-

Posts

986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by EricWilliamMarshall

-

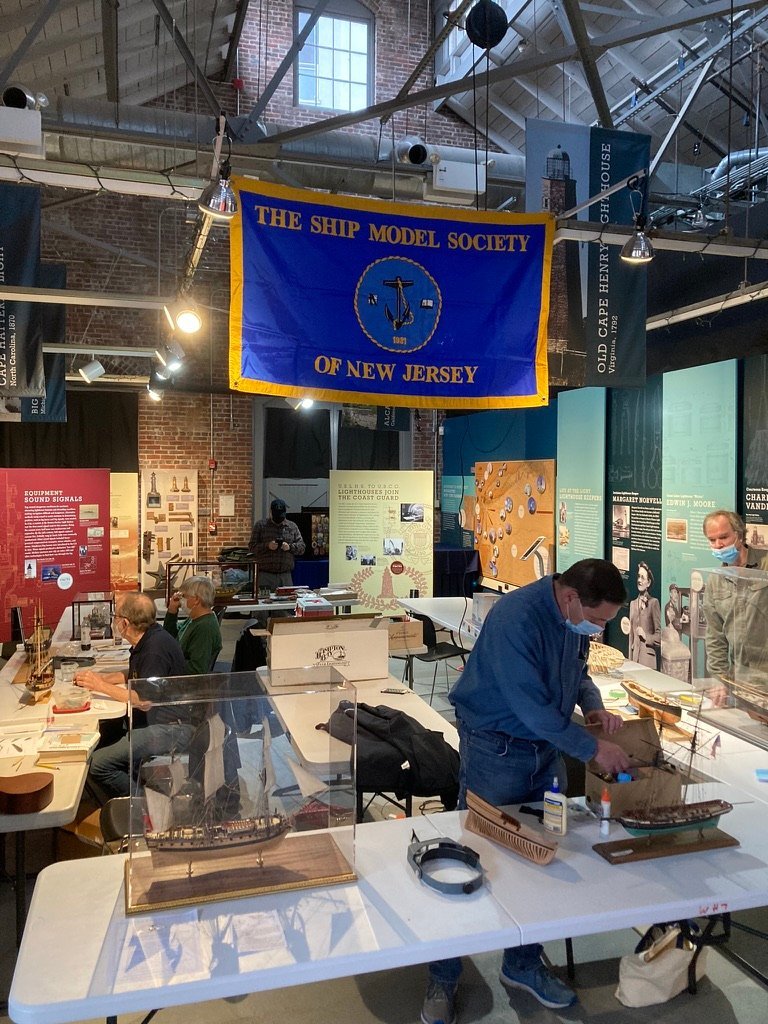

I can't recall if it was @VTHokiEE or @ccoyle, but someone mentioned that Amazon had a few of these paper models and at $12 dollars, I was game. I attended an event at the National Lighthouse Museum (https://lighthousemuseum.org/) yesterday as part of a demonstration of ship modeling by the SMSNJ (http://www.shipmodelsocietyofnewjersey.org/) (of which I'm a member despite their better judgment). And I thought, I can't lug all the stuff I need at this point my wooden model build, so I'll try a paper build. I figured I would share here. May the bridges I burn light the way for others!!

