-

Posts

3,980 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

Yes very tricky Andy. I think I would have been tempted to start with a piece of dowel and then bore it out to form a pipe. Then cut the pipe into strips before shaping / reassembling the strips to give the desired shape. However your effort looks pretty good to me.

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

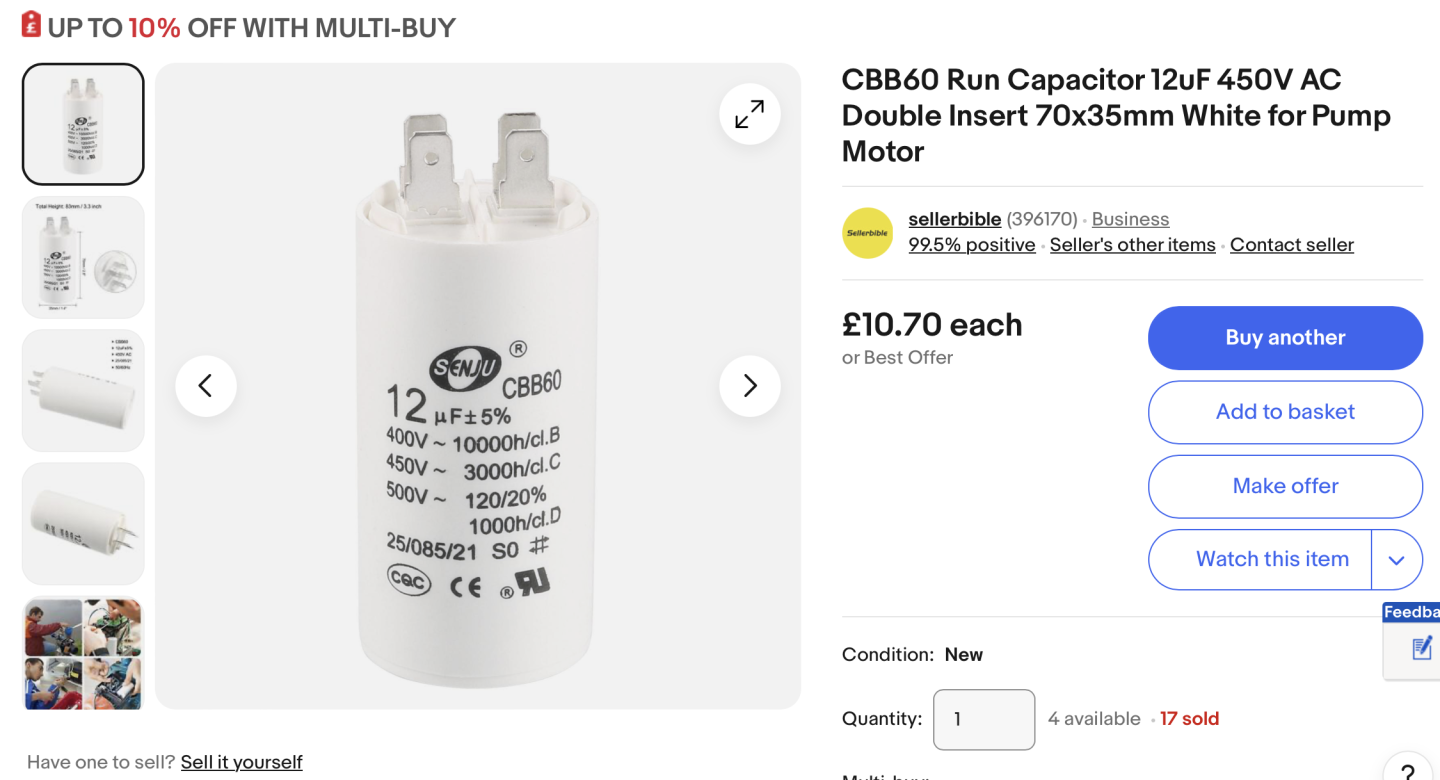

I replace the capacitor recently - The original lasted about 8 years. I bought this on eBay and it worked fine. The simple test for a capacitor fault is to switch the motor on and kick the blade over manually (not with fingers). If it's the capacitor that is dud this should cause the motor to run. The function of the capacitor is to facilitate starting.

-

Cap San Diego by mikegr - 1/160

KeithAug replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

Looking very smart. Welcome back. -

Fascinating back story Phil. I look forward to more.

