-

Posts

1,285 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by reklein

-

Adding Weight to the Keel of a non-RC Model

reklein replied to Julie Mo's topic in Wood ship model kits

Try pouring some shot into the hull till it feels right. Then solidify it by pouring in some epoxy. -

I think the Billings Oseberg Viking ship might be a good place to start. The planks are all spiled and laser cut for you. You have to be very careful and take your time, but , seeing you are already a model builder and understand the use of tools you should be able to handle it.Theres a couple build logs on it too. But its straight forward and the pieces are large.

-

Excellent cabinetry, Thanks for the little video. I have a friend in wood working club who makes those nice boxes.

- 291 replies

-

- bounty

- billing boats

-

(and 1 more)

Tagged with:

-

Great Bounty build Steve ! That's a great choice you made for a first R/C plane. With your skill in building things you shouldn't have much trouble getting it done. One thing tough, be sure to get an experienced R/C flyer to check out your plane and test fly it . Then get him to teach you to fly it. I can guarantee failure if you try to fly it yourself. That model works great on floats too. On another subject , did you build your tool boxes I see in your studio pics. They are really handsome.

- 291 replies

-

- bounty

- billing boats

-

(and 1 more)

Tagged with:

-

Mystery Model - Question for Moderators

reklein replied to David Lester's topic in Wood ship model kits

I'd leave it as a representative of where you started. -

My biggest build was the GPM Arizona in 1-200. Took Years to find the time to finish it among other projects. Learned to make railing from wire for it. Then made a dozen or so planes including a Stuka, Mig, F-86. and a B-17. Did some heat forming of clear plastic salvaged from bubble packs for the canopies anad nose bubble. Lots of fun. I've got a stash of paper kits too. The Missouri, a large Japanese ship, a Shipyard Bellona etc. Won't live to see them built probably but I might try. Lot easier to collect than build. I thought getting old took a lot longer than it has.

- 106 replies

-

- digital navy

- v108

-

(and 3 more)

Tagged with:

-

I love card models. They have a lot of character, both ships and planes. I kinda like the fact that they come with the finish already done.

- 106 replies

-

- digital navy

- v108

-

(and 3 more)

Tagged with:

-

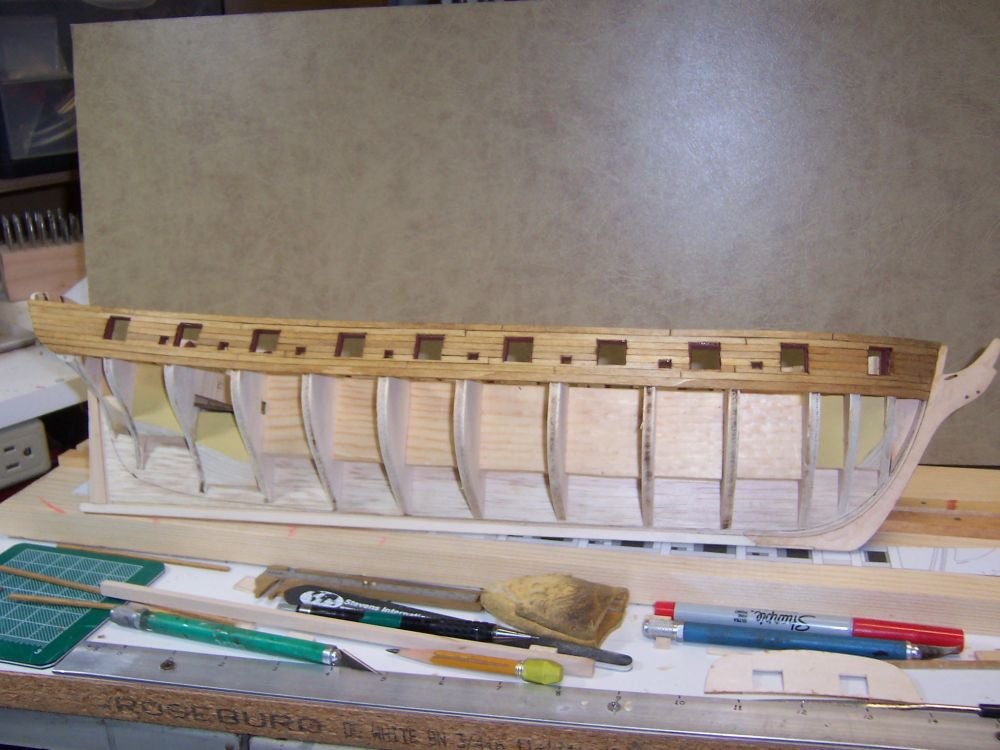

I like how you're doing the tuck in thee stern. It becomes quite obvious where the stealers will go.

