Zarkon

-

Posts

205 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Zarkon

-

-

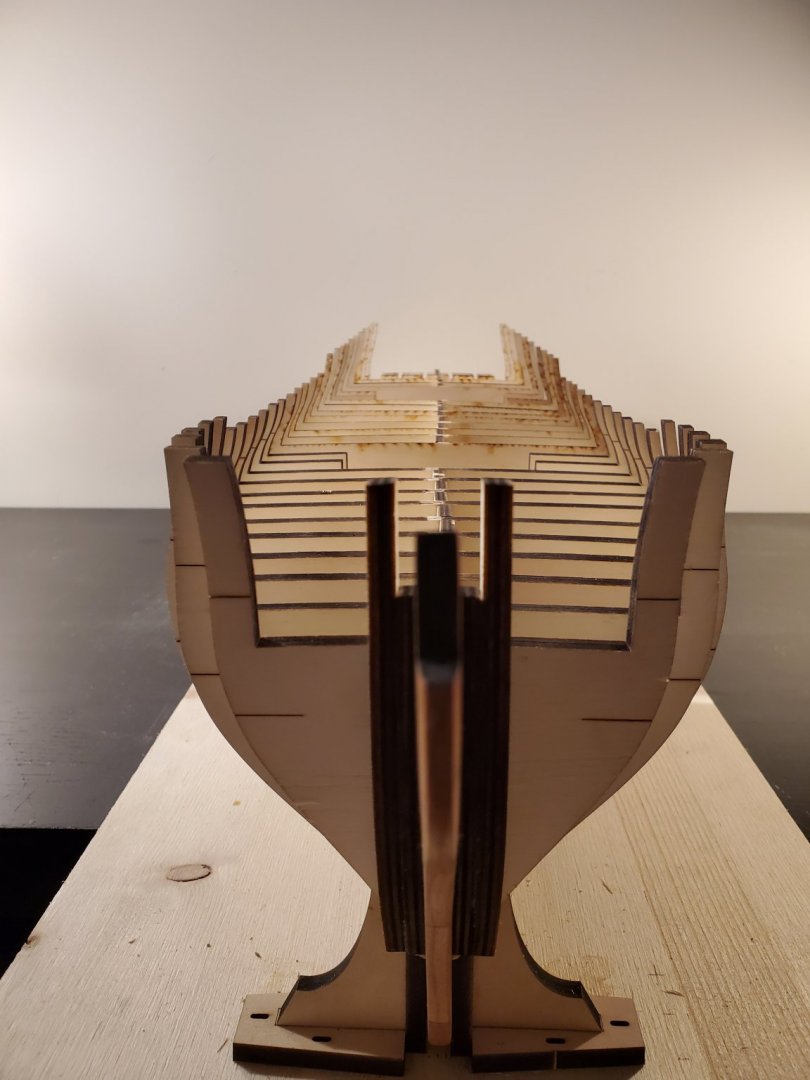

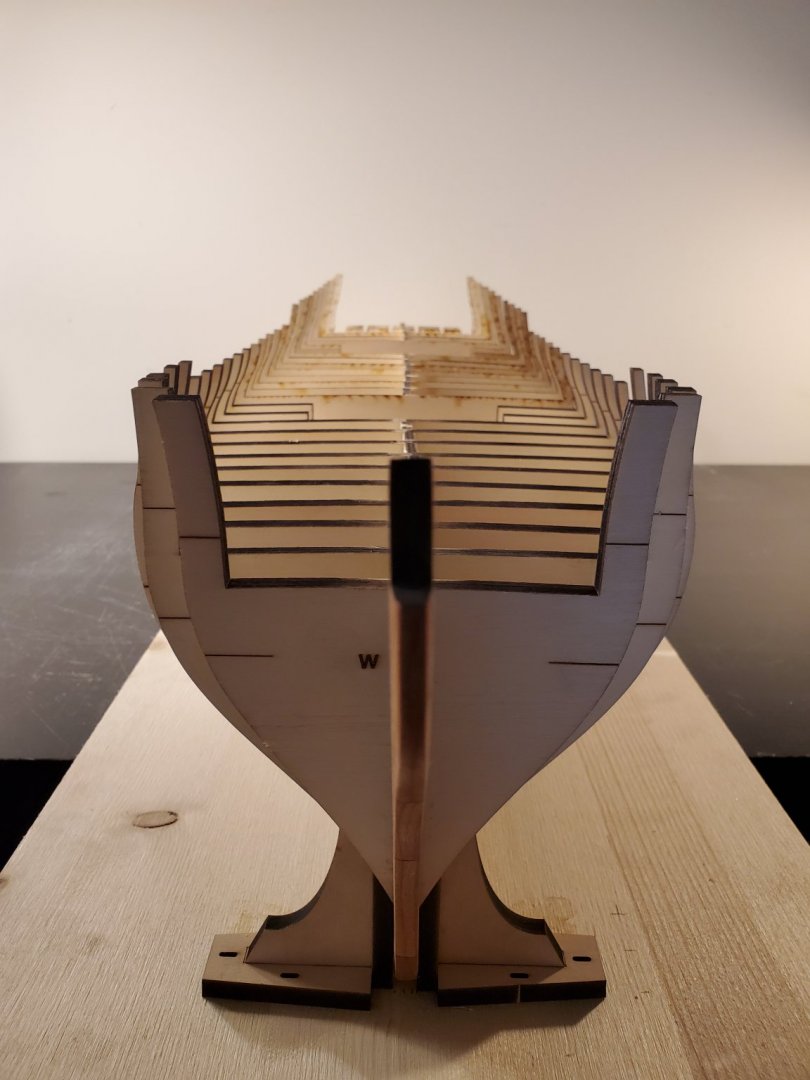

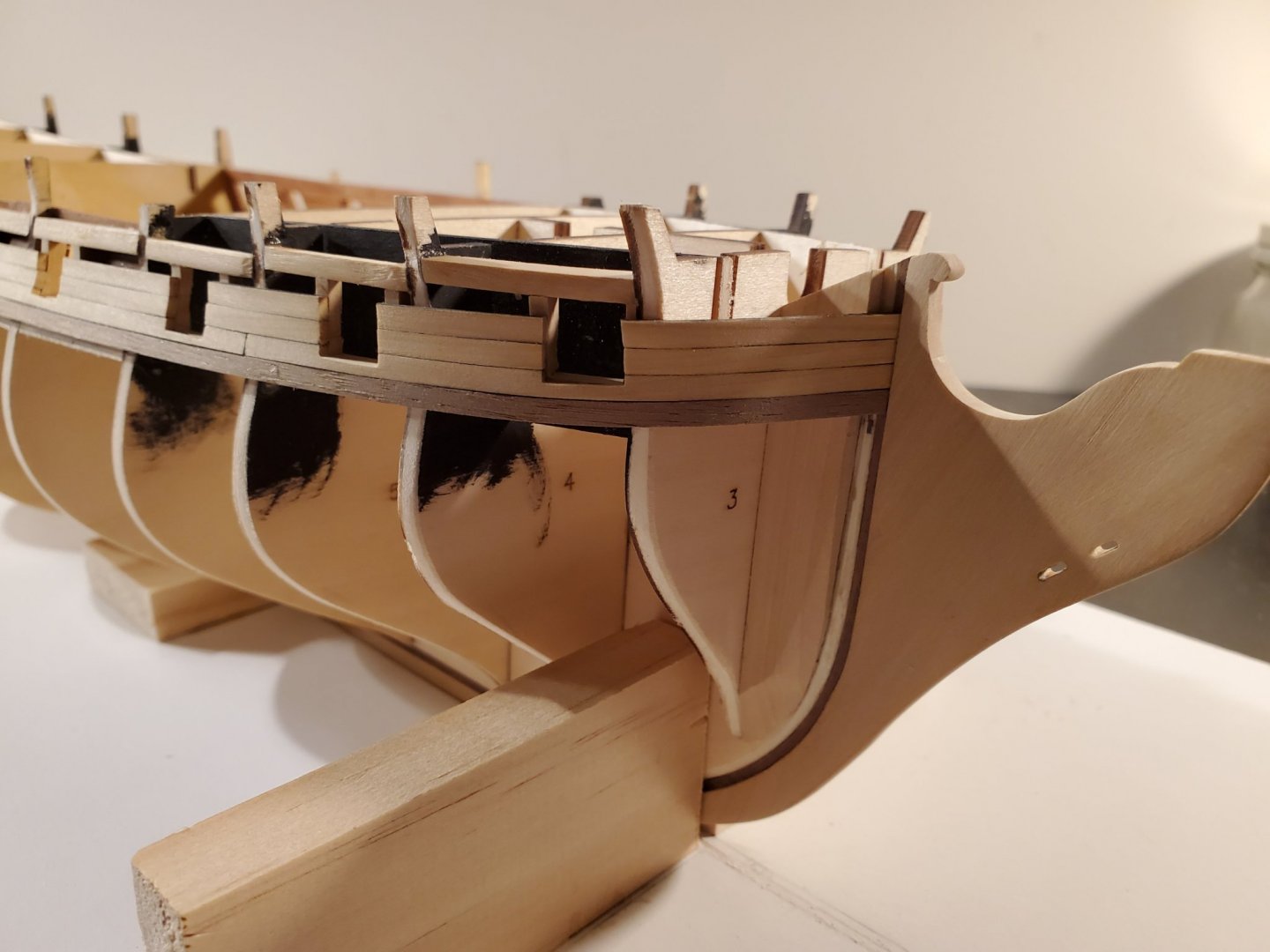

Thank you everyone for the likes!

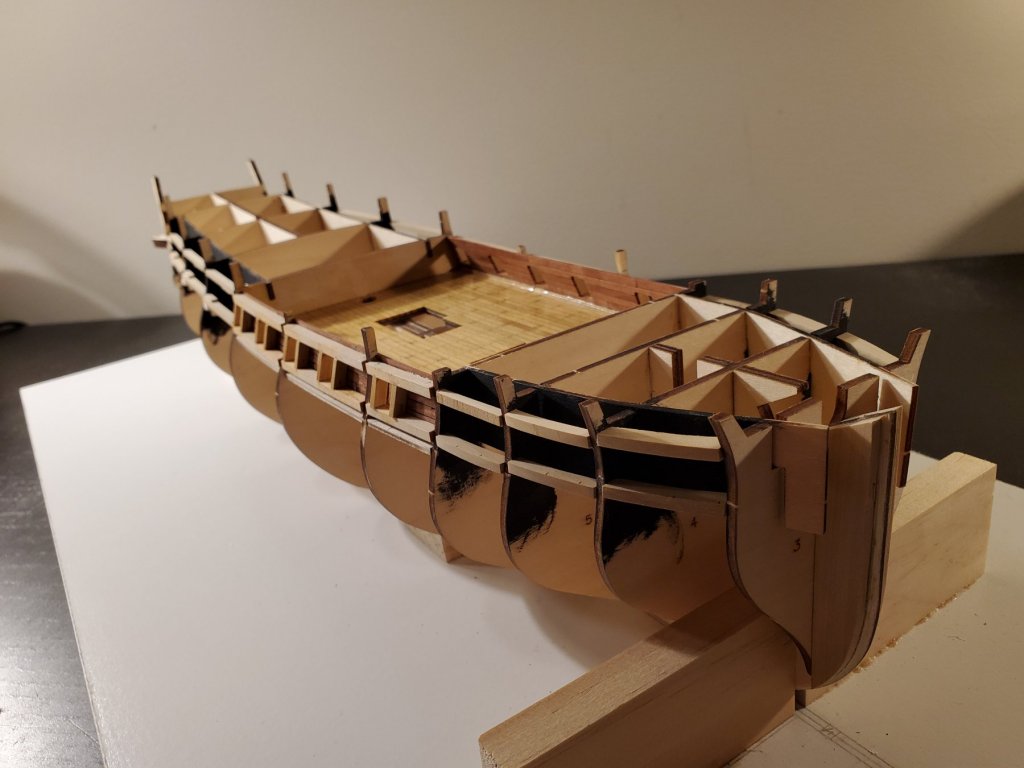

Today, I finally finished gluing on the bulkheads! For the filler pieces at the stem, two of them were pretty warped. So I had to douse them with water and clamp them to my building table to straighten them out. After they dried, I glued them on one at a time. Only unclamping each piece when I was ready to glue them on.

