-

Posts

662 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ras Ambrioso

-

Dan: After I read your post I went and ordered a kit. Today it arrived. It is The Kartonomy Arsenal Spitfire Vb Trop. I assume that the "trop" indicates the tropical version of the Spitfire that fought in Africa. This model can be distinguished by the blunt air filter on the nose and the kaki camouflage paint. I think that this looses a little of the beauty of the Spitfire" slick nose but, I will go along with it. I am at awe. I have have built Spitfire models in 1/72 scale and I figured the 1/33 would be much larger. Well, it is larger but the details are microscopic. I see myself buying a new set of pincers and really sharp scalpel blades. I am still working on my Fifie but I will definitely try to start this beauty. As soon as I do, I will start a build post. I will be following your methodology because this is my first card model

-

Ives: A beautiful model. Jacques Cousteau is one of my heroes. In 1950 I read his book: The Silent World, and got hooked on skin diving and later scuba. Spent my early youth in the water. When I came to the US I joined a diving club in Florida when diving wasn't cool yet. This were the early 60's and the SeaHUn came on TV and now everybody dives. I have been thinking of building this model for a long time and maybe I'll do it after I've done with my current projects

-

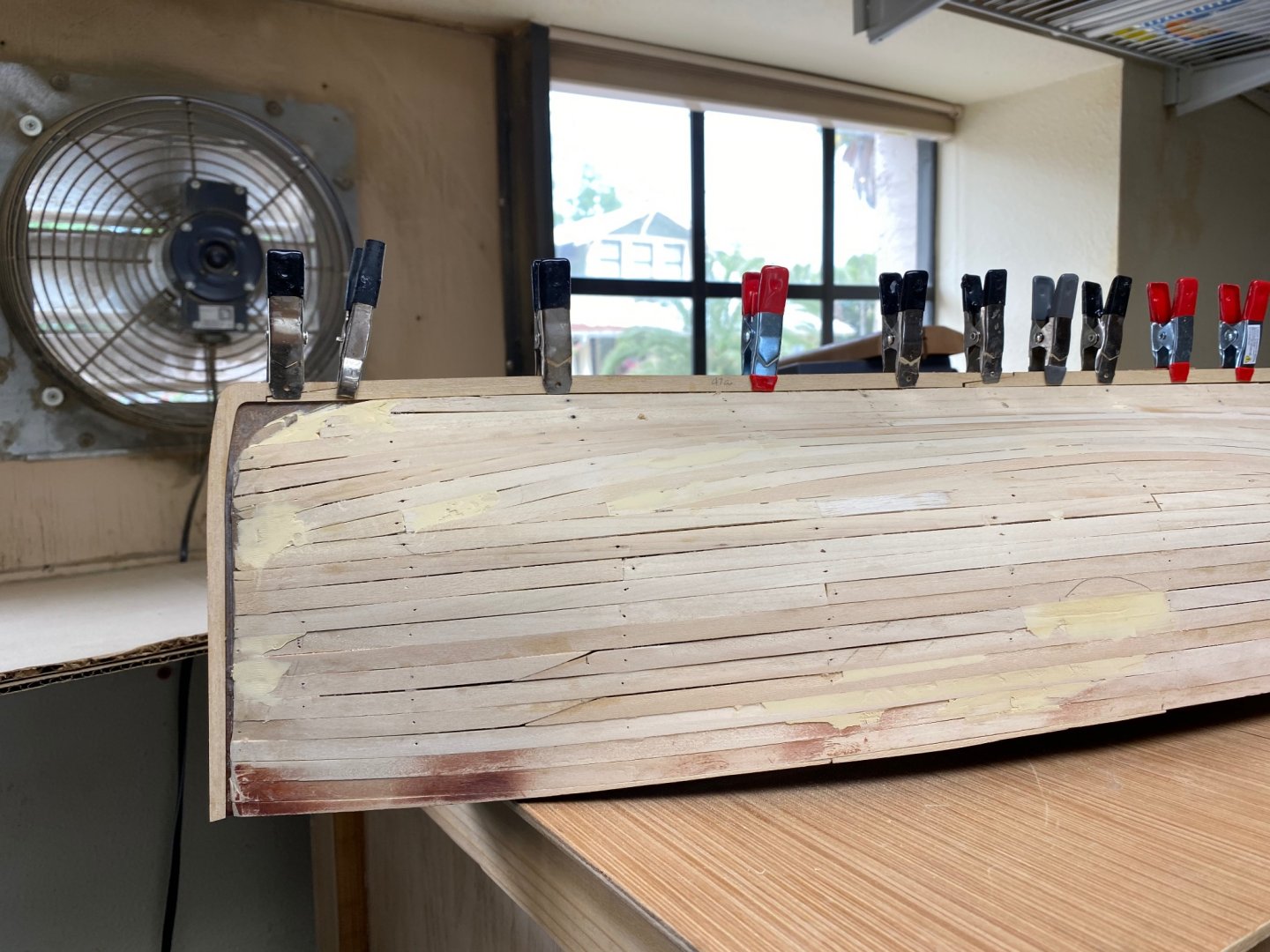

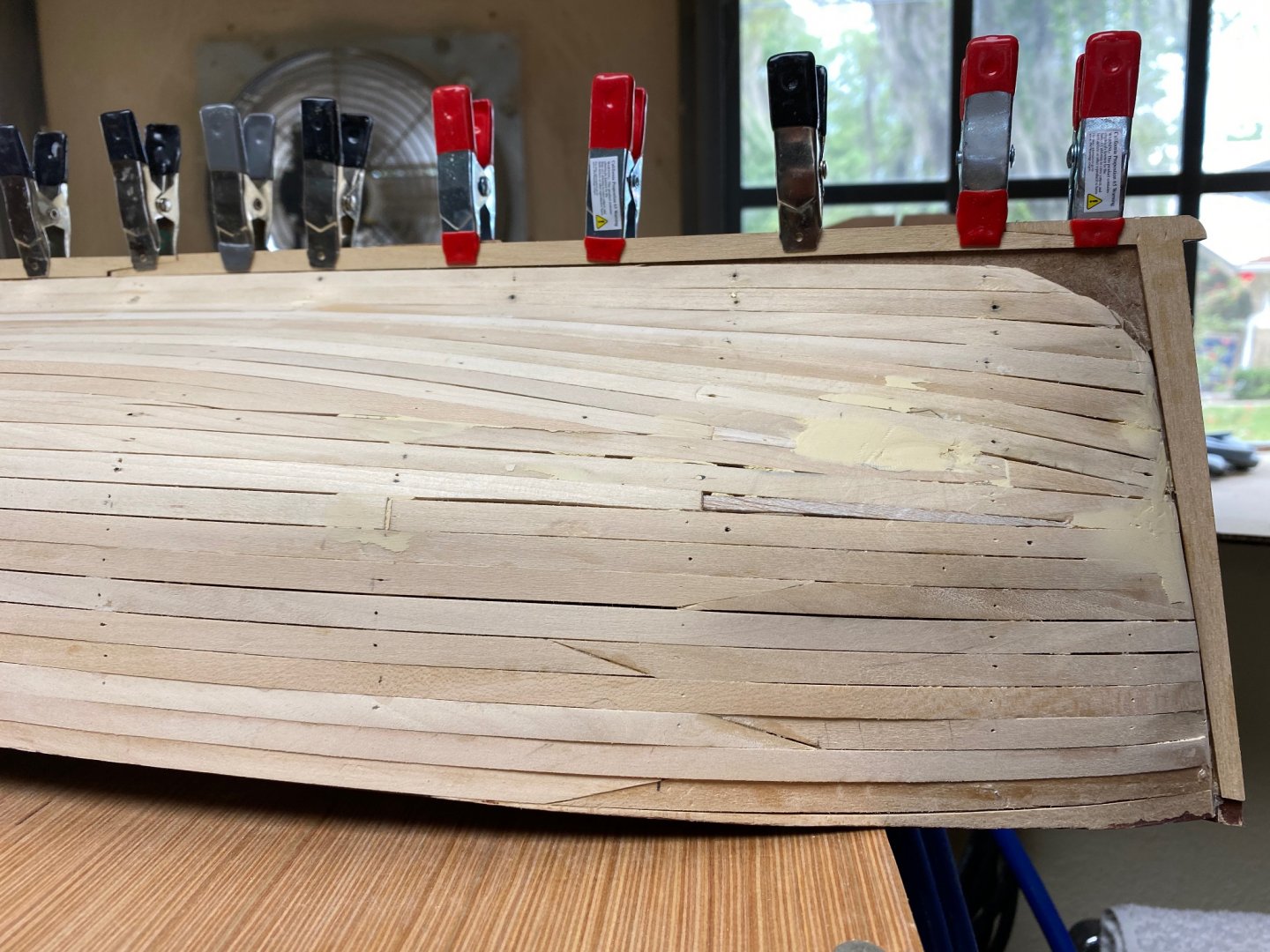

Starboard side is complete. Not the best planking job but, I've had a lot of fun doing it. I knew that a curve is a polygon of infinite sides. Therefore, if you have a very curvy surface, you could break it into into smaller pieces to cover it with a flat objects. If I was working on the shipyard, I would be fired on the spot. But this a hobby and we are here for the fun. Port side next.

