src

Members-

Posts

2,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by src

-

Grant, that looks awesome and deserves every bit of praise you have received and more. Put her on a shelf and she will be an eye catcher for sure. I agree with what Keith said though, a little more leveling and she will be a show stopper! Just my two cents, carry on! Sam

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

Carl, traditional foam double sided tape or carpet tape would definitely be too think but there are some transfer tapes that are only 0.002" thick that might work although the scotch tape trick from Bill might work better. https://www.uline.com/Product/Detail/S-5748/Adhesive-Transfer-Tapes/3M-924-Adhesive-Transfer-Tape-1-2-x-36-yds?pricode=WY488&gadtype=pla&id=S-5748Q3&gclid=CKHWyMX8wtACFU06gQoddpwOTQ&gclsrc=aw.ds Sam

-

Julie, Thats a tough call. Strike a line down the center and miter the port and starboard planks were they meet? Run a plank along the mid point and miter the port and starboard planks to that? In the end you will make the right decision. Sam

-

Sjors, Thank you. Almost finished?? I guess if I was the average builder here I would say yes, a couple more months, but, most likely if I finish in 2017 it will be towards the end of the year. Build time continues to be at a premium, and several times I have sat down to work and set my tools aside to go read or spend time with the Better Half. Thanks for all the likes and comments they are always appreciated. I have formed the Fore Top Cross Trees. Hopefully Saturday I will be able to make the Trestle Trees and get them glued up. After that a couple fo caps and and two more small masts and then I think I can start looking into some shrouds and stays. Sam

-

Russ, Like the others I think she looks great. What could you have done to make the sails more to your liking? I have heard of silkspan but am really not familiar with it. AS far as your customer, she sounds like both a blessing and a curse. A blessing because if you have a little wrinkle she will still love it. A curse because if you slip up and have a little wrinkle, she will still love it but YOU know the wrinkle is there. Sam

-

Mark, coming along very well. How did you assemble your stairs? I struggled with mine. Sam

-

Thanks Julie! Always nice to see fresh faces here. I love it when other builders use a macro too, really lets us see what they are doing. Now If only I had a way to get the "on deck" shots some of the other builders get. That means buying a point and shoot though and it would probably end up collecting dust and then donated like my last PnS camera. Ok mini update time and a question/advice. I glued up my Main Top Mast Cross Trees yesterday and placed them on the Top Mast to see how they looked. They seem a little spindly and small. Based on the proportions given in Lee they are correct or I screwed up the calcs somewhere. The Top Masts are still long, I will trim the tops at a later date after the caps are built. Pictures below. The close up is next to one of my earlier Main Cross-tree/Trestle-Tree attempts for a size comparison. The only difference in the Lower assembly in the picture and the one one the mast is the addition of the 3rd cross tree. Otherwise the dimensions are the same. Main Top Mast Cross Trees set in place. They seem small to me. Main Top Mast Cross Trees set against a rejected Main Cross Tree for size comparison. Comments, questions and constructive criticism all welcome Sam

-

OH no!!!! That is unfortunate. I feel for you, not only the hours but the computer issues. I did something similar when we set up a new router several years ago. Better Half set a super simple password that was our dog and cats name combined. In the words of Pink Floyd, "This Will Not Do, Call the School Master!" I took a phrase and created a password with numbers, letters, caps and symbols. It all made perfect sense when I created it. Until we wanted to give a guest with a lap top access.....There is a reason I call her the Better Half. This to shall pass. Sam

-

Julie, Instead of working on my own build this morning I sat down and finished reading your log. Wow, well done! And your improvised clamps with rubber bands and zip ties, brilliant! Regarding your bending on the life boat, your massaging technique seems to have worked out, as I was reading and you mentioned spring steel for a backer I thought of shim stock. This has been in the back of my mind for a while now and I just havent had a chance to try in out, I may never now that I have seen your massaging technique. If I were to try it though I think McMaster Carr would have what is needed in the way of thin spring steel. Sam

