-

Posts

1,920 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by hamilton

-

-

I see it's been quite a while since I've updated here.....not that I'm on a schedule or anything!

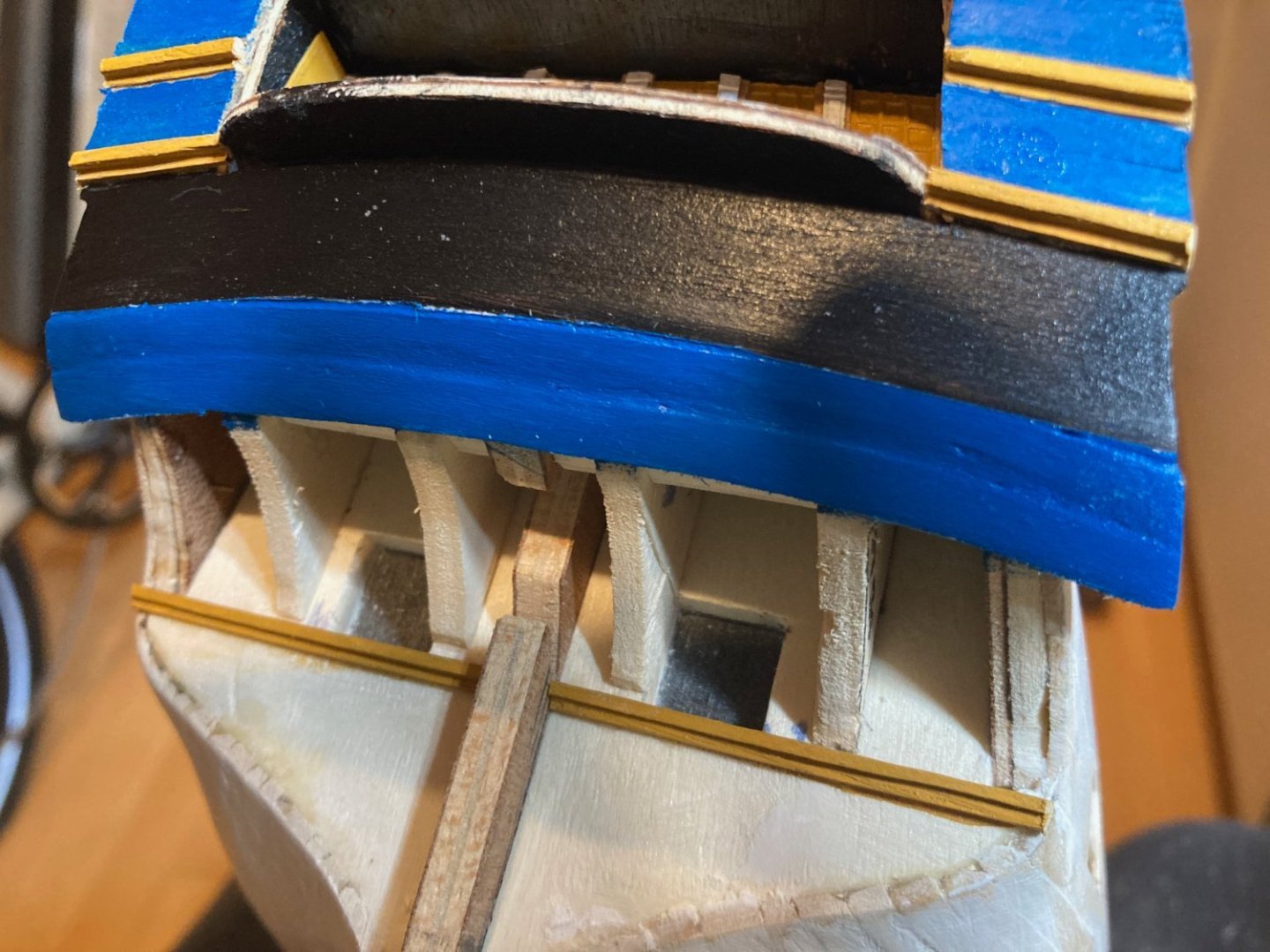

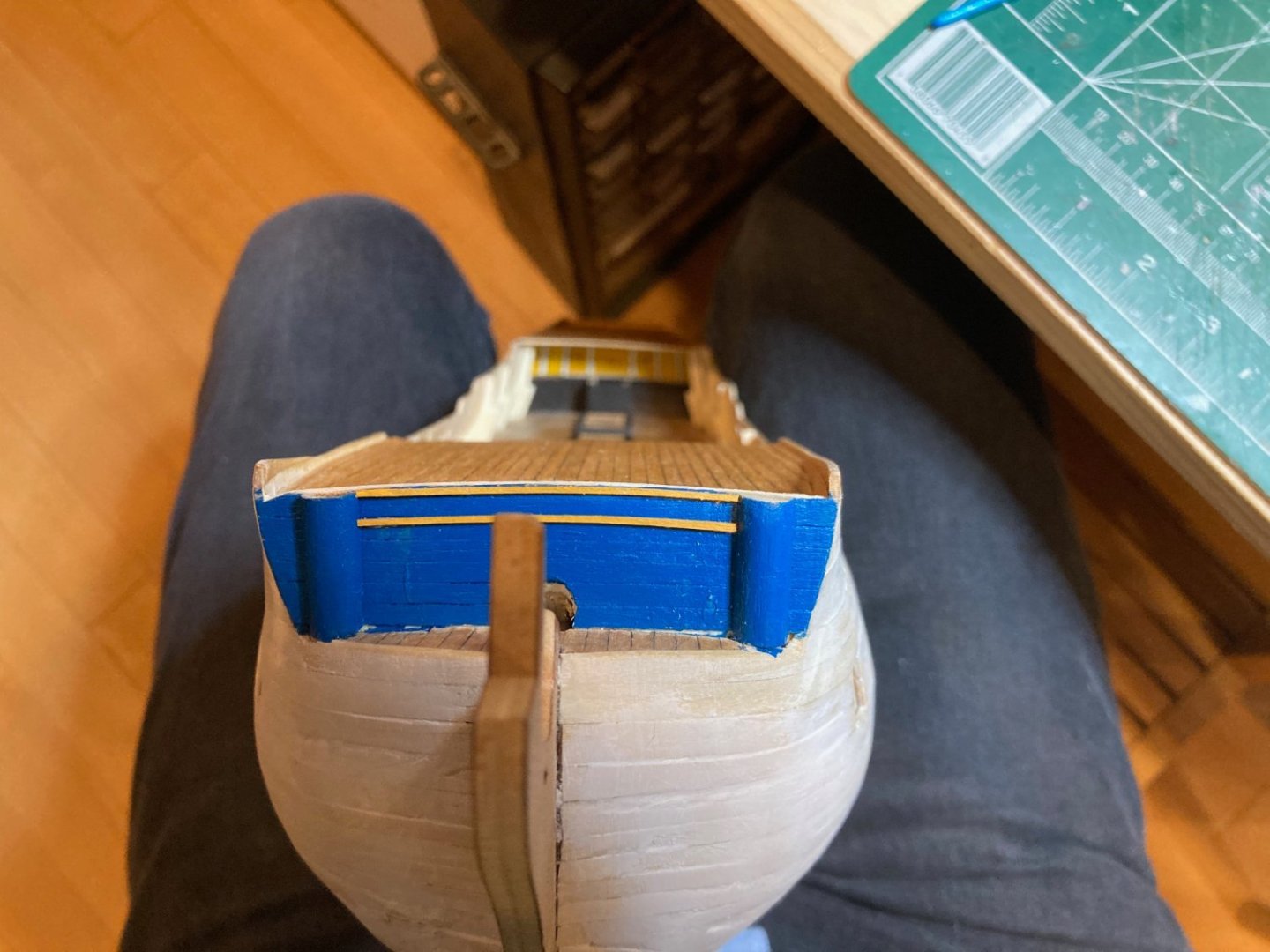

In any case, I didn't get as much done on Bellona over the holidays as I hoped. But since the new year, I've managed to get a start on the second planking - starting with the outboard bulwarks. The first element laid here was a strip of molding that runs flush with the top of bulwarks mid-ships and follows the sheer to the beakhead forward and quartergalleries aft. This was a more or less straightforward operation, though it was eased by adding this strip in 3 sections and then blending these with acrylic modelling paste. The first section ran in line with the ship's waist, the second ran forward to the beakhead and the third aft to the quartergalleries. I finished this in Golden acrylic yellow ochre.

