-

Posts

1,009 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by WalrusGuy

-

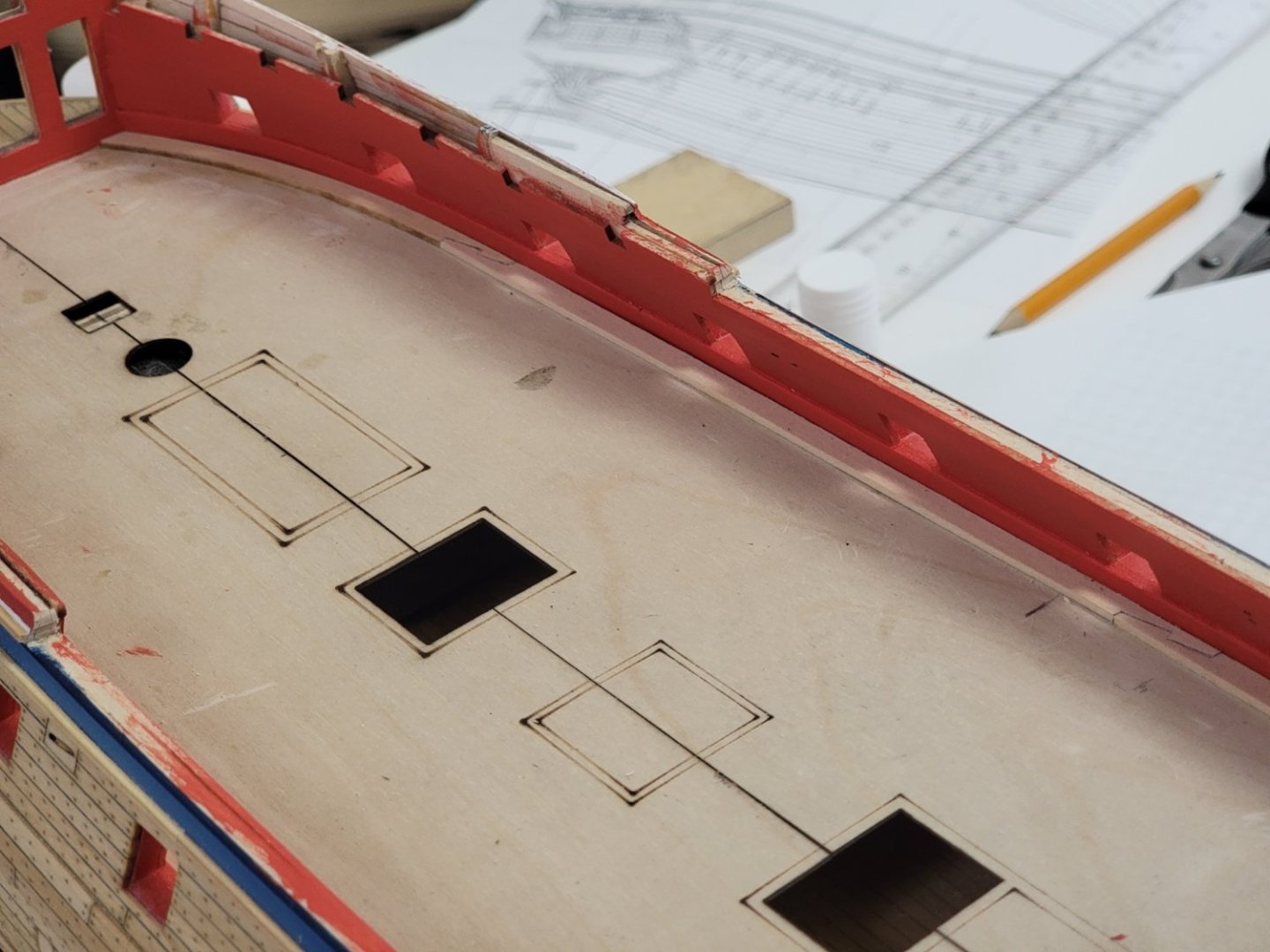

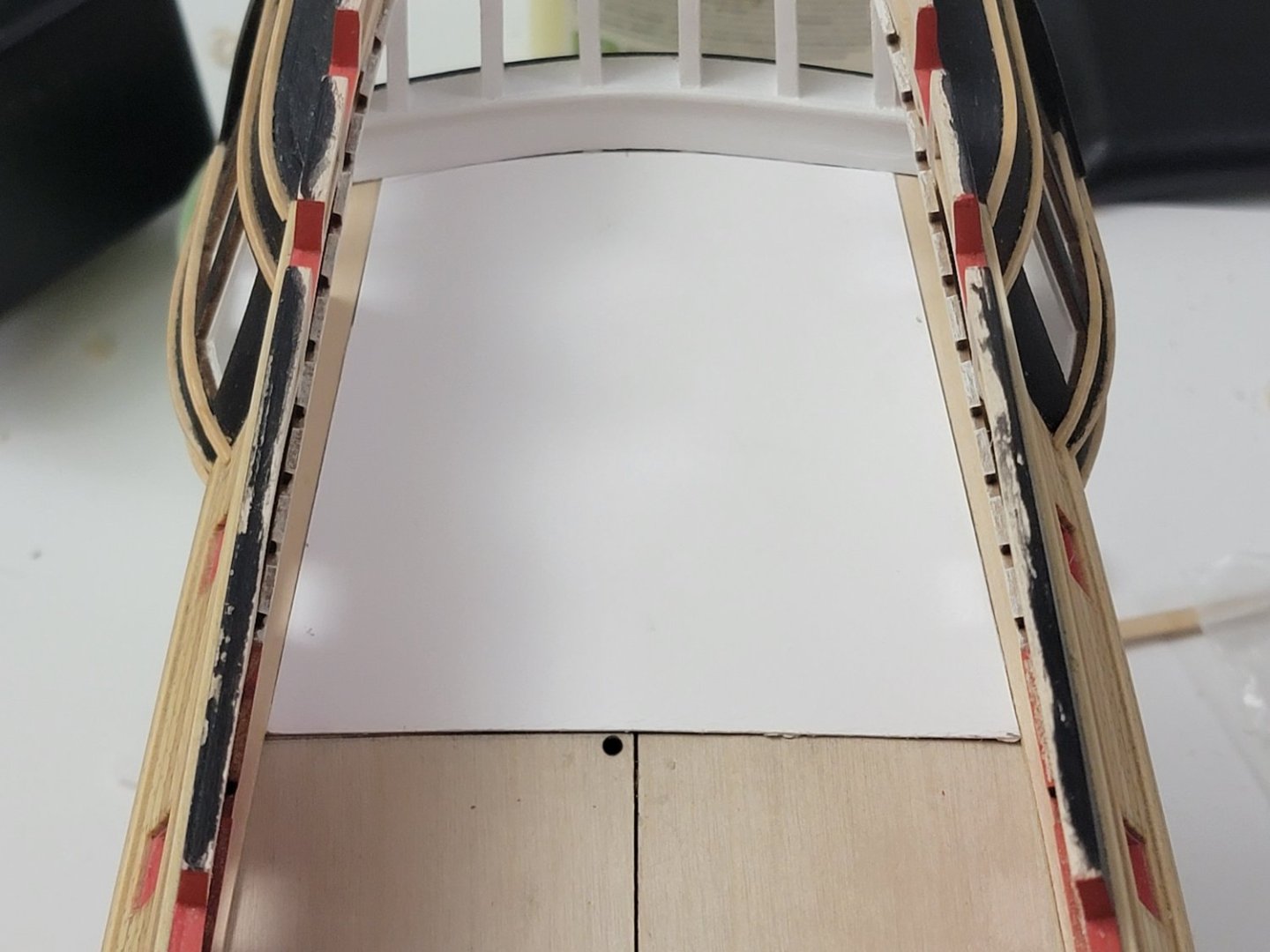

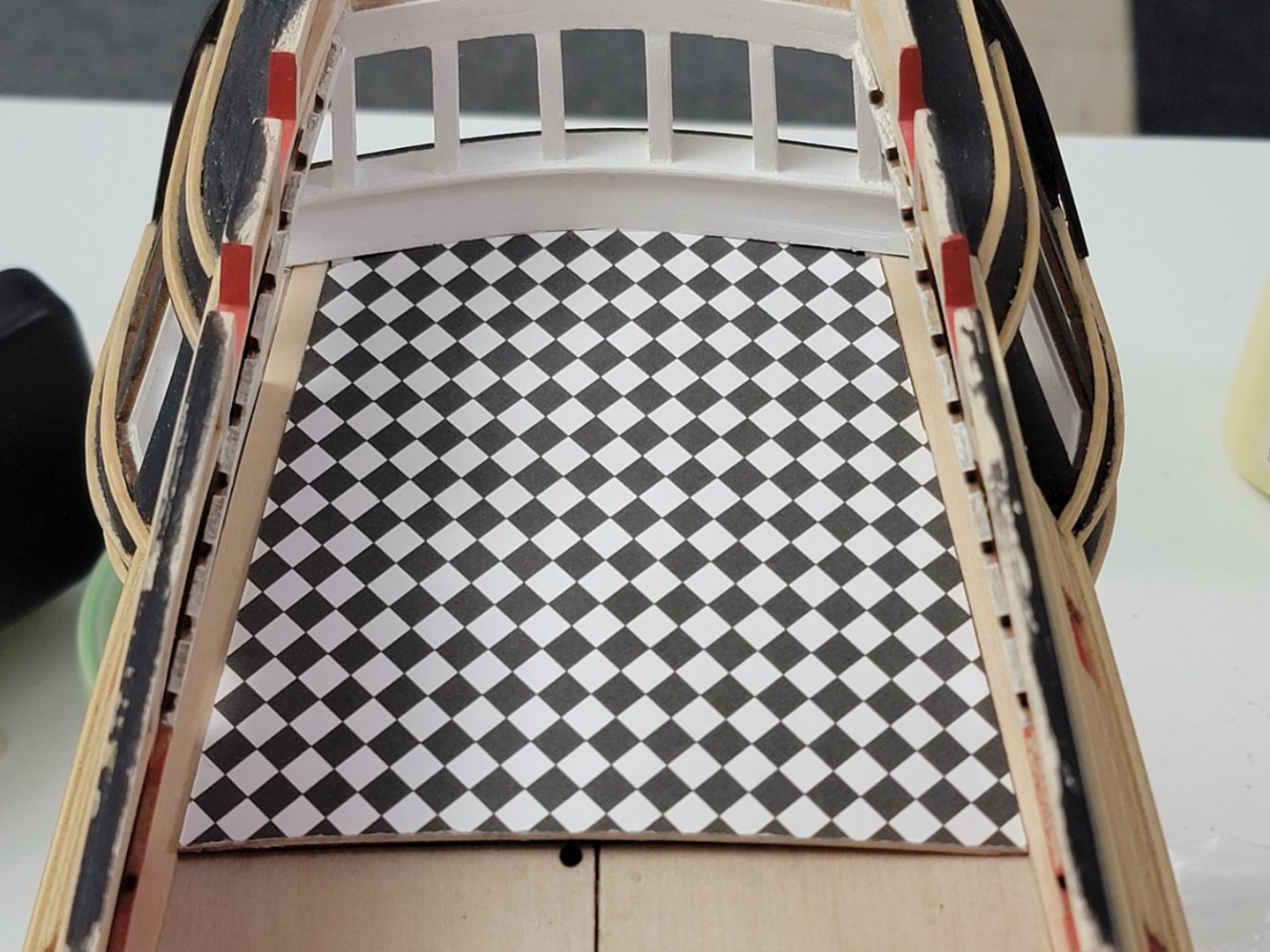

It's been a while since my last update! I am back to model building, and have made a bit more progress. I planned to continue working on the quarter gallery and carvings, but after some failed attempts, I decided to start on the decking to get my feet wet again before diving into the deep end! The margin planks are now glued in place. I decided to scratch build some of the pieces as there were 1 mm gaps in the scarph joint when using the supplied ones as shown below. Here are a few photos of scratch-building the planks: Some more photos the margin planks installed: I was inspired by @wernerweiss's build to have a black and white checkboard pattern instead of the wooden one as the instructions suggest. I used a card template for the overall shape before printing out the pattern on card stock and gluing it on a 1/32" sheet: Here, the checkboard pattern is not glued to the false deck. It will be permanently glued once all the decking is done and sanded to avoid any mishaps on the card stock.

