-

Posts

1,285 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by reklein

-

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

reklein replied to Torbogdan's topic in Non-ship/categorised builds

This is an old build,maybe around 2011. sorry. Someone had asked weather I sanded off all the laser char. If you're interested I could PM you a few photos of the build. -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

reklein replied to Torbogdan's topic in Non-ship/categorised builds

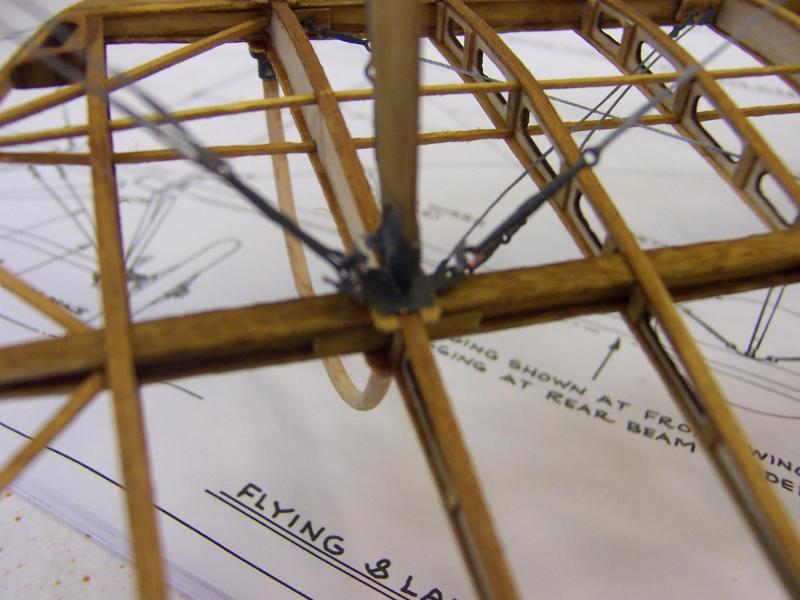

My wife found the photos as she is the designated archives keeper. Looks like I only sanded gluing surfaces. Here's the pic. -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

reklein replied to Torbogdan's topic in Non-ship/categorised builds

Its been a few years since I built the model,maybe even as much as ten years. Probably I sanded the ribs as there were small bumps left after removing from the fret. I'll see if I can find photos. -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

reklein replied to Torbogdan's topic in Non-ship/categorised builds

Dry fit the spar and compare it to the holes in the ribs to get the right configuration. Have fun with this kit. I built the Jenny and it was a fun build although time consuming. Which is what its all about anyway. -

Welcome aboard SGT Mac. This is indeed the place to get info on a model ship build. Use the search feature and you should be able to find a ton of pics of the connie.

-

Good solution. This is an old model airplane trick for making rounded wing tips and control surfaces. When one is thinking ships sometimes different techniques fade into the background.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

AHHH ,with the horse trailer. Be sure to clean em out good,before hauling your household goods.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

I've found that a nice big horse trailer is very handy for moving furniture. They're low and have a ramp.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

Model Railroaders have a paint remover product called ELO Easy Lift Off By Polly S paints but unfortunately I don't think they're in business any more. I've used it for removing lettering etc. on train models. However you're probably done with this part by now.

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

8 microns shavings

reklein replied to Gaetan Bordeleau's topic in Modeling tools and Workshop Equipment

I have quite a bit of experience with AYC as I lived in Sitka Alaska for 30 years. Its quite common there but large clear trees are hard to find. Its also the area Sitka spruce comes from and has supplied the aircraft and music instrument busines probably since WWI. AYC is very nice to carve but it is fairly hard. The growth rings don't have that marked hardness that some types of red cedar do. A problem with it is that the dust from sanding can be a real irritant to the skin and mucus membranes. It used to raise little blisters on the sides of my fingers. It takes detail really well. Also because ts a little oily it doesn't stain well and some types of paint don't adhere well. -

Shop Made Dremel Drill Press- Not my idea

reklein replied to Mike40's topic in Modeling tools and Workshop Equipment

The plywood mount is a clamping device. See the screw heads exposed in the end view? That birch plywood is very good material for jigs. Its much more dense than construction grade ply and it has no voids. Weighs twice as much or more than the same thickness of const. grade. This seems to be a pretty good idea. I need to make a similar device to hold one of the small slow turning screwdrivers to use for drilling styrene as a Dremel is so fast that it melts the plastic at high speeds and has a lack of torque at slow speeds. -

Nils, how did you cut the rims from the eyelets for your ports? Bill in Idaho

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

The thing about building a large passenger ship is that when you are finished you have become a master craftsman because of all the repetition required to complete the job. Bill in Idaho

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Antiquing a wooden ship

reklein replied to Bill Hime's topic in Painting, finishing and weathering products and techniques

One of the Vasa builds has a great antiqe finish ,but I dont think he explains much about it. I'll give you a link if I find it. check out md1400cs Vasa build or Moonbugs Santa Maria with a good antique type finish. Bill in Idaho -

Wood masts for a plastic model... Tips?

reklein replied to SomethingIsFishy's topic in Plastic model kits

I'm a fan of making masts from straight grained square stock. Its the only way you can get a predictable taper. Mark the center of you spar on the end with a dot. Then taper the spar equally on four sides keeping your center dot in the middle. Then carve your tapered square stock into an octagon, again keeping your dot centered. Once you have an Octagon its easy to sand it round,and did I say keep the dot centered. Its pretty toough to taper bamboo although its true that its strong. Id recommend basswood just be sure of the straight grain. As you care the wood ,you can use a knife or a small spoke shave. There will be some grain direction so if the blade wants to dive into the wood revserse the direction of carving. Good luck anyway, and replacing weak plastic aint a bad idea but proper rigging can strenghthen it just as on a real ship. Bill -

I like the ships from that era,they all have a nice traditional shipshape look to them. I spent 9 months on the USS Intrepid,Aircraft carrier and mustered out of the Navy after another year on the USS Yosemite AD-19,destroyer tender. Basically a floating machine shop. Something about haze gray. Bill

- 227 replies

-

- BlueJacket Shipcrafters

- Stephen Hopkins

-

(and 2 more)

Tagged with:

-

Really nice job you are doing here. Its great you have the luxury of visiting the prototype. I built Bluejackets Victory ship in the military configuration and had a tough time documenting the details. I'm happy with the results but could have done better. Bill in Idaho

- 227 replies

-

- BlueJacket Shipcrafters

- Stephen Hopkins

-

(and 2 more)

Tagged with:

-

I'd recommend CA also. You'd just be going round in circles trying to solder and resolder joints However you should be able to find a 12 watt soldering iron online. Used for soldering tiny LEDS. Things would need to be jigged up to hold while soldering which you probably know already. Bill

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hey Nils, Nice work. My wife , a business secretary calls those "bagfeet" , brads. In her business they are used to fasten the pages of a multi paged document together. Thats a pretty clever use you have made of them for your bowls. Bowels are our intestines. Sorry to be so picky, I speak about 6 words of German so I can only wish my language skills were as good as yours. Bill in Idaho

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.