That seemed to work and the filler blocks are now glued into position! I did my best to straighten the tops of the frames. They are somewhat better positioned, but not perfect. That's okay though, because the bulkheads themselves are straight. You will see what I mean with the pictures.

As you can see though, on the last pic, the back part of the frame is twisted. I will do what I can to straighten it out before the end of chapter 1.

Onto fairing the hull! After looking through other logs here ar MSW, I know this will take a while. But its VERY important to get right or planking the hull will get more difficult. I hope to start fairing this weekend!!

Thanks all!

Jeff

- Chuck, Edwardkenway, JpR62 and 11 others

-

14

14

-

Thanks all for the likes!

Slowly but surely, I am adding the bulkheads. This is a small update, but I can't just quickly add and glue the bulkheads or the bulkheads will be way out of alignment. The bulkheads themselves are slightly warped, but they are a small enough warp to fix when adding the supports later in chapter one. The bulkheads are off by 0.5 - 1mm.

Little over half way done!! It is fun though. I have never seen a 1/48th scale so this is exciting!

Thanks!!!!

Jeff

-

On 1/7/2020 at 5:15 PM, Chuck said:

If you wanted to, you could clamp those mis-aligned BF tops when you glue the bulkheads in position.

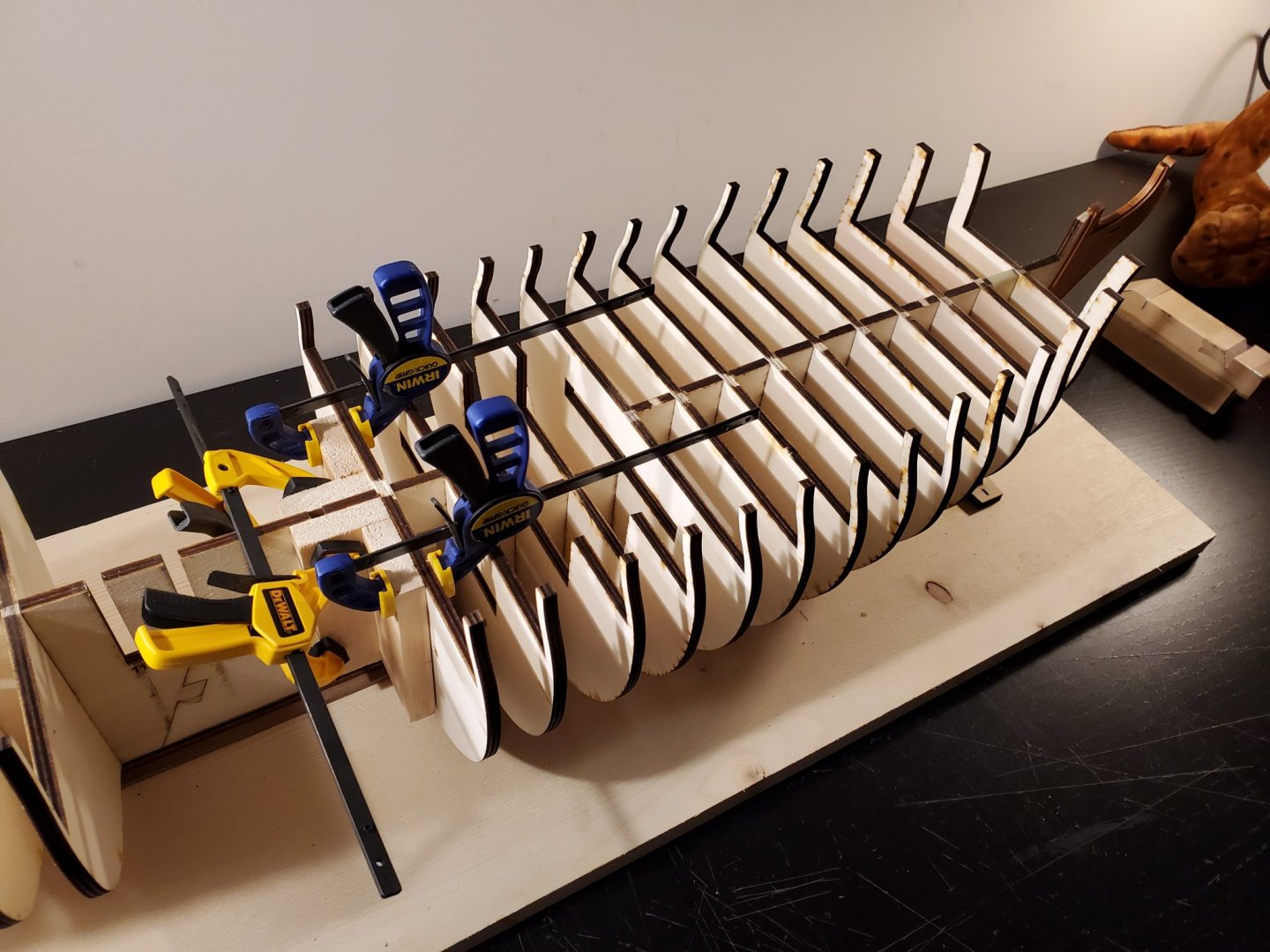

Great idea Chuck!

It was pretty warped at the top, so to help make sure that each bulkhead is perpendicular, I created some right angle blocks and used clamps to help position them back to where it needs to be. The pictures are a better explanation.

