-

Posts

9,660 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

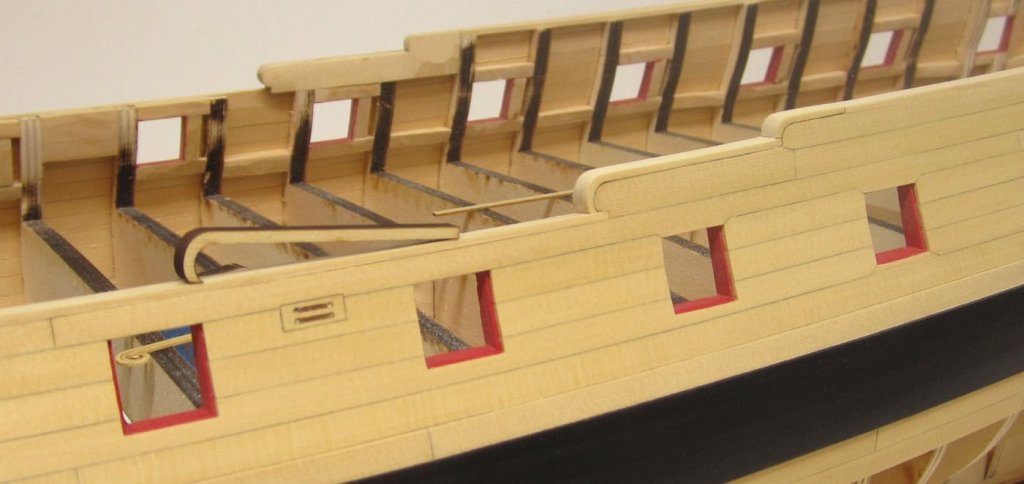

I finished the wales and black strake on both sides and painted them black. But I still had to add the anchor lining. Rather than use individual boards I just laser cut the shape from some 1/32" sheet. This will cover the wales but then an additional strip of thicker wood must placed on top of this to cover the black strake. They are all flush outboard but the strip on top of the black strake for the lining remains bright. The 1/32" sheet for the lining was gradually sanded thinner as it worked down towards the bottom of the wales. Now before I start planking below the wales, I have a few things to do first. One of them is to fair inboard. This is not a fun task and it will make a mess. But I want to get it out of the way now so all of the dust falls through the hull rather than just fall into one that is fully planked. One thing I notice when folks build my kits (or any kit for that matter) is how they fair inboard. They never quite know how thick to make the bulwarks. In most cases they are left way too wide which makes the entire model look clumsy and kit-like. To help with this on the Winnie, I designed a "fairing cap" that will be 3/16" wide. This needs to be placed on the top of the sheer. Then when I start fairing inboard I will be better able to maintain that 3/16" measurement consistently for the bulwarks. Some portions of this "fairing cap" were laser cut like the area above the hances and at the bow. For the remainder a 3/16" x 1/16" strip was used. See below. NOTE!!!! IMPORTANT NOTE!!!! DO NOT place the 3/16" x 1/16" fairing cap in the waste. It is only to be used on the hance pieces and along the quarter deck. AND in addition......along the forecastle at the bow. Using it along the waste which I show in the photo below will make the waist too high and screw up the placement of the molding. The top of the external planking will be the sheer along the waste and the 1/16" strip would make it too high. I made this mistake and later removed this strip along the waist. This may look odd at this point but dont worry....this "cap" will be completely covered by the fancy molding and volutes. These wont be added to much later in the project but here is a look at some prototype "scrolls" I worked on. One of the things that was troubling me was how I was going to handle these scrolls. Sure, many people can carve them and they look great. But these are difficult for most. I could have provided castings but then the profile molding would be impossible to match so it looks good. So I have been experimenting. This is what I have at this point and I think it looks pretty good. This of course means that I know have to provide all of the molding for this project along with the carved scrolls. They may not be as good as those that are hand carved or scraped, but I think they look better than most and will do the job nicely. I still have to tweak a few things. What do you guys think? By the way...the top aft scroll and molding behind it is made from boxwood. The forward scroll and molding below it were made with the same process but out of Yellow cedar. I think the results are pretty similar although the boxwood version is slightly darker. The Cedar version of the scroll was much more fragile to sand than the box version. I will have to decide which to include. There was no carving what-so-ever or scraping. The scrolls and molding were laser cut. I just sanded the sides to remove the char and rounded the sides off a bit using 420 grit sandpaper. The notches or grooves were laser etched at various depths and I just left the char in those untouched. I applied wipe on poly over them and it looks pretty good. These are just test fit against the hull to see how they look.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks great. I am so glad you enjoyed the project. Chuck

- 39 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Not yet.....I will put one together once I start production. But remember that the thread I am using is not the same. I am using a blended thread now which is made in the USA. The sizes are different. I never made a chart when I was making the stuff for the museum using the Guttemann stuff. I will check my notes though. Chuck

-

Dont forget......we have shirts and other merchandise available emblazoned with the MSW or NRG logo on it. Who wouldnt want to look as sharp as this guy.....buy one for yourself, or for you entire family. They make great Anniversary presents for the one you love dearly.... Click the link below. https://nauticalresearch.qbstores.com/all_products.html

-

I will very shortly start making some Poly/cotton blend rope. I am going to call this Syren's "Ultra Scale Rope" . It will cost the same as my other Cotton/Linen rope which I will continue to sell as well. But if one is preferred a great deal over the other I will discontinue the least favorite. Only if sales really drop off on one of them. Otherwise I will try and offer both.