-

Eamon: All is well in Ras' land. Today I build the narrow ladder and it fits. Unfortunately is not long enough. The hell is in the details. The forecastle has no floor. I measured that ladder's height for the fish hold which I had detailed. But, since the forecastle is not going to be detailed, I will hang the ladder from the deck beam. With the hatch partially opened , it will do the job. I also worked on the hull planking. I am definitely need to practice. Its coming out OK but not the best. I purchased the half hull planking project from the NRG. It is sort of a practicum on planking. The instruction manual is 73 pages long. Photo didn't come out too good but ,you may go to the NRG site and get the information

-

While browsing the forum I came upon your Spitfire build. Dan, I don't know what to say that other have already posted. I am building boats now but I am a fanatic of aviation and the Spitfire is one of my favorites. I have never assembled a card model and your post is showing me what can be done for reality. I just put an order on E-bay for one of the Spitfire 5V from Halsenki. I will use your post as a guide. Excellent work, congratulations

-

Thanks for the comments guys. The top of the cran in the picture is out of focus but I did cringed the tails. I will take another picture closer to the top of the basket. It is fun to do all these experiments. For the main build, today I was getting the hull ready for the top planking doing a little more sanding and filling. Then I decided to take a break and work on the final detailing. The project this time was to build the ladder to get to the hold from the fore hatch. I thought of making a jig but decided on a different system. I measure the opening in the deck 20 mm. I established the angle of the ladder and measure the height if the ladder. I then cut two strips, leftover from the base planking, and marked the steps. Then I cut little pieces at the right angle and glued them between steps. Then I cut the 8 steps precisely at 20 mm. I assembled my ladder between a piece of wood measuring exactly 20 mm. I was so happy. Finally, I took the ladder off the mandrel and presented to the hatch opening Holy cow. The I forgot to deduct the 3mm thickness of the ladder rails. The finished ladder is 23mm wide. BobGarcia says: "Measure once, cuss twice". So right. But no big loss. I am going to enlarge the reach hatch that appear awfully narrow in the kit. I will carefully will measure the width so my ladder fits. Then I will make another ladder 22mm wide. And that is the lesson for today

-

Peter you have me crawling the floor laughing. Your post is one of the finest I've read. Now, seriously, your post interested me because, as a matter of fact, I was talking to my neighbor about this pop-pop boats. I live in an adult (old people) "independent living facility". Because of the Covid, we have been literally isolated for a whole year. All our activities were cancelled and if it wasn't for my wife, who is an adventurer, I would have died of boredom. Since the beginning of the year the facility has started to open up a bit and now we are planning our summer entertainment. Before Covid we have common activities that included video bowling, pool playing, horse shoe tossing and, specially for old folks, we were having pine wood car derbies. These were small cars ran in a wood track. We built the track in our shop and made car kits for the people to build their own cars. So this year we were talking about reviving these races and, to do something new, we are planning on running little boat races in our swimming pool. We talked about making kits of either the pop-pop boat or paddle boats powered by rubber bands. This week we are meeting with our general manager to see about the allocation of funds to develop this project. And again, congratulations for doing this with you grandson. I have seven grandkids and none of them have shown the slightest interest in any of the things I like to do.