-

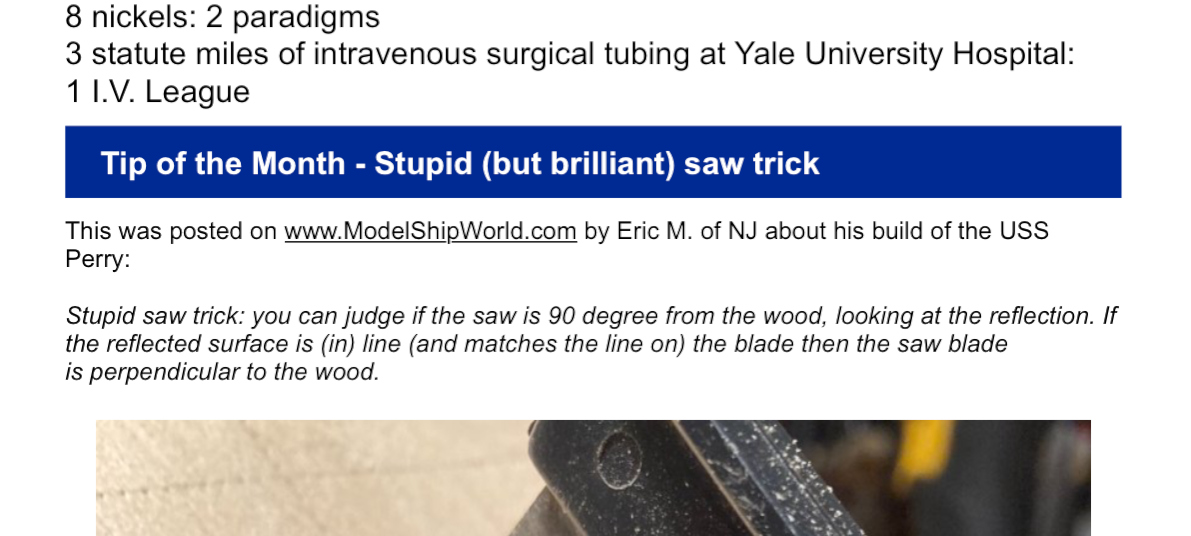

I should note the stupid saw trick also applies to other tools, most notably chisels. A follow-up trick: generally folks can judge if a 90 degree angle is spot on or off by eye. So you can cut fairly accurate 45 degree miter cuts by judging the angle of the chisels reflection vs. the wood to be cut. And it is very fast as well!