-

sharpening stones which are best for the price

src replied to John Allen's topic in Modeling tools and Workshop Equipment

John, Some great advice here, you cant really go wrong with any of the tools/abrasives mentioned. I happen to be a fan of water stones for hand sharpening and Tormek when I have a lot of sharpening to do. Water stones cut fast and can give a great edge but they wear faster than the others mentioned above. If price is your main concern, why not try the Scary Sharp method? http://primeshop.com/access/woodwork/scarysharp/ Several people I know use it and they are very happy with their results. More than anything I believe its HOW you sharpen rather than what you use, others will argue that, just my two cents. Learn the proper angles for what you are sharpening and how you use the tool. Get some fixtures/guides if that helps, and keep the backs of your chisels and planes flat. Oh, and dont forget a strop of some sort, I use one from FlexiCut. when I was doing residential carpentry I would use one of my leather tool bags as a quick strop. Looking forward to your decision. Sam -

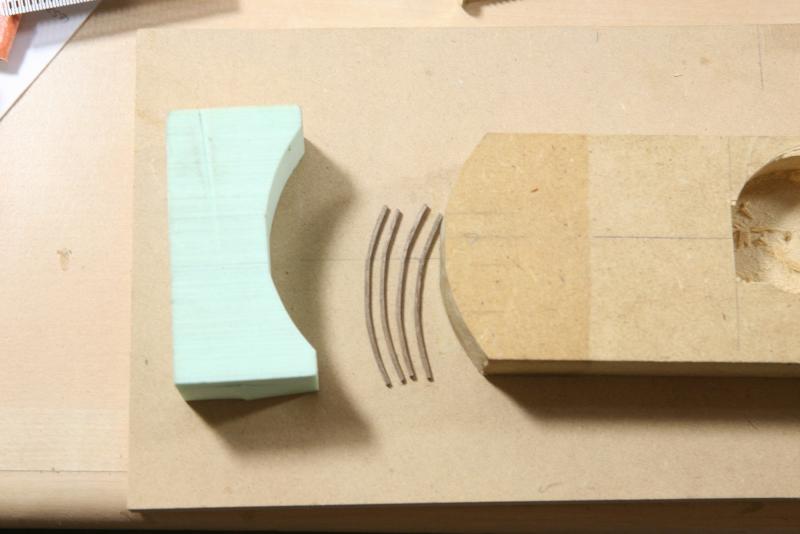

I am back, sort of. Over the last two months I have managed to form the Main Top Mast Cross Trees. Still continuing to use TFFM and Masting and Fitting for inspiration. Once again I have deviated from Constructos plans and will build the third masts, (Top Gallant??) Forming the curve of the cross trees was relatively easy yet somewhat time consuming. We have several blocks of varying density urethane foams at work and I had access to the scraps I grabbed a couple of small chunks of 5 and 10 pound foams out of the trash and started carving a female mold, after first making a male mold. I used the profile of the male mold to sand a matching pocket. I screwed and epoxied the male form to a base and made my first attempt. The faom mold wanted to rock on me so I had to use an additional clamp to keep it in place, by the time I did this the wood had cooled so much it didnt hold its shape, after all night clamped up they sprung back to almost their original shape. I Reheated and tried again this time they stayed clamped up for several days as work took over my entire life. Results below.

-

Julie, I have finally had a few moment to start reading your log. Great job so far. I am only on page 11 ATM but I have been enjoying watching how you problem solve. Good luck with your computer issues. you will back up and running soon. Sam

-

John, I would think you would have less control using a chopped glass vs a manufactured cloth of a given weight per sq foot. In my experience the final weight and thickness of a part with chopped glass is dependent on the skill of the operator. The shop I work at fabricates a lot of fiberglass parts both with chopped glass as well as hand laid cloths. When we want to control weight and thickness on say and animated part we will hand lay and then compact under vacuum. For a static part where the either the thickness or the weight is not so critical we will use chopped roving for layup and compact with rollers and stippling brushes. Hope this helps, back to you Grant, Sam

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

Looking real good Mark. The Death Star can really make a difference in fit up time it appears. For the plank line, do you run at a lower power, faster feed or both? Sam

-

Grant, that looks great. I never thought of using peel ply like Pam recommended. We use it when vacuum bagging complex parts and will be doing a second layup as, like mentioned, it leaves a texture for the next layer to adhere to. Looking forward ti the final product. Sam

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

Looking real good Mark. The day you stop learning is the day you close up your build bench. Sam

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.