-

Posts

1,528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by VTHokiEE

-

None taken, the issue (currently) isn't with his planking process; at the moment the issue with my shoddy fairing 🙂. I tapered the bow about 20%, I could increase that some, but I don't think tapering and edge bending (believe me I tried) can overcome the lack of fairing that I unfortunately did on that bow filler. I think my bow is in better shape; planks fit nicely on the first 3 bulkheads but I haven't had time to really sit down with it and test a plank or two.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Those are still to be faired. The last picture is me making headway on the other side :-). Kind of wishing that I didn’t learn that the hard way; but it’s salvageable at least. I’m glad! I hope you have a much easier time with your first planking run. I was tempted to simply press onwards and not post the partial planking pictures since they were so bad. I’m really glad I didn’t do that now.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

This was the issue, it might be hard to see but the planks weren’t laying flat. However after significantly fairing that front filler block things are looking up. I still have a good bit of fairing to do on one side (and make certain that it’s good for the full run in both sides). It’s a tough place to get into with the stem on but I’m getting there.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Thanks, I’ve been sanding away and things look better. The planks touch all the way around at the top edge of the plank but seem to have a tough time “twisting” at the bow to make contact all the way through to the bottom of the plank. I soaked a plank and clamped it against the bow to let it dry today in the hopes that it helps. This is quite the learning process (and I can see how you can frustrate yourself quite quickly). EDIT: Thinking further I think the filler block right on the stem is my issue. With the stem in place this is a very tight spot to sand. I’ll have to think about how to address this.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Planks are off, that was much easier than I thought. I soaked them in some isopropyl alcohol and gently pulled them off. They came off in “sheets” though so there will be no reuse. It looks like Cornwall sells the right lime replacement planks so I’ll probably order replacements there. I think (?) basswood strips would work as well but the OCD side of me fines it hard to mix and match.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Thanks for the feedback, given this I think I need to order more planks.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

It may not look like it in the picture but the planks are tapering. I made some tic strips to guide that process so I feel relatively confident about the taper.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

This is what led me to believe the issue is with the bulkhead fairing since no amount of soaking/heat would solve my problems 😞. As much as I dread this, it’s be foolish to ignore someone with more experience. I used PVA glue (but glued the edges of the planks). I’ll try to pull off the planks and restart. Do you think that I could number the planks and maybe reuse them? If not I need to order more planks... Thanks, unfortunately I didn’t want a clunker hull, my inexperience in planking simply created one. Time to restart and hopefully salvage what I’ve done.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

I read everything I could on planking, I watched Chuck’s videos and I thought to myself my first layer of planking (and first planking ever) is going to be so smooth and beautiful. I was wrong, completely wrong. I’m not completely certain but I think that I didn’t fair the bow of the ship anywhere near as well as I thought that I had. I believe this caused a clunker effect to develop which, to put it lightly, was quite disheartening. I think the pictures make it look a little worse than it really is, but a beauty it is not. I’m learning a lot in this process and, since this is a first layer, I’ll be able to use some filler and I believe everything will clean up just fine but I need to, and have, reset my expectations for this build. I blame you all with your beautiful masterpieces (sarcasm) 😁.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

The only thing that I would add on to the above is various clamps in all shapes and sizes (also “odd” clamps including binder clips, rubber bands, etc).

-

If you feel that the deck is flexing I would highly recommend (based on my experience laying the false deck on my Alert) to check and see if the upper bulkhead gets cut away like it does on the Alert (I assume that they do). If they do slightly sand the interior side of the upper bulkheads to allow the deck to slide in easier. I wouldn’t mess with the slots on the deck they’ll be fine when you get it down.

-

This is exactly the route I'm currently planning on taking; I might have to pick up a byrnes table saw to rip planks if I want to do it in AYC (which given how nice Chuck's build looks is very tempting) The scroll saw would be my other tool of choice if I wanted to somewhat limit the laser cut parts. Of course I have to consider if I actually have room for both tools (and the time/skill to cut out the bulkheads accurately).

-

From where I’m sitting it looks like you are doing a great job! If my current build goes well I may heavily consider doing the Winchelsea, but I’ll probably do it less scratch and more kit-like. I’m really impressed by your scratch work; someday I’ll have to give it a try (when I have acquired the right tools).

