-

Posts

3,033 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Edwardkenway

-

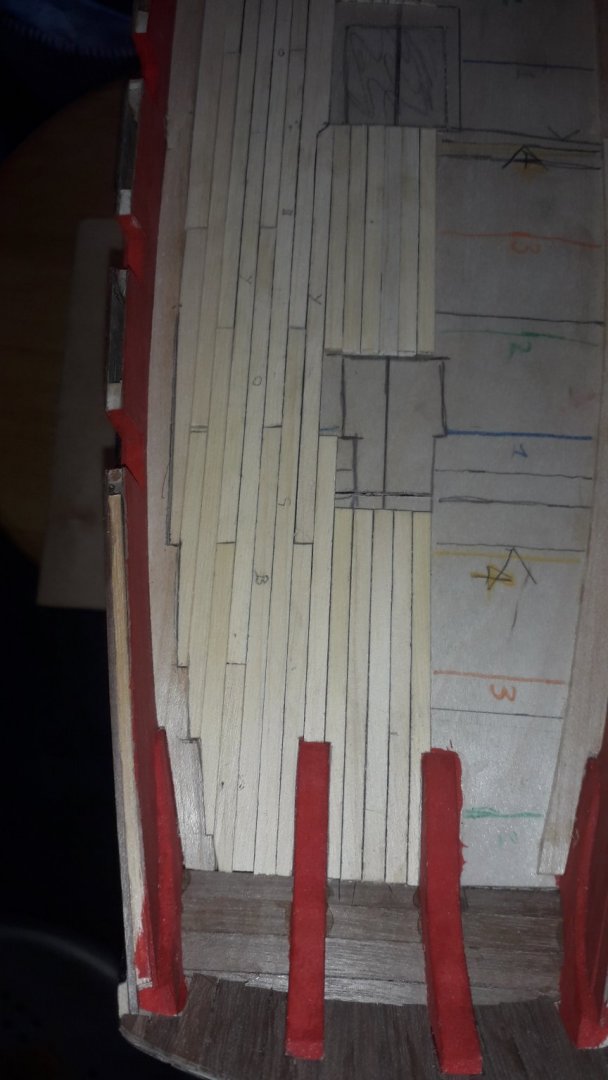

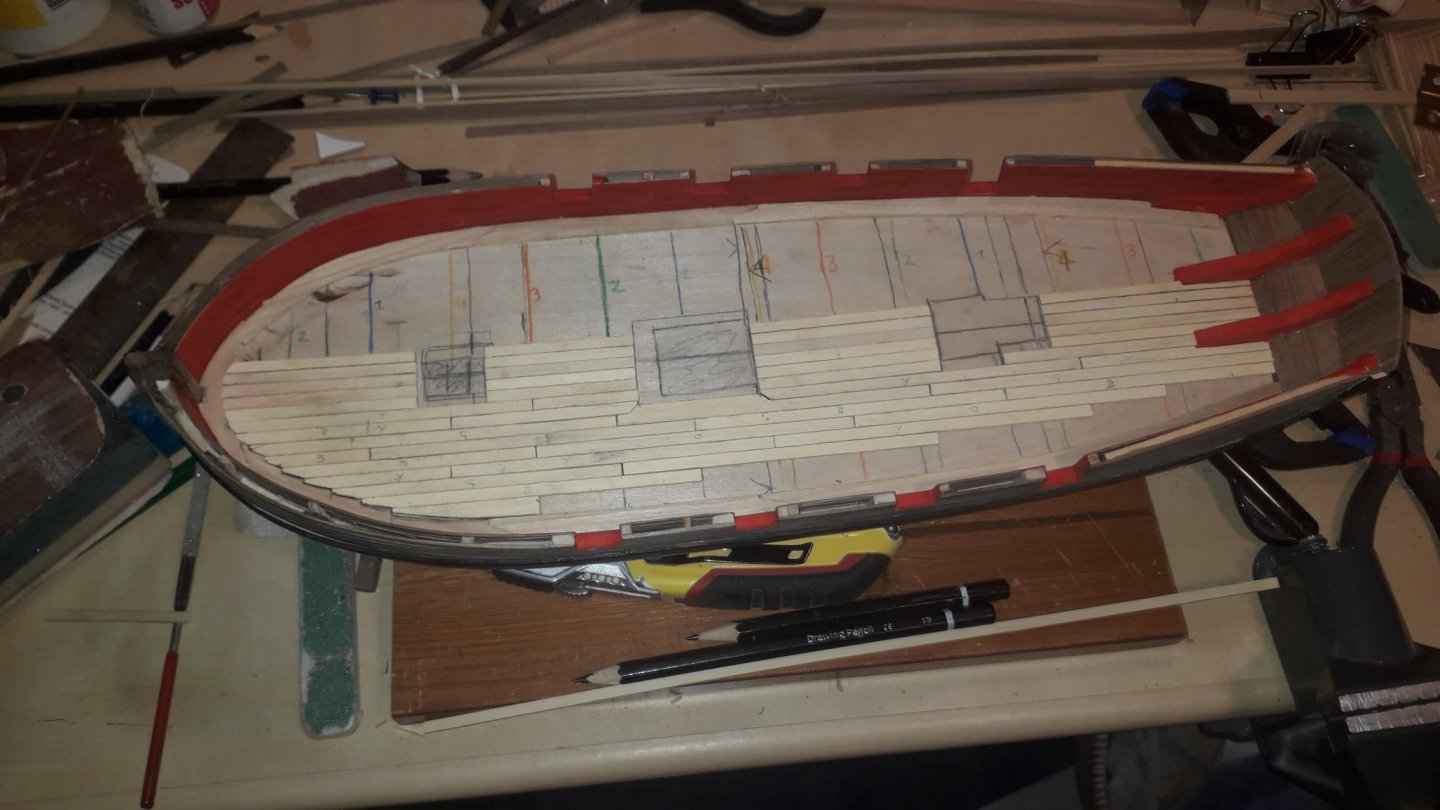

With the weather bad and being at home for a few days I've been able to crack on with the starboard side deck. started at the bow again. I've noticed on the nibbing at the stern there is one more cut on the starboard then there is on the port. As all is glued now I'm going to leave it as is and hopefully once the deck is populated it won't be noticeable 😏 Thanks for all the likes, comments and looking in. Cheers till next time 😁

-

welcome to MSW

-

Thank you OC and Mugje. To all who looked in and the likes 👍thanks. So today saw the completion of the port side deck, the next task is the starboard side. Take no notice of the coamings as they are ones I made up for Triton and are not quite the right size! Only a couple of mm small but it sticks out like a sore thumb. Once I've finished on the starboard it will be getting a scrape and light sanding before a coat of varnish. Thanks till next time Cheers 😃👍

-

Welcome to MSW, very nice powder horns, great work 😃

-

Thanks alot Tim and Derek. Got two or three hours at the bench tonight. Carried on with the nibbing/joggling, completed the port bow section. The coloured lines are solely for my benefit as I would totally mess up on the butt shift pattern if it's not marked on the false deck🙄 also did the fancy planking by the main hatch. Saw @mugje do this on his build, so since I'm trying new things, I'd give that an attempt as well. Lots of filing, happy that the Cedar deck planks are easy to shape. next time I'll fill in the port stern deck and maybe make the hatch coamings. They will have to be mahogany as I have some 10x3mm which I can rip down. Thanks all for the likes and comments, till next time. Cheers 😉👍

