-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Silver Soldering Tools

dgbot replied to bundybear1981's topic in Metal Work, Soldering and Metal Fittings

It takes practice but well worth the effort. David B -

Silver Soldering Tools

dgbot replied to bundybear1981's topic in Metal Work, Soldering and Metal Fittings

The solders you are showing are for use with a soldering iron. Silver Solder melts at over 1250 degrees F. I believe there is a tutorial on this sight that can better explain what it is. You can buy silver solder from any jewery supply store. David B -

I am waiting to se the end project. I hope you have good optivisors. And a microscope. Have fun. David B

- 52 replies

-

- steelgolem

- missouri

-

(and 1 more)

Tagged with:

-

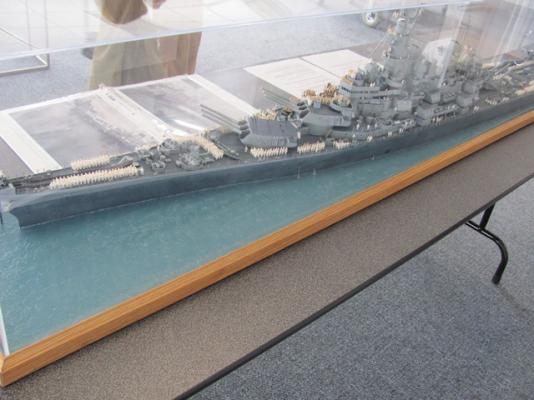

The Missouri was a large ship. You could alway build it a 1/192. But the size would be rough. Heres a photo of the Missouri I took at a contest.. David B

- 52 replies

-

- steelgolem

- missouri

-

(and 1 more)

Tagged with:

-

Homemade Rudder Hinges

dgbot replied to lamarvalley's topic in Metal Work, Soldering and Metal Fittings

Nicely done and well thought out. David B -

Years ago I purchased a Jarmac 4 inch table saw. A perfect waste of money. Very underpowered and not very accurate. My Minisaw from Preac had more power. When Jim Byrnes came out with his saw I threw the Jarmac into the trash and forgot about it. David B

-

Homemade Rudder Hinges

dgbot replied to lamarvalley's topic in Metal Work, Soldering and Metal Fittings

For hinges stay with brass strips. After annealing they can be shaped and soldered to the desired shape. You can then either blacken them or paint them as I did. David B -

Increadable work Dan. Reminds me of a couple of chinese puzzles I have seen over the years. How many parts are in that assembly if I might ask. David B

-

Beautiful work. Where did you get those wood clamps, or did you make them yourself? David B

-

Welcome aboard Dan. Question, what kind of wood are you using for your lifts that you need a wood hardener? David B

-

I shudder to think of the bits you must have broken. Or else you have a very steady hand and a ton of patience. David B

-

Homemade waterline markers

dgbot replied to Long9Ron's topic in Modeling tools and Workshop Equipment

-

The Bluenose makes up to a great looking model. There are many build logs to look at as well. David B

- 152 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Painting brass fittings

dgbot replied to Monarch's topic in Painting, finishing and weathering products and techniques

Your fittings may be too smooth. For paint to stick the surface must have a little tooth. Try soaking them in some vinegar for a while. After insing and cleaning try the paint again. David B -

Be very careful of any tool you buy from Harbor freight. The tend to sell cheap import knockoffs of many tools. From airbrushes to a foredom. They do have good deals. But know what you are getting first. David B

-

Toni, Your joinery is flawless as usual. I will miss looking at your log. Have a good time and have fun. David B

- 1,449 replies

-

A good test in patience and determination. How many were scrapped before you were able to get them perfect? David B

-

Greg, You need to be certified. It is a shame that half of your beautiful work will never be seen once yur model is done. Do you prefer a padded cell or a nice workshop? David B.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.