-

Posts

3,867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by KeithAug

-

-

I thought I would carry on with the production runs by starting to make the turnbuckles - the body components are fairly straightforward so I thought I would start with the end brackets. I wanted to make them uniform so parting them off from a pre-shaped billet seemed to be the way to go. I needed therefore to do a bit of planning to get the machining sequences right. I started with a roughed out design.

I had some .125" by .500" brass bar which I decided would form the basis of the end brackets, a row of brackets being cut from each edge. The finished brackets being .1" x .125" x .200" maximum dimensions.

The through holes for the retaining pins (.040" dia) were all pre machined into the bar before slots were cut along the thin sides using a .030wide slitting saw. Holding the bar for the slitting operation involved a bit of head scratching but in the end I improvised a clamp using an upside-down lathe tool post with the workpiece held in the tool clamp. The slices out of the corner of the tool post were made by a previous owner - honestly!

It worked reasonably well - nice clean and uniform cut.

The bar was then hacksawed down the middle and end milled to the finished height.

I then hand filed the rounded end shape and polished the strip on the buffing wheel. Finally the individual brackets were parted off from the strip.

I then made the treaded rod using .050" wire. I quickly became board with hand screw cutting - mannnnnnny rotations per inch.

So I improvised and stuck the rod in the lathe and finish it in a few seconds.

I don't really know why I bothered as the threads were virtually impossible to see with the naked eye.

-

Nils / John / Richard - thank you.

Today:- A quick paint job followed by a day of small part production.

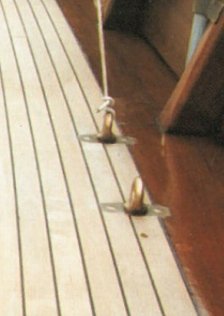

The deck is festooned with deck eyes - over 50 in total - today I made all of them.

I wanted to sort out a relatively straightforward way of reproducing consistent version of the mounting foot. The sketch gives the details.

I decided to make the mounting foot out of 1/4" brass bar, drilled with a central hole and then thinned to .100" on the mill. The feet were then sliced off .020" thick using a .025" slitting saw, again mounted in the mill.

I then polished each one by hand on a 400 grit diamond stone followed by hand polishing using polishing compound on a MDF board. I now have no skin left on the ends of my fingers but at least I won't leave finger prints when pulling off my next heist.

I have seen tools for forming eyes but I don't have one - so it was down to hand production using round nose pliers.

in passing I notice the various spars lined up on the deck and thought they made an interesting collection.

-

Nils

You seem to make progress very quickly. Do you spend a lot of time on the build or are you training for the model making olympics?

- Chasseur, Mirabell61, Omega1234 and 1 other

-

4

4

-

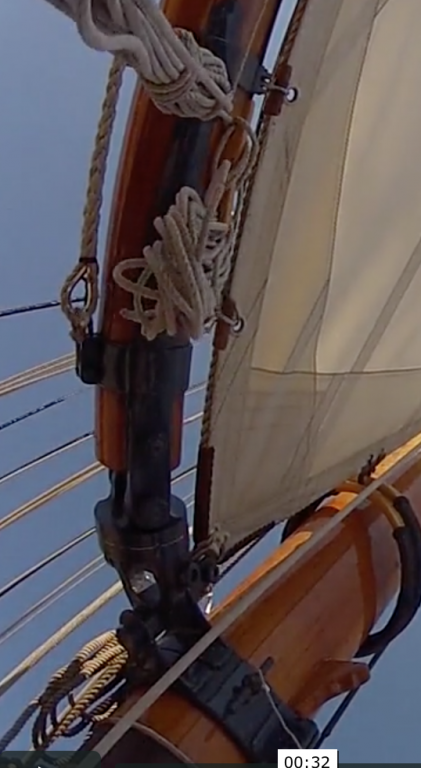

After a few days away I got back to the workshop late yesterday afternoon and commenced the last phase of making the foresail boom and gaff and the staysail boom. The latter item isn't always deployed and I find a lot of photos with it omitted from the sailing rig. Both conditions can be seen in the next 2 photos.

I think she looks more interesting with it fitted and this is the way I will go.

I made and mounted the various wooden appendages:- Most are .080" wide to give an idea of scale

I also made and installed the .035" wide sheaves.

This time the track went on easily. Wonderful what taking a little care will achieve.

The gaff saddle was also finished with the stirrup installed.

For some light relief I went back to the yards and made the lights, GPS antenna, beacon etc. The lights are cut down LED's. I decided not to have working LED lights. I find I hardly ever switch them on and the batteries rot away and make a mess.

The antenna / beacon will be painted white.

- tadheus, Mirabell61, Nirvana and 4 others

-

7

7

-

Don

Re Bristol Pilot Cutter kit, this may be of interest http://www.kingstonmouldings.co.uk/products.html

- popeye the sailor, Piet and mtaylor

-

3

3

-

Greg, thanks for the feedback and the doggy advice.