-

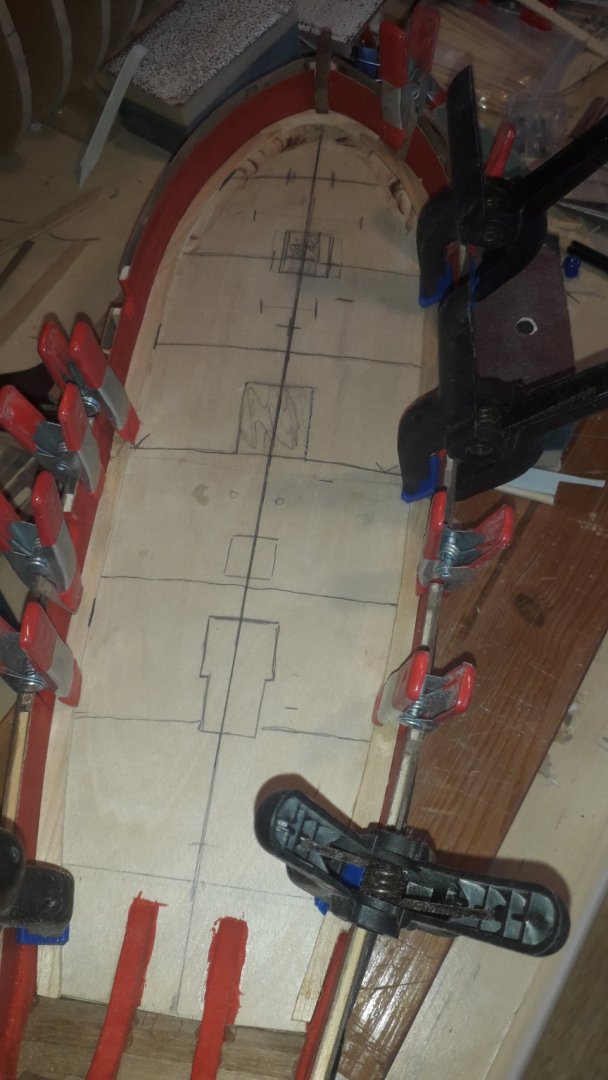

Thankyou, I have started with this method and upto now it seems to be working for me. Thank you Derek, I must admit it was your Speedy deck that decide me to give it a go, but don't worry I know you've got a lot on with Glenn's cannon rigging and spars so I won't be asking if you could do it for me😉 these planks are just placed and not glued, and I'm quite happy with the results as this is the first time I've tried this. Thanks to all who have stopped by and hit the button👍 Till next time, Cheers

-

Beautiful build Tony, your detail is superb and processes wonderfully explained. As Mark said, thanks.

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

Yes, it is strange! I wonder if someone were to mail some to the USA privately, as a gift, wether customs would confiscate it as illegal or contraband, just a hypothetical "what if"

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

I fear you may be disappointed Glenn, as when looking at their boxwood pieces, it does have a note in the info: Castello boxwood is CITES listed and requires special licences for export. We regret that for practical reasons we are not able to supply this item to countries outside the EU Sorry to be the bearer of bad news 😬

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Great but of kit Derek and it's only gone up £1 to £15.75 including VAT, I'll order one before they disappear.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Good morning, started on the deck planking. When I did the Sherbourne deck I wanted to do a margin and nibbing? but was beyond my skill level and probably still is but I'm gonna try anyway. Starting with the margin I traced the outline of the deck and transferred it to some card and then cut into the different parts. These templates were then glued to some wood sheet(not a clue what it is) and cut them out after lots of sanding, filing and remakes, I got something I'm happy? with, and glued them down. To finish for now I've placed and glued the centre plank and one either side. Going to trawl through deck planking articles now to see if I can get some tips on nibbing or joggling. Thanks for looking in and hitting the like button. Cheers till next time 😉 Edit: sorry about the poor lighting on the photos.

-

This is something that I'm trying at the moment. I cut the profile into a 2mm thick old brass hinge and practiced on a piece of AYC. I found a thinner scraper tended to dig in! Anyway that's my pennies worth.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Glenn, your patience and diligence has paid dividends, for the planking on Cheerful is amazing. With your detailed step by step posts, this log will be a go to source for future builds. Please keep them coming, I've learned lots and no doubt many others feel the same. Cheers 😏👍

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That guest is part of the rigging crew, leave Pelican alone too long and she'll be festooned in silk rigging 😁👍 Mast tops are looking good, nice job😉

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

I've been reading this thread with interest, as I'm going to be making my own planking strips soon. Unfortunately I don't have a Byrnes saw, but will be using a Proxxon fet, so I assume the method can be applied. The idea of a block to keep the wood steady instead of the hand is great. Thanks Glenn 👍

-

Thanks Mark, trouble is I feel at home here🤪. I've attempted to make some moulding trim, I filed the profile on an old brass hinge, passable but a little disc cutter would be a better tool to make the profiles. First pieces of trim fitted. I think I'll go and see what rotary tools are on offer at the local DIY stores. Thanks for the likes and comments 👍 Till next time cheers. Looking at the photos in this thread has made me think I really need to keep my bench tidier 🤔

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.