-

Posts

699 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jeff-E

-

A video about attaching blocks to spars and masts

Jeff-E replied to Modeler12's topic in Masting, rigging and sails

Thank you I will use this method when I come to this point in my build, very well explained -

HI Kieth, Looks like a very nice and detailed kit of Bounty's launch, I do like your method of bending the frames and I will keep it in mind for the future altough it may not work in all situation You are off to a great start and I will follow progress with interest

- 78 replies

-

- model shipways

- bounty launch

-

(and 1 more)

Tagged with:

-

Hi All, Another small update. I have shaped the middle and upper wales and fitted the middle wales and I have done a little more copper plating, I have been cutting the plates with a pair of scissors, the big angles only the slighter angles have been adjusted with a file only, and although there is a little bit of curling of the plate I can straighten this out by sitting it on the jaws of my vice and tapping it lightly with a small hammer. I think the results are OK so far but we will see how it pans out as I progress down the hull. I do know it is time consuming little process to make sure each copper tile sits right against the one above and next to it A few pictures follow

-

Hi Ollie, You could try a few different treenailng metohds on a sample deck and see which , if any, you prefer

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi Vivian, Hope you had a great Christmas and congrats on your move to a new house. Great job on the hand rails around the stern castle, very neat and from what I can see the masts look good. I have a question about the mizzen mast, as it looks to be at the wrong angle in your first photo, shouldn't it be in the same line as the other two masts and have a slight angle towards the stern in stead of leaning forward?

- 188 replies

-

- latin caravel

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi Ollie, Excellent job on your deck planking looks very nice. Are you going to treenail it whenyou are finished? A merry Christmas to you also

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi All, I have made a little bit of progress today I have attached the lower wale strakes above the waterline and shaped the lower strakes for the other 2 wales. Because I had no way of clamping them to the hull while the glue dried I drilled and pinned the strakes with brass nails which were later removed and bamboo treenails fitted into the holes these will be sanded flush with the wale and as the hull will be painted they will not be seen. I am going to fit the lowwer strake of each wale first to get them even and lined up properly with the ports and then the next strake will be easy as it only has to fit up against the one below it I also got a few more copper plates laid

-

Hi Antony, Ollie, Ron, Matt and Dragzz, Thankyou all for your kind comments and tips Antony - I had a bit of frustrating day cutting plates with the stanley knife and a piece of wood and you are right the knife does follow the grain , so I have bit the bullet and just ordered a pair of 'Xuron' photo etch cutters which they say are also suitable for cutting sheet brass. I probably won't recieve them until the new year so I will persist with cutting them with the stanley knife but I will use a piece of MDF instead of timber Merry Christmas to you Ollie - They seem to hold OK with just finger pressure on the steel rule as long as there is a hard surface underneath, my problem was trying to hold them down on a flexible suface. Laying the copper plates themselves is not a bad job I quite enjoy it. Merry Christmas to you Ron - As mentioned above I have ordered a pair of good quality cutters which I hope should make the job alot more enjoyable Congratulations on your early Christmas present and please feel free to use any of the ideas in this log that is what this forum is all about, sharing ideas and techniquies Merry Christmas to you Matt - I hope you and your 3 lads have a great holiday and a Merry Christmas to you and your family Dragzz - I know there is copper tape, which is actual copper strip with an adhiesve backing is available, maybe from a hardware or craft store, this is probably the best solutoin for you if you want to copper your hull as you can cut it to the size you want as most of the pre cut copper plates available from hobby stores that I could find were all 1:64 or 1:72 scale or bigger which is to big for the scale of your model Merry Christmas to you

-

Hi Grant, Looking very nice with all the yards up on the fore mast . I agree, when you get to this stage of rigging it becomes rather complex and tight and it does pay to plan your moves so you don't get to a point where you can't get to a line that you have missed Hope you have a very Merry Christmas

-

Hi Slog, Kester and Ken, Thank you all for your kind comments and your sugestions to help solve my little problem Slog - You are right the cutting mat must have enough give in it so that the plate cannot be held firmly. I just tried cutting one on a board and it was much easier thanks Ken - Thank you for your helpful hints and as I mentioned above I just cut one and used the end of the rule to hold it down, which worked really well, it took about ten passes with the knife but it finaly cut through. One question by a safety rule do you mean a steel rule?

