-

Posts

176 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Ron Burns

-

-

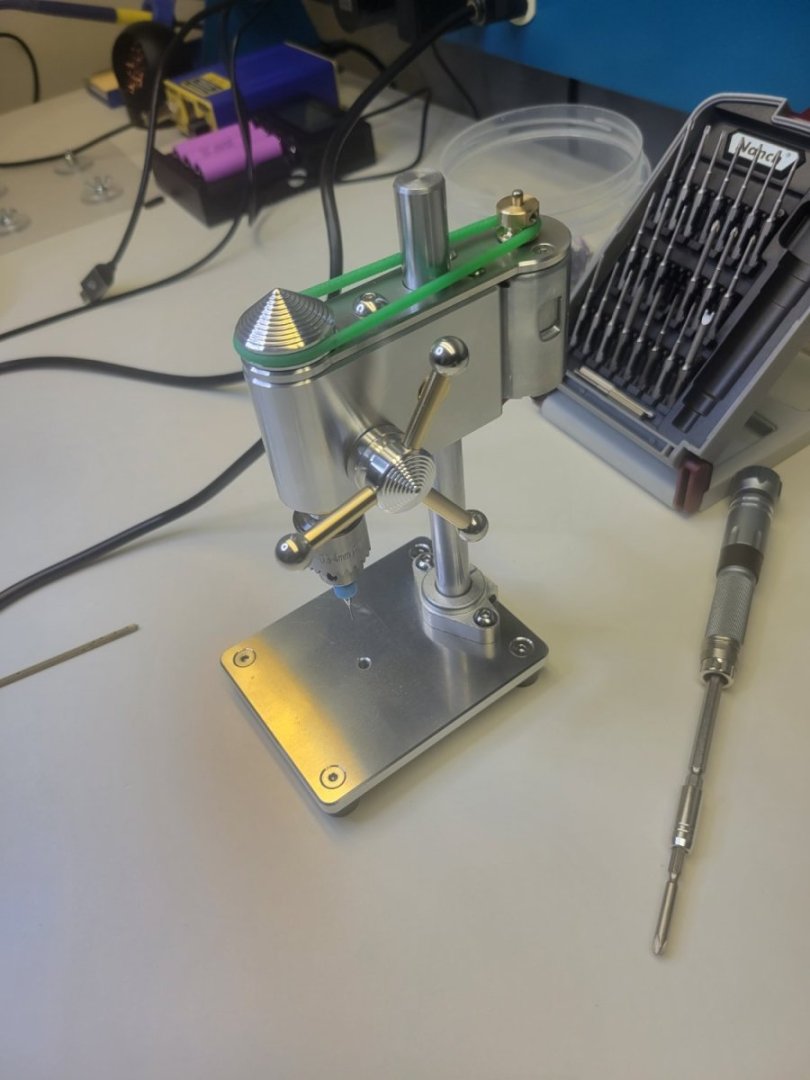

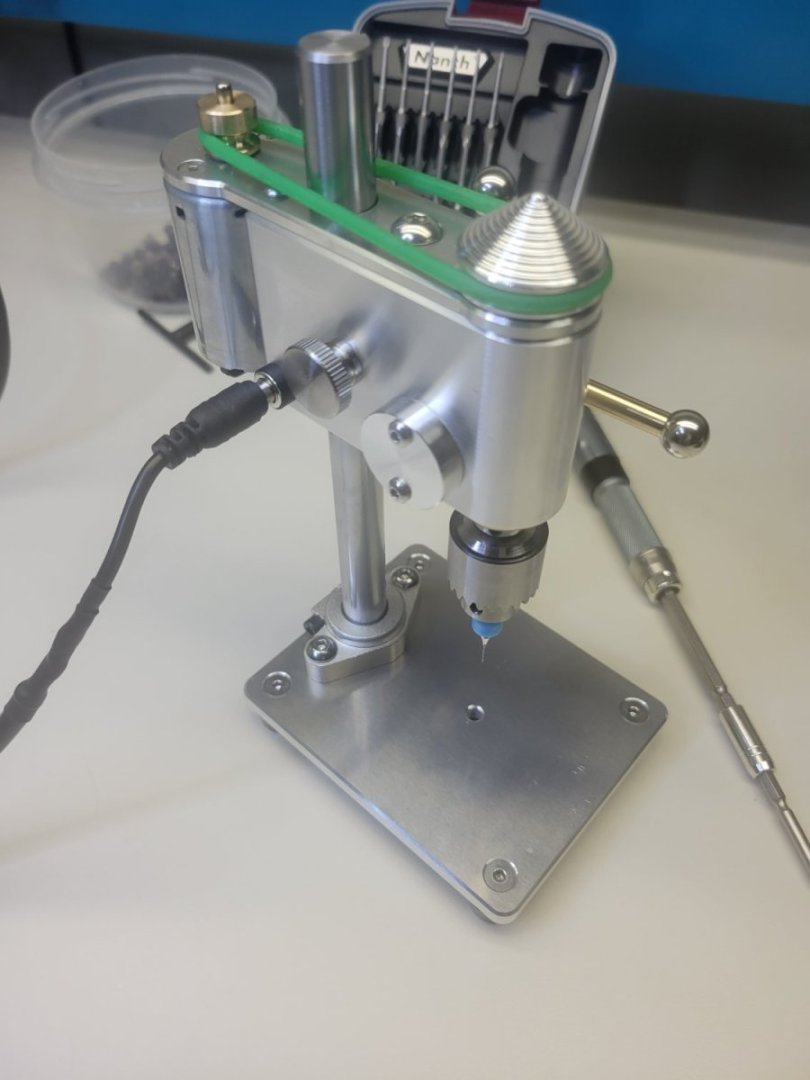

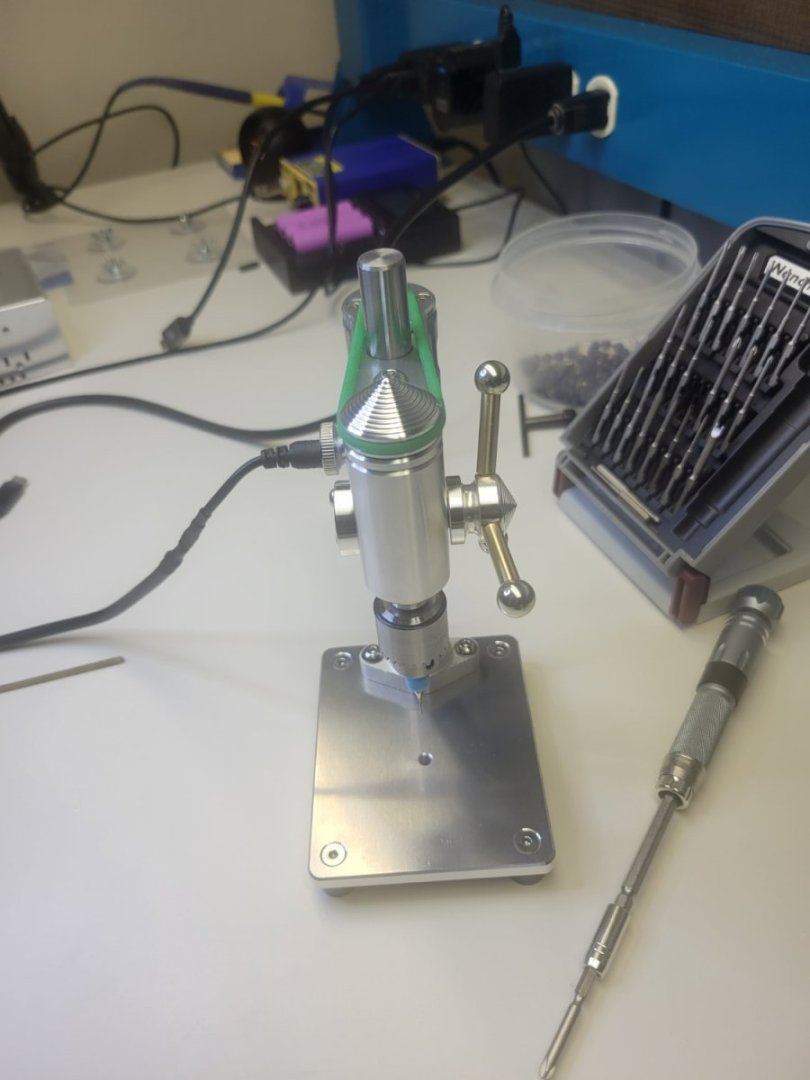

Hi everyone, it's been some time since I've been here on MSW. For the past few years I've been out for medical reasons and recently had the urge to get back to my Winnie. Drilling tiny holes in wood and soft metal has been my nemesis. I've wasted more money thinking I could 'shoemaker' something together rather than just dropping the coin. Anyways, I think I finally found a tiny press for under $100.00 that doesn't break carbide bits drilling aluminum, brass and wood. It runs on a dc supply anywhere between 6 and 14 volts with the tiny motor running between 1600 and 7500 rpm. The chuck holds from .3mm to 6mm. So far, I've experimented down to .6mm using a carbide pcb bit with no breakage into brass about 70 times. For me, that is a world record! Its small enough to almost fit in a pocket at aprox. 18.5 cm height, 13.5 cm depth and 8 cm width. I'm not sure what one calls the distance a spindle can travel but in this case it's about 1.3 cm. I found this wee guy on Ebay in case anyone is interested. I've never been so happy since I bought my Byrnes saw! It's really nice to be back!

