-

Posts

986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by EricWilliamMarshall

-

Thanks for the kind words, Mike. Definitely stressful! As for a great job, ahh, it could better! If you zoom in on the photo, you can put see small shadows where the two piece don’t mate cleanly. I think it will clean up well enough but it could have been cleaner. I did think about going the long way around and making my own and cutting gun ports, etc. I keep thinking if there is an way the lessen the “size of the leap”. Perhaps paper patterns to pre-fit the curves. I don’t know but I’m still thinking about it. The hull is to be painted and that will hide some of my sins. There is a definition of an expert that goes like this: an expert is someone who has made all possible mistakes in a small domain. Well, I’m trying to become expert by that path!

-

Stupid sanding trick: For my current task I wish to sand top of the bulwarks nice and flat. (I called them gunwales earlier but the instructions call bulwarks - my bad.) The problem is - it easy to be a bit off and not sand perpendicular to the deck or waterline or just horizontal.. Stupid trick: use an overly long sanding stick. Use only one tenth of the stick for sanding, letting the rest stick out away from the hull like in the photo. Now when sanding, alternate watching both ends. One, to see what you are sanding. The other to see a dip or rise. If you sees dip or rise you are no longer perpendicular! The longer the sanding stick, the more amplified the effect and the easier to see when you stay from the horizontal. All of this is more accurate if the sanding takes place at eye level. In one photo, I’m good and the other I’m off and sanding too much from only one side. Does all this make sense? (My hand position is not my usual but tweaked for the photo.)

-

We are still waiting. Nudge, nudge. I hope all is well.

- 153 replies

-

- Ancre

- Bruno Orsel

-

(and 2 more)

Tagged with:

-

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)

Tools described

EricWilliamMarshall replied to bruce d's topic in Modeling tools and Workshop Equipment

And the belt sander can be used to create the need for the ‘filler’! See self fulfilling prophecy, tool use/misuse. -

Interesting material, interesting ship - I’m grabbing some popcorn and looking for an open seat in the back!

