Roger Pellett

-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Roger Pellett

-

-

Greenstone,

There are period sketches of sweeps in bundles stowed outboard over the quarters of brigs, cutters, And Schooners.

Frank,

I would assume that her stability certification involves her range of stability as from what your observation indicates that she is plenty stiff. With her large open gun ports her righting arm would dimish once her deck edge becomes submerged.

Roger

-

-

All models of ships built prior to the advent of iron and steel shipbuilding are to a degree approximations as wooden ships were not fully engineered. By that I mean, they were not “built to print” to close tolerances. They were either built using geometric rules, from carved half models, or from to scale lines drawings. When built from models or drawings, the lines taken from measured offsets had to be redrawn full size (lofted) introducing intentional design changes, interpretations, or changes necessary to produce a fair surface. Once frames were erected they were “dubbed” to produce a fair surface, introducing another change.

Even when we produce a model from mould loft offsets or from lines taken off from the real thing we introduce new interpretations when we make our drawings and make the adjustments necessary to produce fair surfaces. I am not convinced that CADD eliminates these problems as the lines produced are no better than the algorithms used to produce curves and to make the fairing decisions.

For those interested in exhibiting their models in a competitive environment I believe that the model should accurately reproduce the distinctive characteristics of the vessel being replicated. For example, Late Nineteenth Century American Vessels often featured a distinctive, elegant elliptical transom. Does the model of a Gloucester fishing Schooner being judged accurately reproduce this feature?

Roger

- dvm27, mtaylor and FriedClams

-

3

3

-

Being a Steel hulled vessel, is the wood laid on top of a steel deck? If so, planking might be embedded in some sort of mastic. On a high end yacht this new I would assume that there would be some sort of moisture proof deck beneath the planking.

- mtaylor, KeithAug, FriedClams and 1 other

-

4

4

-

I have only bought one or two things on EBay and each time that I did so PayPal accepted my credit card. I don’t have a PayPal account.

Roger

- mtaylor, bruce d and paulsutcliffe

-

3

3

-

-

Very small two bladed propellers can be made by twisting thin wire into a figure 8 shape, skewed to represent pitch. The two lobes can then be filled in with modelling putty or even thick paint.

Roger

-

Susan,

Before investing in an expensive kit, all representations of Santa Maria, full sized or models are conjectural as very little is known of the actual vessel. Therefore, such fundamental things as the shape of the hull are only guesses. In addition kit manufacturers are notorious for “jazzing up” their kits with anachronistic details to add marketing appeal. Building a Santa Maria model from a kit may provide many hours of enjoyment but cannot with the present state of knowledge result in historic accuracy.

Roger

-

-

-

-

-

Chapelle’s book includes 130 full page plates of fishing Schooner plans (hull lines drawings) including one of Benjamin Latham, but the real reason why I think that the book would be helpful is that the last 300+ pages are a reproduction of Chapelle’s notebook detailing in minute detail the construction and fittings of these interesting vessels. This information was taken from actual vessels and contemporary marine equipment catalogs. BTW any of the 130 plates in the book should be available in a larger sized format from the Smithsonian Institution.

Roger

-

-

The US Navy used to copper its launches (ships boats) in the Nineteenth Century. A SNAME paper from 1900 describing the first generation of standardized boats says that as of 1900 launches were no longer to be coppered. I don’t know when this practice started but Navy Ordinance manuals published in the 1850’s show coppered launches.

Launches were large and seaworthy enough to make extended voyages away from the parent vessel so the Navy apparently considered protection necessary. Smaller boats were not coppered.