-

Thank you for the compliments! It's really appreciated 🙂

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Congratulations! Your model looks so beautiful, especially in the case. Very nice job 👍

- 157 replies

-

- model shipways

- syren

-

(and 1 more)

Tagged with:

-

Gorgeous model, Toni. Your log will be a great reference for me when I get started on a cross section scratch build.

- 52 replies

-

Some of the best planking I've seen 🙂

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Awesome model and photos! What's left to complete the model?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very inspirational work, Toni. The details are amazing.

- 52 replies

-

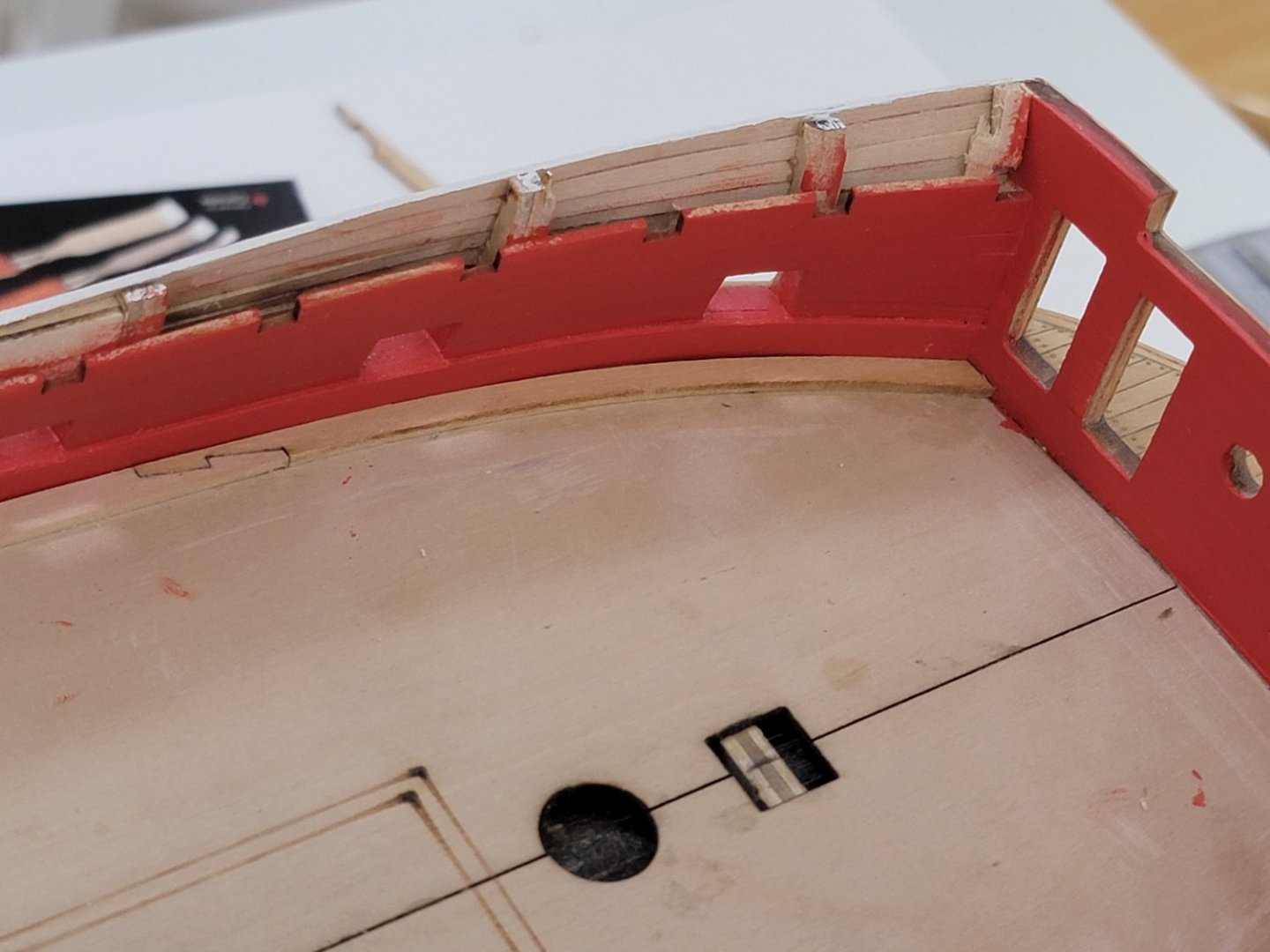

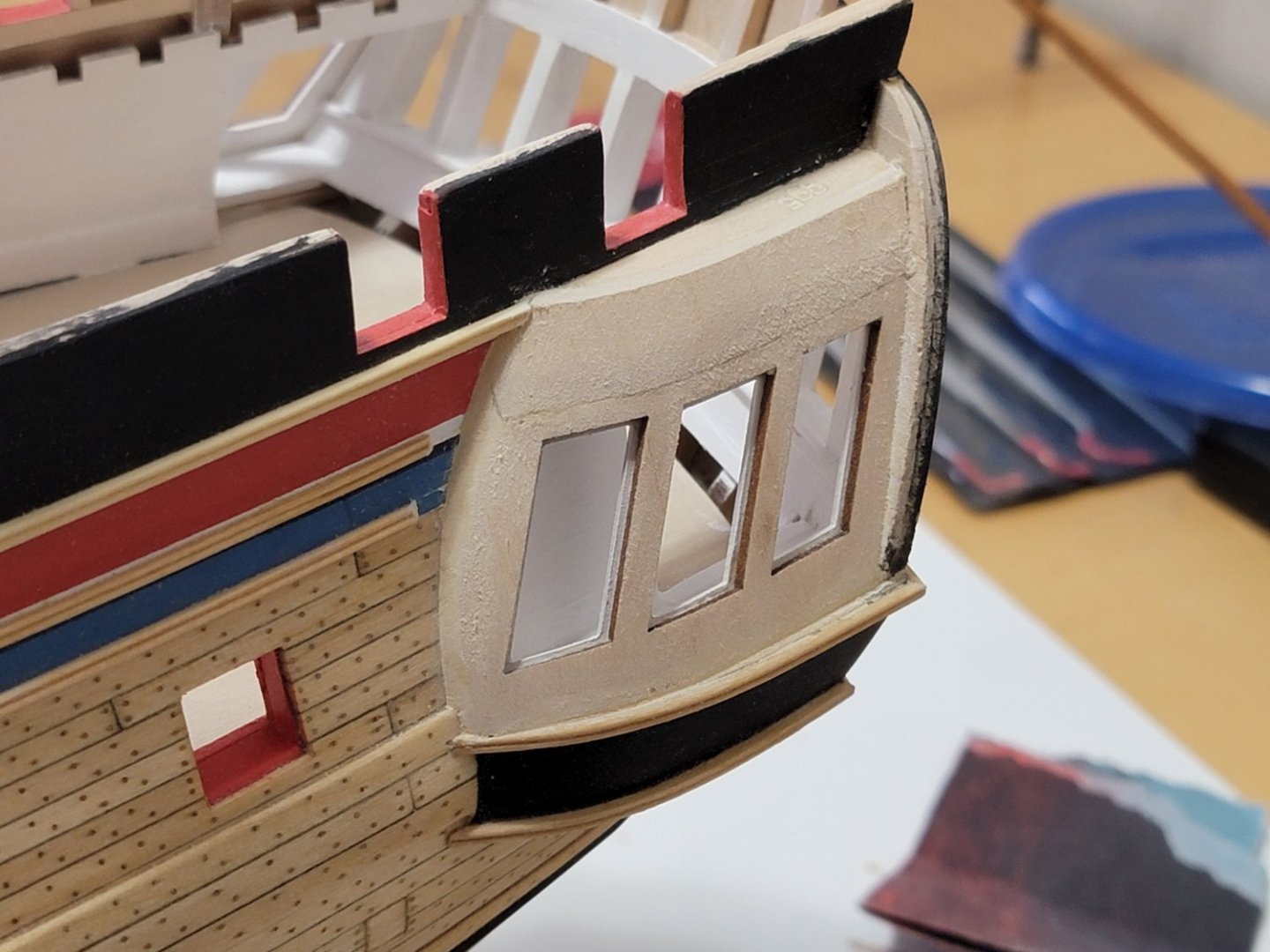

A small update before I commence on carvings. The cove and final moulding strip below the lights are installed. The cove was a very tricky and frustrating part to sand and shape. Just looking at it wrongly made the wood split, crack, and chip. I ended up using filler in the chipped parts and painted it black. Here are some photos:

-

Thank you so much David! After some thought, I decided to leave the cap rail pieces as-is. Painting them black would make the quarter gallery too plain looking imo. I was afraid I will damage the thin delicate pieces if I try to replace them. And the added decorations would make the pieces harder to spot. I learnt for next time to apply the finish before hand to make sure the strips are of the same color (or use a better quality wood with less color variations per piece 😉).

-

Hi Werner, thank you for writing. And thanks all for the likes 🙂 I used basswood strips for both the top and side pieces and did not see the color differences until I applied the tung oil finish. Funny enough, I did not use the laser cut cap rail pieces I was afraid of the color differences when I apply the finish (since the wood curves towards the end grain). The color difference is bugging me more now, so I will see if I can replace the side ones to match the top. The color of the top one matches the mouldings so I think I'll leave that glued permanently. Another option I am considering to paint the cap rail black as shown from the post below. Let's see...

-

Gorgeous work, Werner. The details and the decking are very crisp and tidy. Can't wait to reach there myself 😄