I am noticing that it is helping. So this will be a slower process, but I know that this step is very important to minimize bumps and valleys from bulkhead to bulkhead when it comes time to both fare the hull and for planking.

Lastly, the first 2 bulkheads needed to be sanded a little at the bottom so their bottoms didn't hit the stem pieces. Doing this now is a lot safer that trying to take off the this access after it's glued into position.

Thanks everyone!!

Jeff

- Rustyj, Edwardkenway, Matt D and 11 others

-

14

14

-

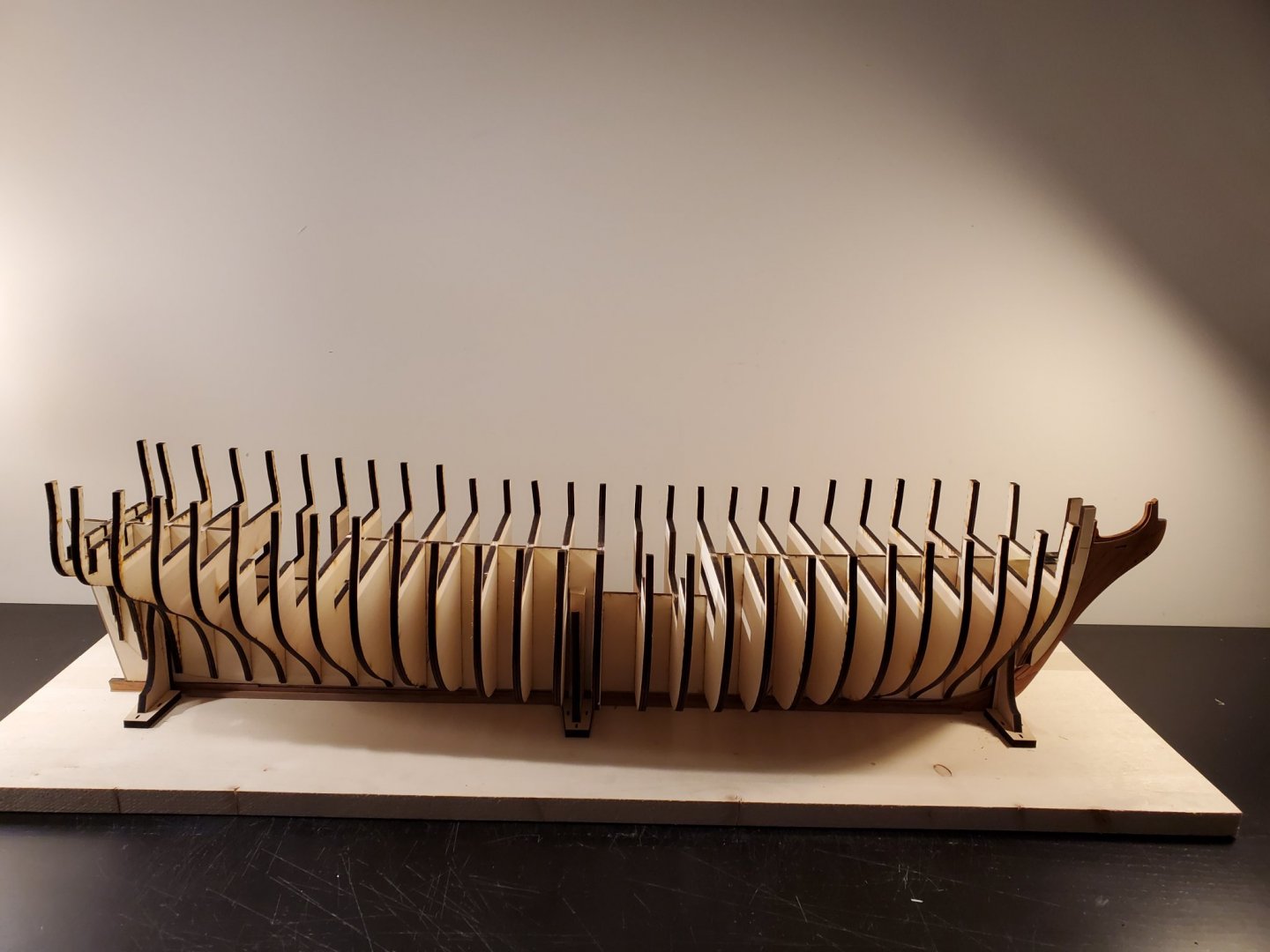

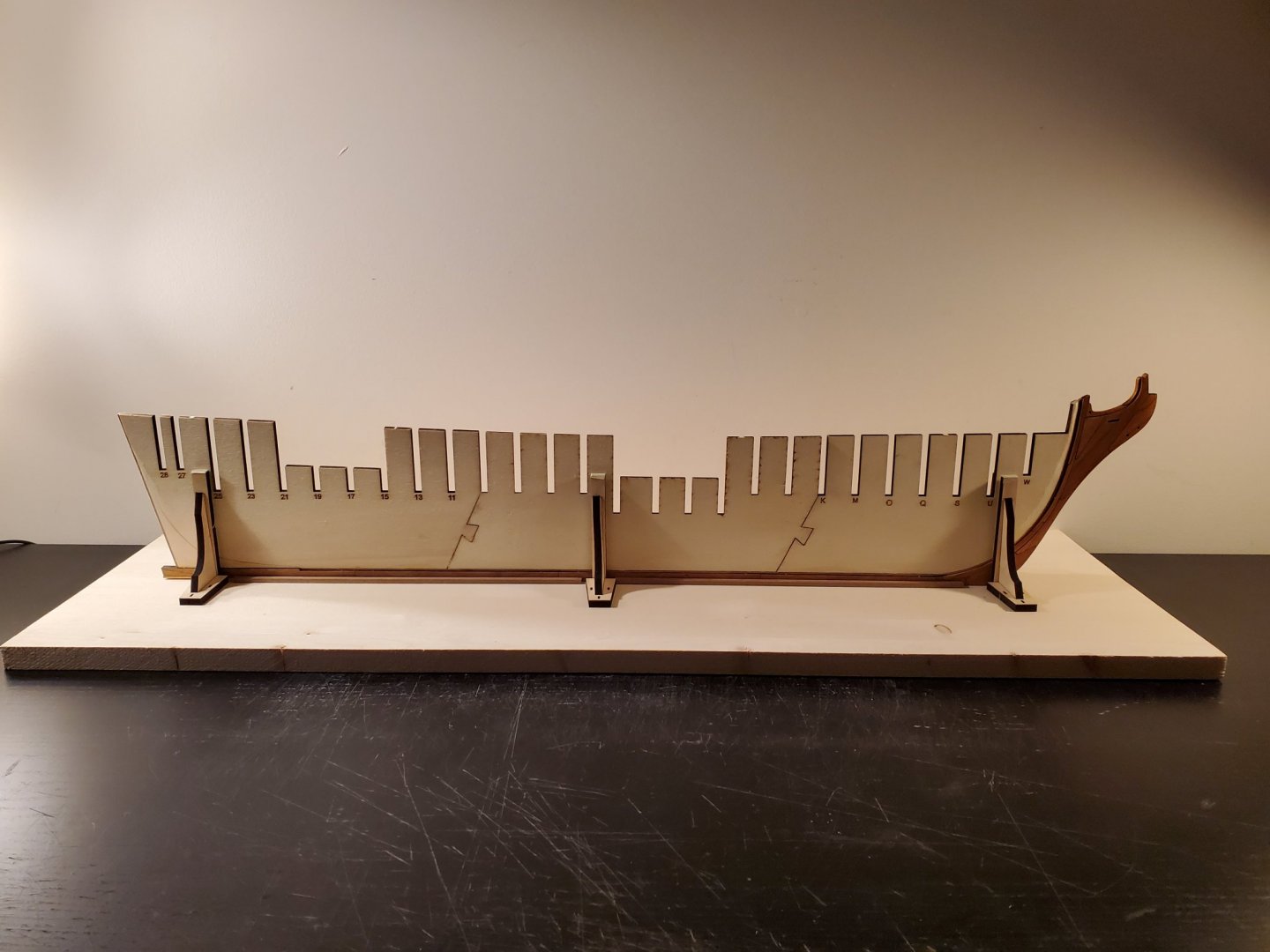

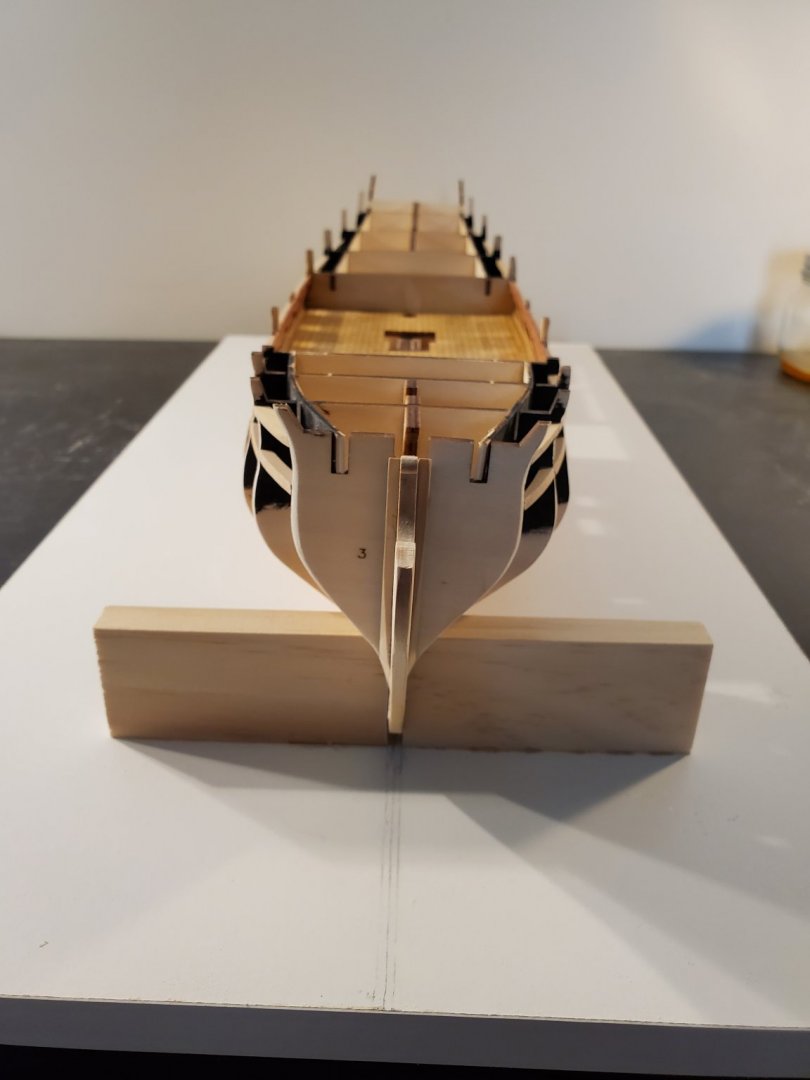

Thanks everyone for the likes! Today since it snowed, I had some time to remove the bulkheads and dry fit them into their slots. First thing I noticed was how big this ship is! It will be very impressive when it is completed!!!

Here are some pics of the dry fitting.

All but 2 pieces went into place nice and snug. I had to sand those 2 to allow them to slide down nicely. There are a few that need to be sanded in a different way because they do not sit perpendicular to the frame. Just some slight slot modifications. It looks like its leaning to the right in the middle picture, but its really not. It is just my bad picture taking! Haha!

My building board is straight and holds the frame very snuggly. The tops of the slots on the frames are warped. This causes the top of the frame to look out of alignment. The bottom where the false keel lies is straight, so the bulkheads actually are positioned straight on the frame.

