GrandpaPhil

NRG Member-

Posts

4,959 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

New way to mount your mast

GrandpaPhil replied to Geoff Matson's topic in Masting, rigging and sails

I will have to try this when I get around to installing my masts. Thank you. -

I usually lay the model on its side when planking. I just put it on the building board so that the board supports the model and use a tack hammer to drive in pins, or nails, if they are needed. I would read some of the planking tutorials on the site. Chuck, one of the admins, and an expert model builder, pre-bends the planks and uses CA to attach to the model. He doesn’t even use pins or nails.

- 87 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

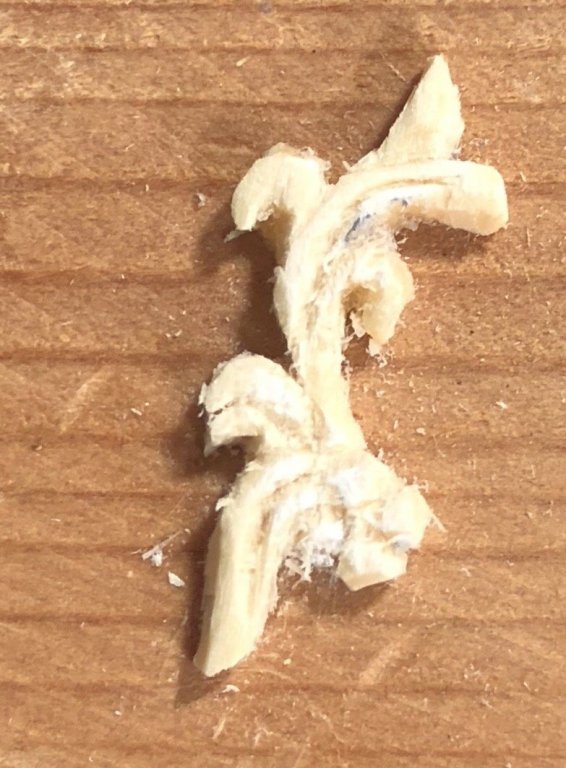

Still working on the entry ports. After one massive failure, I realized that I needed to develop my carving skills, and buy some better quality wood to make my carvings from. Basswood doesn’t hold tiny details very well. However, I ran through the carving tutorials in the group project, which were very helpful, and I’m going to press on with the entry port carvings.

-

Looking good! I’m building the same kit and I’m about a year and a half into it.