- 482 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Rick, that is marvellous. For some reason I hadn't thought that it would be possible to get details of the masts. Information on the masts and rigging is a big black hole in my knowledge and based upon the photos I should be able to do a much better job on both masts. Many thanks. Thank you Richard.

-

Ras - I always think that I should build the same boat twice to correct all the mistakes in the first one. I never do of course.

- 128 replies

-

- zulu

- sternwheeler

-

(and 1 more)

Tagged with:

-

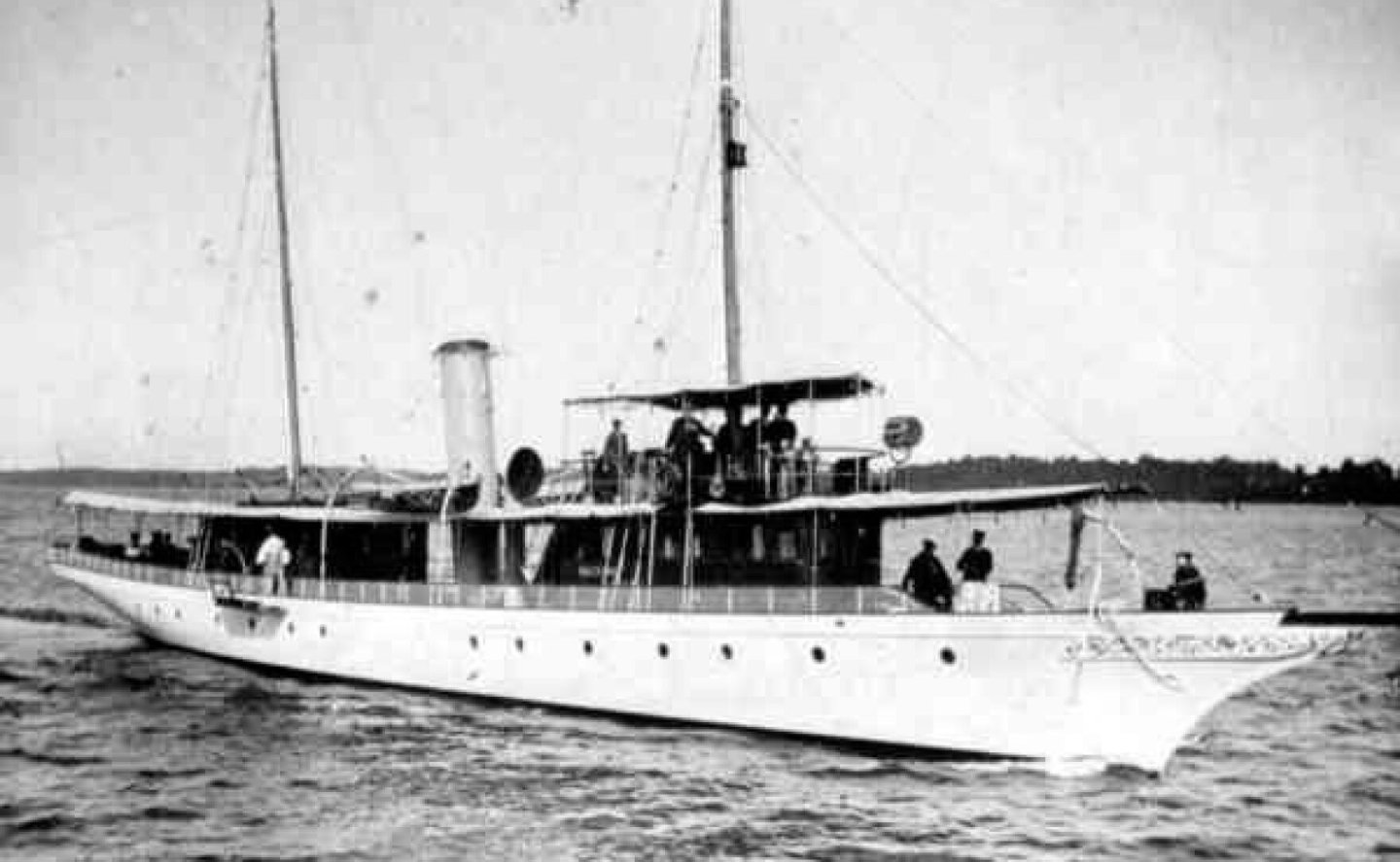

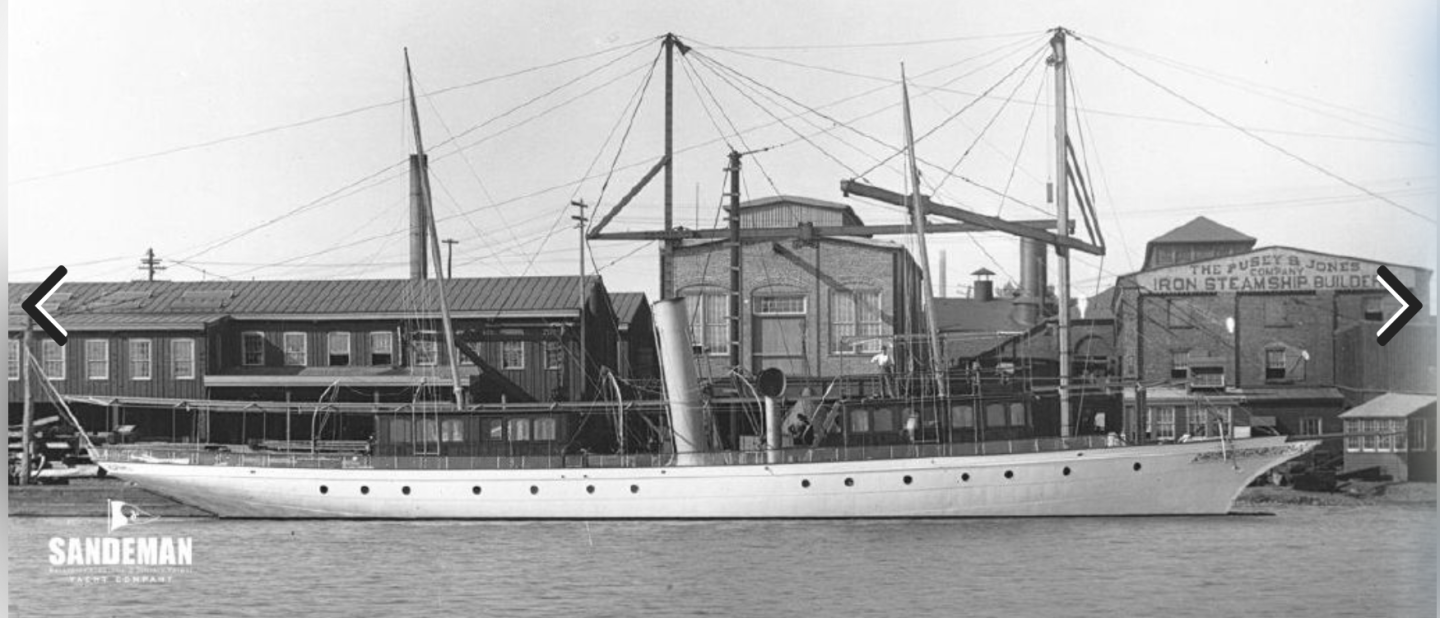

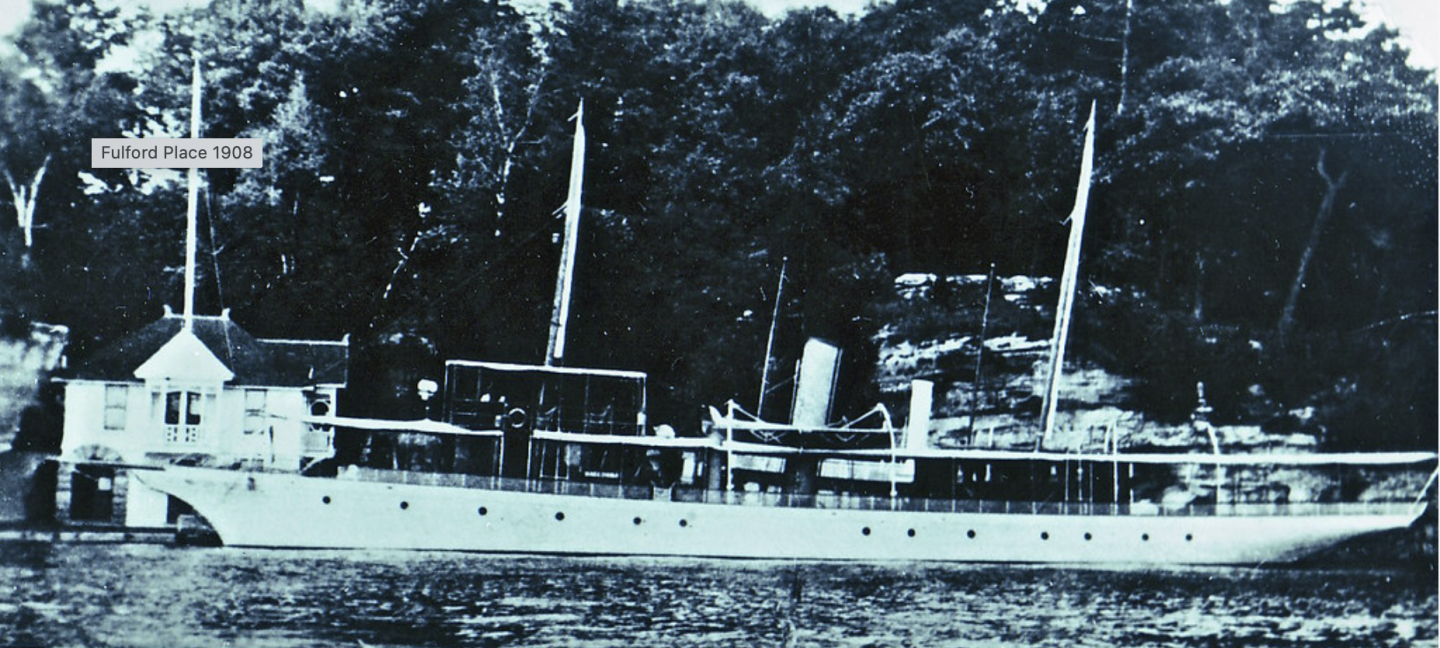

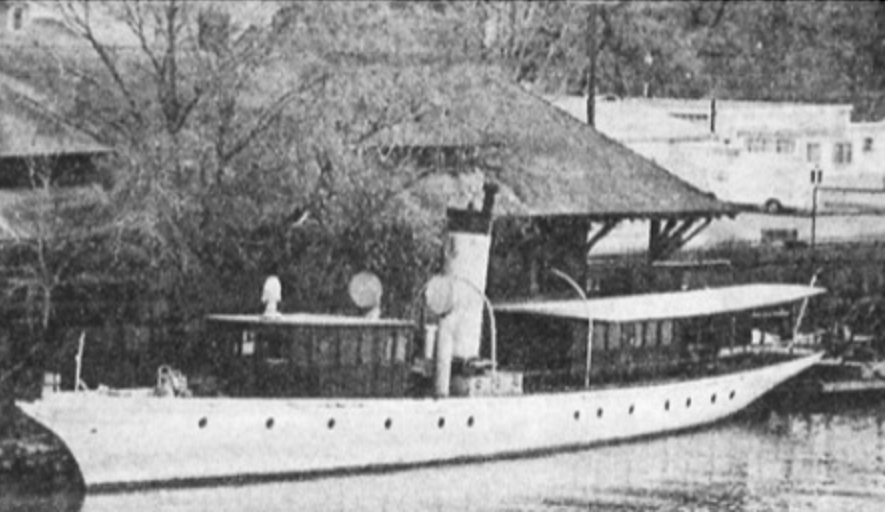

I'm not that clever Andy. So am I John. It tends to develop further each day on my dog walk. Thank you Rick. It is inevitable that I find the very bit of info I need the day after Cangarda departs. The only areas where I am a bit short of info is around the bowsprit - the various deck fittings and the protrusion through the bulwark. I think these were fairly inaccessible when you were aboard due to the covers being on. Also do you know if the roofs of the deckhouses are really white or is this just a protective covering? The details of the awning supports are very useful thank you.

-

Ras - It is funny what I miss in passing. I have only just realised Zulu has two paddle wheels. Are they on a common shaft or can they rotate independently?

- 128 replies

-

- zulu

- sternwheeler

-

(and 1 more)

Tagged with:

-

Very crisp work Richard - the plan looks a little daunting.

- 454 replies

-

- Union Steamship Company

- Stepcraft 840

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.