- 60 replies

-

- Confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

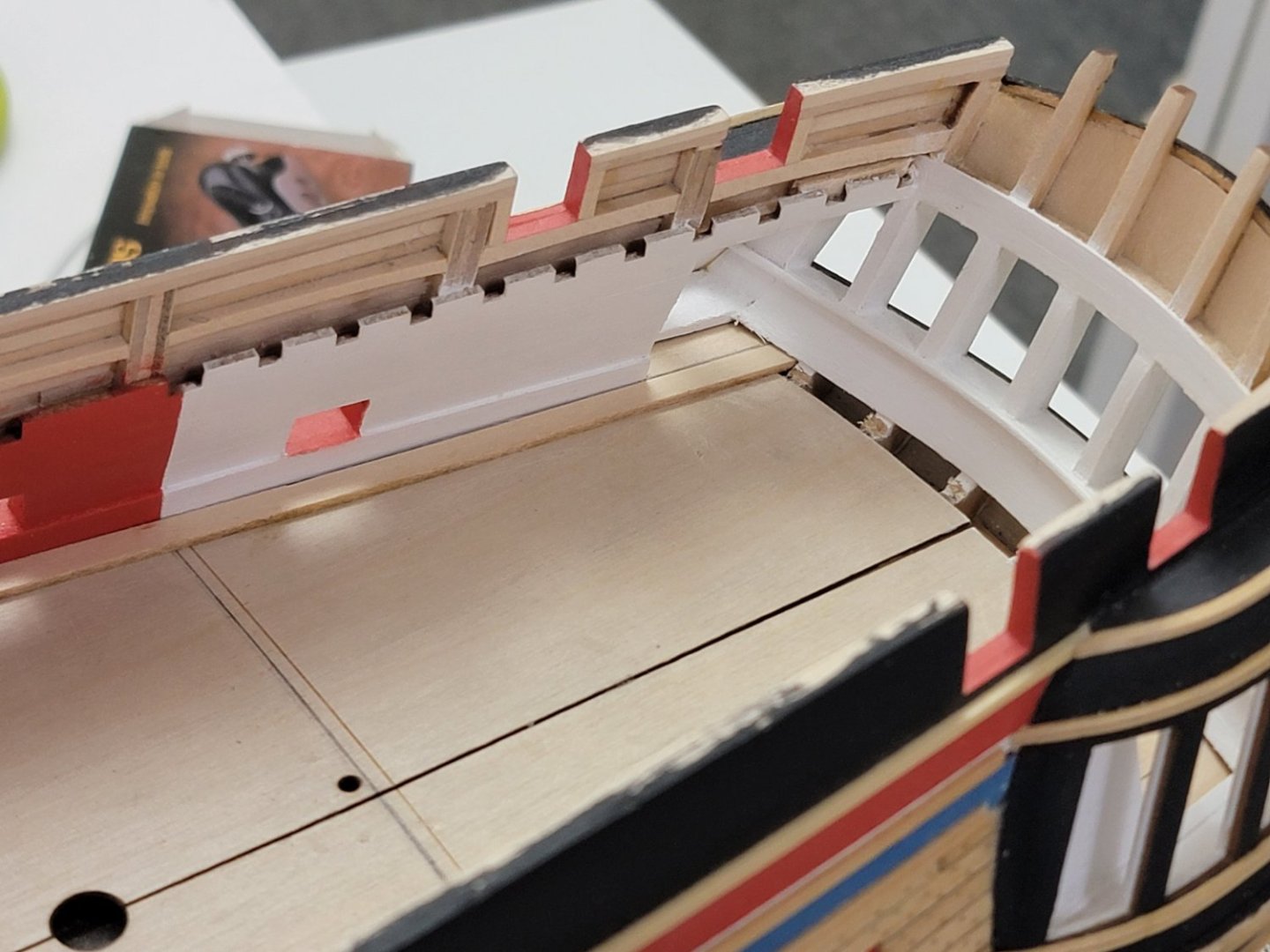

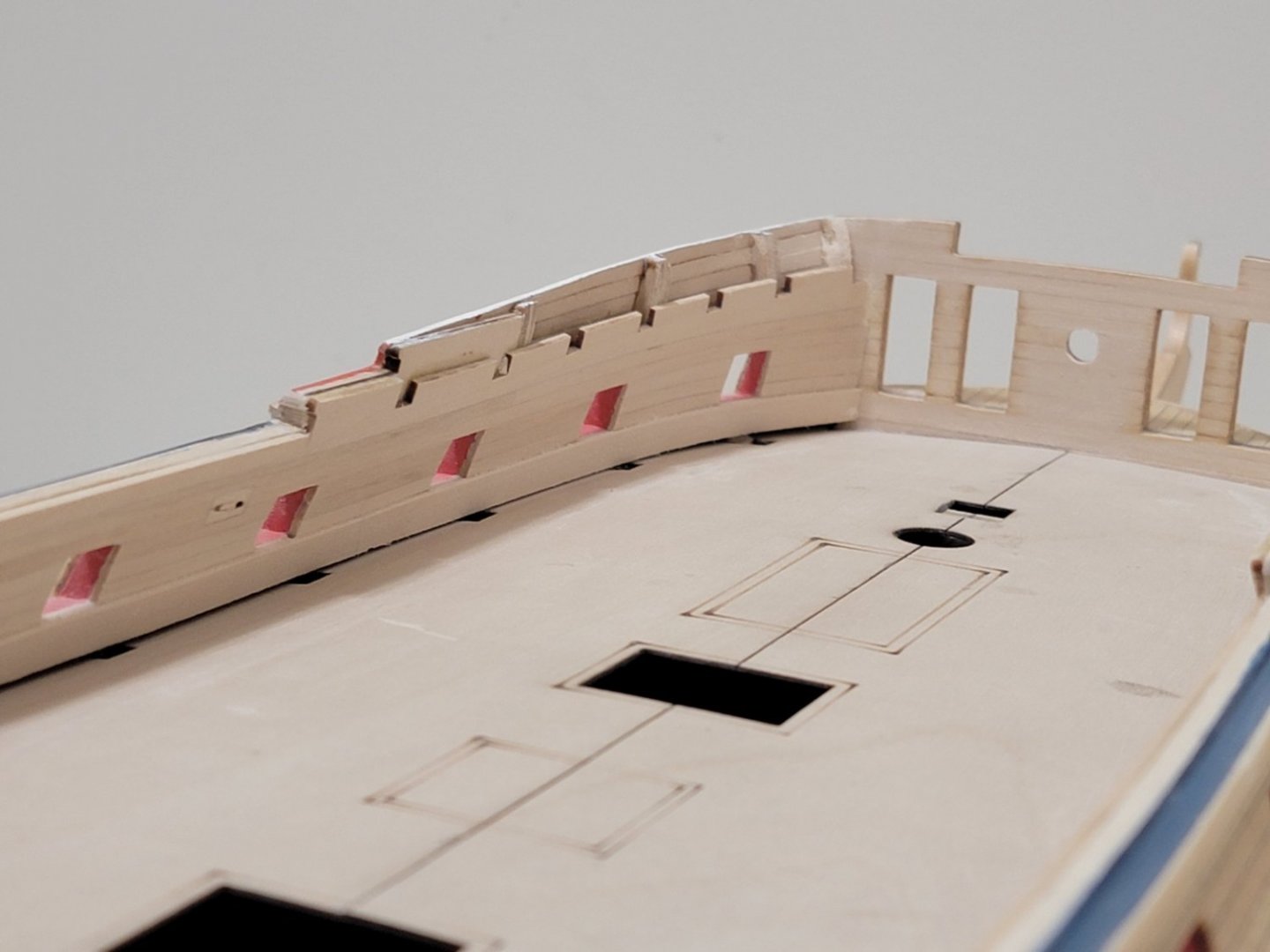

Thank you for the kind words, Richard and Steven! 🙂 Continuing on with the quarter gallery construction with the mouldings and cap rail. I opted to go for two mouldings on the roof instead of the three as depicted in the plans and instructions. Reason being, the space between them was too narrow for the brass scrollwork, so I decided to omit the middle strip. I will try to carve out some larger scroll pieces that fit in the larger space. After gluing the cap rail, I realized that the middle piece was a slightly different tone of color than the side pieces. I think it will be less noticeable when all the carvings are in place. So I decided to leave it as-is (and I was also afraid I may damage the other delicate areas surrounding the piece if I tried to remove it). Below are some photos of where I have reached: Lastly, I placed a 1/16in thick strip as a sample deck plank, and it seems like I do not need the extra plank below the bottom white plank. Any comments would be appreciated! Now I am thinking to finally start working on the carvings. I have no idea how they will go as it is my first time trying it. If my attempts fail I will use the supplied pieces.