-

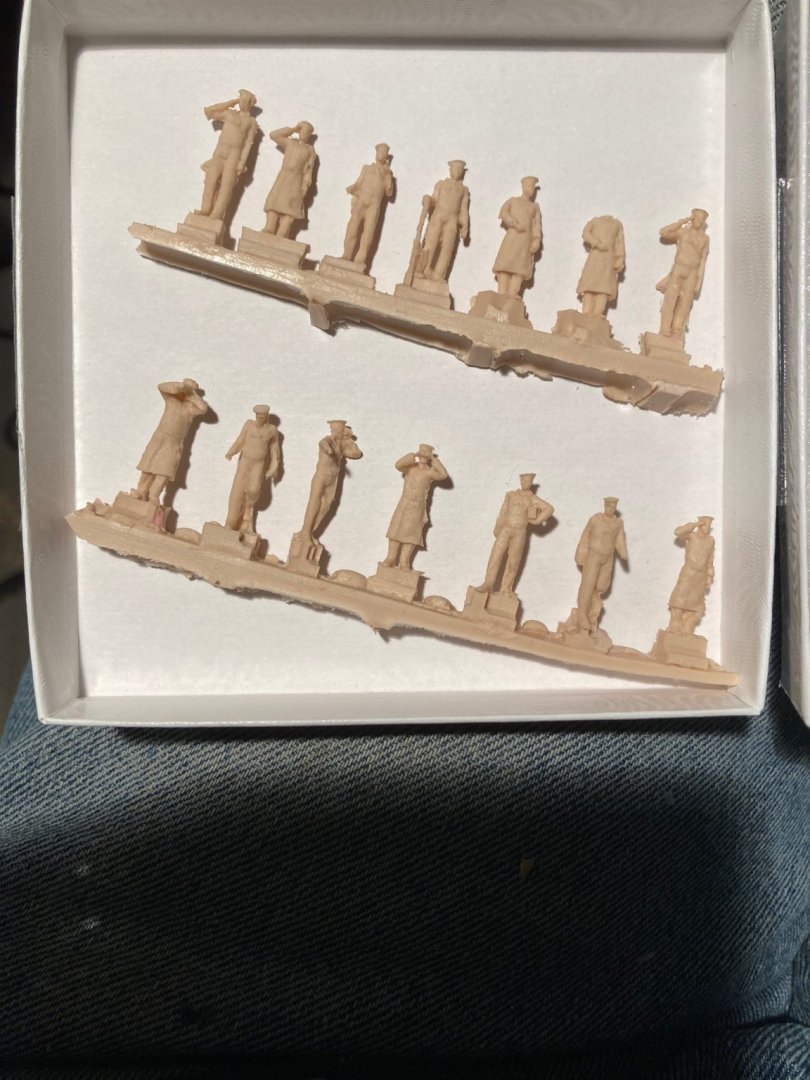

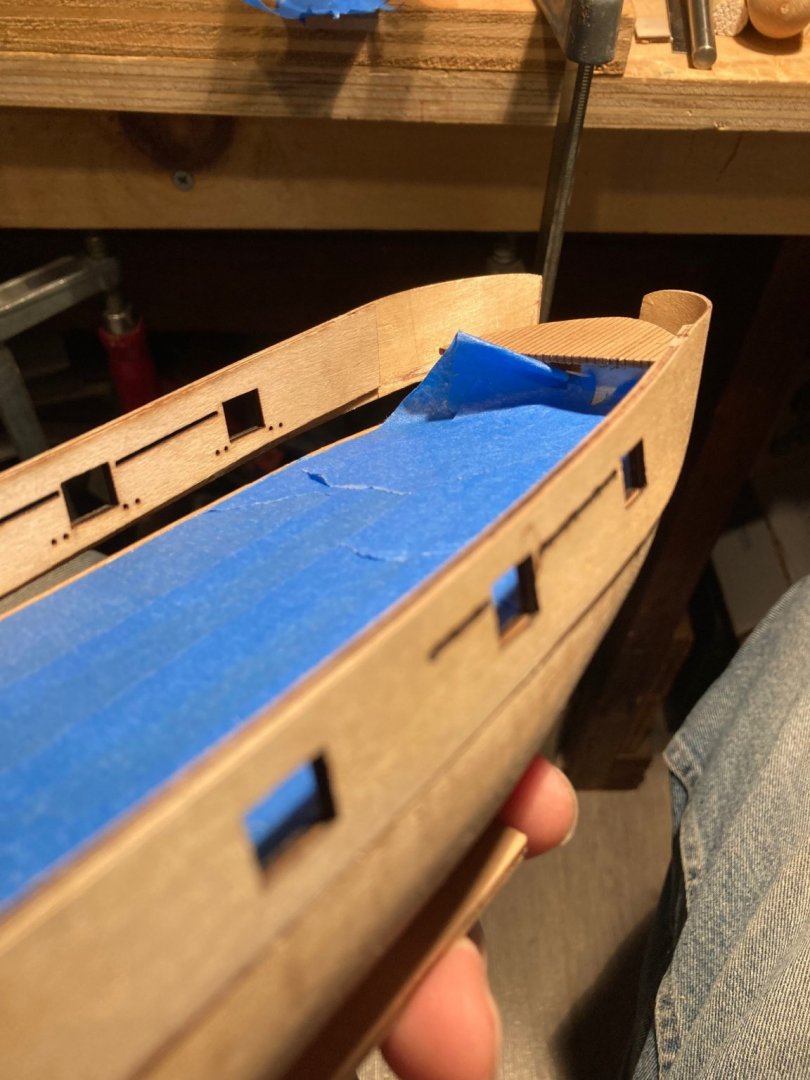

I wrestled with adding wood to the curved part of the bulwark in the bow. I tried bending a piece of solid wood which bent a bit and broke. Then I tried a bit of plywood and broke the bulwarks off the front of the boat! So I repaired the damage, not making any progress at all (other than experience and wisdom gained). The model is no worse for wear after the repair. I also cleaned up the resin figures I received; the will need some reshaping as well. Following up on @TomShipModel’s suggestion, I have reached out to the Smithsonian regarding plans for the Perry. I also found a set of plans at http://www.taubmansonline.com/ and have inquired as well.

-

Haha! I get the impression that this is a new kit and is still being debugged/refined. None of them are show stoppers and unlike some other kits, they show where parts from the kit should be on the ship plans which is a plus. It’s not a bug, it is a feature!! I also applaud having a date in the manual, allowing the tracking of different versions as well as updating of versions.