Michael & John. Thank you for your continuing intrerest and comments.

Richard. The problem with the track was all of my own making, I was a bit pushed for time so I was rushing. A case of more haste less speed. I had a look at frets on the web and they do look like an interesting resource for the future. The fret domed top wasn't quite what I was looking for as I don't think the flat bottom / sharp edge will work well with the slider design I have in mind -

I did the riveting like this - nothing special really.

-

Thank you Richard, for both the build and dog compliments.

Thank you Per, and I'll give the bone trick a try.

I continue to make progress on the booms and gaffs.

The foremast boom and gaff have all their machining complete, the straps for the mast attachments etc are made and riveted in place and the track and rubbing strips are cut and glued with CA. Various wooden fittings (pulleys etc) have yet to be made and fitted. I found the track fitting to be quite a challenge - for some reason it kept going on "squint" and I had to apply heat to break the bond and try again. I did it 3 times in the end - not a good day.

The straps were cut from .030" sheet - using a slitting saw on the mill to get them accurate. they are 0.1" wide.

The gaff with straps riveted in place and the rubbing strips inserted:-

Making the saddle - the soldering clamps work great. Soldering was done using a butane torch.

Finally a few views of the various bits. The dressmakers pins give a feel for the size.

- mcpwilk, Erebus and Terror, BANYAN and 8 others

-

11

11

-

I seem to be in rather a repetitive phase of the build. Having completed the main boom and gaff I started on 3 similar elements, the foresail boom and gaff and the staysail boom.

All were turned from mahogany dowel.

The only fairly unique part was the attachment for the staysail boom. This is a bracket that sits at the base on the foremast stay.

I decided to cut this out of flat brass bar - initially a bit of milling followed by shaping with a piercing saw, hand filing and machine polishing. The bracket is just under 0.3" long.

The mating bracket on the boom was turned on the lathe and slotted on the mill.

The foresail boom and gaff end fittings are at a very early stage of production. The wire holding the bracket in place is a "wondering part controller".

My helper is starting to develop very bad habits. I settle her down in the lounge and sneak off to the workshop. After about 15 minutes she notices I am missing and comes with her ball to retrieve me. I am then forced into 10 minutes ball throwing before I escape once again. This has happened 4 times today and it is very disruptive.

- GrantGoodale, robnbill, tadheus and 6 others

-

9

9

-

Martin

Nice work. I know earlier you rejected the idea of artificially deepening the keel to improve the sailing characteristics. Like you I like the hull to be true to scale and I hope your decision proves workable. The other area of departure from scale that is usually built in to scale sailing models is in the size of the rudder, working models having much broader rudders. This is a compromise easily made as the sailing and display rudders can be made to interchange. You may get away with it but if you design in interchangeability it could be a worthy investment.

-

Dan,

Thank you. Its easier when you are working at larger scales. I am equally impressed by builders like yourself that manage to create detail at much smaller scales.

-

Tom,

Thank you for taking the time to look at my log. The topping lift on Altair runs from the base of the mast to the head of the lower mast and then down to a position 2/3 way along the boom. I don't believe that the slack line below the boom is the topping lift.

JD.

I did 30 weeks of machine training at the start of my engineering apprenticeship in 1969. We got a good grounding in turning, milling, grinding, casting, fitting, sheet metal work and metal forming. I then didn't use the skills seriously until I retired in 2012 when I bought a small Lathe and mill. Fortunately I had remembered the basics from 43 years before. So no I am not a jeweller but thank you for the compliment.

-

-

Nils, reference "no models in the living area of the house"

have you you thought about convincing your other half of the benefits of reducing the occupied areas.

1 less cleaning

2 less heating

3 less space to attract unwanted visitors

If you start the brainwashing now in a decade or so she will believe it was her idea all the time.

As my wife ocassionally looks at my posts I will have to delete this thread in case she gets ideas about display location bans.

- Piet, Mirabell61, Eddie and 2 others

-

5

5

-

Hi Pawel

Have you tried modelling the fire for an added touch of realism?????????????????????????????????? just teasing. Nice work as always.

- Piet, Gerhardvienna, mtaylor and 1 other

-

4

4

-

Thank you Richard - I was allowed extra shed time as a present.

So to continue todays work.

I needed to make the gaff saddle. A slightly tricky little number.

The body was made from solid bar - very wasteful, tube would have been better but I just didn't have the right size. Tin bashing was also an option but it is one of my least favoured skills. I remember in the apprenticeship school being let loose on fabricating a funnel. Mine seemed to be a bit of a mess. So bar it was - bored and turned on the lath and slotted .001" wide at its waist to take attachment of the straps. The bore is about 5/8".

I drilled the straps, bent them to shape and did a test fit. Straps .100" wide by .03" thick.