-

While I wait for the glue to dry, I continue my search for "silver darlings" (herrings) to fill my "cran" baskets. As I mentioned before I found aluminum foil to be a great medium to provide the silvery look. Today I tried to perfect the method by adding some black paint to the silver "fish". It didn't work beacuse the paint won't stick to the aluminum foil. Then I tried the back side of the foil, which is matte. Success. Following are the steps I took to build my "catch". First: make a little strip of foil Then, using an Xacto gouging tool, I cut first the head and then the tail. I cut in succession, which means, that the head of one fish is the tail of the next one across the aluminum foil strip. Then with a small needle nose plier or, better yet, your nails you pinch the fish at the tail. The results follows What do you all think IMG_6835.MOV IMG_6835.MOV

-

Well guys, Back to business. I successfully completed the first planking and even though it may not look too pretty, it is smooth as a baby's skin. Hopefully the walnut final planking will go uneventful. Starboard side And port side

-

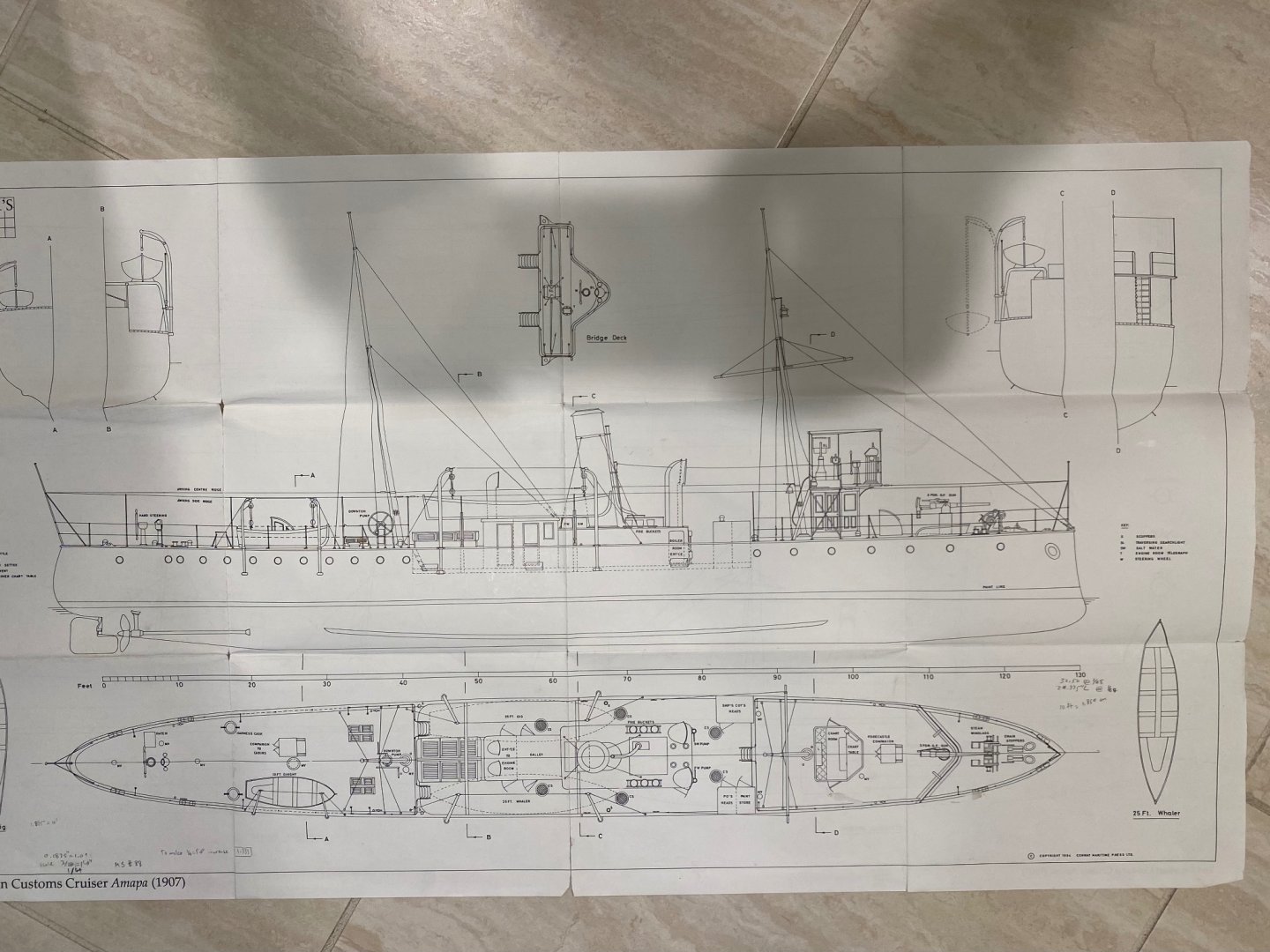

wefalk: I hope Valeriy won't object. In answering your question about the Brazilian gunboat, I lived for awhile in the Hague and subscribed to the Model Shipwright Magazine. They provided a plan and a brief description of a selected ship in every issue. I saved these plans for the day when I had enough time to devote to my hobby. The plans show the Brazilian Custom Steamer Amapá that was built by Yarrow Scotstoun in the UK in 1904 and issued to the customs authorities in 1907. It is a simple ship model in 1/64 scale with plenty of detail that will allow me to see if I can follow Valeriy's methods. Sorry Valeriy, I love your work. I will try to do soldering as good as you do.