- 32 replies

-

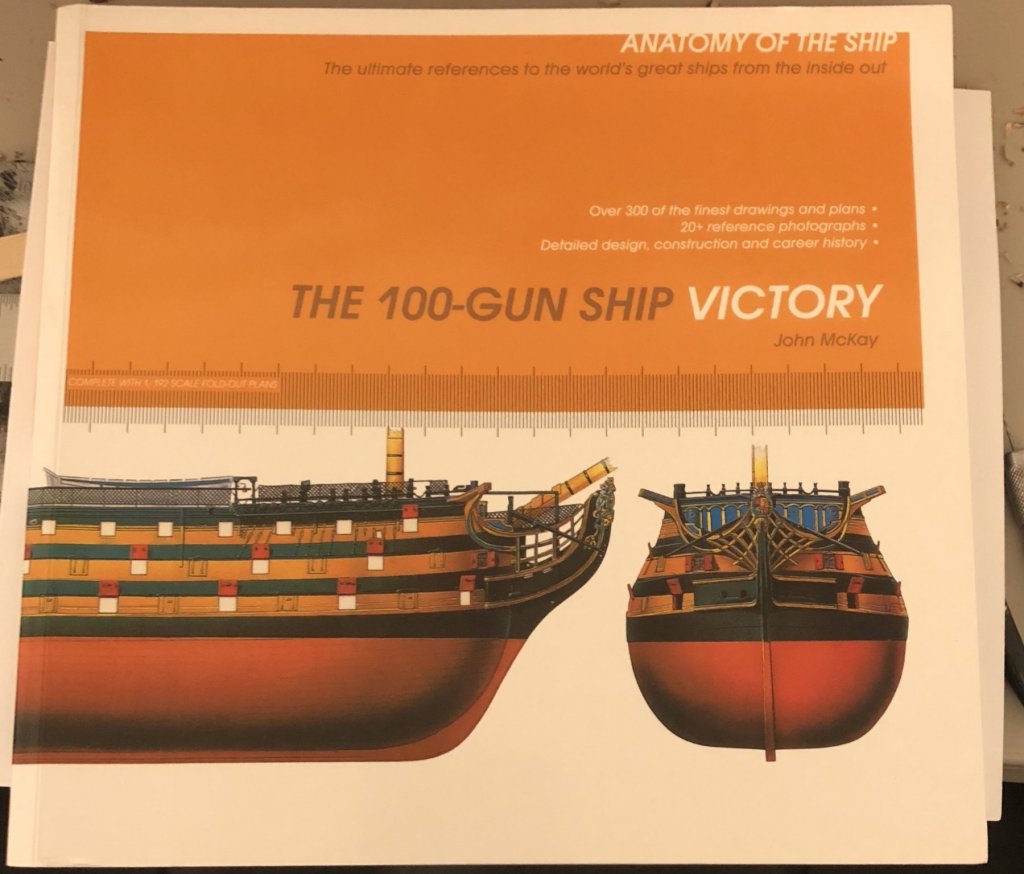

I made the crown cipher on my third attempt. I bas reliefed it into 3/16” basswood. It’s not perfect but it’ll do for now. I made it with a #11 x-acto blade. Among my lessons learned is that basswood is not really effective for miniature carving (which I already knew, but I wanted to try it anyway, because I have a lot of it, lol). I also learned that I am going to have to buy some pear or boxwood for the carvings on the Victory, because these are giant in comparison.

-

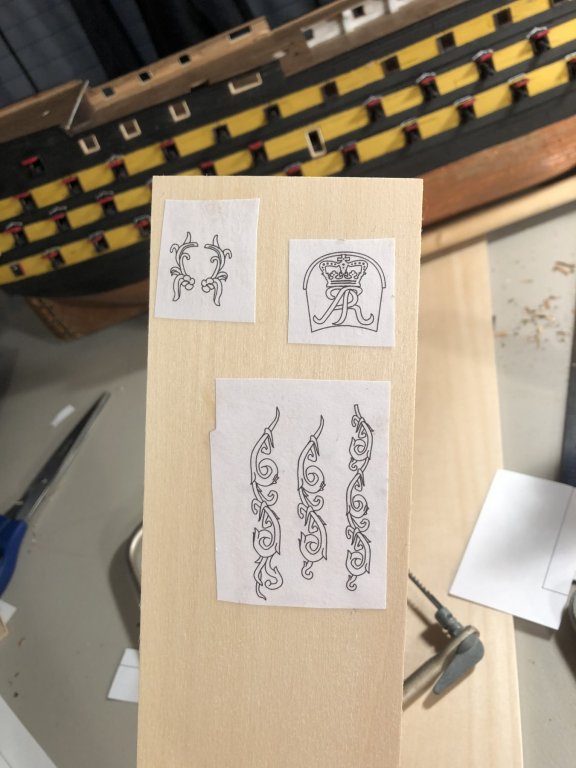

I’m currently trying to carve my entry ports for my model of the Victory. It’s a steep learning curve, which is a nice way of saying that it’s not going well. I have carved a bas relief before, but at much larger scale. I am going to give these carvings a try. I printed the patterns out and pasted them down to the board. I’ll let y’all know how it goes.