-

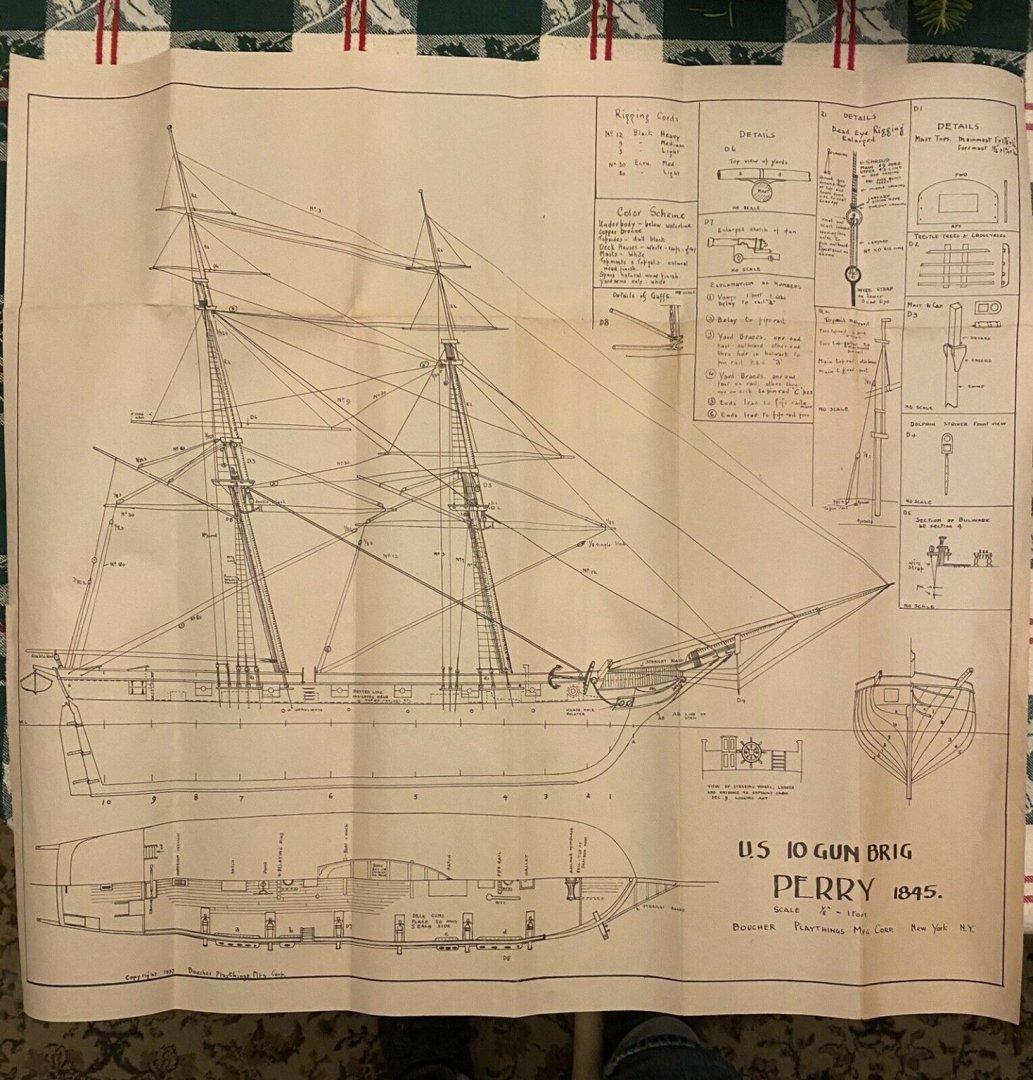

In a different thread @Jaager shared a few thoughts on this period of American naval history: "the era between 1815 and 1860 as regards USN vessels is not a popular one with modelers. It is difficult to find resources. I suspect that as much as possible of on board equipment was obtained from the then new on the scene private manufacturers. The plans and pictures would likely have to be obtained from long vanished companies. The corvettes tended to be sleek and graceful but also cut to the essentials as far as any decoration, so they were utilitarian in appearance. ( I am a fan.) The frigates and larger were just plane ugly. If you are a fan of Stalin Era architecture then frigates and liners of the era are just your thing." I believe I have the just the skills and aesthetic sensibilities to honor the nuances of Stalin Era architecture. Watch me go!

