-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

Thanks Rich. There are better pictures of the ladderway and it's railing at p.55 of the log. The stanchions are brass parts that I had on hand (I believe that they originally came from Model Expo). Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Thomas. I always feel the same way looking at your work. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

The copper looks great Sjors. It's never a mistake to redo something you don't like and this redo has got to make you glad you did it. Bob

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Thanks so much Joe, Antony and the "likes". Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Grant, I am blown away by both your commitment to excellence and the quality of your work. The cutters are tiny gems. Bob

-

Thanks so much Nigel and the "likes". I really appreciate your comments Nigel because no one does more with a kit than you. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

A relatively simple, but tedious, job underway. I am making and installing the remaining gunport lids (earlier, I had done a few just to see how they would look and fit). As can be seen from the photos, I added the PE brass hinges and eyebolts only to the lids that won't be covered by the channels. For whatever reason, the tight tolerances under the channels wouldn't allow for them (they will be completely covered and invisible in any event). The lids are made from boxwood strip matching the hull planking with an inner piece painted red. The PE hinges are from the kit. The lids are pinned as well as glued for strength. Next will be the channels. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Nils, Vol. 4 contains a full description of the various fore and aft sails (jibs, staysails etc.) and their rigging. Bob

-

Thanks. Good luck on your build. I'm sure that you'll enjoy it. Bob

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

-

Great looking work on the bowsprit and masts Nils. Vol.4 of TFFM is as complete a source for the rigging of a Swan class as you can get. It's well worth the investment. Bob

-

Ray, I have just looked at your log and am really impressed by the quality and crispness of your work. Absolutely first rate. Bob

- 536 replies

-

- diana

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks so much Augie, Kevin, Mark and the "likes". I never expected so much interest in something as mundane as bending stripwood, but the reality is that I was as surprised as all of you by how well it worked. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks guys for all the generous comments and the "likes". Greatly appreciated as always. No former Grant. I made adjustments by hand as they dried to get a fit to the stanchions. As I said, I was kind of surprised to see that this could be done by bending. I really hadn't expected it to work. I don't know if it would with anything wider. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

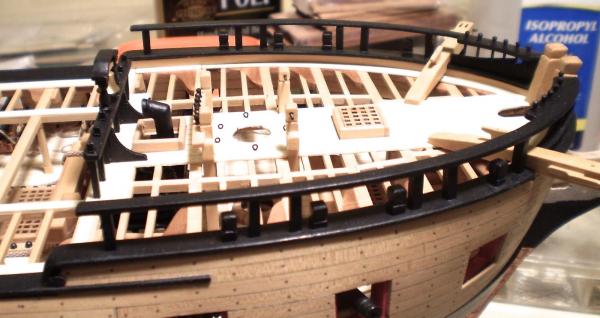

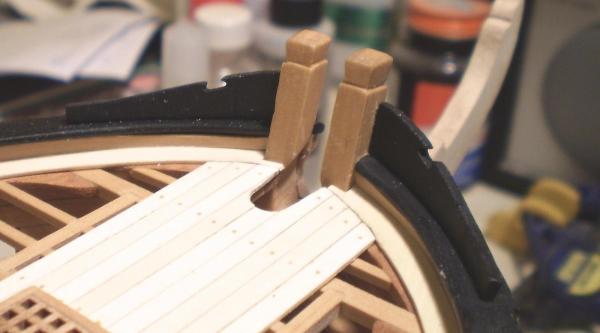

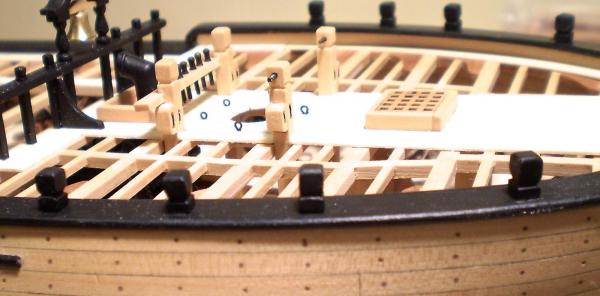

Work on the forecastle is now complete. I have made and added the roughtree rail. This was a straightforward task, but still fussy, mostly because of my desire to strengthen it by pinning all of the pieces. The first job was to make the stanchions from boxwood strip, paint them black and then pin and glue them to the cap rail. I then made the rails themselves. Initially, I had thought that I would cut them from boxwood sheet, but decided to try bending them to shape from boxwood strip. Somewhat surprisingly, I found that I could edge bend 1/16" x 5/32" strip using boiling water and my old electric plank bender. I added the pin rail portion with additional pieces of bent strip. After rounding the edges, I prepainted the rails, drilled the holes for the belaying pins, added pins for the attachment to the knight heads and then glued the rails to the stanchions and the knight heads. Once the glue had set, I drilled through the rails and into the stanchions and used brass wire pushed into the holes with a drop of CA to pin them. After cutting off the wire and filing it smooth, I then did the final painting and added the belaying pins. The result is a fragile looking structure that should be strong enough to withstand rigging stress. I'm pleased. My avoidance of the headwork will continue for a while as I do the channels and the remainder of the port lids. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks so much Mark and Ken. Ken, I'm afraid that you're going to have a wait for the head. I'm "head phobic" and keep putting it off. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Many thanks B.E., Michael and Remco and also the "likes". Greatly appreciated. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks so much Tim, Augie, Terry and the "likes". Your continuing interest is appreciated. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

I'm just back from a week long golf trip with my wife and three other couples, and after playing 6 times in 7 days, I was ready for a rest from golf and eager to get back to modeling. This combination resulted in a burst of activity. I returned to work on the forecastle. First I realized that I had left off the knees on the belfry/barricade, so made and added them. Then I made and added the splash guards at the bow. These were cut from boxwood and bent to shape. Next, I made and mounted the 8 required timber heads. Theses were done from boxwood strip in the usual fashion of shaping each of them fully before cutting it from the strip. They were then painted and pinned and glued in place. The last and most intricate work was making up the catheads. These were made from boxwood. notches were cut with a chisel to fit over the rail and the remainder of the shaping done with files. I did simulated sheaves, as I have done throughout this build. Next, I made and mounted the cleats and thumb cleats. Lastly, I added the necessary eyebolts. The catheads were then mounted in place. I'm now moving on to the rough tree rail, which will be the last of the forecastle work. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Good story, but even better modeling Remco. Bob

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

You're off to a great start on the rigging Ken. Bob

- 455 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks so much Robert. I've always been a believer that if you can't see it, you can't find it. Bob

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.