-

Kurt...I have a bunch. You can always use mine and come pick them up when you need them. Good ones are expensive. I have a lot of them and hardly use them because I prefer to do most work by hand. Next time you come to the shop you can check them out. Chuck

-

Nice photo set-up. I will have to rig something up like that.

- 31 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

That really looks good. Its coming together. Just make sure when you start gluing those planks on that the planks are very secure to each and every frame. This prevents the frames from breaking once you go to remove the centers.

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Bob, One of these days you have to make the trek up to a meeting in Roseland. I know its a haul for you, but I would love to see you and the model in person. Chuck

- 87 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Really looking fantastic. ☺️

- 87 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Those parts really should be redrawn to fix those issues using the plans and laser cut over again. I am pretty sure that the bulkheads would fair if cut from the plans directly, but I must say that it looks impossible after seeing your photos Bob. The outside edges of the bulkheads just look like they are the wrong shape in many instances. My guess is when they were originally traced for laser cutting they were badly done. I am watching your progress but also shaking my head because I cant see how that hull can ever be faired properly without adding at least another 3/32" of meat to many of those top=timbers. Its the only way I can see getting a smooth contour to the hull outboard. And its no guarantee that it will match the plans at that point. Sorry to see that. There needs to be a new corrected "starter package" for this project sold with full sized plans.

-

Its OK with me....They look pretty good. I used some 320 grit sandpaper folded up to smooth things a bit. I used the fold to get in those nooks and it made a big difference. I got a bit better with each new try as I gained confidence. I am so happy to see someone try and use the carved versions they make rather than the resin castings. It will mean so much more when the model is finished.

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I am about half way there with more kits. Getting another wood order late next week because I wasnt happy with the quality of the 1/32" sheets of cedar I have left. There were to many imperfections/graininess for my tastes. Maybe another week to 10 days. We dont churn these out in a sweatshop so they take more time to produce. Quality control and the best materials are super important to me. Chuck

-

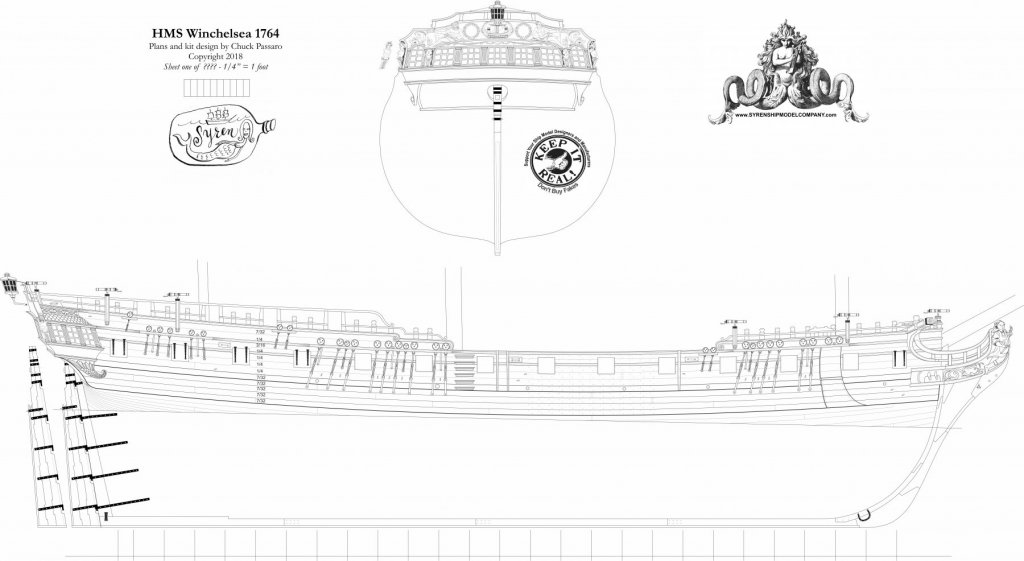

I am not sure if I posted this yet but I want to give everyone a detailed view of the model as it will ultimately appear....hopefully. Here is a link to download sheet one of the plans. I am going to shoot for launching this before it is completed so it is important that you guys see what the Frigate Winchelsea will ultimately look like. This shows the profile and stern view. Dont worry, like all of my plans, this first sheet wont contain any parts so no need to worry about pirating. Download and have a look!!! Because the image has very fine lines so a jpg like posted above is just too light. Click below for full size sheet. Winchelseaplanone.pdf

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Take it easy Nic....rest up. When you are back to work you will be able to work twice as hard now!!!!! You are all fixed up.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

I was just checking everyones progress. I noticed there are a bunch of guys who started logs but havent started building yet. Hows it going with those? I checked to see if they were indeed shipped out and they were. I am just trying to keep the momentum going on this build. I look forward to seeing some of you guys start your models. If anyone has any questions please let me know. I am waiting on yet another batch of milled cedar but hope to have more kits available in a couple of weeks. Its never too late to join the group if you are interested. While you wait, check out the other logs and be sure to encourage those already building the model. Thanks Chuck

-

Nice start...Is it me or is the bulkhead former severely warped and bent? I would also caution on that forward bulkhead. The top timbers dont look like they have nearly enough thickness to fair them properly. Just an observation. I think fairing that hull is going to be a challenge. I see you already added a bunch of strips to fix what looks like mis-shaped bulkheads. Am I correct? We shall see. Chuck

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.