Ron

-

1 hour ago, Matt D said:

but here’s a quick shot of mine so you can see what we’re talking about

Matt, thank you many times over! Your Winnie looks awesome! That pic really helps get me on track again, especially with your confirmation of the tapering. A person can't beat a build-group when it comes to getting and giving support.

- FrankWouts, Matt D and scrubbyj427

-

3

3

-

Silly questions plaguing this fragile mind.....

I've finished the first 2 strakes below the wales and am going forth to plank off the rest of the hull. The tick strips seem pretty self explanatory except for the strip that sits along the lower counter. The first and second strake are 1/4inch wide pretty much the whole length right to the counter. The 3rd strake *appears* to me (if I have it right) to terminate at approx. 4mm width with a gentle taper from around mid ship . The 4th strake again gently tapers from 1/4" mid ship to 5mm at bulkhead 27. This then appears to widen up again to 5.5mm at the counter. Is this correct? Perhaps I'm messing up the counter tick strip position?

Sorry about the convoluted problem description. I just need to know if i'm barking up the right tree....

-

JJ,

Absolutely stunning work! What did you use for nails? You probably mentioned it already but these days I feel like I'm hiding my own Easter eggs

The ports look great and look like they will match up perfectly. Can't wait to see how you deal with the hinges.

Ron

-

Hi everyone! First thing, Thank you for the encouragement and likes. It feels good

Minor little update. First 2 strakes below the wales are in. Chuck, your pre-made drop planks stole the show! They actually went in with very little refinement needed at all. Planking up to the counter brought out my Temporary Acquired Tourettes in a big way. My wife was making 'wash my mouth out with soap' cracks for a little while there but all ended up working out (even though I borrowed from Carlin's 7 dirty words). I imagine the tight bends will be less obnoxious as they are getting larger. Please excuse the photos. I'm stuck with the cell camera today.

Next stop, tick strips!

-

I have a confession....I did exactly the same thing (only using *very* fine paper) and again when applying the W.O.P. It left a really nice burnished sheen

if that can be a description. Now seeing yours and Chuck's in red, I think I will have to make another or paint over that finish. Beautiful capstan Greg! I'm assuming we'll be making the bars to go with it...