I've now also completed the first strakes of outboard bulwark planking in 1mm x 3mm walnut - 2 strakes laid below the first molding strip and cut around the main deck gun ports. This posed few difficulties. All of these elements will be finished in yellow ochre eventually, so the contrast between the limewood gunport lids and the walnut planking will be masked.

One thing I noticed on installation of these first planking strakes is that the gunport lids already installed on the model will in some cases stand a little proud of the hull planking. Once these strakes were installed, I had to commit quite a bit of elbow grease to sanding the lids down to be more or less flush with the surface of the planking. Here are a couple of photos - not great or very interesting ones, but....you get the impression.

Bye for now and happy modelling

hamilton

- yvesvidal, Nearshore, Panteg Models and 1 other

-

4

4

-

-

Looks good so far - I'm not sure where you're located, but I'm in Vancouver and have visited the St. Roch many times. I have a tonne of photos of the reconstructed vessel as she sits in the Vancouver Maritime Museum and I'd be happy to share these with you if you like - not sure how detailed you want to get, but they might be helpful.....PM me if it's something you're interested in.

hamilton

- Panteg Models and Diver

-

2

2

-

-

-

That person is me!!! Planking drives me crazy!!! But I love building deck structures and absolutely love rigging.....The hard part is - who gets the finished product!! It's easier to ship a hull than a fully rigged model, after all......but I've always wanted to visit Tennessee!!

hamilton

- MajorChaos and GGibson

-

1

1

-

1

1

-

-

-

I think your build looks really great! Very neat work at this small scale!

hamilton

- Kelp, Tony28 and Knocklouder

-

2

2

-

1

1

-

Great work on the topmasts!

hamilton

- mtaylor and Paul Le Wol

-

2

2

-

Thanks for the suggestion, Thunder. The fairing down option does seem ruled out at this point.....But I'm not sure I'm daring enough to go for any major surgery.......the problem is that once I start on any solution I won't be able to stop and the chances of really messing things up after that is pretty high.....On my Bluenose log I spent a bit of time explaining that, as someone who models for pleasure only, I'm not too worried often about historical accuracy and am perfectly happy if things look more or less tidy. I did want to hold myselkf to a higher standard on this one, so I'm feeling torn - my "natural attitude" is to just press on with an anachronistic transom, but then there's part of me that wants to intervene.....I've been working on other parts of the model to avoid making this decision, but it's gotta happen at some point!! But first.....coffee!

hamilton

-

A bit more work on Bellona today - finishing up the counter planking, stern chaser gunports & the filler blocks at the bottom of the quarter galleries. The lower counter planking was initially a little confusing - the kit calls for 2 layers of planking here but the total thickness (2.5mm) seemed a bit much, so I installed only 1 layer of 1mm x 4mm strips here. I added some extra framing around the gunports so I could plank up to them and painted this framing red, which will be slightly visible once the gunport lids are installed. The last plank to be laid was the one up against the upper counter planking - I made a template for this from card paper and transferred the curve to a wood strip - it took quite a bit of trimming and shaving and sanding and carving until it fit reasonably well - a little bit of filler, sanding and painting later and the results look pretty good, I think.

The next step will be the make gunport lids for the closed gunports in preparation for the second layer of planking. I decided against using the dumby gun barrels provided with the kit and to keep any ports that featured these closed. The plan is to install the gunports (minus any hardware) prior to second planking, so I can plank around the ports - hoping this can lead to clean results. In the meantime - enjoy the photos and happy modelling

hamilton

- KurtH, Tony28, KARAVOKIRIS and 4 others

-

7

7

-

Hello there:

A bit more work on the stern area - I installed planking on the upper counter - spiled from 1.5mm x 10mm stock - and started on the quartergallery framing. In working on the latter, I decided to scrap the 1.5mm plywood support piece - it really did not seem necessary to me - and took a different approach.

The first step was to make a tracing of the general quartergallery outline from the plans and transfer this to the model - I was happy to discover that the tracing needed no adjustment and that it fit very nicely in place on both port and starboard sides. Once this was done, I used the outline to trim the framing pieces in their length and width so they fit nicely in place - the aft edges of all pieces and the inside edges of the lower two piece also had to be chamfered slightly to fit. I used the trimmed pieces to mark out their locations on the hull. Filler pieces could then be added using 1/16" scrapwood. It was then a very simple matter of installing the frame pieces.