-

I’ve started using an iron on the first planking of my alert and I think it’s great so far. I haven’t used a hot air gun but a cheap travel iron is working great for me. I can’t wait to see your second planking pictures.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

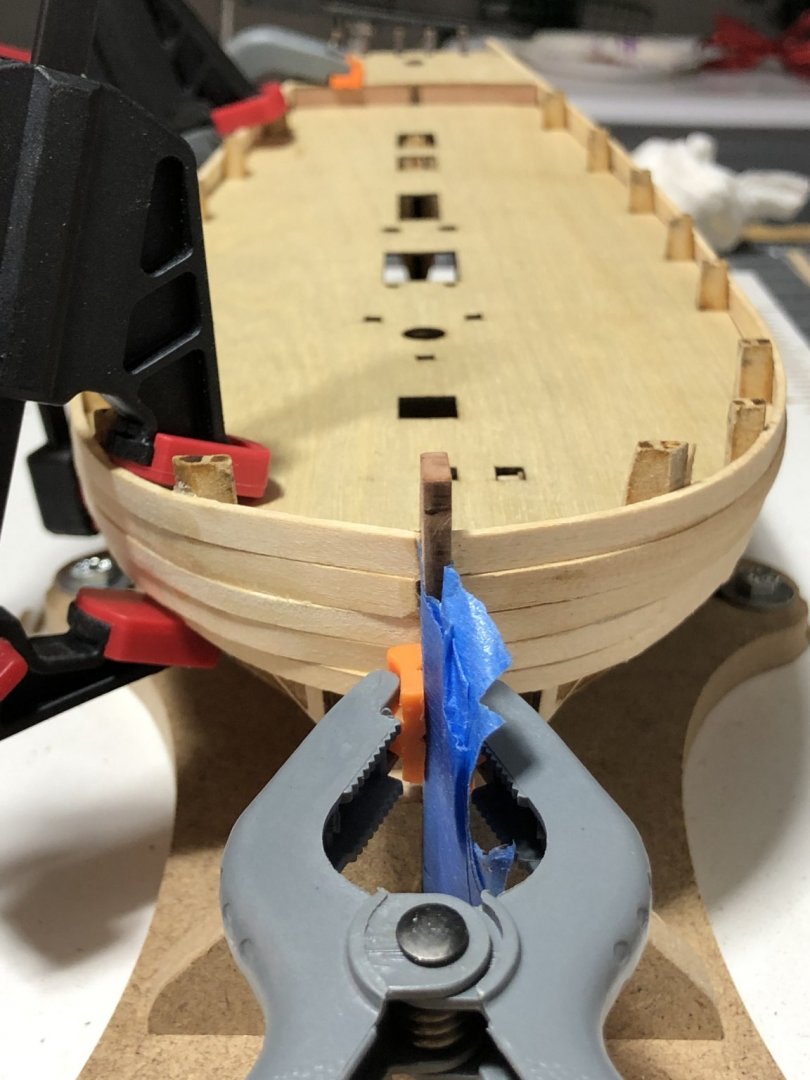

And so it begins. First plank on down 4mm from the bulkhead tops. This feels like a huge achievement for me but I promise not to bore you with pictures of every plank that I lay down. I'm currently prepping the corresponding plank for the opposite side. Given the time it takes me to prep and place a plank this log may go a little silent while I continue to work in the background. I'll post an update when I hopefully have several planks on each side.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

And with the keel on I’m about to start my first planking (thankfully it’s a double planked hull but I’m still a little apprehensive).

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

As a respite from fairing I'll add a small update as I am lowly progressing further along. I attached the pieces in question above to match the curve of the deck. Unfortunately when I went to remove the keel pieces and install the keel I noticed that the laser cutter did something funky and didn't cut all the way through the sheet for this (and one other part) and may have caused some overburn (?): It was a little bit of a struggle to remove the keel pieces (I unfortunately left a touch of it behind as seen in the above image) and creating a tight fit left a small gap at the stern where the rudder post attaches. This will all be painted white in the end so my current plan is to taper to rudder post slightly to meet the keel and fill in the hole with some filler. When I get to that other piece that may not be quite symmetrical I'll address whatever modifications are needed (and hopefully do a better job of removing it from the sheet. Now back to fairing...

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

I keep eyeing the Dusek Greek Trireme whenever model expo has a sale. A few times it has come close to that $100 mark and I’ve almost fell victim to the sale. I work slow, so I’m doing my best to hold off buying models until I’m close to finishing what I’ve started. (...and I keep buying upgrades to my build so there goes the ship budget anyway 🙂)

- 114 replies

-

- small

- Peterboro Canoe

-

(and 2 more)

Tagged with:

-

I’m excited to see this build; I really like the riverboat models (someday I’ll hopefully build one). I’m sure you’ll do a great job on both!

-

It looks really nice! I completely agree about the Midwest kits. They are a great intro for beginners. It’s a shame they aren’t still being made. What do you think you’ll tackle next?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.