-

Posts

864 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rik Thistle

-

Hi all, I first tested my 10V with compressed air a few weeks ago. She runs well, from a slow speed to a 'bouncing off the bench' speed. Highest pressure I've dared use is 20 PSI. It's quite amazing the power these engines develop. OK, it's currently being fed compressed air from a 500W compressor but I believe steam contains even more energy so would provide even greater power. I now have a better understanding of how a single steam power plant had the oomph to work multiple machines in workshops over a century ago. I'd post a short mobile-phone video of her running but I don't think that's possible ...one needs to link to a YT channel? Richard

-

Steve, A great project to get you through the winter months. As you've noted there are now a number of Lady Eleanor builds on here, ranging from no 'bashing' to quite heavy bashing .... all ending with very satisfied builders who, if they are like me, were kinda sad when she was finished. Mine is sailing about four feet above my right shoulder and is a very pleasing sight to start each day 🙂 Richard

-

Focus Stacking

Rik Thistle replied to Dennis P Finegan's topic in Photographing your work. How to do this.

Gregory, After reading your post, I took a closer look at a Panasonic FZ80 I had my sights on for a camera upgrade. Turns out it has 'focus stacking' and calls it 'post focus'. Your images show that the focus stacking feature works well.... certainly good enough for showing our work here. I'm quite impressed that all of it is done 'in camera' and that the camera processing has enough headroom to take on such a task. All in all, it's a very neat and free feature from Panasonic. Richard PS: Wouldn't it be nice if all camera manufacturers standardised on a common camera OS, menu system and terminology. I know there is absolutely zero chance of that happening. Some of the menu systems are a nightmare...looking at you Sony. -

Focus Stacking

Rik Thistle replied to Dennis P Finegan's topic in Photographing your work. How to do this.

After reading this thread I discovered my (2016) Panasonic DX80 had a Firmware update available that added focus stacking. The update means the camera can take a very short 4K movie and (in-camera) stack the frames together. The first image below was taken on a 50mm lens at f8, 1/160th, ISO800, tripod mounted, camera lens about 12" (300mm) from the front of the model... f8 was the smallest usable aperture I could select without the pic becoming too grainy. As you can see the middle is in focus but the front and back isn't. I then used the focus stacking feature to take another pic. And now the whole ship is in focus. The focus stacking procedure took about a minute. As I mentioned, all this was done in-camera...no PS involved. For a free firmware update I think it's not too bad. Richard -

Very neat work. You've picked a perfect first model IMHO. After Druxey's explanation, I thought I should find out what a 'Banks dory' actually is .... https://en.wikipedia.org/wiki/Banks_dory "The Banks dory, or Grand Banks dory, is a type of dory. They were used as traditional fishing boats from the 1850s on the Grand Banks of Newfoundland.[1] The Banks dory is a small, open, narrow, flat-bottomed and slab-sided boat with a particularly narrow transom. They were inexpensive to build and could be stacked or nested inside each other and stored on the decks of larger fishing vessels which functioned as mother ships. Banks dories have long overhangs at the bow and stern which helps them lift over waves. There were one-man and two-man versions. Most could be fitted with sails. The dories became more stable in when they were loaded with about half a ton of catch." A simple but elegant solution to a need. 'The Fog Warning is a great painting of a dory...wouldn't it be neat to turn your dory in to it? ... 😉 Richard

- 23 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Alex, Yes, 'clamping' is a bit of a black art in my opinion. There are some real gurus on this website ...just Search 'clamps' etc and you will see some amazing solutions. Some are quite complex but most are simple and effective. I guess experience and figuring things out before hand are two main 'clamping' skills. Richard

- 23 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Alex, Looking good and a fine commentary as well. Yes, this hobby can be addictive, as can delving in to the multitude of builds and shared info on MSW 🙂 Richard

- 23 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Ron, I had a Google for the model you mention but no luck...it sounds exquisite though. I did find this YT video on how museums actually built models of the day down to very fine detail ... https://www.nms.ac.uk/explore-our-collections/stories/science-and-technology/corliss-engine/ That would be a very pleasant job, working in the museum caring for those models. Richard Edit: I wonder if this might be the model you refer to Ron?... https://www.youtube.com/watch?v=TXOJ1UEfikI

-

Hi Roger, I hope that you get to run it, at least on compressed air. I'll post a short report when I do - a compressor is on order. Just done a quick read-up on the Corliss engine ...very impressive, and 30% more efficient than any other competitor, which is a huge advantage. Here is a model version which looks superb .... https://www.1stdibs.co.uk/furniture/more-furniture-collectibles/collectibles-curiosities/models-miniatures/complex-working-corliss-steam-engine-model/id-f_6868103/ No info though on the builder that I can see. Richard

-

Popeye, Thanks. It was a fun build. These little engines and their full sized cousins produce a lot of power ...some say a can of spinach is added to their boiler tanks at the start of each day 😉 This gentleman runs a professional steam powered workshop using no equipment made later than 1925* .... https://www.youtube.com/watch?v=9WXHNBMLZZM He deserves a medal for doing this. Interestingly, steam still provides most of the power we use today. Richard *He does admit to using some modern measuring equipment but tries to keep it out of sight.