-

Errata for the Building Manual (for pages 1-17). For anyone else who is working with this set of the instructions, I have the found the following: This is for the 05/05/20 version of the USS Perry (kit no. 1112) in 1/8 scale. Typos: p.8 near top of page - “Cut the hull and deck templates from sheet px-x” should be “from py5-5” p.8 bottom of page - “mark the location of the hull templates (0-T)” should be “templates (0-8)” p.10 top of page - “work slowly and check each hull station (0-T)” should be “hull station (0-8)” p.12 top of page - “Remove the forecastle deck waterways (LPY01G)” should be “waterways (LPY1G)” p.17 near top of page – “Remove the transom moulding (LPY02E)” should be “moulding (LPY2E)” Not typos but ambiguous. p.11 middle of page – “Align the long edge of one of the main deck halves (LPY1AP or S)”. Neither LPY1AP or LPY1AS are shown on the ship plans, but as a single unit marked LPY1A p.13 top of page - “CAUTION: The outer bulwarks (LPY2AP, LPY2AS)” are not on the ships plans. However, LPY2A is shown as a single item. There are two. Each one is combined with LPY2AP and LPY2AS. I believe the S and P stand for Starboard and Port.p.16 bottom of page - “Remove the fore cap rail caps (LPY2F)”. LPY2F isn’t shown on the plans. p.17 near top of page – “Remove ladder rails (LPY31A) and treads (LPY31B)”. On the ship plans, these two parts are shown as a single unit LPY31. None will cause great heartache. But since there is enough head-scratching in ship modeling as is, I thought this might help.

-

It is hard to get to cut the wood. If you don't have the right force it bounces away. While it can chatter, mostly if used incorrectly it doesn't do anything. Note: this may be a side effect of this unskilled/untrained/idiot user not knowing the proper technique. I lightly stained the pine and then used the floats 'poorly' so you can see the effects yourself.

-

In the great rasp bake off, I missed chatting about planemaker's floats. In my opinion (i.e. take with a dose of salt) they are hard to use well but cut quickly and leave a smooth surface. They are designed to finish the throats (insides) of wooden hand planes. They are hard to find but Lee Valley and Lie-Nielsen still sell them.

