src

Members-

Posts

2,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by src

-

What a neat project Dennis. You are one of the most prolific builders I have seen. Watching you build this reminded me of the train museum at the Pomona Fair grounds in So Cal. The last time I was there the fire boxes were open and you could climb right in some of the larger ones. A bit dirty but kind of cool walking around on all the dampers(?) and liners on the floor. Sam

-

Mike, Thats looking good! Dont worry if its another year, you will most likely still finish before I do.... LOL! Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Thats a novel way of doing it Rich. I see you knotted one end but how do you finish off the running end of the lanyard? Sam

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

Cleaning Small parts prior to blackening

src replied to src's topic in Metal Work, Soldering and Metal Fittings

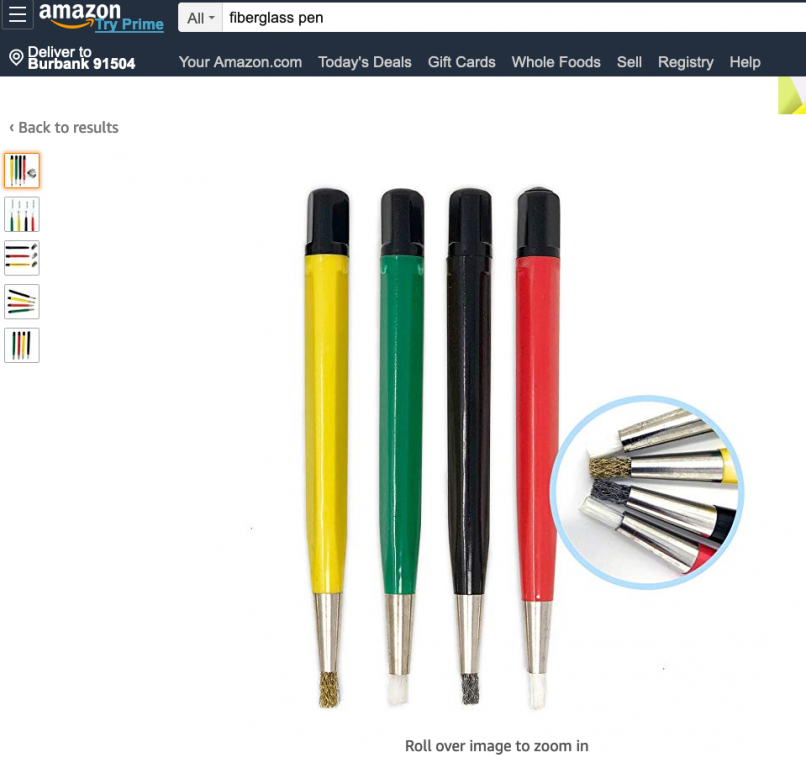

I will take a look at both the Sparex and citric acid. I have a small min crock pot laying about somewhere. Citric acid shouldn't be too hard to find, even in California. There used to be a place near where I live called TRi S Sciences, they sold very small quantities of most any chemical you could think of to students. Sadly they went out of business some time ago. Are these the fiberglass etching pens mentioned above? -

Cleaning Small parts prior to blackening

src replied to src's topic in Metal Work, Soldering and Metal Fittings

Roger, Never thought of acetone as I assumed the annealing process would burn it off. We have many gallons of the stuff at work as well as other chemicals not available to the general public. As an aside acetone, at least in California, is not considered a VOC. I understand chemically it is but legally it is not. One of the automotive finishes we work with is considered "zero VOC" although as I understand it acetone is a main ingredient, go figure!! Sam -

Really enjoying your attention to detail. Sam

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Cleaning Small parts prior to blackening

src replied to src's topic in Metal Work, Soldering and Metal Fittings

Mark, I might try that. I need to find out what is in the powder that came with the cleaner first. Vossie, I have been doing something similar; dropping the parts in a small amount of agent letting them sit for a few minutes and agitating regularly, taking them out rinsing them off in distilled water. After they dry a quick buff with a clean dry cloth for camera lenses. back in they go for two or three cycles. Roger, that might be something to try at some point. Although I see Murphy hiding behind me with a little hand card reading "Watch this guy demonstrate the Bernoulli Effect!!" 😂 Murphy thinks he and I are good pals. Most of the parts I have had issues have been parts made from K&S brass. Even after annealing and a good scrub with a maroon scotch bright pad I have had inconstant results. After reading Pats comment I think those issues might be related to the brass itself. I don't know. It sounds like I don't need to try the tumbler though from what I am hearing. That's good, I have enough other things to keep me busy without adding more steps to the process. Sam -