Ron

- mtaylor and Keith Black

-

2

2

-

1 hour ago, tenderfoot said:

This build will likely take me a year or so before I am ready to remove from the board, so hope is holds up. Anyone have ideas on better material to use?

It is exactly what I used for my build board and it has held up really well so far. You can't beat them for being factory straight and flat. I'm at the point (finally) where I have flipped her over and have Winnie resting on some great chunks of pink construction styrofoam. I used the same stuff after I had all of the bulkheads glued into place in order to fair the girl. Next stop will be removing those wonderful support brackets and replacing them with a cradle.

Nice job so far! Good call on using the ply factory edges as your straight edge

Ron

-

Hi everyone,

Just another post to say we're still afloat

The new saw made things so much easier. This time around I didn't have to look so closely at plank thickness and just grabbed one and kept going. I must say that when I first saw Chuck's Winchelsea, my mind's eye said 'Hell yeah,I can do that! Well, one is never too old to A: be humbled and B: learn a whack of new tricks. Thank the Lord and you guys for all of your build logs because without them, I would have been screwed! Now it's time to flip her over and get going on the rest of the hull. I hope I don't regret not placing the first two strakes and drop plank prior to adding the second layer of the wales. I was out of 1/4 inch stock when I had done it as I wanted to keep going. Crossing my fingers! Please forgive my terrible photography skills!

The new saw made things so much easier. This time around I didn't have to look so closely at plank thickness and just grabbed one and kept going. I must say that when I first saw Chuck's Winchelsea, my mind's eye said 'Hell yeah,I can do that! Well, one is never too old to A: be humbled and B: learn a whack of new tricks. Thank the Lord and you guys for all of your build logs because without them, I would have been screwed! Now it's time to flip her over and get going on the rest of the hull. I hope I don't regret not placing the first two strakes and drop plank prior to adding the second layer of the wales. I was out of 1/4 inch stock when I had done it as I wanted to keep going. Crossing my fingers! Please forgive my terrible photography skills!

- Vladimir_Wairoa, wyz, JpR62 and 12 others

-

15

15

-

I'm lifting my Pepsi to you and your amazing planking job! I wish I could raise a glass of the real stuff but it would P.O my docs and my wife

Next to Chuck's planking videos, your log will see me through. Thanks again Greg for documenting it all. Simply brilliant

Next to Chuck's planking videos, your log will see me through. Thanks again Greg for documenting it all. Simply brilliant

Ron

-

22 minutes ago, Vladimir_Wairoa said:

cutting planks by hand. ill stay with poor lime, baswood whatever despite of fuzziness

Vlad, you cut those planks by hand? I'm so far away from where you are so I don't have any idea how to treat the deck. Perhaps making a small trial deck

with a few planks glued to some stiff card. I like the idea of scraping as it doesn't lift up the fuzz. I love the look of your Winnie and really enjoy following along!

Ron

-

2 hours ago, Roger Pellett said:

Thanks to all who commented

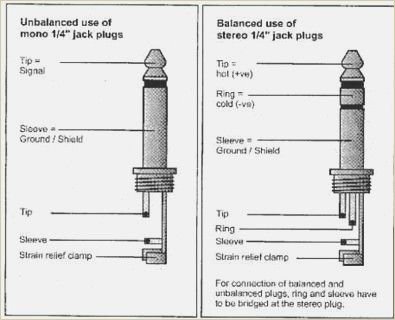

Gosh, was my guess wrong! Just looking, it resembles a 1/4 inch plug but like life, looks are deceiving

I'm glad you got it solved Roger. I looked around a bit and found a DIY site that had a guy re-wiring his own secondary windings on a transformer to supply his device. 8 wraps of #6 AWG! The connectors were huge! Again I apologize for sending you down the wrong path

I'm glad you got it solved Roger. I looked around a bit and found a DIY site that had a guy re-wiring his own secondary windings on a transformer to supply his device. 8 wraps of #6 AWG! The connectors were huge! Again I apologize for sending you down the wrong path

Ron

- Canute, Roger Pellett, thibaultron and 1 other

-

4

4

-

- thibaultron, mtaylor, Roger Pellett and 1 other

-

4

4

-

I have a 12V DC supply rated for up to 15 amperes still sitting in it's box. Was wondering what I might do with it...

