjects built 1501 - 1750

Hello Kay; an absolut marvelous piece of work! kindly Hartmut -

Thanks mates!!! Giannas stern decorations are finished now. Naturaly, when al the wood work will be done, there will be some refinishing operation, in the coloured or goldareas. regards Hartmut

- 67 replies

-

Sjors! call me an old romantic if you like, but I can just image myself standing on the balcony around time of the dog-watches sipping some Madeira whilst watching the wake stream away into the distant sunset. Very well done. Best regards Hartmut

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

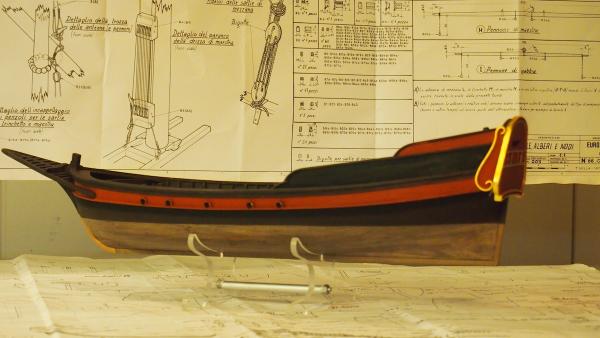

Part 5 It's the first time that I have to carve decorations. My first akantus pieces and than the next parts with leaf gold and in place. That's my pinco today. Last but not least : I belive that a ship must have a name. Her name is Gianna - and that's in german Hanna. Cheers Hartmut

- 67 replies

-

Part 4 The decoration of the transom was a interesting area. First problem was the framing. I wasn't able to make it from wood. But the solution was to make it from 2mm soldering wire. In a vice I formed it into a fourcorner. Some shots after painting the hull. I use distemper coulors. Tar = van Dyck brown decorationareas = english red rails are black. The frames of the transion and the decoration = leaf gold

- 67 replies

-

- 67 replies

-

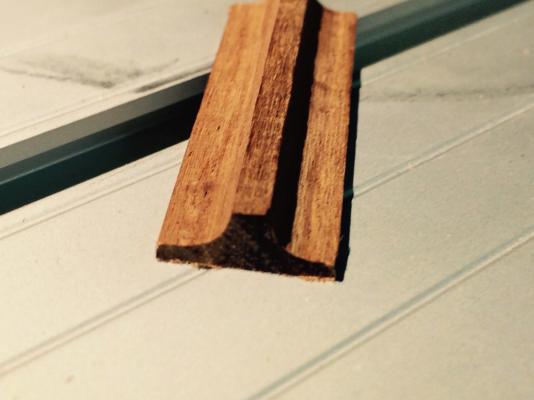

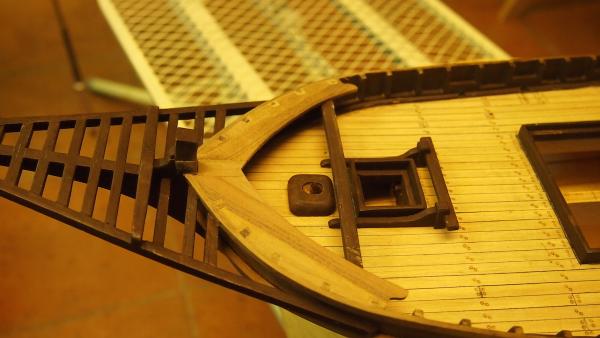

Part 2 The Gallion I think that the wood of a sail ship from the early 18.century was protected by tar. The guys in the International Maritime Museum, Hamburg told me, that this tar was not black but dark brown. And so I take "Van Dyck Brown" for this job, as I have seen the ships in the paintings of Rembrandt and van Dyck. To cover the wales I scratched an angle trim. That had been a very fiddely job, for the 2*3mm wallnutbeams are very sensible under progress. The skupperports are from 9mm Ramin. To make these parts was not a difficult job: first drilling the 5mm whole, than cutting into 2,5mm slides, some sanding - ready.

- 67 replies

-

After many years of useing kits as the base for modelling, I started my first scratch model. Therefor I have choosed a smal ship, not a big one like my HMS Agamemnon. On the Mediterranean took place since the end of the 17th century two particularly fast, lean and sharply built sailing vessels whose hull was probably developed from the galley and the caravel: a native of Venice Galeotte and Xebec. The warships of Geneva and Venice, and also well known as the ships of the northern African pirates. At the same time Pinco was the typical merchant ship in the Mediterranean. In principle, a Xebec. However, not so fast, lean and sharply built, but with a good load carrying capacity. Typical of these ships was the double rigging. In good weather latin sails. In bad weather square rigged. I like this Mediterranean ships, and last but not least at the stern of the Pinco are not so much decorations. I have never before carved such ornaments, but I will do my very best. I began the build August 15. by the plans from Euro Modell Como. Before I started the first planking, it was necessary to make the transition in the forecastle completed. After the first planking I do not get off there. I have made the first planking in a special way. 3mm plywood strips are glued between the bulkheads. The bow and stern sections are filled with balsa. After sanding is the result a strong base for the second planking Second planking is made from wallnut After mounting the hatches on maindeck planking was the next step. I didn't find any information how the scuppers are to be made, and where there position is. And this is my solution: after reinforcing the bulwark at the positions, drilling in the scuppers.

- 67 replies

-

very fine and very nice work! Hartmut

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Saettia Genoese by maurino

Angarfather replied to maurino's topic in - Subjects built Up to and including 1500 AD

Hi Mauro! thanks for sharing your photo. merry Christmas to you and all yours Hartmut

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.