-

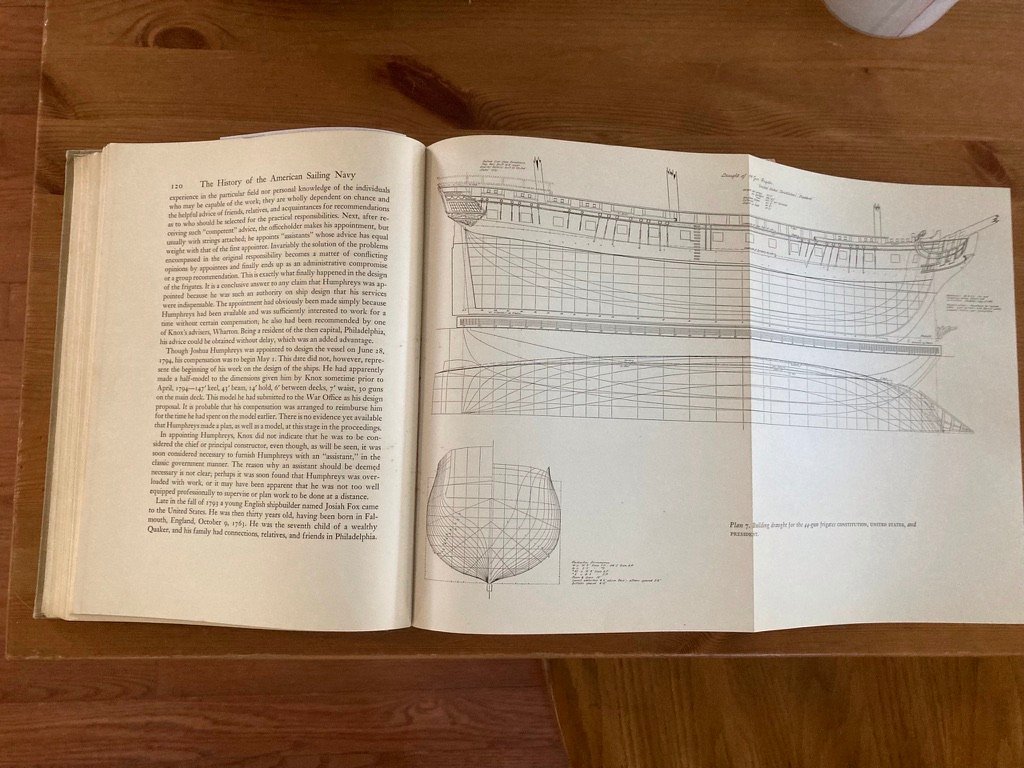

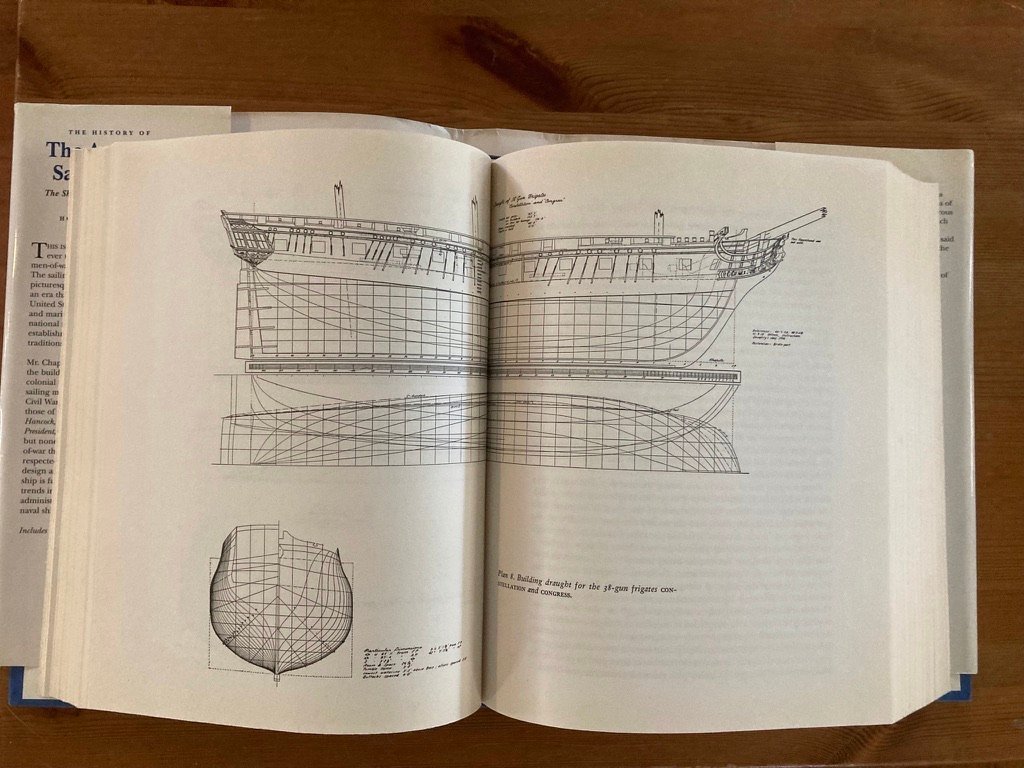

I 'upgraded' my copy of Capelle's The History of the American Sailing Navy. I noticed someone posted a picture of the book with a fold out - my version did have fold-outs. So for eleven bucks and shipping, I have a first edition with fold-out and nicer photos (on old-school coated paper)! I have shared the same part of the book for comparison. All rights reserved by Chapelle and W.W. Norton & Co.

-

Carry on! I think this where a lot of folks throw in the towel and take up bowling, gardening, etc. The ship will look great when finished!

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

To me that is the "value-add" of MSW literally! You are poster-child for the the growth that is possible with a bit support from the community here (at least to me). We both built Chesapeake Bay Flatties about the same time and now you're scratch building!! Boom! (Not all of us can be like Marc who hit the accelerator so hard as to leave a dent in the floorboards!) Thanks, occasionally it works against me since the tools and responses of the wood don't always scale as well as I would like. But is does mean I have all the hand tools someone might use and I mean ALL! (I'm light on machine tools though!)

-

My personal experience with layered (regular commercial) veneers and PVA is that it sets hard but you can set it in curves (depending on grain direction) and then glue it. I would try a few samples with the grain in similar directions as well as part of your experiments. I'm very curious to see your findings!

-

It’s all good, my tongue is often planted in cheek. And I am new to the model ship game - I started in October of 2019 with small plastic sailing ship model and I’m working my way up to my 1/48 scale dream diorama of the HMS Victory towing the Wasa towing the Soleil Royal!! I did do a ton of 1:1 scale woodworking in my mis-spent youth but as you may know, it doesn’t quite transfer to the smaller scales!

-

Sorry, this is the prep for the yet-to-come rails. I’m just removing char for the plywood. No cap rails were harmed! A great idea - you are obviously a greater craftsman than I since your bulwarks are the same height from the deck, same angles,, etc. Mine less so. The stupid sanding trick works in a number scenarios but perhaps this isn’t the best application. Did mention it was labeled ‘stupid’? Whereas your suggestion is clever! Thanks!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)