-

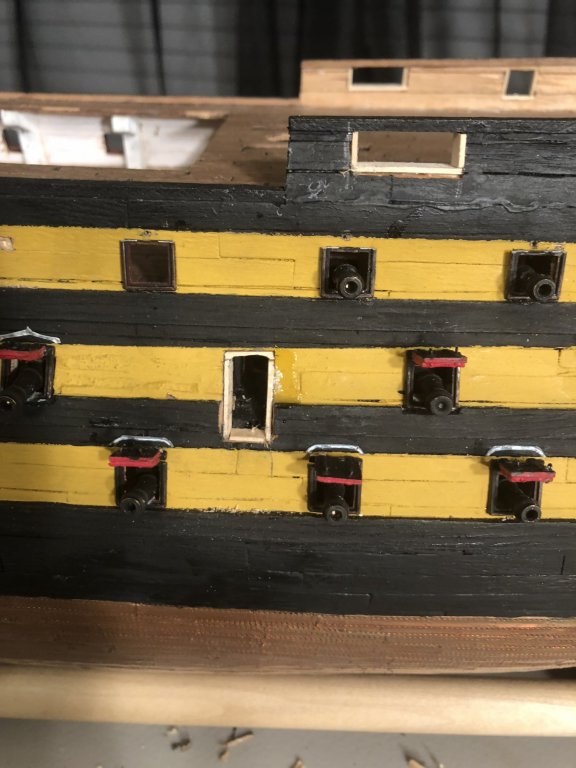

Thank you! I made some adjustments to my bulwarks and opened up the entry ports. I have one framed. I will be making the canopies after I frame up the other one. I’ve never done this level of model building before. So, I am developing much of my woodworking skills on the fly, lol. I’m having fun with it and learning a lot, which is the whole point of this project.

-

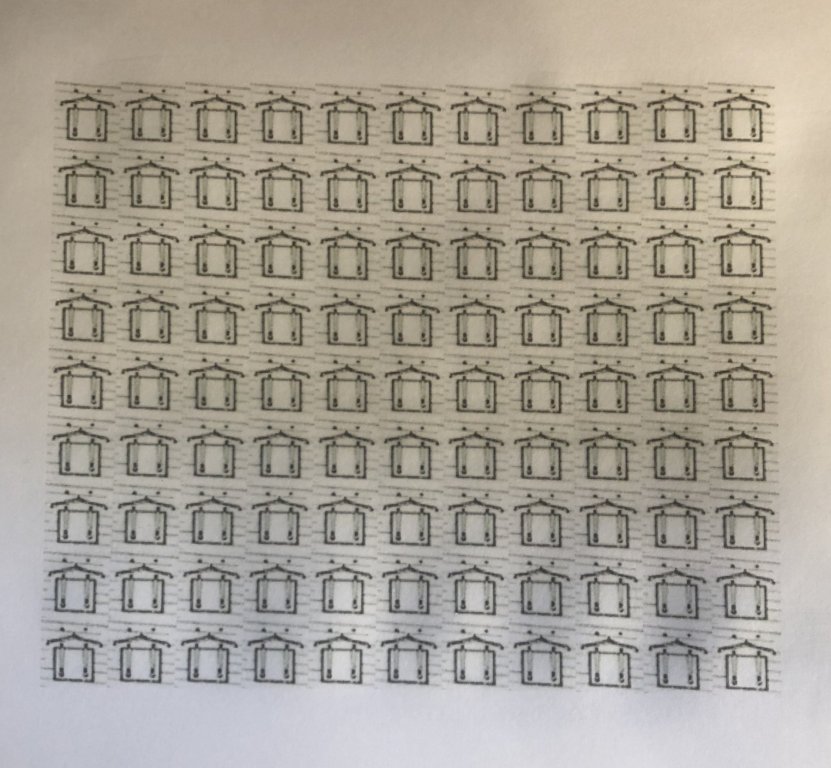

I made the lower gundeck drip shields and installed them! They are made from cardstock. I cut them from the sheets that I made for the port scuttles. I made sure that I made plenty of extras. Next, I’m going to scan a picture of the rest of the drip shields (which are different), and cut them out. Quick lessons learned for everyone, make sure you use sealant on cardstock parts before you cut them out. It makes life much easier.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.