- Canute, thibaultron and mtaylor

-

3

3

-

Looks like the same male plug that is referred to as a 'mono phone plug' . The center connector will be the tip or + and the barrel would be ground.

Hope this helps keeping in mind that it's an experienced guess.

Ron

- mtaylor, thibaultron and Canute

-

3

3

-

16 hours ago, scrubbyj427 said:

Looks good Ron! I think I need that saw blade for mine. Cuts look really clean!

JJ

Thanks JJ

I picked up the blade at the same time as the saw. It's the 3 inch 90t .03 blade. First thing I learned was to touch the blade with the candle every 2-3 planks and it cuts like butter and smooth as satin.

14 hours ago, Vladimir_Wairoa said:

I picked up the blade at the same time as the saw. It's the 3 inch 90t .03 blade. First thing I learned was to touch the blade with the candle every 2-3 planks and it cuts like butter and smooth as satin.

14 hours ago, Vladimir_Wairoa said:what a machine. i envy you Ron. in a good sense

enjoy.

enjoy.

Than you Vlad

My little Chinese saw was making great cuts but the stupid fence on it was always trouble to make square. Getting the same distance from the blade after doing some other job was a real pain and I would waste at least 5 planks just getting it close. We all know that close only counts with horseshoes hand grenades and poop fights...not ship models! Surprisingly, it had enough power but was pretty sloppy. You wouldn't envy my wife's reaction when I told her how much it was after shipping, duty and converting US dollars to Canadian. So much for NAFTA and free trade! I don't regret a thing though!

My little Chinese saw was making great cuts but the stupid fence on it was always trouble to make square. Getting the same distance from the blade after doing some other job was a real pain and I would waste at least 5 planks just getting it close. We all know that close only counts with horseshoes hand grenades and poop fights...not ship models! Surprisingly, it had enough power but was pretty sloppy. You wouldn't envy my wife's reaction when I told her how much it was after shipping, duty and converting US dollars to Canadian. So much for NAFTA and free trade! I don't regret a thing though!

- Matt D, Vladimir_Wairoa and FrankWouts

-

3

3

-

Hi everyone

Back in business! My Byrnes saw arrived Wednesday and I am one happy camper! This saw is everything good that has ever been written or spoken about it. In all honesty it took a bit to become accustomed to its ways but it was minimal. What a difference from what I was using. Once again I should have listened and saved my pennies instead of trying to get away with cheap. Anyways, Winnie is back on track, some new planks are cut and I'll start building again tomorrow. Having consistent results from the saw should make a world of difference!

-

Hey guys,

Although I don't have a large table saw and a Byrnes saw literally coming in 4 days from now (thanks Jim and Donna!), I watched a video that was rather intriguing. Kevin Kenny of Maximum Guitar Works is a luthier that first got my attention with his Byrnes saw review. He does a pretty good video on resawing and micro kerf large blades. Have a look here Maximum Guitar Works. The blade he is using is pricey. I think it was a 12 inch however, smaller ones are available. Looks to me that if one was to invest in a good blade it would last years and do all you need. I can only imagine the danger and pucker factor cutting 3/64 planks on a 12 inch blade!

-

Greg,

You have no idea how many times I end up doing things. You at least have the courage to post your mistakes to let folks learn from. Me, I kinda bury the mistakes and admit to many but rarely show them. It's how we learn and you must admit, we get so much better after each foul-up. I'm about 2-3 days away from starting the bottom of my hull. For sure I will be following yours!