-

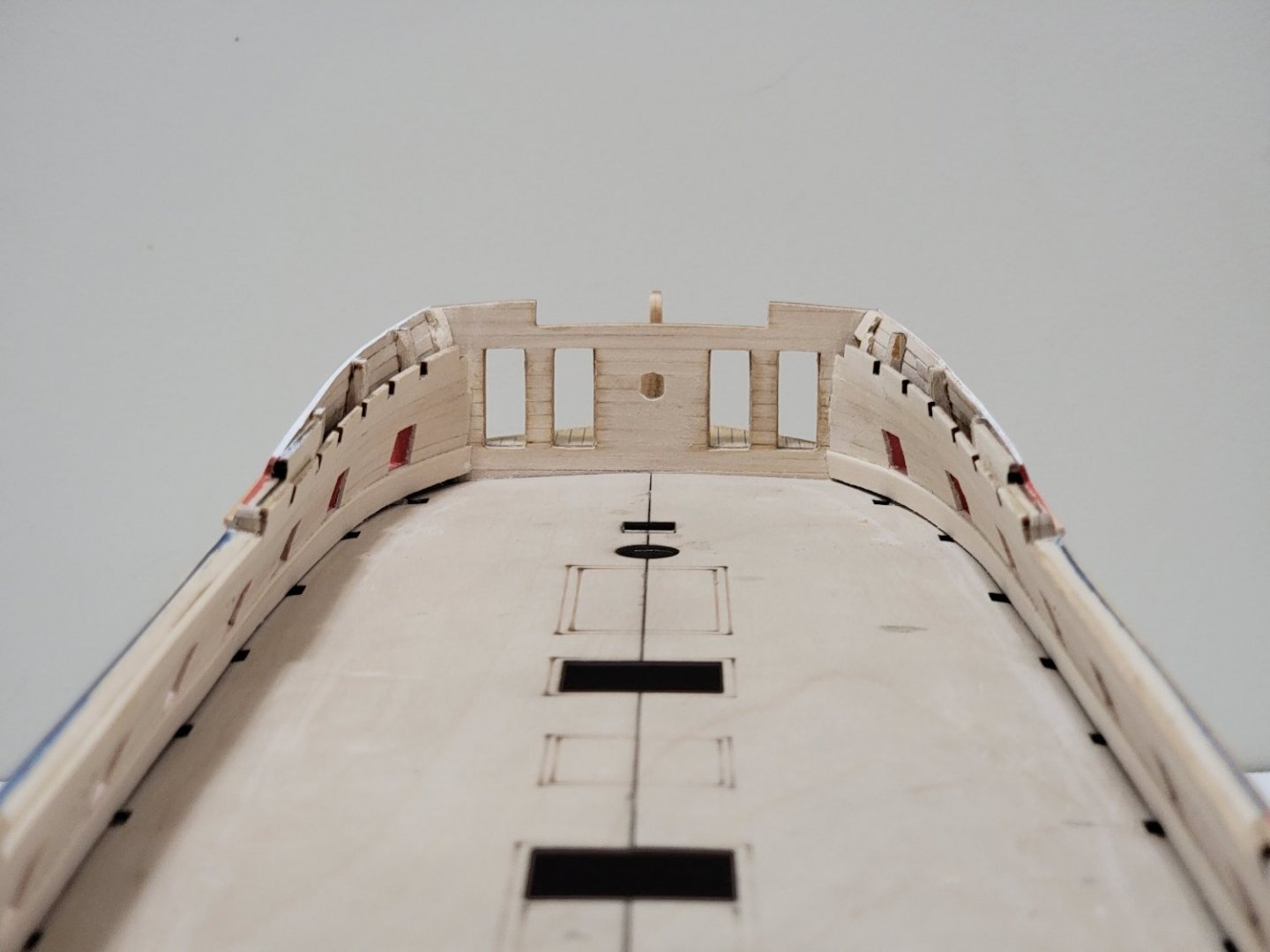

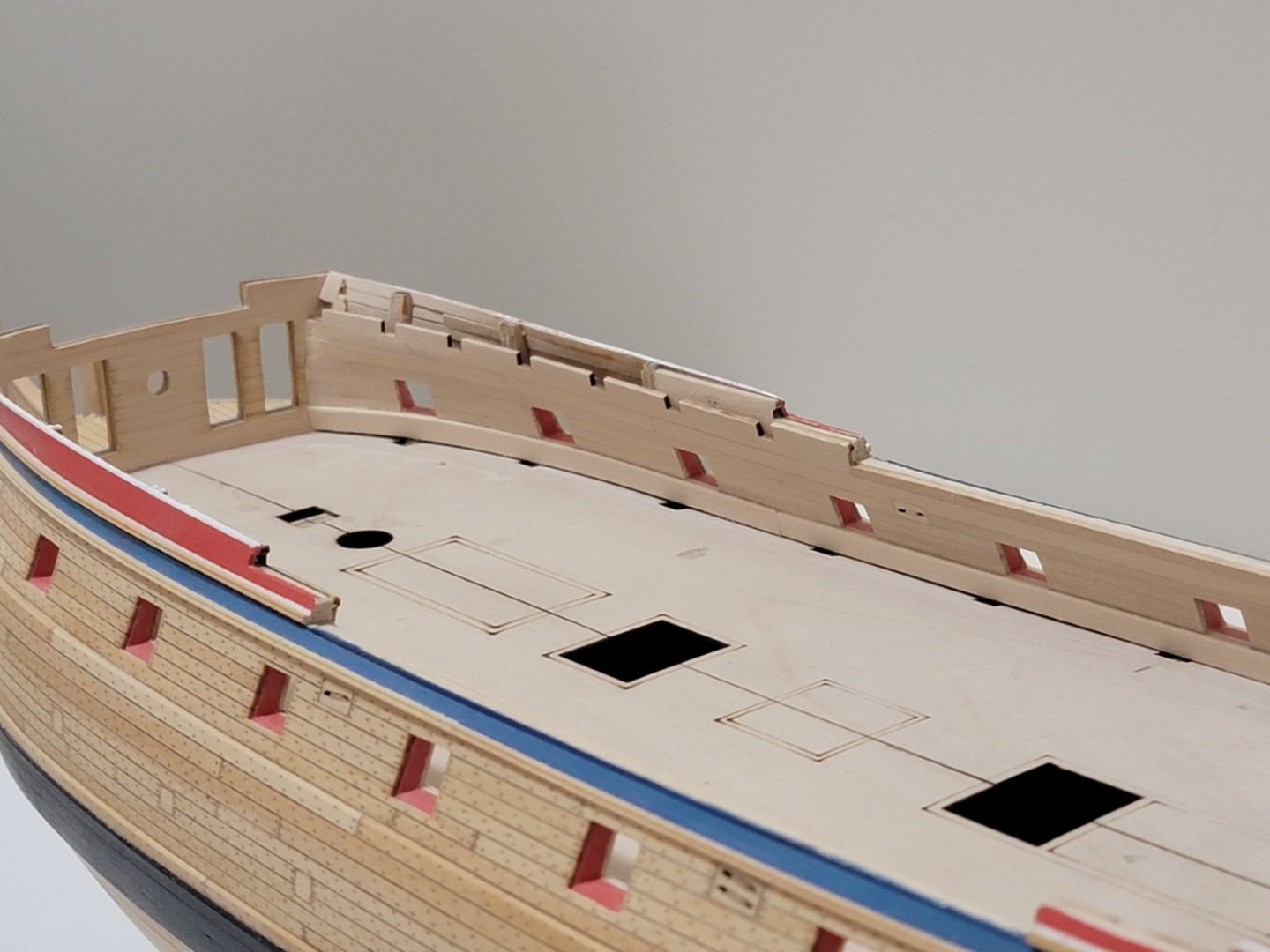

After some consideration, I decided to paint the bulwarks before drilling the holes. Reason being, the paint will clog up the holes, and I will need to pierce the holes again after painting. And I chose to paint the bulwarks in the great cabin white after seeing Werner's and Dirk's gorgeous builds. Also, I ended up using the kit's shell pieces for the sides of the quarter gallery instead of scratch building them. They needed a lot of tweaking for it to fit well, and not to mention a lot of filler as well 😁 Shaping and gluing these pieces is probably the trickiest part of the quarter gallery construction. There are a lot of angles to work with. It's not perfect, but I am happy with the outcome. And here are some photos of the painted bulwarks: I will be gluing a thin veneer on the false deck at the portside of the bow since there is a large gap beneath the spirketting which is very noticeable. The starboard side has a more consistent gap throughout the entire hull. I was afraid to remove the false deck neatly, so that's why I am thinking of following this route instead.

-

No, unfortunately I did not do this. Wish I thought of this earlier! I did check if the false deck is rigid near the beakhead bulkhead and it does not seem flimsy at all. I hope problems do not arise because of the lack of support underneath the sheet. Thank you for forwarding the image of the template, it will be very handy in the coming week.. Much appreciated! 🙂

-

Hi Werner, Thank you for these tips! I especially found the drill template idea very interesting. It will save a lot of time trying to find the correct location for each hole. Do you have photos of your model with 2nd layer of the veneer sheet on the deck? I'm wondering if you only glued this sheet on areas of the wavy "dip". Did you glue the sheet before sanding the area flat? Thanks again! And thank you all for the likes 🙂 Harshil