-

Hi All, I have fitted the batterns to follow the previosly marked waterline, you may also notice that I have also adde the top wale and I'm in the process of bending the rest of them. These will be fitted over the next few days I have also started to lay the copper plates on the port side. I discovered that cutting these plates is a horrid job, the method I'm using is to try and hold them down on a self healing cutting mat wtih a steel rule and cut them with a stanely knife, but it tends to grab the plate and slide it out from between the ruler and the mat and when I can hold the plate tight the knife only seems to score the plate not cut it. I don't know if it's the plates in this kit or I'm using the wrong techniquie to cut them. I know I can't use scissors or cutters to cut them as they distort the plates to much and they do not give a clean cut. The angled plates in the above pics was achiieved by filing them down and the last on on the top row I managed to score a line deep enough to hold in the jaws of a pair of pliers and bend it a couple of times till it snapped off. Any suggestions or advice on cutting these plates woud be gratly appreciated

-

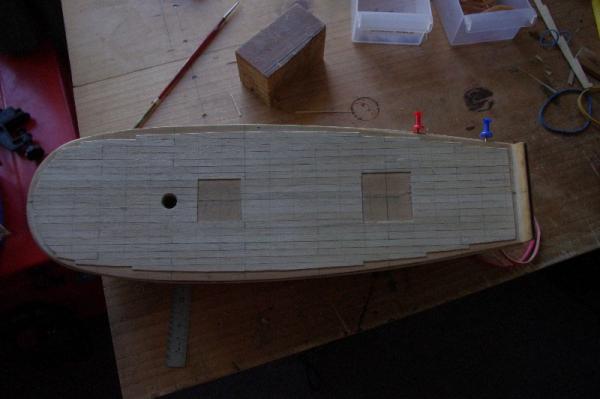

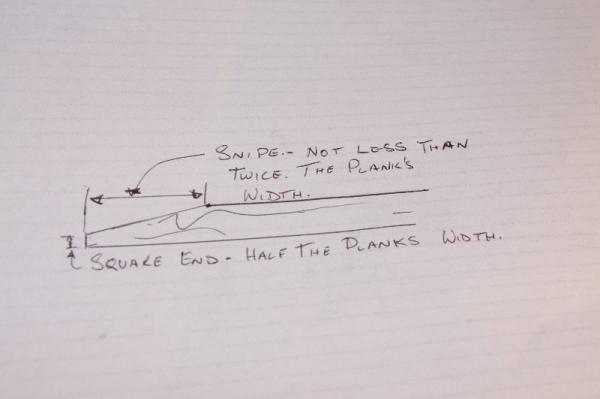

Hi Ollie, Very nice start to your deck planking , with regard to question on when to joggle a plank C Nepean Longridgre gives an excellent explaination in his book and I quote " there are two shipwrights' rules about joggling" (1) The square end of the joggled plank must be half the width of the plank, thus with a 9 inch plank, the square end left and after cutting must be 4 1/2" wide (2) The plank must be joggled when the snipe is more than twice the width of the plank. The snipe is the technical term for the diagonal cut across the width of a plank (see pic below, sorry for the poor drawing) A pic of how I joggled the planks on the Norfolk I hope this helps

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi Sailor, You could try the HM Cutter Sherbourne by Caldercrtaft models she has eight 3 pounder guns and 10 swivel guns and is rated as a beginers model with a bit of imagination I'm sure it could become a 10 gun ship, it is available through Cornwell Model Boats based in England or through Jokita the manufacturer also based in the UK' Ollie - I hope you don't mind me using your log to give a bit of advice

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi Vivian, Welcome to my log and thank you for your kind words. I like the extra detail a section shows how the ship was constructed, I too would like to a scratch build some time in the future, I have seen a photo of a half section model of the Victory, it would be something I would like to do when I gain a lot more skill.