Ron

- FrankWouts, dvm27 and Matt D

-

3

3

-

Hi Jan,

I'm happy your first chapters arrived

Just a word of advice from someone who didn't get Chuck's bulkhead set...pay particular attention to the placement of the markings on the bulkheads. A millimeter off here or there will mess things up later on. I learned this from experience. Looking forward to pictures!

Just a word of advice from someone who didn't get Chuck's bulkhead set...pay particular attention to the placement of the markings on the bulkheads. A millimeter off here or there will mess things up later on. I learned this from experience. Looking forward to pictures!

Ron

- Vladimir_Wairoa, Matt D and FrankWouts

-

3

3

-

2 hours ago, Expro said:

Be prepared to do lots of work to get any accuracy from this Piece......t.

Looks like I would have been trading fecal matter of one sort in for a whole pile of freshly stepped in fecal matter

Thank you for the warning

Thank you for the warning

and I'm so happy the company never responded to my last email! I did however buy a Byrnes Model Machines saw and will forever be done with

Chinese made saws. Expro, I'm sorry you have to wade through so much of it. I hope you can sort it out. If you do, maybe you could post your adventures here?

Thanks again

Ron

-

JJ, that floor looks awesome! I agree with keeping the light segments AYC whole heartedly. I'm curious how you did such a bang up job painting the black so cleanly. Your hints with the panels will be stored in this aging bean for later as well. Always a pleasure to watch your work

Ron

- scrubbyj427 and FrankWouts

-

2

2

-

-

1 hour ago, Justin P. said:

The sliding table is excellent, and something I use very often.

I really wish I could have ordered it but I had to get my small Syren order in as well. I'm gonna get crucified!

- mtaylor, Justin P., thibaultron and 1 other

-

4

4

-

Well,

I did it. I ordered the Model Machines saw. I figured the Hyuda was just a copy of a good saw and I would be replacing my junk with more stuff that I would be unsatisfied with early on or down the road. I don't think there is any comparison really to the horsepower (or fraction thereof) of the Jim Saw and the small DC motor and I really liked the idea of having someone right here on MSW that will, should it be needed, support his product. From what everyone has written, the Model Machines saw will be working still when my bones are dust. The other thing that threw me was that I was considering trying to build my own. Locally and as far away as Saudi Arabia I have been quoted 250.00 and upwards of 320.00 for just having the aluminum top milled! You can see the logic! I ended up ordering the micrometer stop, the extended rip fence, adjustable miter gauge extension, accessory pack and a 3 inch Martindale .03 slitting blade. Soon I will be able to use my existing saw as a anchor for my Winchelsea

Any changes you guys can think of? I wish I could have grabbed the sliding table but I still haven't told my wife about the saw. I gotta be real nice in the coming days

Any changes you guys can think of? I wish I could have grabbed the sliding table but I still haven't told my wife about the saw. I gotta be real nice in the coming days  Before I forget, thank you for your input on this old subject. I truly appreciate it

Before I forget, thank you for your input on this old subject. I truly appreciate it

Ron

- Ryland Craze, gjdale, Bob Cleek and 5 others

-

8

8

Tiny "precision" drill press

in Modeling tools and Workshop Equipment

Posted · Edited by Ron Burns

Fading older brain forgot a point...

Hi Bob, no I didn't forget to post a link as I really didn't want to advertise for any one individual. As you found, it wasn't that hard to find. For what I need, more than 1.3 cm wasn't a requirement. Changing out the chuck to a collet wouldn't be a problem. Trusty Allen key to the rescue. Id have to check on the size adaptor needed. Believe it or not, no brand name and I bet there isn't more than 3 grams of plastic on the whole thing including the PU belt. It's construction is what attracted me. All aluminum, brass and steel. It really is a gem. .3mm bits should satisfy most with that chuck. It sure makes me happy 😊 A bigger base would be nice and I have a cute vice on the way too. As to runout, I don't have such a device to check it. Me not snapping carbide bits while drilling brass without a vice should be a good indicator. Passing wind around those stupid things will snap them!