I will double and triple check the bulkhead alignments and make any modifications before I will do any gluing. I find these pictures fun because there are so many bulkheads!

Jeff

- Chuck, FrankWouts, JeffT and 5 others

-

8

8

-

I came in late to the build, but you have done an excellent job on making a wonderful model! Very impressive!!!!!

Jeff

-

I am almost done making my building board. I just need to fasten the brackets to the board, then I am ready to cut out and fit the bulkheads!

It took a few days because I forgot to order the brackets from Syren on my original order! The pic above is a test fitting of the ship on the build board.

Like what Chuck said earlier, the frames were somewhat bent, but after test fitting it into the building board, it looks like it will straighten out just fine!

Jeff

- Matt D, Jack H, GrandpaPhil and 9 others

-

12

12

-

About the figurehead, I plan to try out the fruit wood gel stain and see how that goes. If needed I can also apply some wet wash to accentuate the crevases of the figurehead. Lastly, I can dry brush the top layers for more depth. But it's really a subjective thing as to how much painting will he needed.

Jeff

- FrankWouts, Rustyj, BobG and 1 other

-

4

4

-

Thank you everyone for the compliments!

To answer your question Jack, I did not use a layer of wax. I followed Chuck's instructions:

First I sanded with 220 sandpaper. I then sanded with 400 grit. I dont have 300 grit right now. I made sure not to touch the wood I was varnishing with my hands so no oils got on it. I then took a soft painter's brush and brushed off the sawdust. Lastly, applied 1 coat of wipe on poly with a foam brush. Waited 1 min, then wiped the access off with a lint free towel.

I noticed that it was important to do the last step because that helped to eliminate brush strokes. I realized it really doesn't take much wipe on poly to cover what I was varnishing.

Chuck's instructions are the best I have seen, and his tips make all the difference!

I hope to complete my building board this week so I can start placing the bulkheads

Jeff

- Jack H, BobG, FrankWouts and 2 others

-

5

5

-

Thank you everyone for the likes!!!

Thank you Chuck, I won't worry about the warping and will straighten it out on the build board.

A small update,

I glued thr stem and false keel on the ply, and also put 1 application of the wipe on poly and described in chapter one.

I also added the nails as well. I REALLY like how the wipe on poly looks on the cherry!

I am ready to build the building board!

I will give an update once its built.

Happy new years!!!

Jeff

- Gregory, Tigersteve, GrandpaPhil and 12 others

-

15

15

-

Hey all!

After seeing so many wonderful build logs of this ship, and also following along with Chuck's log, I couldnt resist and had to start a build of my own. I don't have as much time as I would like, so I decided to order the bulkheads, chapter 1, and chapter 2 from Syren. I ordered it on dec 22nd as a Christmas present, and I was very surprised I received it on the 26th! With the holidays, I was sure it wouldn't come in until after new years. Thank you Chuck! You never stop impressing me!

From what I have done so far, I have completed the stem except for adding the wipe on poly. It is amazing how well the laser cut parts fit together! It really required very minimal sanding.

The Chery is very beautiful and I am very happy with the result. It was great that Chuck included a few extra cuts of the smaller pieces in case any of them got damaged while sanding or trying to fit the part. That did come in handy for me.

I then looked at the bulkheads and false keel pieces. I noticed that quite a few of the plywood boards were warped some. So this will need to be corrected.

I glued all 3 pieces of the false keel together on my desk. Since 2 out of 3 pieces were somewhat warped, I took a wet towel and dabbed it over the curved sections and put weights on those places to straighten it out. Once I have my building. Board made, I will move the false keel to the building board to make sure it's as true as I can get it.

I am surprised at how big the ship is! It will be very impressive to look at through out the entire build. I did talk to my wife and got the approval to get a nice table saw to mill the wood I will need. I will be ordering it in January.

Jeff

- Tigersteve, MEDDO, BobG and 11 others

-

14

14

-

I couldn't help myself! I ordered the plywood laser-cut bulkheads and the Chapter 1 and 2 cherry packages! I will make time to start

This build looks so much fun I can't wait! Chuck has made an excellent product, and I want to support his efforts.

This build looks so much fun I can't wait! Chuck has made an excellent product, and I want to support his efforts.

Jeff

- Edwardkenway, Rustyj, Chuck and 4 others

-

7

7

-

Chuck, you are doing a fantastic job! I wish I could start my build, but life keeps getting in the way!

Jeff

- Chuck and FrankWouts

-

2

2

-

Wow! Exceptional repair and continuation!

Keep up the great work!

Jeff

-

Hey all,

It sure has been a while since my last post.

That is because I had to have a 5 hour ear surgery. The recovery time was over 5 days. The actual recovery was very hard. I still get dizzy and asking the doctor for help. BUT the good news was that the operation was a success!

I have not worked on her since then because the dr said I need to rest , not get dust in my ear, or do anything very physical. But below are pics I took starting the planking.

I will probably not post much until my ear has healed and get the okay from the Dr.

I have completed a little more than this, but not much.

I hope to be able to get back to her in a month or so.

Thanks!

Jeff

-

-

Hey all,

Finally started planking the hull!

Instead of using the supplied basswood of the kit, I will be planking with boxwood and walnut strips. These strips will he much more accurate in width for the ship than the kit supplied wood.

I am trying to upload pictures, but I think I have a poor connection for my location. I'll upload some pics later.

Jeff

-

You are 100% correct!! I spent 100% of my time with him on the weekends and until he is asleep on the weekdays after work. I really enjoy spending time with my son and wouldn't change it.

Would I like to have more time for the build? Of course! But family always comes first. I only work on her at night after everyone goes to sleep if I have enough energy.

Thanks for the comment Dutchman!!

Jeff

-

So small update!

I've been so busy and tired after work and running around with my 4 year old son, I have not been able to work too much on her.

But, I have finished adding the vertical gunport walls so now, all I need to do, is to sand them and make sure the hull is ready for planking!!!