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

I have broken both the flat piece and twisted the handle off the screw. I made some plastic washers to replace the flat pieces. Right now I'm more worried about closing up the space with an even umber of planks. Next few days will show. I got a couple extra books on the subject. Also I'll be saved by the fact I'm going to copper her. So as long as she comes out smooth ,I'll be happy.

-

Lisboa Tram and Diorama by puckotred - OcCre

reklein replied to puckotred's topic in Completed non-ship models

One of my college profs. had a sign in his office that said "Good things come to those who wait, as long as they work like hell while they're waiting". Looks like you've done your work Mr. Pucko. -

Try Prieser model railroad figures. Germany product. probably be 1/87.

-

Aww Shucks Jesse. We're sorry . Tough break.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

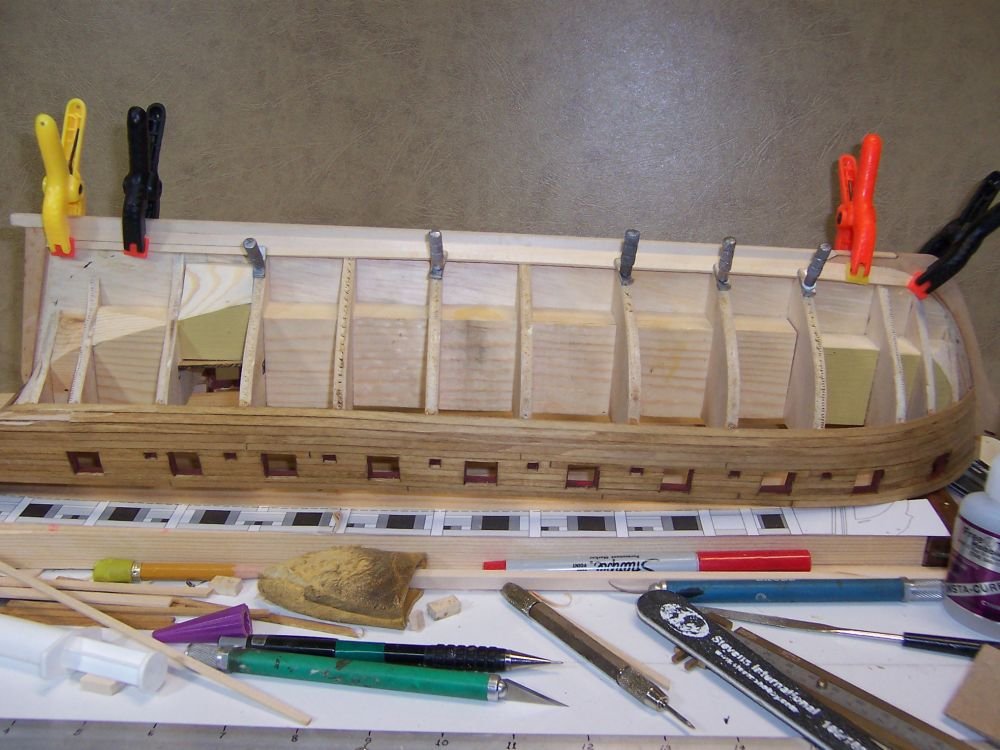

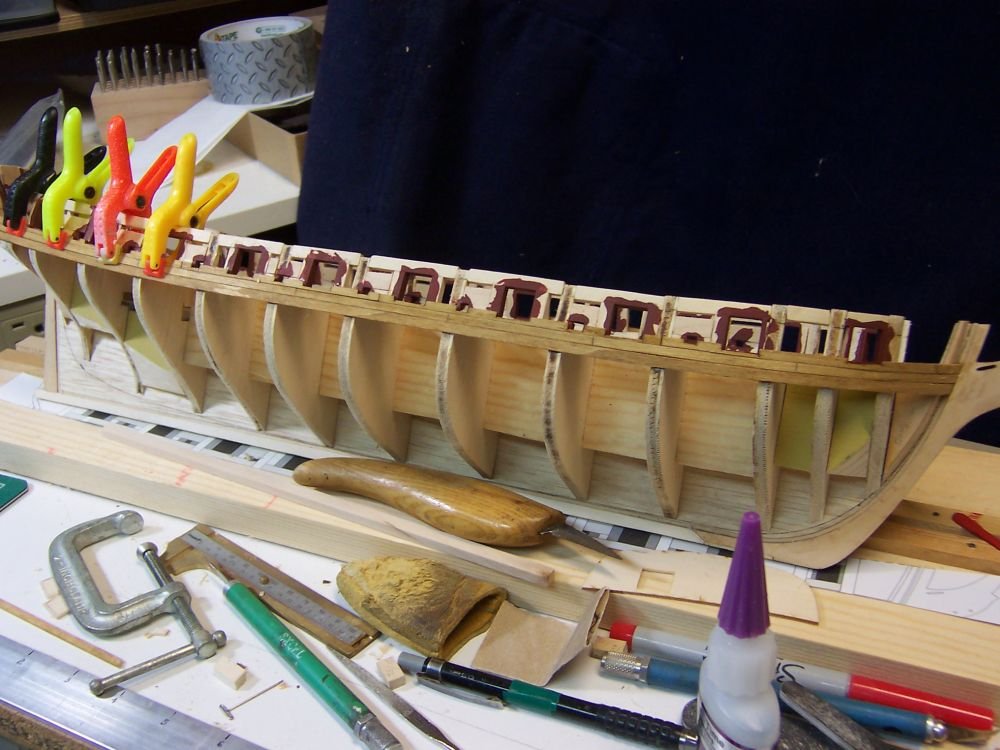

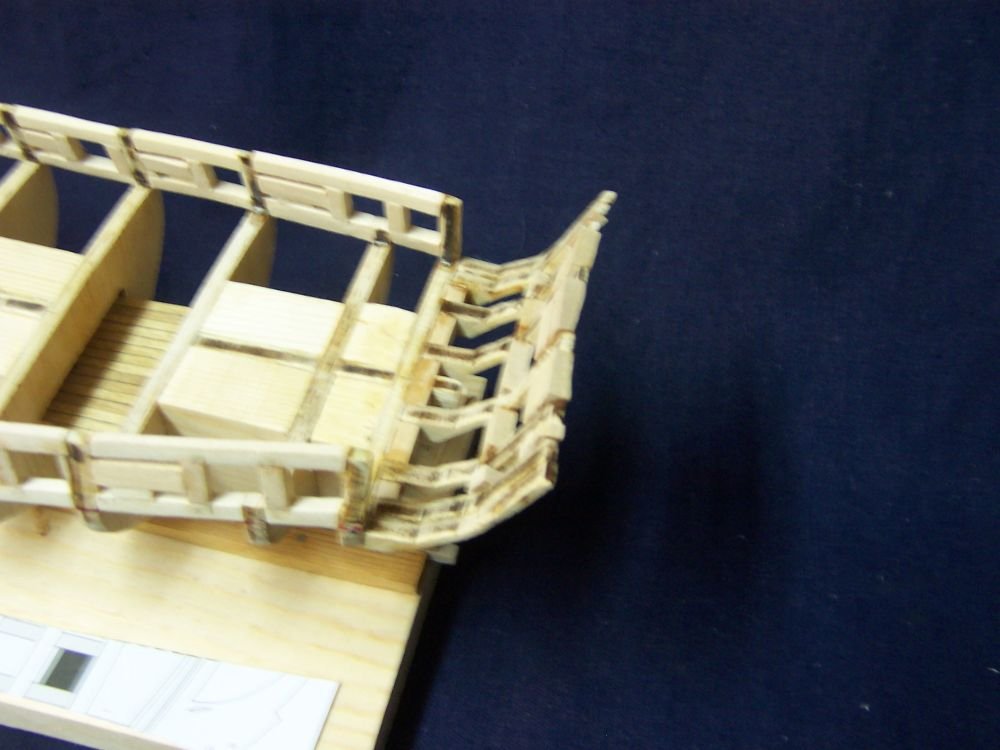

OK here are some poor photos of my stern framing. Chuck was right, very fragile. I'm just about ready to start a little planking.Lots and lots of small pieces of wood.Am using an exacto razor saw and miter box for most. For the gunnel blocks there are some 40 identical pieces for the gunport uprights those I cut on the scroll saw.

-

ancre Chebece 1750 by Jeronimo - FINISHED

reklein replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Holy cow !!! That first pic in the series gave me the impression that a large fish had died on your work table and only the bones were left. Then I continued looking and found a wonderful piece of workmanship. -

Supposed to be nice on Sat. again David. Be sure to take in Whitebird days on Sat. You have to play horse poop bingo.. You but a piece of tapea and put your name on it and stick it on the street in Whitebird. If a horse poops on it during the parade you win half the money collected. The other half goes to the local school functions.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.