-

Posts

1,718 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by flying_dutchman2

-

-

AVOID AMMONIA SOAKING

"soaking in Ammonia breaks down and liquefies the Lignin in the cells making the wood more bendable. When the Ammonia evaporates while the wood is clamped in place to the desired bend, the Lignin solidifies in a somewhat degrade state weakening the wood.

So true AND it screws up the wood. As it says, 'degrade" the wood. It becomes a 'different state', it no longer is the original piece of wood. In the long run the wood degrades and becomes wobbly.

There are many processes of bending wood but water/steam is still the one of best method to bend wood. It has been around for centuries. There are several Dutch naval painting's that show the bending of planks for ships. Some of the replica's that were built in the Netherlands (Amsterdam and the Utrecht), the bending of 3 inch thick planks were done with steam.

On a later date I will add another quote on chemical bending vs natural bending.

Marc

-

Main mast and its sail are (almost) ready. Some better pictures:

Looks to be ready for display in het Scheepvaart (Naval) museum in Amsterdam. I like the sails on the ship. My motto is, " a ship is complete with the sails". 95% of the model ships in museums have sails, either fully open or furled.

Excellent job. I love the stern on the Batavia.

The "Michiel de Ruyter" is a movie I have to see. I will just wait for Netflix or VuDu.

Marc

-

While I was on vacation at the naval museum in Amsterdam I took these pictures from the model Volvo 70 ABN-AMRO. It was part of model display of 400 years of yachting in the Netherlands. Antique models from 1600 to modern models of 2000.

btw. I took 500 pictures of models, paintings, figureheads, etc. all from Dutch ships.

Marc

-

-

-

-

:)Hans;

The Batavia is coming along very beautiful. You are doing an excellent job on this ship and I have been following closely on your built. I love the lines of this ship as well as the colors.

What book/article is the ezelhoofd and rakketalie from? The "rakklootjes", (bottom right)...... . Interesting name LOL.

. Interesting name LOL.

Marc -

dgbot;

Thanks for the similar advice.

I removed the too thick of the frames and redid them so after measuring the hull I am off by 2mm. Which is fine by me.

I also measured where the canon holes should be and I am good to go.

Mirabell61;

Lots of scrap wood which is always used for something. Cutting and sanding wood is best done outside as I do not have a vacuum setup indoors to remove sawdust. So I plan to do most of the cutting and sanding of wood in late spring, summer and fall.

Marc

-

robin b. - Thank you for your interest. You will not be disappointed.

tlevine - Thank you for this important tip. I did not even think about this. I will take your advice and redo the incorrect frames.

Thanks,

Marc

- popeye the sailor, mtaylor, dgbot and 1 other

-

4

4

-

Several boo-boos have been made. Some of the frames are 1/4" where they have to be 3/16" and vice versa. There are more 1/4" frames than 3/16" so the boat is about a 1/2" longer than the original plan. I thought of re-doing these frames but it is all wood, so one can manipulate this very easily.

I checked the plans from Hoving and Emke and it is not significant. The boat will just be a wee bit longer.

Marc

-

-

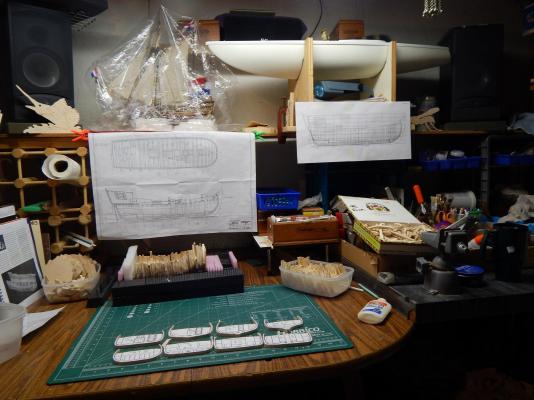

Table full of Tupperware with frames in them. The real boat will be a POF but there are also frames for a simple POB hull I will be building.

The table is a bit messy, with the Mary under plastic (she is waiting for her display case and the hull on the left is a R/C Soling 1 meter. This model I bought used from a member in my local club. The fish in front of the speaker is a small puzzle. I create simple nature puzzles for kids with the scroll saw.

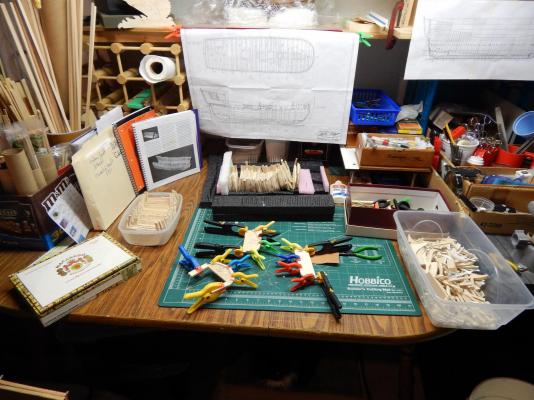

Chocks that are being glued to the frame.