Finally!!! I cant wait to start planking! I will plank above the wales first. I will be using Chuck's technique described in his Winy project. I have to say, I am super impressed by his ability to not only craft his models, but also how to explain his techniques! His explanations will really carry me through the planking.

Thanks!

Jeff

-

Just found your log. Your plaking looks great! I look forward in reading your updates!

Jeff

-

- Dutchman and GrandpaPhil

-

2

2

-

Hello all!

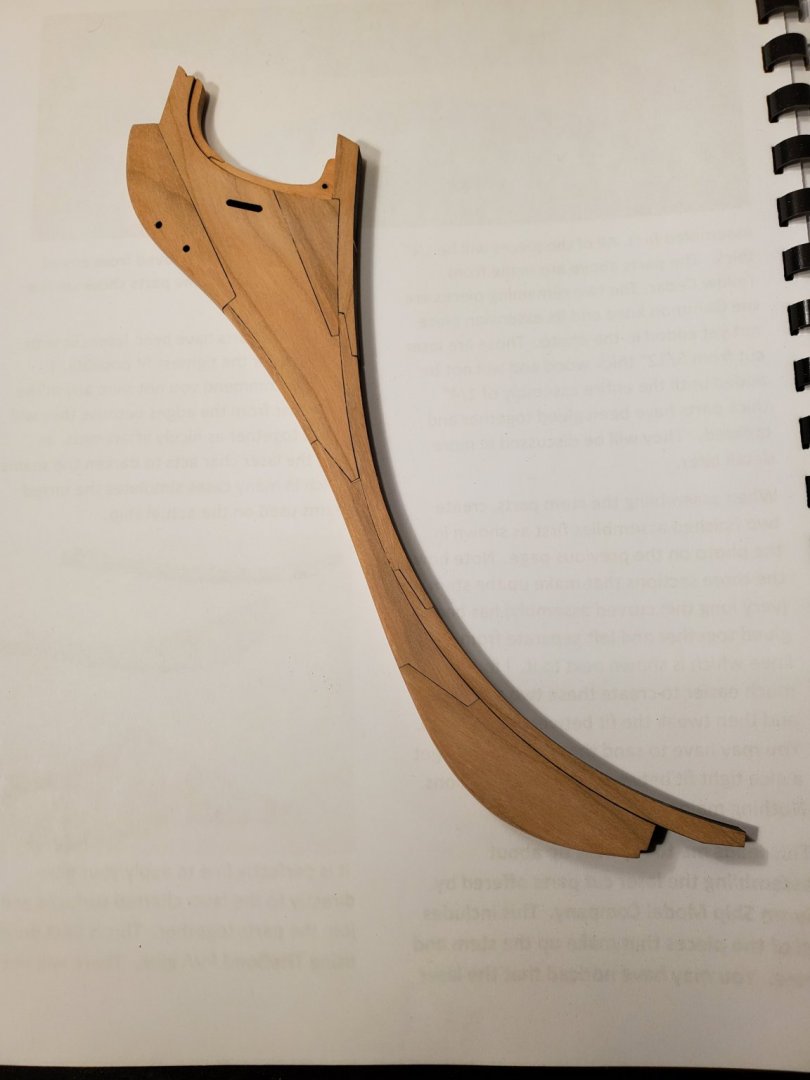

I've been super busy, so not too much time to build. But for an update, I have faired the hull as well as finally added the correct rabbet strip. This should help with planking.

I also have had to create a new stem piece because the one provided wouldn't fit properly with the rabbet added. I debated on making the individual pieces or making it as one piece. I decided on 1 piece because of a few reasons. First, it's small scale, so it would be harder to make all the pieces. Two, this is my first time trying to make a stem out of just a sheet of boxwood. So making one piece would be a good intro into making custom parts with my scroll saw.

This is how it turned out:

I am pretty happy with it! All that is left, is to cut out the holes according to the plans. It is slightly (1%) bigger than the kit supplied stem piece.

Hopefully I will have time to finish it this long weekend.

Thanks!!!

Jeff

- GrandpaPhil and Dutchman

-

2

2

-

-

Thank you Rick!

I really appreciate your kind words! Your encouragement inspires me to do my best, and beyond!

I hope to be able to sand the hull this weekend. I also hope I will be able to order a small hobby table saw soon because I will need to make my own strips.

This Monday, I have ear surgery. I have had a constant ear infection in both ears for 3 months now. I really hope it will be fixed. So I might not be able to work on her for a few days next week.

Thank you everyone for your kind words and likes!