That's all for now - enjoy!

hamilton

- Tony28, Mr Whippy, Knocklouder and 1 other

-

4

4

-

Some progress on the transom while I continue to ruminate about the second planking at the stern.....looking at the small number of other Bellona logs on MSW, I'm struck by how different the transoms are on each - all look good, but all are slightly different - for example, on Harlequin's excellent Bellona log, the balcony, moldings and bottom edge of the transom seem not to have the same athwartships curve (not sure if I can use "camber" in this context) as mine does - certainly not as pronounced. This led me to angle the molding pieces on the transom face so as to follow this line, which required also some fine fitting of the transom planking. The planking between the moldings will be covered by photo-etched parts, so I just laid these strakes in line with the molding. The transom was finished blue to show through once the stern figures are added at a much later stage, while the area beneath the balcony was finished black - some other p-e parts will be fitted there eventually. I also added moldings at the joint of the lower counter and the transom - these mark out the sills of the stern chaser ports.

This has been an interesting experience - I haven't made this complex a stern area since my Blandford build over a decade ago, and that was quite tricky to work out. This one is a bit more complicated than that, so I'm trying to go slowly and to be as methodical as I can - but I'm bound to make some mistakes - I wonder if I've already made some and am just waiting to find out about it!!

In any case it's still fun, so all is well. Enjoy and happy modelling

hamilton

- KARAVOKIRIS, Mr Whippy and yvesvidal

-

3

3

-

Thanks Allan - I'm still open to trying something to correct the issue - Roger, your solution could work - I'll have to develop some more confidence before trying it - but the exposed section of the sternpost gives an indication of the correct angle along the sheer plan, while it is relatively straightforward to determine the section line at which the issue begins. My main concern is my ability to actually do this without seriously compromising the model...I wish I had another hull to practice on! In any case, it's not always terrible to have problems and since I won't have time to work on Bellona for a while there will be plenty of time to mull over how to proceed....I thought I was decided, but I may find a way of working up to something like what you suggest here, Roger.

hamilton

-

Thanks Nearshore - I had pretty much decided to go the historically-inaccurate-but-structurally-convenient route, but maybe I'll spend a bit of time studying the model and seeing if I can't manage to correct things as you suggest above....it seems that the planks would need to bend at a really sharp angle without removing quite a bit of material from the bottom edge of that bulkhead....in any case - thanks for the suggestions, illustration and support!

hamilton

-

Checked out the wikicommons images and the round tuck transom is pretty obvious from the draft of "Dragon" and the paintings, though the profile drawing of Bellona is hard for me to read - I assume that the arrangement of the transoms below the wing supported a round tuck, though my familiarity with draughts is pretty limited.....I am leaning towards continuing with the build as-is, disappointing as that is, since I definitely do not want to risk the kind of major surgery that a re-build of the stern of the model would involve at this stage.....and I don't have the patience to see how far I can sand the stern down to the degree that would be needed - I'm not even sure that's possible......sigh......

hamilton

-

Thanks Allan:

Sanding feels like the only option for bringing into line with Bellona's design - but I feel like the risks to the model of attempting this are pretty great...I'll take a look at these drawings and see if I can work something out...I'm honestly confused as to how I got to this point - there is no indication on the plans and Lavery's stern drawings in the AOS are highly equivocal on this part of the ship. Indeed, on at least one of the Corel plans (a profile drawing) it certainly look like the lower hull planking ends at a square tuck transom....but I haven't seen any other builder of this model make the same error, so obviously I missed something really crucial....

hamilton

-

Hello there:

I posted this question in my build log for Corel's HMS Bellona, but thought it might get more traction here....

I seem to have constructed the stern area all wrong - Bellona had a round tuck transom, but you'll see in the photo below that my build has produced a square tuck transom. This seemed logical to me as I was building the framework and installing the first layer of planking - the rudder post only protrudes aft of the last bulkhead by about 1/4" so adding fillers there to create a round tuck wouldn't make sense.....but when I look at other build logs (Nearshore, e.g.) there's the round tuck and I see fillers added....I'm not sure how I missed this!! But it is bugging the hell out of me now.....and I'm not sure what, if anything, can be done about it.