-

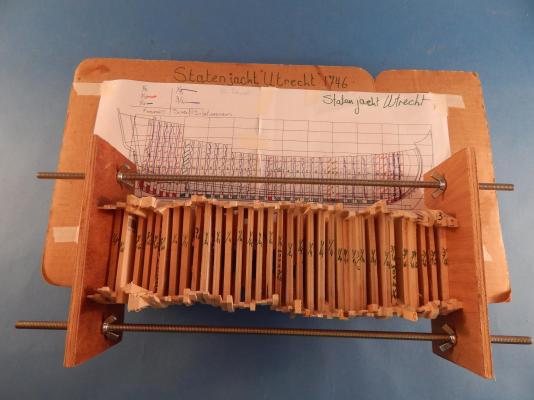

This is a clamp that I copied out of the McArdle book. The clamp has 2 - 1/4" threaded rods with nuts and the wood is old plywood. It will hold any size hull together. Depended on the length of the threaded rods.

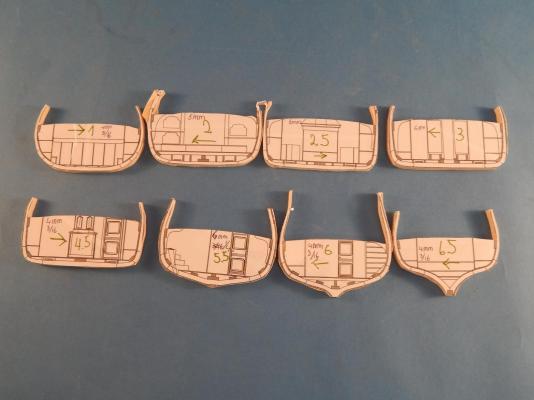

The cut out frames.

The scrap wood that I will be using for the ‘in betweeners’ of the frames or I think they are called chocks. Pieces of wood that go in between the frames.

- cog, mtaylor, popeye the sailor and 3 others

-

6

6

-

- mtaylor, kees de mol, Piet and 1 other

-

4

4

-

The boat looks great and agree, I love the color of the stain. The nails look neat as well.

Marc

-

The built looks great, lots of steps that I will remember when I built this boat.

When I look at the hull, it looks like half a boat because the stern is so wide. I expect it to tapper.

What are you going to do about sails? Create your own or is there a manufacturer that makes custom sails for this type of model.

In between working on the Statenjacht Utrecht, I am also working on a Soling 1m. Because this boat is one of the most popular RC sail model there is company that will create any sails you design.

After doing some advanced searches on Google I found 4 large plans as PDF's (ABN 1 & 2, Illbruck and Ericsson). In due time I will built one of the ABN boats.

Marc

-

-

Looking good already. Makes it look so easy the way you are building this boat.

Seems building these boats is a hit as there are several sites that show others building them as well.

This Aussie has a beautiful build log from the "Volvo 70 Ericsson"

http://www.rcuniverse.com/forum/rc-sailboats-89/8076736-volvo-70-ericsson-build-log.html

Marc

-

Here is a Dutch guy who built the ABN-AMRO as an RC pond yacht

http://www.mijnalbum.nl/Album-HB6GKQON-Foto's-in-Nootdorp.html

Update from the above guy.

http://s694.photobucket.com/user/noordje_01/library/?sort=6&mediafilter=pendingcomments&page=1

Pete, where are you getting your plans from?

Marc

-

-

Here is a bit of history for everyone. Notice when they first started that there were many more boats/crew than the present?

http://www.kriter.tv/history/whitbread_history.pdf

Marc

-

This is going to be an interesting built. I always watch these races when National Geographic has made a movie from it.

I'll be following this one.

The name Whitbread race has been around for a long time. This is also a race where people die while sailing. Especially around the 70's where there wasn't as much modern technology.

It is the ultimate sailing experience.

Marc

-

Hi Jack;

Season is always slow as parents buy stuff for kids for school, family vacations and parties. People have less money until September. I like your phrase of the "brown season".

I am building the Utrecht. Have taken the pictures of cutting out the frames, also the many boo boo's I made (but basswood is cheap) and need to post them. I am using several methods, POF and the typical 17th century Dutch ship building - keel, a few frames, build up hull planking and use a template to add the rest of the frames.

Presently lots of clearwings (hawk moth family) on all the red flowers in the yard and I saw the first Luna moth. They are becoming rare in this area. They are attracted to the mercury lamps in sports fields.

Joining the NRG is a good thing. Having these two organizations together (NRG & MSW) is a win win situation for everyone. It creates a powerhouse in many areas of ship modeling. All that talent together under one roof, so to speak.

Regards,

Marc

-

In the 90's I created a similar program in MS Access with a SQL database attached. Does pretty much the same thing. I spent around 2 years putting this together. Works well but after looking at this book collector program I think I am going to switch. I hope I can import all my data from Access to the Book Collector app.

In addition it is from a Dutch company and I always like to support my fellow countrymen.

Marcus

VOLVO OCEAN RACE Open 70 By Pete48 - FINISHED - Scale : 1/4" = 1' - 0"

in - Build logs for subjects built 1901 - Present Day

Posted

I am working on that. Will post a thread in the museum part of the forum. One for the Rijks museum and on for the Naval museum.

Marc