-

Posts

797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Seventynet

-

Sherline Mill Ring Light

Seventynet replied to Some Idea's topic in Modeling tools and Workshop Equipment

Mark, I don’t foresee any problems making the carrier out of aluminum, I am just a bit hesitant about drilling the hole through the spindle headstock. It seems like drilling through 4 or 5 inches of aluminum would be quite an adventure and I don’t own a drill press. But it might be easy enough to mill a slot in a 1/2 square piece and epoxy it into the headstock inside corner to hide the wire. I’ll figure it out. Thanks again for the excellent design. Ian -

Sherline Mill Ring Light

Seventynet replied to Some Idea's topic in Modeling tools and Workshop Equipment

Hi Mark, Thanks for the explanation. The hole in your spindle stock stumped me until I realized that the headstock I have predates yours by a few years when there was no through hole, which as you say is perfect to run the wires up out of the way. That’s too much aluminum for me to tackle so I’ll try to find a different solution. Best, Ian -

Sherline Mill Ring Light

Seventynet replied to Some Idea's topic in Modeling tools and Workshop Equipment

That is a nice idea, Mark. Since I see you are not CNC did you use a fly cutter to make the hole? I think I will make this too. I notice there are dimmable RBG and possibly white light rings on Amazon that could address brightness levels. How did you run the wires up? It looks like the wire comes out the top of the headstock spacer…? Regards, Ian -

Your planking job looks first rate. As far as what to finish it with I can’t help you but I do understand your sentiment as I felt the same way when I finished the walnut on my catboat. I often look at it and think I’ll paint a waterline and some colour below it, and maybe I will someday. Anyway your beautiful ship inspires me to get at my kit. Ian

-

Really nice explanation of how you made the windows. I remember that same challenge with my Haying Hoy. Now I am configuring the windows using cnc which should do a good job. The biggest obstacle is figuring out how to get a good enough bitmap and then converting that to vectors. I really like your project. Ian