-

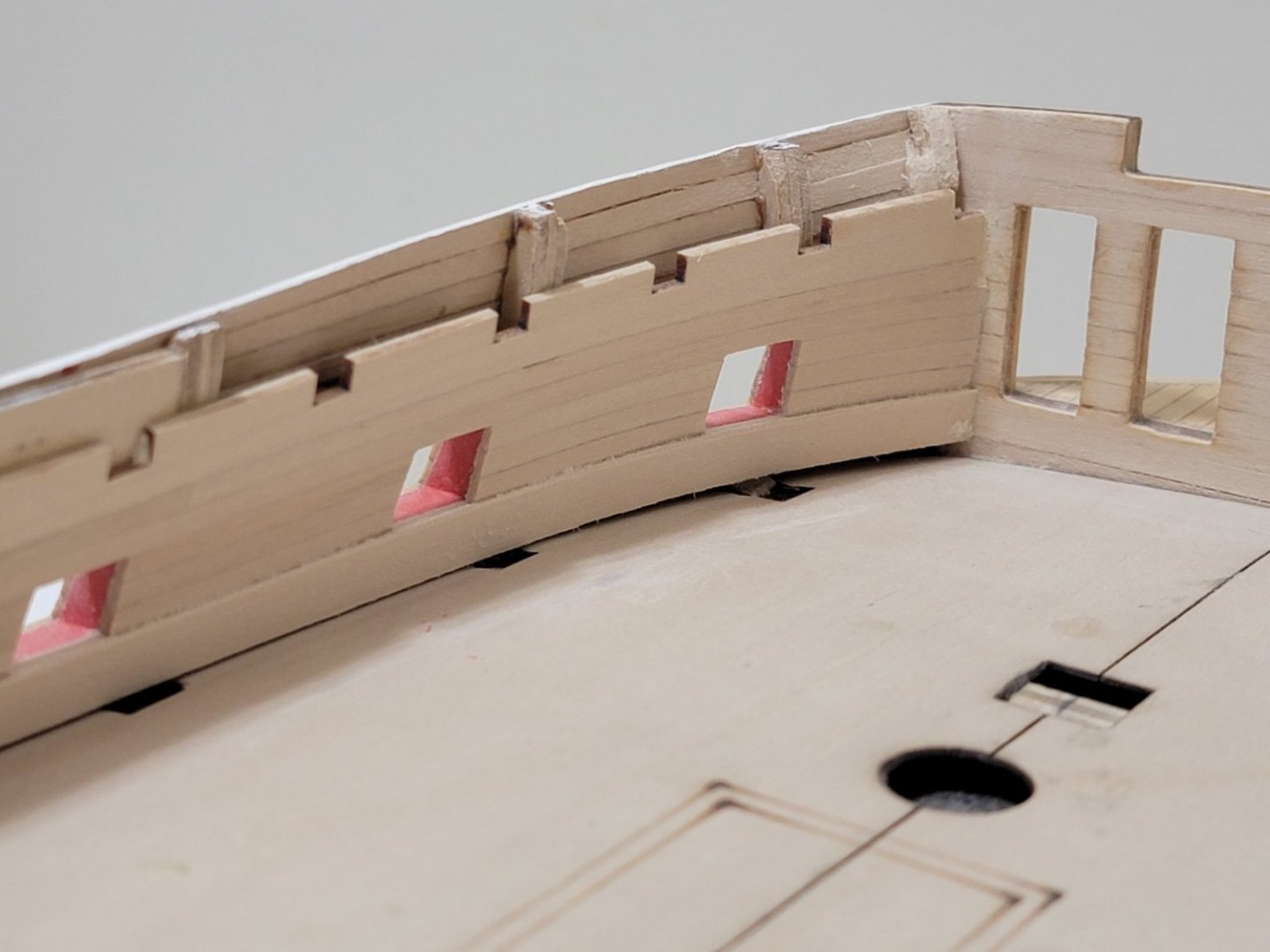

The interior of the bulwarks are now planked. The foreword piece with the notches was around 1-2mm short, so I had to trim the exterior planking slightly. I found the spirketting the most challenging part of this chapter, especially at the bow. I needed to use slivers of wood beneath the plank while the glue set so that the plank was oriented with the top of the port sills correctly. Here are some photos before I start painting:

-

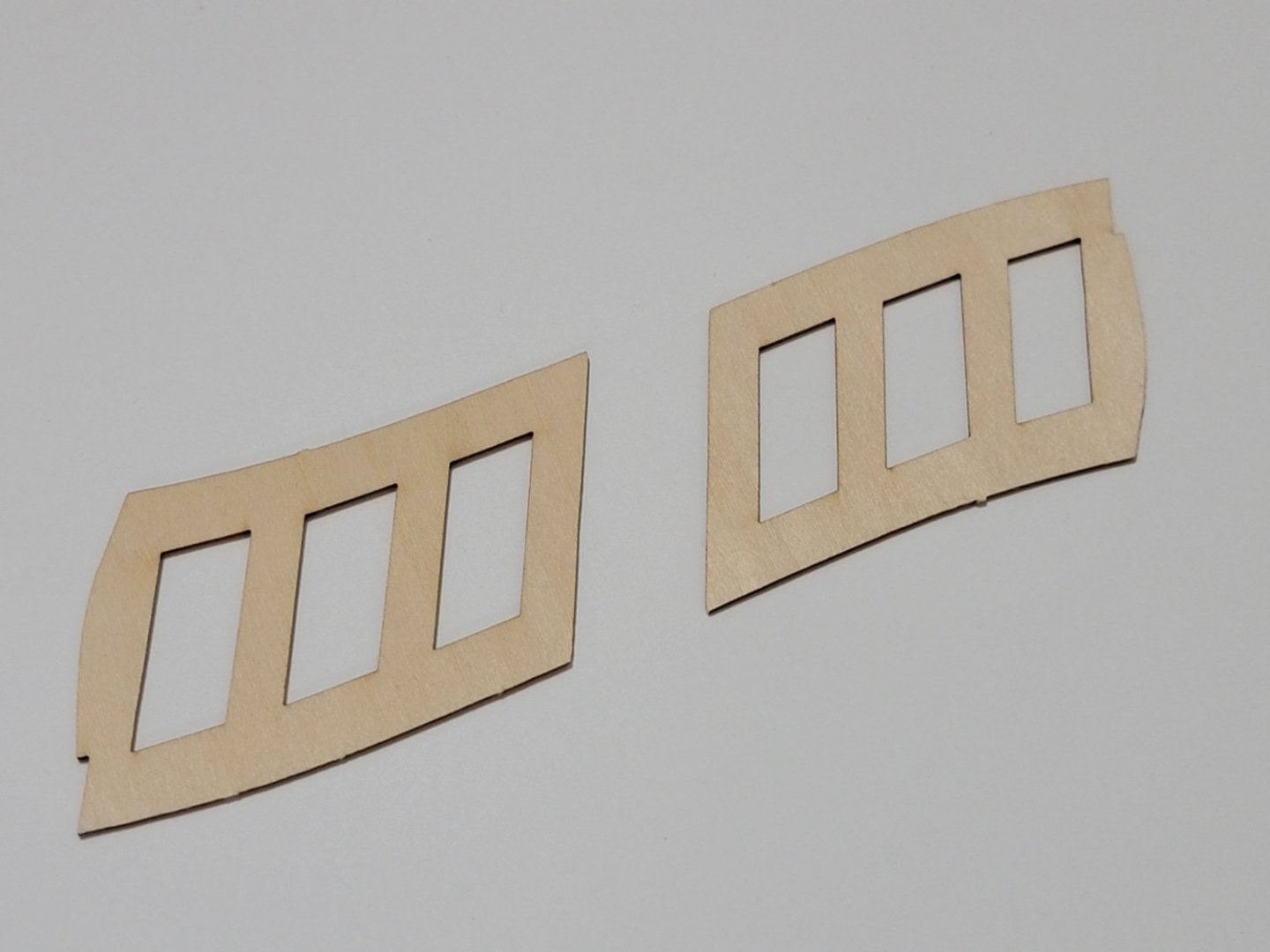

Hi Werner, Thank you for your kind words! By shells I mean the parts that contour around the sides of the quarter gallery that holds the lights in place (see the image below of these parts). No matter the orientation I try, they don't fit nicely so I'll need to make my own parts. I plan to carve out the drops with boxwood (it will be my first time ever trying miniature carvings like this). If my trials don't turn out nicely I'll be using the supplied castings since they will also look good once painted. Harshil

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.62d1d69fed1f32364417cb1f9cdeb009.jpg)