The holes turned out to be in the wrong place so I threw them in the bin and made another pair - it just seemed to be one of those days.

I drew two oval templates to make 2 bodies and stuck them to the pre turned bar using double sided tape. The shape was then roughly cut out with a piercing saw and finished with a file and wet and dry paper.

The remade straps were then soldered in place while being held by forceps. The forceps were removed early (before adequately cool) and it all fell apart. Messy clean up of the components and try again.

At least I'm on the way to making the second one.

-

Nils

I had great fun mentally wondering around the deck. Thanks for posting these shots.

Do you have plans of how and where you are going to display her?

- Piet, Chasseur, Mirabell61 and 4 others

-

7

7

-

Progress on the main gaff has been fairly rapid (for me).

Once again the boom was machined on the mill. 0.040" wide longitudinal slots were machined to take the rubbing strips and various other pockets were cut to take surface mounted pulleys and strop restraints. The fittings were then mounted - predominantly glued with CA.

I needed .100" x .030" strips of brass from which to make the straps for the throat. These were slit from sheet on the mill to ensure accuracy.

...and once made they were drilled with .040" holes to take rivets.

I made myself an anvil and used the brass wire to form rivets. No glue required.

The boom is now complete awaiting the manufacture of the gaff saddle.

-

So finally the main boom is complete and awaiting rigging.

I had missed the final pair of "side" pulleys so added them and I also put the sheaves in place (.100" diameter x .035" wide).

I cheated a bit with the boom cleats as I had some of the correct size left from a previous build. They were however too bulky on the base so I cut them down and attached a central mounting pin.

I then made a start on the main gaff. It is .275" diameter and I needed to turn down the dowel to size before cutting to length and adding the end reinforcing rings.

-

-

-

-

-

Michael,

No, the large and small helical gears are fixed, as is the face plate. The larger gear is however mounted on a bracket and bolted to the main frame to make it easily removable. This is a design feature to allow the lathe to be quickly converted to belt drive.

I have never seen one of this pattern that is as nice as this one. The baseplate and pedestal are typically made from wood or at best a rough piece of iron. This one is machined from bronze and the whole thing weighs 18kg.

It has very few signs of damage or wear and is still silky smooth after a century and half. My guess is that it was never used in anger and was a demonstration model or something of that sort.

it has however one flaw. The hand turning rest and mounting bracket is missing. I have spent a long time looking but as yet have not found one. It's on my to do list to make one but at the moment is some way from the top.

-

Richard and Herask - thank you.

Also thank you to all who have liked my recent posts.

Michael, I hadn't thought of the cleat option - I may look into that.

Jon. thank you for your detailed and considered reply which I read with some interest. It felt right but then spurred me on to dig further. You may have further thoughts on my ongoing investigations:-

These are different but quite poor views of the end of the main boom. The mainsail seems to be lashed to the 2 fixed eyes and i can't see any sign of an outhaul. I'm wondering if the sail is fixed and does not have an outhaul. It may just be re-tensioned occasionally when not under sail.

In the photos below the line below the boom is quite slack even though the sail is full. It the line were a conventional outhaul the line would be tight????

In this shot looking up at the mast end of the boom the "assumed" outhaul line does not exist - but yet again the sail is full.

Also I thought i would add the following to feed someones tool envy:-

Altair 1931 by KeithAug - FINISHED - Scale 1:32 - schooner

in - Build logs for subjects built 1901 - Present Day

Posted

Richard / Michael - Thank you.

I made up a couple of turnbuckles - but have still to round off the square ends. They are about .750" long.

I then moved on to making the belaying pin rails which sit inboard of the bulwark on either side of the main and fore masts (4 in total)

The rail was made from 1/16" brass wire - 2.2 inches long and cross drilled with 5 holes of 1/32" diameter. At this size I find even my finest centre drills are not pointed enough so I "drill" the starter holes with a broken .040" end mill ground to a fine point.

The thickening where the belaying pins penetrate was created by slipping on pre cut and drilled sleeves.

The wire was then bent to shape with pliers and a small hammer. The first 3 went well but then I switched to another wire for the 4th which was much more brittle and broke twice. I softened the 3rd attempt with a butane burner and all was well.

The sleeves were aligned with sewing pins which formed the core of the belaying pins. (pins .025" x 0.7")

Micro-bore tube was used to create the belaying pins.

The centre position is a support come bracket. Making this involved some "fine" turning. The bracket was made from .125" rod with the mounting spigot turned down to .030" to go through the hole in the wire / sleeve. My lathe isn't very small but by making very small tools and taking small cuts I manage to make 4 good ones out of 5 attempts. The mounting leg was made from tube and inserted over the spigot.

I then did a bit of polishing and made the mounting brackets for the 3 legs.

I then stopped to admire the sunset from the garden. Quite dramatic - taken without any filters.