Roger

-

-

-

- mtaylor, JerseyCity Frankie and Matt H

-

3

3

-

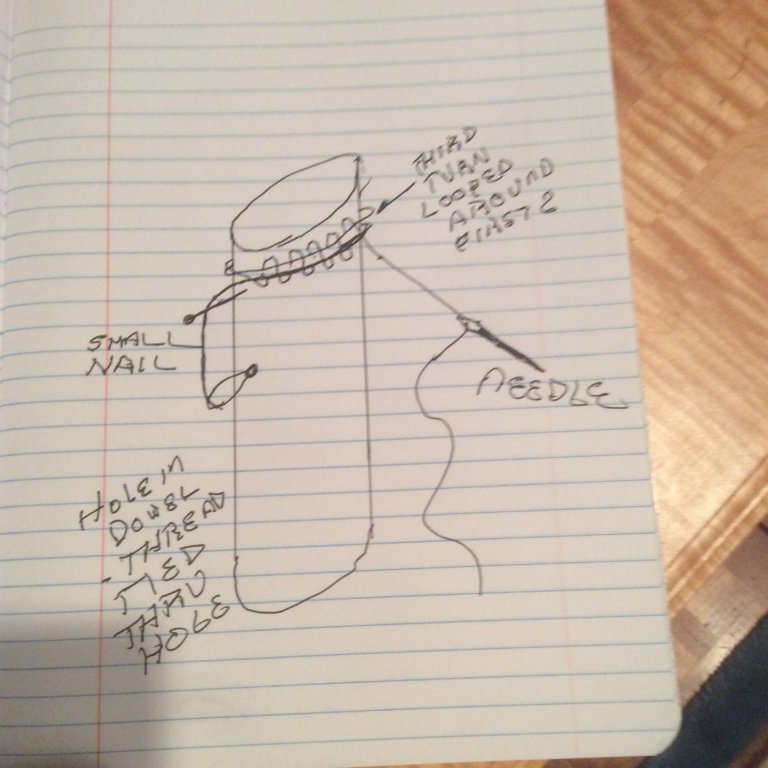

True strops for blocks are easy to make:

1. Using a piece of soft wire strop the block and the thing that you intend to attach it to. Straighten out the wire, measure the length and divide the result by three. This is the diameter of the strop.

2. Find a short piece of dowel close to the calculated diameter.

3. Wrap three turns of thread around the dowel- using a needle, the third turn should be a series of overhand knots “sewn” around the other two. Tie off the ends of the thread around the three thread turns.

4. Thread a piece of thinner thread to a needle and serve the twisted rope turns around the dowel, and tie off the ends of the serving. A dab of clear nail polish is good for securing knots.

5. The finished product will be a served grommet. This is then slipped over the block and seized as Frankie shows above.

6. It is easy to add a hook by passing each wrap in step 3 through the eye of the hook.

This procedure is easy and quicker than it sounds. It provides a much mote realistic appearance than a tied knot.

Roger

-

A dissenting opinion- Leave it alone! From your photos it doesn’t look that bad. Assuming that you intend to reattach deck houses, hatches, etc, they will break up the pattern.

This appears to be a nice piece of folk art. Much nicer than the decorator models we often see. The somewhat haphazardly scribed deck is in keeping with the folk style of the model.

Roger

-

Bob,

It was not my intention to give MicroMark a pass. Actually since I have belonged to the Model Ship forum I have bought a lot less from them as I am now aware of other sources for the same stuff. I have never purchased any of their proprietary tools as they appeared to be something that I could rig up myself.

I was pointing out that they have been able to use a well financed marketing campaign to offset other shortcomings, a common business practice.

We are fortunate here in Duluth to still have a well stocked old fashioned hobby shop that I would like to support. The proprietor is, however, such a @#$& that I hate going into the place.

Roger

- kurtvd19, thibaultron, Canute and 2 others

-

5

5

-

As the old slogan goes, “It pays to advertise” and this is one thing that Micro Mark Does in spades. It seems like the only organizations that out advertise Micro Mark are the Cruise Lines. I must get at least half a dozen Micro Mark catalogs a year, some on the heels of the previous one for no apparent reason.

On the other hand I don’t know who NorthWest Shortline is and therefore, have never bought anything from them.

A business needs to grow to a certain “critical mass” to be able to advertise extensively which rules out small shops. On the other hand, the MicroMark catalog for many is a one stop shop, and the Chinese issue is overlooked because buyers are used to things coming from China. In the case of propriety items like the Chopper, If it is in the MicroMark Catalog many would not recognize it as a knockoff and look for it elsewhere.

Micro Marks stuff is not inexpensive. They just have reached a Volume that provides the revenue to fund their ad campaign.

Roger

-

-

I agree with Kurt’s posts above. The reason for the double planking is economic. It allows kit manufacturers to provide more widely spaced bulkheads, reducing material and shipping costs. It also provides a marketing bonus- “you get to build the model just like the real thing” which of course is untrue.

Since you you are building from scratch a better system would be to fill in the spaces between the bulkheads with easily carved wood blocks. The hull is then carved in the usual manner. You now have a solid, fair base for planking.

Ed Tosti demonstrates this method in his build log for Young America. He actually built two hulls, a plank on bulkhead one and a plank on frame one.

Roger

Sweep ports and oar

in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Posted

Picture below of an American Schooner with sweeps stored in bundles ootboard on each quarter. Antoine Roux painted vessels that he saw in the Mediterranean from life and his work is generally considered to be highly accurate.

Roger