-

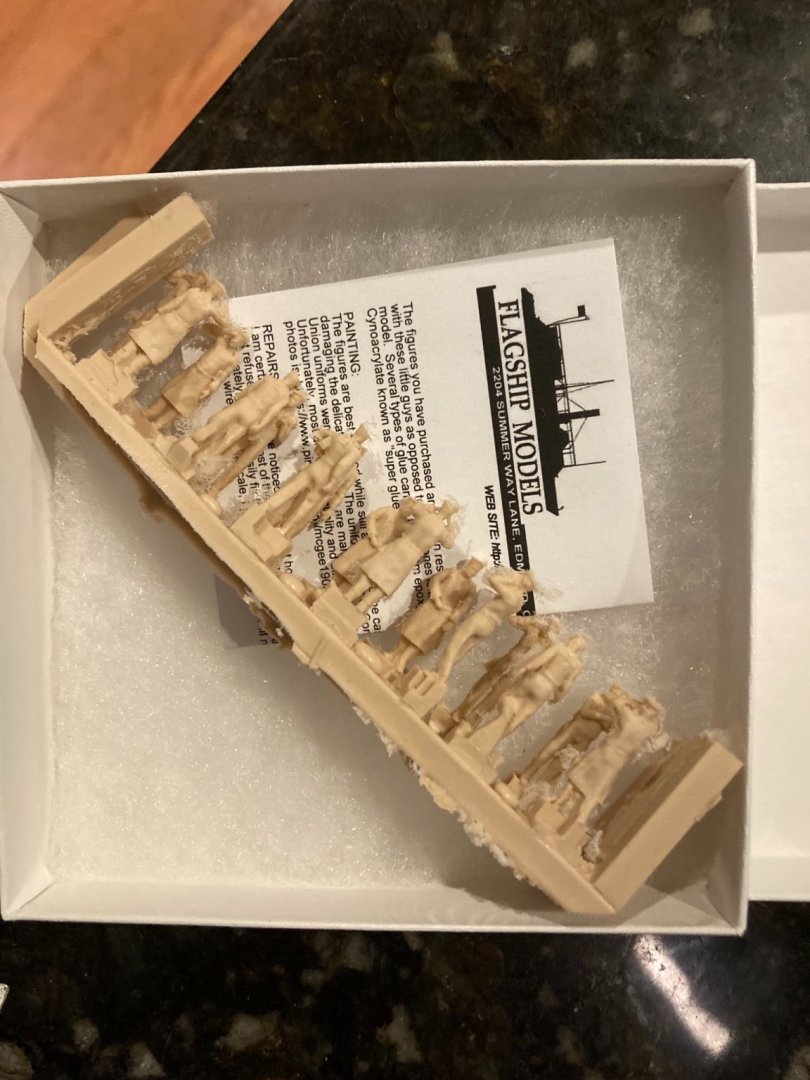

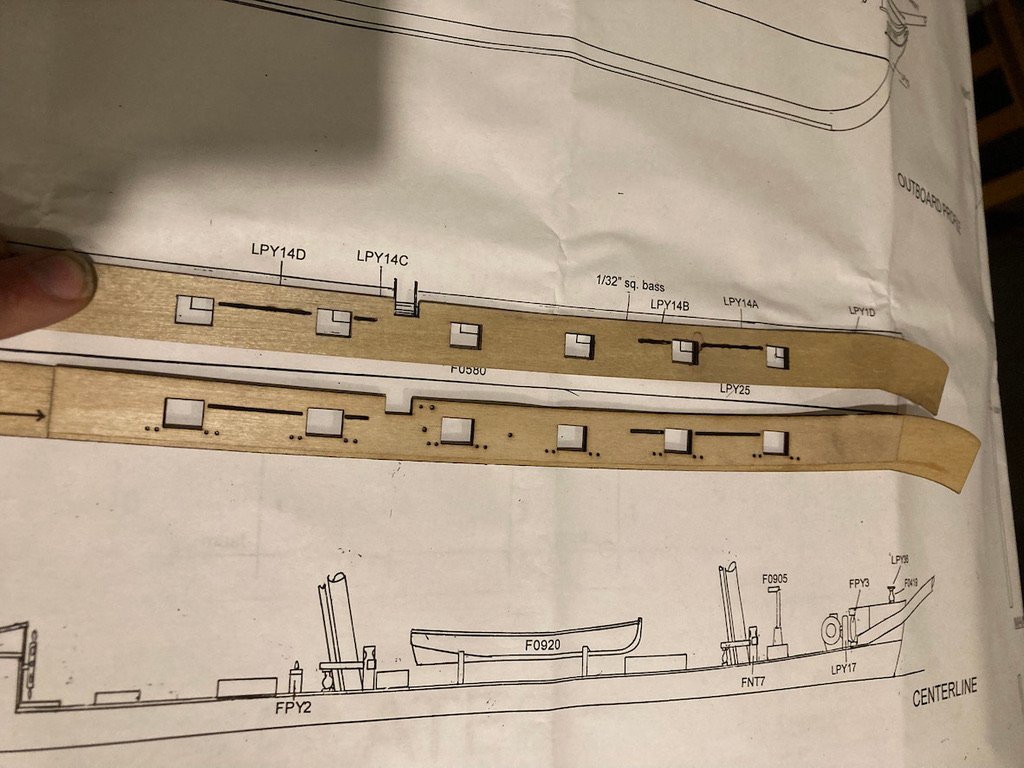

Meanwhile back at the dockyard, havoc ensues!! A number of laser cut parts don't match the plans or my work! I thought I screwed up (and I may have) but I see that @sjanicki also had some problems with the sides and added a some wood by the quarter deck and I will mostly likely follow a similar path. The last six parts are at variance with the plans. I'll share just one pic. The cut out for the side entrance (i'm not sure of the naval term) doesn't match the gun ports and the whole length isn't quite long enough for my ship though end to end I'm within 1/8" and the internal cut-out is spot on (well, less than 1/16"). Many thanks to @sjanicki for sharing his progress and pictures! For the last few days, I was trying to figure out where I went astray. The plans and the profiles from the kit do match for this part. USS Putty, here I come. Once I get to the deck fittings, it will matter less. So I'll push on.

-

I sorry to hear of your heart ache. Hopefully the hurt will pass quickly and you find a way forward. I believe it happens to all of us; certainly me! Regards