My first instinct was to start sanding - but given how much material I would need to remove, I don't know if that's advisdable....the other option (beside scrapping the kit!! which is not a real option) is to just leave it as it is, make it with a square tuck transom and consign it to the same realm as other fabulous and fantastical made-up vessels that can be found here and there among the kit manufacturers of the world....

Anyways, here's an image that shows the problem....it may be that I'm past help here, but......even knowing that will be useful. Thanks all!

hamilton

-

Well - in doing some research into the transom I discovered that I've actually done the stern all wrong!!! Bellona had a tuck stern, as can be seen in Lavery's Anatomy of the Ship, and in several of the build logs here - I took a look at both Yves Vidal's CAF build and Nearshore's Corel build to confirm....But if you look at the photos of the stern above on my build, you'll note that I terminated the lower planking on the edge of bulkhead 19, rather than shaping it as a filler block to define the tuck of the planks at the transom! This is a "square" transom, which can be seen in earlier ship designs....Corel's plans do not make this obvious - though if I was paying attention I probably could have caught this......

I'm not sure what to do about this now - I feel like I have two choices:

1. Continue as is, plank across the square transom and thus deviate in a serious way from Bellona's actual structure;

2. Try to re-do the stern area somehow to correct for my mistake

Option one is obviously easier, but I would prefer option 2 - except I have no idea how to alter the stern area now to bring it back into line with the proper planking arrangement.....I could try just sanding the hell out of the stern , but not sure how effective that will be. Adding filler material doesn't seem possible without really throwing the sternpost/rudder arrangement off......arrghhhh!!! Any suggestions will be most welcome.....

hamilton

-

Hello there:

Work has now started on the transom. I finished the photo-etched bulkhead part in yellow ochre - it comes in two parts with a central pilaster on its tanganyika mount serving to cover the gap between them. Unlike the p-e part for bulkhead 13 on the q-deck, this one fit quite well, with only a roughly 3/64" gap between the two parts when they were fixed to bulkhead 19. There are also two photo-etched doors that are fitten to port and starboard - this leaves a noticeable gap where the framing (painted black) is visible. I'm not sure if there is some subsequent element that covers this gap, or if it is a weird design feature - I'll have to study the plans a bit more to see what's up there....

Attaching the CNC transom was pretty straightforward - just had to mark the centre line for correct positioning and then "clamp" it in place with elastics. Pretty happy with the results so far but I think this work is about to get very complicated and finicky with the quartergalleries, counter planking, etc. Not sure when I'll be able to get back to this in the lead-up to Christmas, but hopefully I can scratch some time out at the bench here and there....in the meantime - enjoy and happy modelling

hamilton

- yvesvidal and KARAVOKIRIS

-

2

2

-

Really nice work!

hamilton

- Retired guy and FriedClams

-

1

1

-

1

1

-

Looks really nice Kurt - happy holidays to you!

hamilton

- Knocklouder and Mr Whippy

-

2

2

-

OK - now that the lower hull planking (lumpy as it looks) is complete I can take a bit of a breather. I've now turned to the beakhead and the stern balcony area before commencing on the second planking. I spent this morning prepping the photoetched parts for the balcony and finishing/adding moldings and doors to the beakhead. I'm still puzzling over how to the bend the 1mm x 1mm moldings around the roundhouses....I'm now wishing that I had added the molding to these half-dowels before installing them in the model....another error in the way I'm staging the build that I'll have to think through.....

In any case, here are some photos of the beakhead. Enjoy and happy modelling

hamilton

- KARAVOKIRIS, Nearshore, Mr Whippy and 2 others

-

5

5

Type of glue to use planking a hull

in Building, Framing, Planking and plating a ships hull and deck

Posted

I always use medium thickness CA for hull planking - and I also get glue on my fingertips. It's a pain! But if you invest in some isopropyl alcohol (nail polish remover) you can remove it once it's dried and crusty - it peels off like a scab once softened by the alcohol - as my skin gets thinner I worry it might take some skin with it when it does, but I prefer to use CA for this purpose as it allows speedier progress on a process I don't always get much enjoyment out of.....I have read of others who use PVA (wood glue), but my impression is that because of the slow setting and curing time it makes for very slow work....I'm willing to sacrifice my fingers for a little bit to get through it!

hamilton