-

Hi All, I did forget to mention in my previous post that this will be my first attempt at copper plating a ship, even 1/3 of one After some further reading and some more thinking I have have come up with a plan on how to attack the copper plating. Most logs and books recomend starting from the keel up in the centre of the hull but, as Grant suggested, I am going to start from the waterline and come down 12 rows to establish a gore line for the bottom half of the hull The first thing to do will be to attach a battern along the waterline so that the copper plates will have an edge to butt up against. From what I can find out after a bit of research is these batterns were about 3 inches wide which equates to approximately 1mm wide at this scale. I took a piece of 3 x 0.5mm saplele and cut it in half and then sanded the two pieces down to 1mm thick, these will glued along the waterline. The next part will be to lay 12 strakes of copper plates from the waterline down, so I can achieve a line on how the strakes would take there natural line from the centre of the ship is to lay a temporary plank underneath the first few plates and let it take its natural line and where it crosses the water line this is where I will start cutting the plates at an angle to sit against the battern and then do the same for the following strake and so on until I reach the 12 rows required. I will then run the strakes from the keel up to this gore line. This all sounds great in theory so we will see how it works out in practice

-

Hi Ron, Grant and Dragzz, Thank You all for your kind words. Ron - Welcome to this log and I look forward to seeing your progress of your build on this forum. Grant - Thankyou and I think I have worked out how to do it, the next update will explain, I hope Dragzz - Thanks, it is made from 3mm MDF with a 12mm plywood base, the pencil holder is made from 19mm pine

-

Hi Grant, I just browsed through your log and i must cogradulate you on your excellent workmanship and attention to detail, especially at this scale. I do remember following your log on the old site and trials and tribulations you had with stern galley but it was well worth the effort it turned out fantastic. The slings and jeers look excellent very neat and a great way to make the parrel ribs very nice I will follow your build from here on

-

Hi Antony, Looking good, it should look great once you have nailed it. Which treenails are you using the light or the dark ones? Great job

- 209 replies

-

Hi Antony and Grant, Thank you both for looking in and your kind comments. Antony, the copper plates are supplied in the kit 500 of them . They seem to be of fairly good quality however some are not quite rectangular. Grant, thanks for the info and that does make sense, I just read trough his section on coppering and he says there are 12 rows of tiles in the first belt which overlaps the second belt that comes up from the keel

-

Hi All, Another small udate. after making a water line marking jig, pics below. I marked the water line onto the hull at the distance stated in the plans which is 70 mm from the bottom of the hull which is to me seems a strange way of doing ti as all the other measurements are taken from the bottom of the keel I set the hull up in my keel clamping vice with the bottom of the hull firmly against the steel top plates and then made sure the hull was level fore and aft and athwart ships then I dedcuted the keel length from the bottom of the hull from the distance from the top of the vice to the table, added 70mm to this and checked it on both rules to make sure the hull was even on the table I then marked the water line on both sides of the hull I also marked the position of the wales using the jig , bearing in mind that the lines for the wales are a guide only and the wales will follow the line of gunports I have run into a slight problem and have been trying to overcome it this afternoon and that is how to mark a gore line for the copper plateing, as it is only a bow section I don't have a centre of a ship to go off,but i have been looking at some logs and Longridge has a nice plan of the coppering in his book.But any suggestions on how to go about it would be most welcome. My lastest idea is to come down about 7 or 8 tiles form the keel at the back and then lay a plank along that line and see how it looks . I think it might be a case of trial and hopefully not to many errors I would also like to take this opportunity to wish all of you a very Merry Christmas

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.