Mark, that will have to be close enough for me. At 12 mm its just a hair over 2', but they dont fall through my holes and filled with rope nobody but us here will know. I managed to retie the hook to my Gaff Peak Halyard. Its was moderately easier than I expected, it only took 2 tries. I was able to move things around and get my fly tying vice close enough to hold the block. The scary part was the stern was hanging off the end of the work bench. I had constant visions of knocker her off to the floor. 😧 I ended up tying the hook to the strop with a constrictor knot and then looping the strop around and tying that off with another constrictor. Then soaking the whole mess with 50/50 white glue and water. After that I walked away it can dry overnight. I will wrap some hitches of fly thread around the join then see how well it holds under tension. Back to where I was last Saturday..😂 Carl, Our "honeymoon" last October was blown off course by hurricane Wilma. 2 hours after we left port the captain came on the PA and announced a change and why. We could still see the hills of above the Port of LA we were so close to home. So, instead of the Mexican Riviera we cruised our home state of California; San Francisco, San Diego and Ensenada just over the border from San Diego....Two cities we go to at least once each year......... I told Better Half right then "this isnt our honeymoon". We still had a great time, good food, good wiskey, all was well. Just a lot of money to see two cities I have been to and a third I can drive to if I had the urge. Sam

-

Cleaning Small parts prior to blackening

src replied to src's topic in Metal Work, Soldering and Metal Fittings

Mark, Pat, thanks. I have a small ultrasonic cleaner from Harbor Freight. I have been using it on hooks and eyebolts but assumed I needed to scuff the surface first with a file or fine sand paper. Am I reading correctly I don't need to do that with a ultrasonic cleaner? That's encouraging, it was why I considered the tumbler and sand in the first place. I will try that before I go to all the extra effort. Sam -

I just received a bunch of brass belaying pins to replace my kit parts. Now I have to clean them up to either paint them or blacken them. I know I can put them in my Dremmel or drill motor and spin them against some fine emery cloth, scotch brite or even a file but I am looking for a more efficient way as I have close to 50. I have a bullet tumbler in my garage that has sat unused for many years (too many) and am thinking of using that. My thought is thoroughly clean the bowl out to remove any polishing compound then replace the corncob media with fresh clean #60 sand from our our sand blaster at work and then tumble away for a couple of days. After that I would soak in vinegar and then then a good scrub with soap and water or an ultrasonic cleaner before blackening. rinsing with distilled water first of course. If this works it would be great for cleaning things like eye bolts, hooks etc as I have had inconsistent results blackening small parts like this. My question, has anybody tried this? Am I wasting my time? Any other thoughts about batch cleaning of small parts? Sam

-

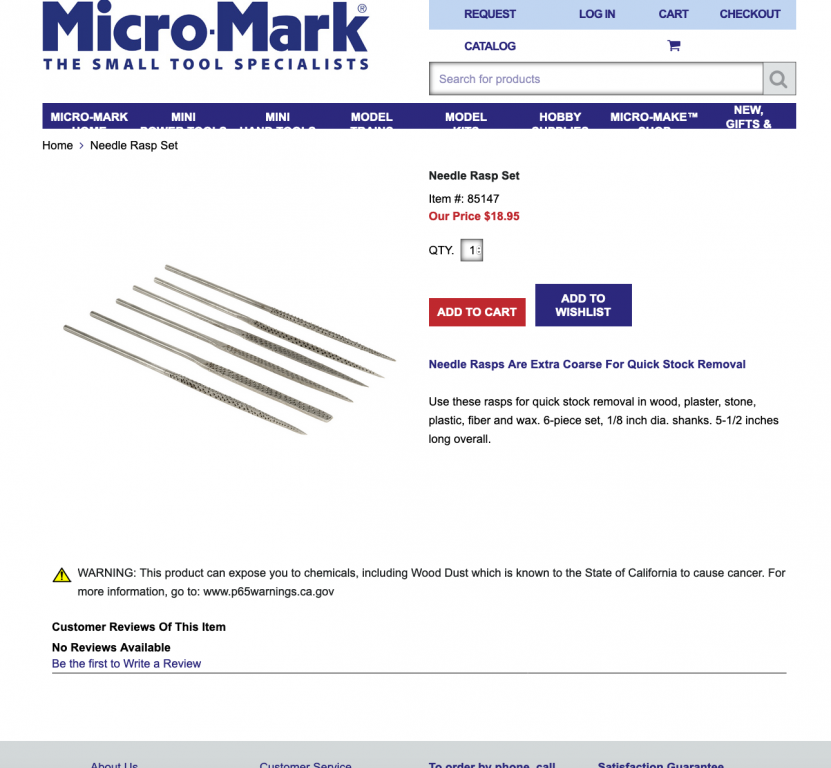

Jim, This is a really old post but I thought I would jump in anyway. I agree with Duff, a reamer would be best. you can get a set from Micro Mark. I use mine all the time for enlarging holes in wood and brass that a drill would otherwise cause problems. They have two styles Cutting and Smoothing. THe cutting are great for enlarging holes. I use the smoothing like a Marlin Spike to undo knots, or even enlarge a stropped eye before I apply adhesive to lock it in. Sam