Jeff

-

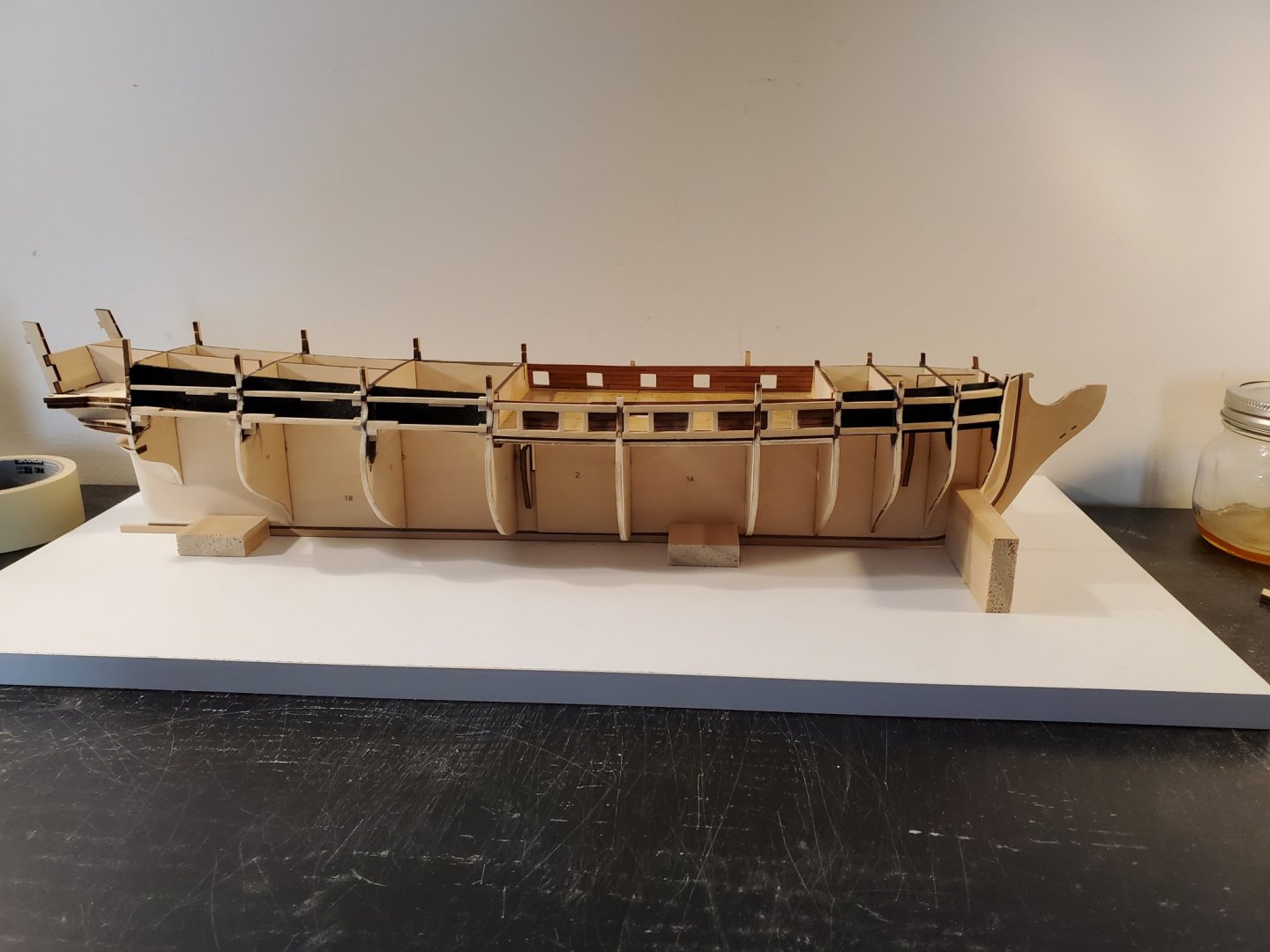

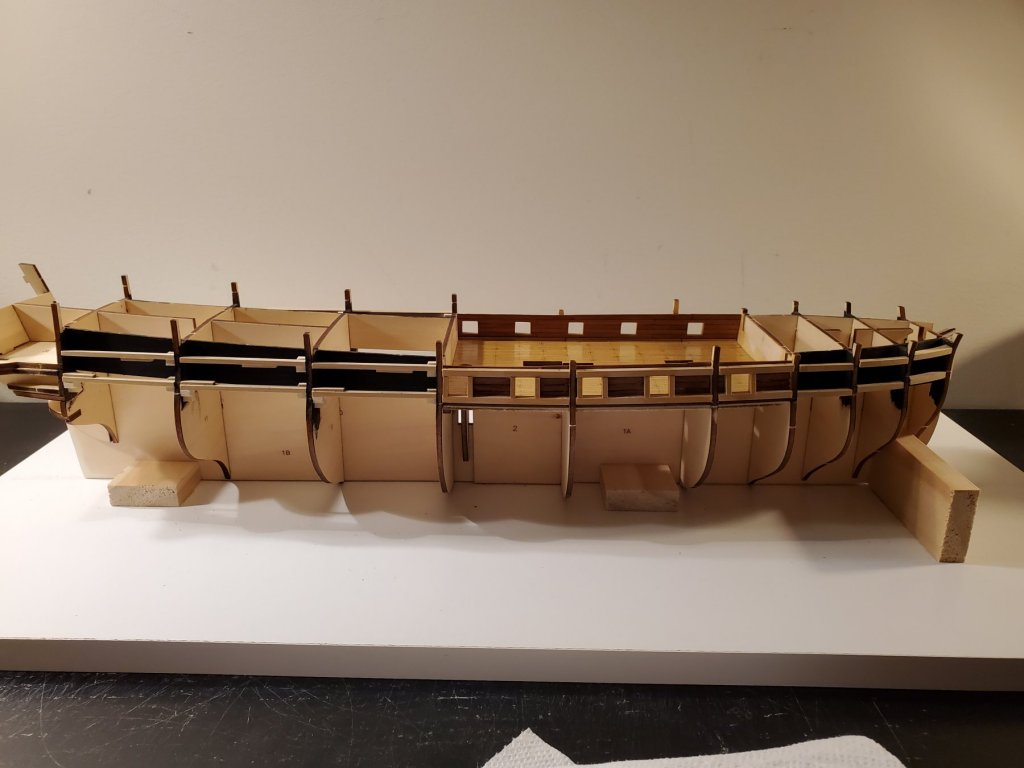

Hey all!

I am still working on her, very slowly!

I have added where I want the gunports to be. I also added supports to the horizontal gun ports so they shouldn't break off when sanding. I want to file/ sand the ships frames now. After that, I will add the vertical sides of the gunports then do a final sanding before planking above the Wales.

My only issue is finding the time to do the sanding. I can't do it where I normally build because it's too much dust. I hope I can get to it this week!

Here's to hoping!

Jeff

- Dutchman and GrandpaPhil

-

2

2

HMS Winchelsea 1764 by Jeff 1/48

in Member Build logs for the HMS Winchelsea

Posted

Its been a while, but it's time for an update! I am currently fairing the hull. This hull is huge!!! I don't have too much time right now to do this work, but slow and steady. I am about 80% done with one side. Then only one more side to go!

I noticed that the glued frame sections were starting to give too much and almost break. So I added supports on both sides to strengthen the joint.

I hope to get some time this weekend to do some more fairing, but my soon to be 5 year old demands a lot of attention!!

Jeff