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

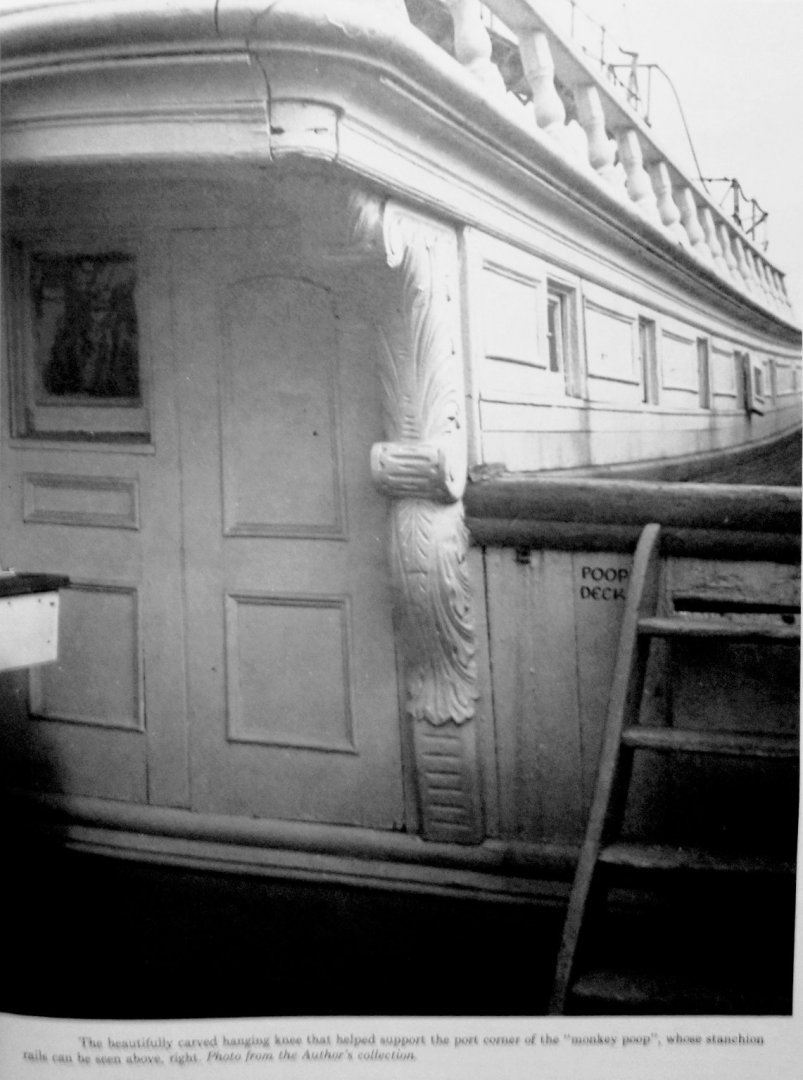

While I speak with a bit of humor, I’m sure there isn’t a document. In the land of antique furniture, where a desk can sell for the price of a house, there is detailed monographs about the history and development of the wood screw, style differences between Boston and New York in the 19th century, etc. As for pigments, there is a literature for curators, artists and those interested in fakes. https://shop.nga.gov/catalogsearch/result/?q=+Pigments Anything can be taken to far!! I have one book on marine carving which is mostly about 20th century decorations and one on figure heads. I haven’t see much beyond that either. Not yet, it is on my list to do. I share the gory details when I come to that operation. Thanks so much everyone for the kind words! From my point of view, there so many more worthy things to read here at MSW, that I’m always surprised when someone stops by! So my thanks again!

-

@Hubac's Historian I wound up looking whaling ships and clippers for ballpark-ish confirmation. I also discovered at 1:96 scale I’m hard pressed to create moldings or panels or other details. So as of today, I’m leaning towards ‘just build the kit’ but come tomorrow I’ll have some other misbegotten idea I have to exhaust. As for clambering the deck, there is a bend in both X axis and the Y axis. It is almost impossible to see camber across the deck but it also doesn’t show in most of the photos I was looking at. Regarding research on the Perry, I did find another reference in Chappelle’s book on the Baltimore Clipper but he only pauses to say they are a heavy-modified off-shoot and, therefore, not worth consideration. Some one could write a book regarding the history of moldings and the like regarding ships - they exist for furniture and for architecture. But expect the audience would be quite limited. @Landlubber Mike, thanks for stopping by! Power tools definitely can work here without taking off too much wood! I was just playing around with sanding drums designed for drill presses. <insert evil laughter> I also found a very fast rhythm for adjusting/ changing the hull ship with 2 gouges, a flat chisel and scraper. As you know, this seems to be the hobby of a thousand skills. Your great work on your destroyer prompted to me to get some PE to experiment with. Well, this kit also includes some!

-

Most sets of drill bits from a box store will have this kind of drill bit. A quick search on Amazon reveals this selection: https://www.amazon.com/s?k=3%2F16+drill+bit&crid=364OHUBBRUYWX&sprefix=3%2F16%2Caps%2C72&ref=nb_sb_ss_ts-doa-p_2_4 The numbers used in the image you shared are for tiny drill bits (needle sized). Bigger ones are in fractions of inch (or metric). Keep at it!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.