-

I am enthralled by your work. I hope you don't mind me taking notes. My next model is a 1907 Brazilian gunboat and I am going to use some of your techniques. I will continue to follow your build in awe of your mastery. Good job.

-

Alan: Those clips work great on the flatter part of the hull but, when the hull starts curving they don't provide sufficient pressure. In going though the planking of my Fifie I finally found the best tool: plastic headed board push pins. I tried the little nails but they are a pain to hold and hammer in. I have two pin pushers but, the nail's head provided on the kit were too big. Eamonn: You are correct. They are called the silver darlings, that's where I got the idea. I am now looking at providing a little shape to fake the head and tail. We will see. I am retired and have all the time in the world to do things.LOL

-

Today I finished the raw base planking for my Fifie. Nothing to be proud of since I used all the procedures available and wound up needing a lot of cheaters at the end. Now I got a lot of filling and sanding ahead. For those that are starting to build this model, I have a few pointers to pass on. The first one is of course read the instructions. I did, and I also read the experiences of some of our master builders in this forum. Second: is to note that the material furnished is shorter that the boat's hull length. Therefore it is necessary to splice the planks or do alternate joints. I started with the splicing but found more convenient to do butt joints. Also, this method, makes easier to bend the planks. Third: and most important, fair the frames and then mark the planking belts using battens. Fourth: use the spiling method to shape the planks. I didn't, and made a mess. My advise is to lay no more than four of the full width planks on each side alternating from the top down and from the bottom up. Then start shaping the planks. And the last one: feather the end of the planks at the bow and the stern. This is the result of missing on some of the above points: The bottom looks like the half of viking ship and the frames were not totally faired. But, I promise, I will do better on my next build. Now we start filling, shaping and sanding. In between planks I kept trying to make scale herrings to go in the cran baskets. Tried several methods since I don't own a Cricut machine. While watching TV the other night I dug into the candy jar and pulled a few Hershey kisses. As I unwrapped I them I noticed the wrinkles in the aluminum paper wrapping. I rolled and flattened the aluminum into a tiny bar and I saw herrings. I cut a few and following is the results. I am going to give them black smears with a black marker to tone down the shininess. What do you think?

-

Mario, after the paint, your planking doesn’t look too bad. I am building a Fifie and have trouble planking it. i blame the poor fairing of the frames. But, in reality, these boats were built by poor people and I’m sure their planking wasn’t that smooth. So, keep up the good work and I’ll be following your progress.

- 27 replies

-

- Lady Isabella

- zulu

-

(and 2 more)

Tagged with:

-

I didn't know about the British capture. The journey of U505 from the Atlantic to the Museum in Chicago is an extraordinary event. When the sub reached the Chicago river, across from the Museum, it had to be raised from the water and rolled almost half a mile over the the streets of Chicago. The first photo is the capture and the second of the dry dock that was built to get it out of the water and the tracks that ran all the way to the Museum.

-

That's a fantastic job Yves. I am also a fan of submarines specially the type VII. Until very recently I had a plastic model in 1/144 scale in my shop but it did not survive my downsizing move. I will follow this built and perhaps try something like this. BTY, I have visited what I think was U550 that is displayed in the Museum of Industry in Chicago. This was, I think, the only sub capture intact during WWII and taken across the Great Lakes to settle in Chicago. A great story.

-

I am on it. Great kit. Maybe ,after I finish my wood Fifie, I'll take this plastic model for a try. Incidentally, years ago, I built the 1/72 Airfix version of the S38 and it was one of my favorites until my sons took it to play in the pool. What I really liked about that kit was the crew. On your model at 1/35 scale the crew will look outstanding. Good job so far and I will be following you.

- 19 replies

-

- schnellboot type 38

- italeri

-

(and 2 more)

Tagged with:

-

Again have to say it: fantastic job on the door

- 79 replies

-

- Fifie

- Victory Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.