-

Lou, sand might be a little harsh but considering it has sat in a box for more than 15 years I think it's safe to say I wont do it any harm. Heck, it may not even work anymore. and yes, not having to pay $5.00 for 50 or more pounds of sand when all I need is a quart or two is a plus. I dont know about kitty litter, we use the clumping kind, I wonder how that would be absorbing the excess polishing compound in the bowl..... Jo, that Carl's a smart feller aint he? Sam

-

Lou, yes, mine is the same way. I figure I would have to clean the bowl out with denatured alcohol and then soap and water. Then use Some #60 sand from our sand blaster at work. I don’t think corncob or walnut husks would do it. I have not had good luck with just a chemical dip for cleaning, I have had better results with an abrasive cleaning followed by soap and water then an acid like vinegar to get the last of the impurity’s off. Even then small parts have never really come out the way I would like. Carl, that’s good to know because at some point better half and I are supposed to take our “real” honeymoon to Ireland. Sam

-

HAHAHAHAHAH!!!! Jo, you should be a comedian my friend! Thanks for that, I needed a laugh. I do appreciate the well intended comment though thank you. 😀 While I am very pleased whith what I have built, I know where the skeletons are and know I can do much better on my next build. Carl, I will try your trick, I thought all purchases from EU no matter where they shipped had VAT applied? Size wise they are close to the kits and I will most likely go with them. In my bumbling way I was saying I dont really know how tall a belay pin should be; I have been too lazy to look it up. I will most likely blacken them as there is no other paint on this build. prepping them for either is going to be a chore, has anybody here ever tried putting brass in a bullet tumbler to clean them for blackening? Might be time to take my own advice to others ond go spend some time in the help forums.... Sam

-

Jo, in addition to what the others have said, it helps to get your hull in some good side light and look at it from all angles. when you have a nice fair curve you will get a smooth even gradient of light to dark. any highlights/shadows interfering with the transition of light to dark indicate an area that either needs more sanding or some filling in.

-

Lou, You (and I) will ALWAYS be bad examples to our Better Half's!! So I got my brass pins in. ME had 8 and 12mm. The 12 mm are just a tad small but fit the holes. The 8s fall right through unless I rest them on the edge of the hole. I may check out some from Cornwall they have some walnut in 10mm, I am just not really looking forward to VAT. When I bought my cannon barrels they ended being much more expensive than I anticipated because of the overseas taxes as I recall. Murphy stopped by for an uninvited extended visit. I have been using Modeler 12's video of Benders technique for tying blocks to yards. In the past when I have stropped my blocks I was using Dullcoat to lock in my knots with good results. It seems to penetrate into the waxed fly tying thread very nicely. However once I started using the technique in the video my knots started failing! I have had to go back and redo every knot related to my Boom and Gaff. Almost every one has failed at least once. I am now soaking them in 50/50 white glue and distilled water. That seems to have solved things. I have one more block to tie a hook to for the Gaff Peak Halyard, that is going to be interesting trying to strop my hook back on without redoing the entire halyard from the tip of the Gaff to the ring on deck. Then I can go and retension my back stays. Murphy, I banish you to the lower reaches of Hades!! LOL! Sam

-

How goes the build Jo?? Get your balsa shaved down? E-gads Tony! Community Engagement Officers??? What is it with bureaucracy's have to assign soft touchy names to everything? Assuming they do what our Parking Enforcement does here in Los Angeles they should be called Revenue Enhancement Collectors, RECr's for short. It might be hard to take a person in feathered headdress serious today, but if General Custer had taken the Sioux and Chief Crazy Horse more serious he may not have ended life looking like a porcupine. Sam

-

Jo, The cautions about rasps are well founded. I cant comment for the others but when I think of a "rasp" for hobby work this is what I think of: They are small and not overly aggressive. But you can still do a lot of damage quickly if your not careful. The trick is knowing when to stop and go to a finer tool. What might actually be better since you have limited experience with hand tools - something I should remind myself of more when talking to you here - is more of a coarse file. Or even the Dremmel that others have mentioned. I personally would make hash out of most anything I touch with a Dremmel. There are many here that do quite well with one. Like Mark said, "Different Strokes" Sam

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.