-

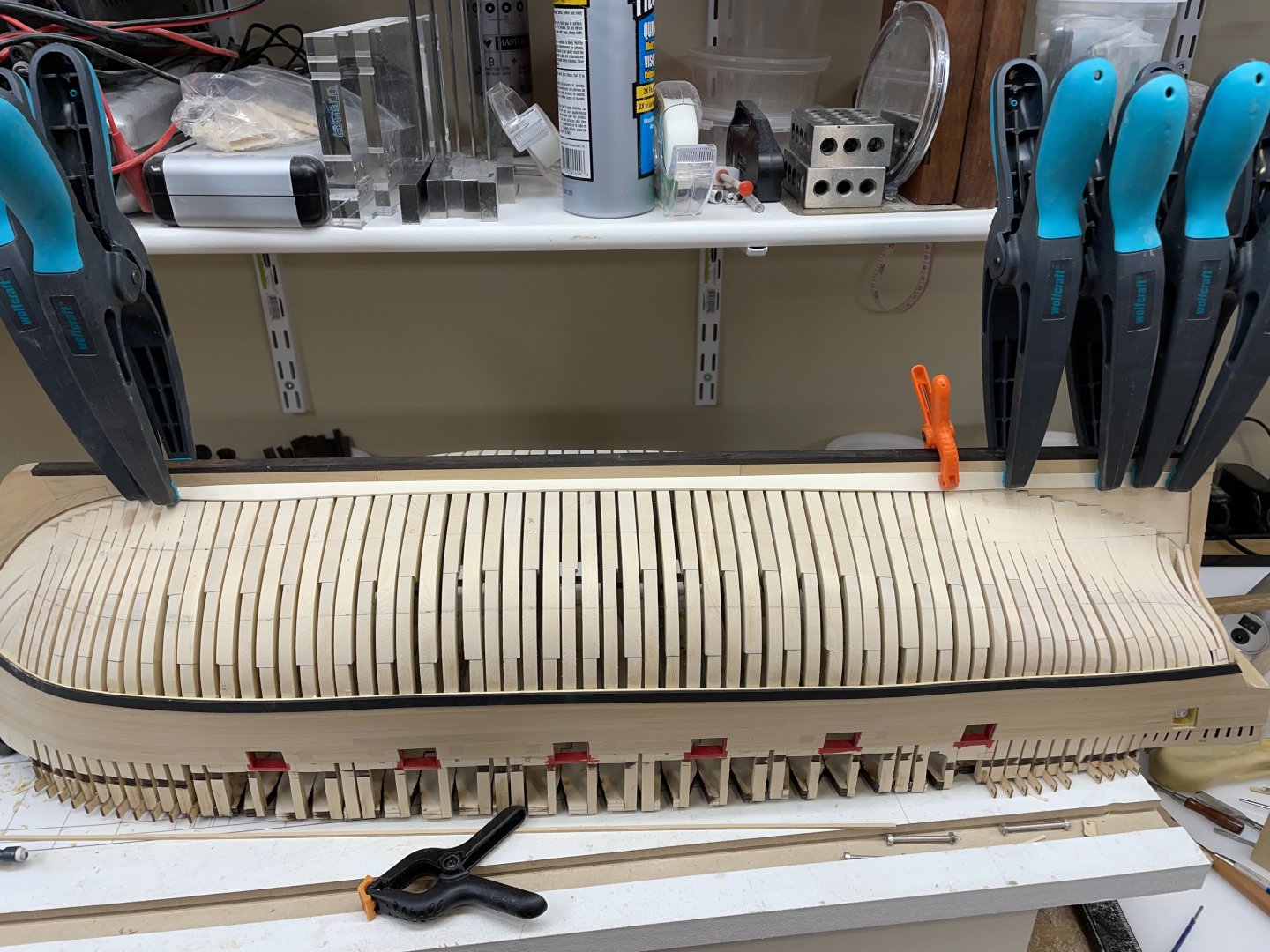

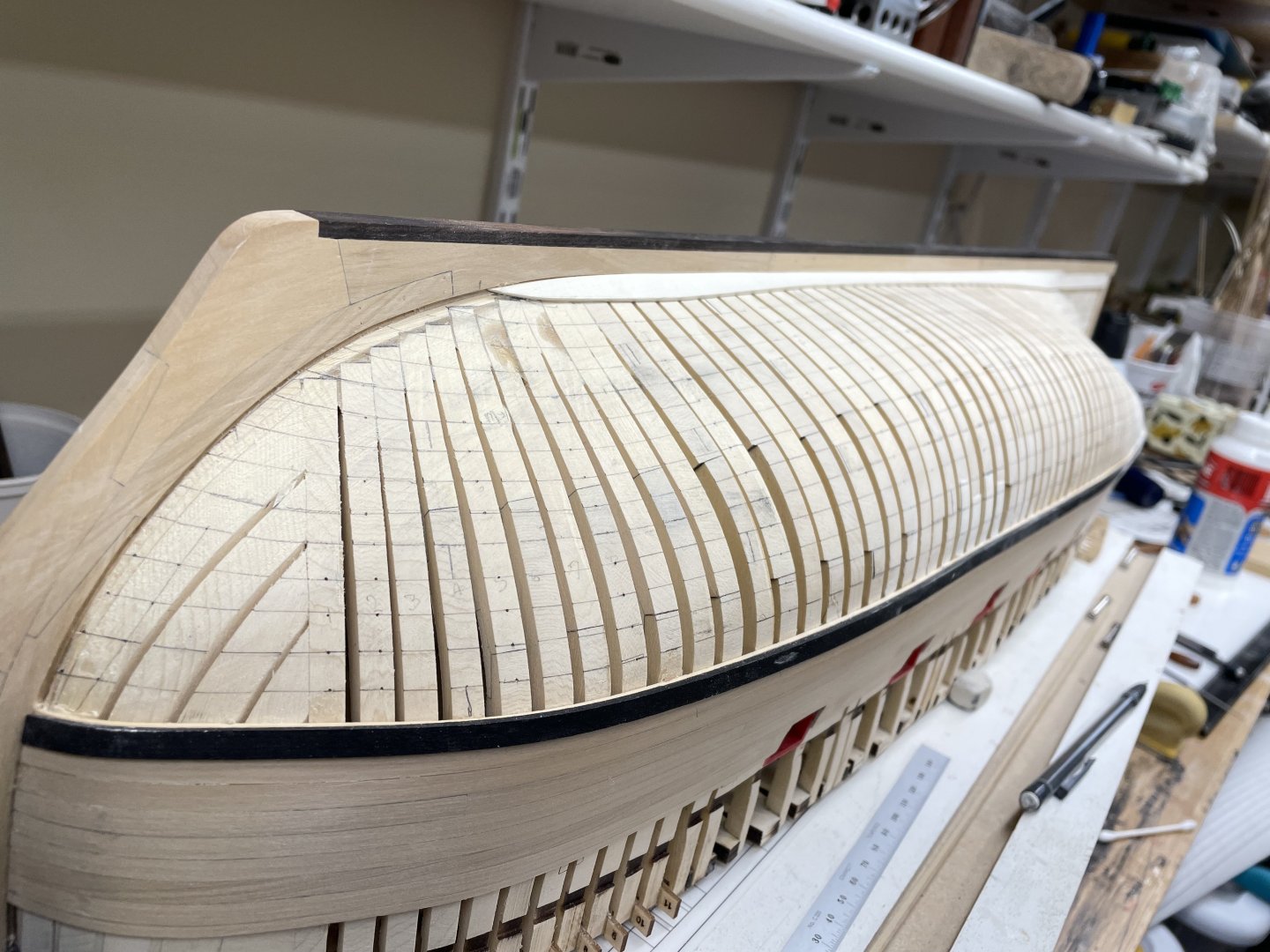

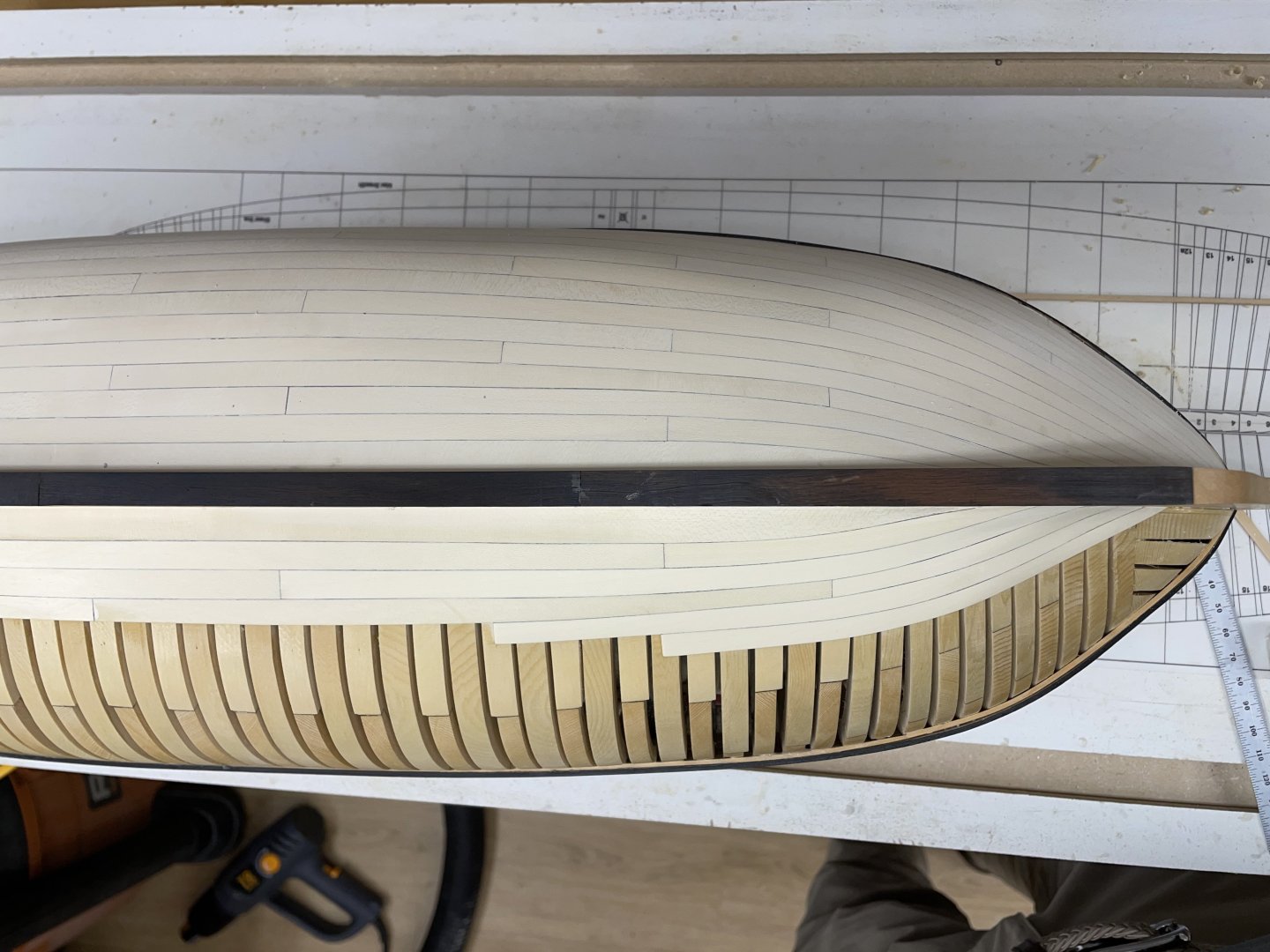

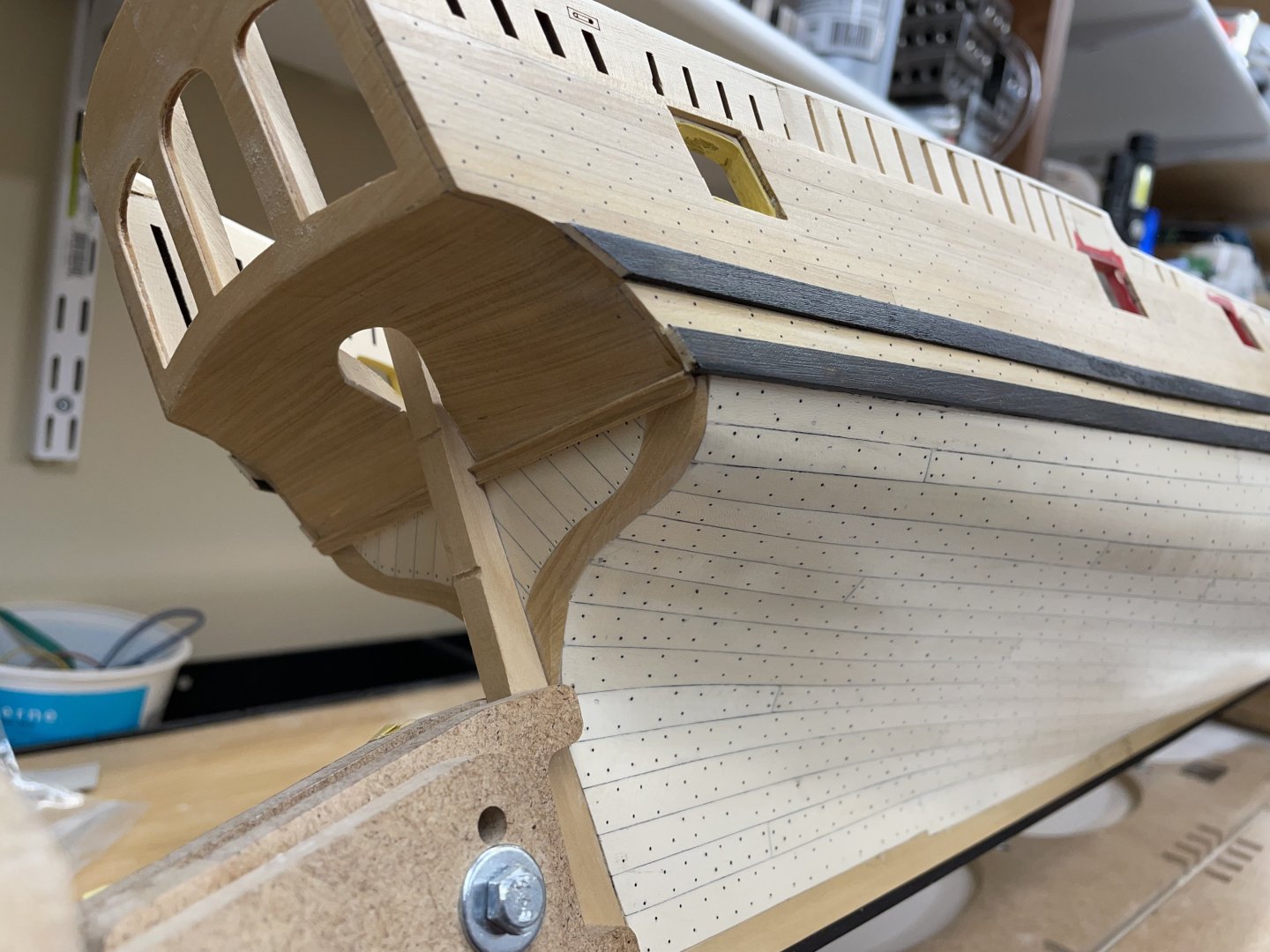

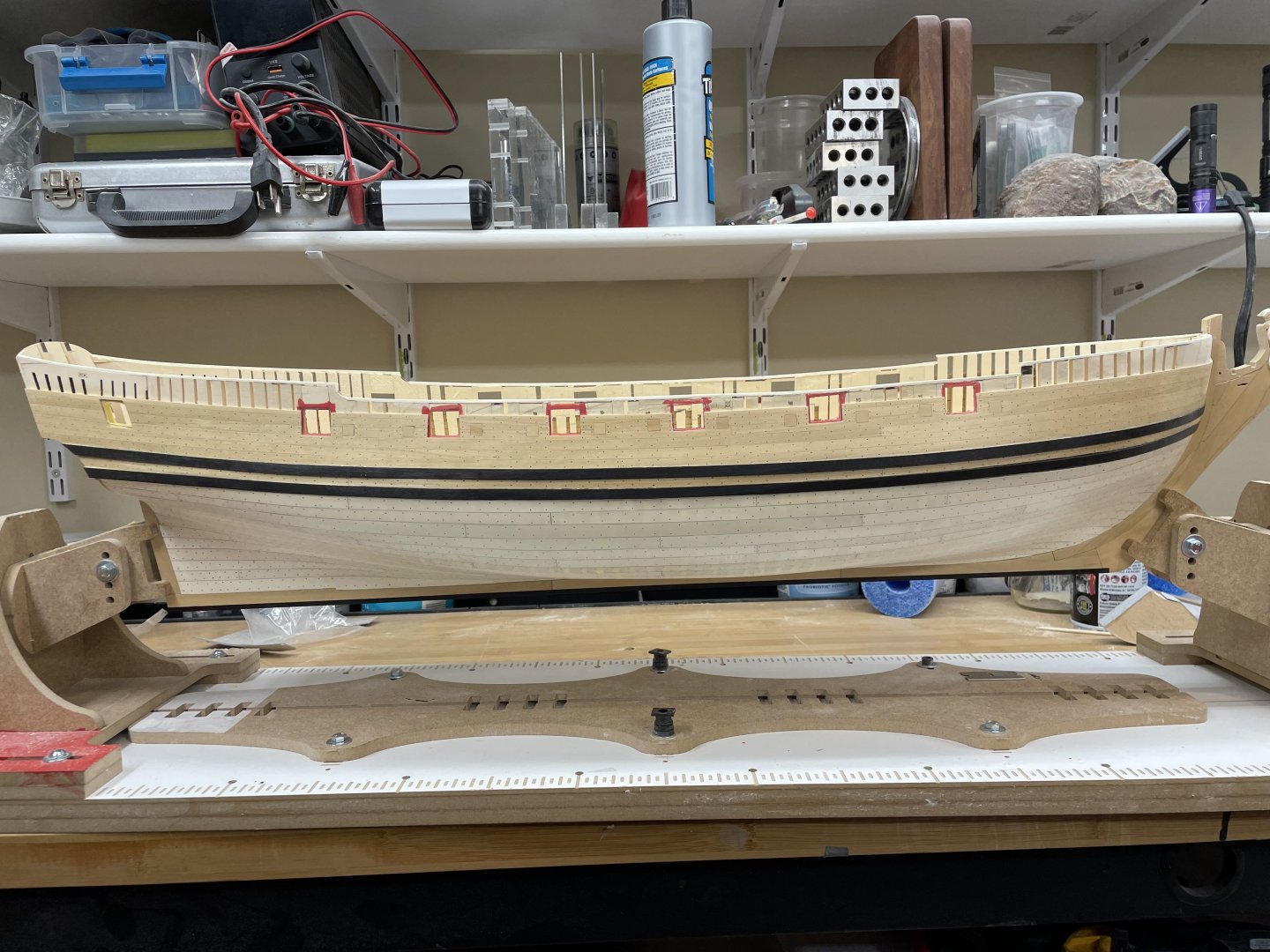

So a little bit of progress. I’m going pause work until the next chapter has arrived. As you can see I decided to partially plank the port side and fully plank the other side. This is how I did my Hayling Hoy and I really liked the effect. I know I’ve made more work for myself because now I will have to plank the corresponding insides. Lining the hull into 3 sections: Laying the Garboard strake: Lining out the rest of the hull: Half way there: Finished starboard side: From the bow: Port side finished: Treenailed with 25lb monofilament: Notice how translucent Holley is. You can see the frames through the hull. If I turn off the overhead light you can’t see the frames anymore. 5/32 Cap rails installed. Inside faired: Cheers all, Ian

-

Great work Tom! Your project has given me some ideas for my Gokstadt. Could I ask what you used for the hinges and clasps for your sea chests? The benches are the one thing I never got around to. ian

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.