-

kit review 1:32 Fifie – The Scottish Motor Fishing Vessel by Amati

Rik Thistle replied to James H's topic in REVIEWS: Model kits

Clive, She looks ready to get to work. Well done. What a good lloking model. Richard -

Hi all, I think I've now got most of the workforce back in the shipyard, after them disappearing off to enjoy the Summer. So just a short post to get the ball rolling, again. I had previously done some initial work on the masts eg turning diameters etc in my little lathe. So I will continue with the two masts. Below - I glued the Bolsters to the 'trees'. Then I sat and stared at the Mast Drawing plan (Sheet 5) for quite a while, and realised that there is a lot going on with these two similar masts. So proper parts organisation seems a good idea, as did much more staring at Sheet 5. Below - the two Topmasts had the 4mm square (Edit: My mistake, should be 3mm square, darn...so sanding down to 3mm) section milled on the end. This turned out fine - the starting size was a 6mm diameter, so I tentatively took a 1mm deep cut, gently holding the protruding section in the Proxxon vice. I thought it might start to flex as I got to the 4th side but by going slowly all was fine. I have a dividing head, but instead used a set square resting on the bed and the freshly cut side to ensure 90 deg rotation - that worked OK. As I mentioned, there is a lot of detail on Sheet 5 that I need to reassimilate. It wasn't a good idea to leave Flirt for months...I should have tried to do a little each week. Ah well, live and learn. Richard

-

Well done Glenn; she's a beauty...and well lit at the window. Richard

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Need help from a model maker in California !

Rik Thistle replied to Ekis's topic in Wood ship model kits

I would be interesting to know what specialist delivery companies do different. Do they control the shipping environment completely from A to B? Here is only one stage in the delivery of 'normal' packages ... https://www.youtube.com/watch?v=jF_w7uSnOj0 From what I've seen and know, marking normal packages with Fragile and/or This Way Up makes no difference whatsoever, unless the item is mounted on a pallet and moved by forklift so improving it's survival chances somewhat. If a valuable three masted ship with lots of rigging, say, was being shipped around the world then what is the optimum solution?... - Design the hull (the part with most mass) so that it can be rigidly fixed to a base plate, and leave the masts/rigging mounted and in free space. - Remove parts from the ship that might work loose in transit and put them is a separate box rather than them becoming missiles. - Securely mount the base plate in an extremely tough box that always maintains a gap of at least 150mm from any part of the ship. - Do not use peanut type packing, or any for that matter, that can contact any parts of the ship. - One of the flaws with the above is that the masts, if suddenly accelerated back and forth (and upside down), may not be able to take shock loading. - Do 'insured' packages have a big 'Insurance' label on them that the handlers see so know that their employers will not be happy if those particular goods get damaged? Just thinking aloud. Richard -

Ron, Yes, I've watched a lot of his videos especially his one on the Stuart Engine ... 'MAKE A STUART STEAM ENGINE pt 1 of 9 tubalcain' https://www.youtube.com/watch?v=6WZykfoKIsA&list=PL6HIFled82YUVmxw4RysNJron441QhyFO He's very helpful. Another one is BlondieHacks...she's quirky but likeable and is good at explaining things. And, as you say, there are a load of videos on sorting out mini lathes. I've lost track of how many I've watched 😉 I got my lathe from ArcEuroTrade in the UK - these lathes all seem to come from one or two companies in China that make the raw castings, then Seig and others buy those castings, machine them up to their desired specs and add USP features. I believe ARC actually spend time in the Sieg factory explaining what they want and the desired quality level that must be met. There's 3 or 4 distributers in the UK of the lathes; they're all pretty good. I wouldn't buy direct from China or eBay since it is a bit of a pig in a poke purchase. At least with a local distributer you have someone you can phone up and discuss things with. Also these distributers stock all the lathe add-ons/tools that one could ever wish ...I'm suspecting it's a bit like the old Gillette safety razor...the handle was sold at a loss and the profit made on the blades! Richard

-

Thanks Mark. All the pics were taken with my Moto G phone, which tends to be nearby most of the time, so they're not the best and some parts are slightly out of focus (...there's probably a setting/optimum distance to reduce that). But the phone's 'convenience factor' is high...especially when I'm in the workshop and I just need a quick pic for reference, and then later attach the phone by USB cable to the computer to save the pic. I have better cameras but they are bagged away...laziness rules. As I mentioned earlier, the engine was a pleasure to build and made a good summer better. After surfing many YT and blogger websites picking up tips, I can see that there are a lot of hobbyists (amateur engineers/scientists) who follow more than one interest which can only help improve their overall competence. Yes, it's a great way to spend one's time, learn new things and 'meet' interesting helpful people. Richard

-

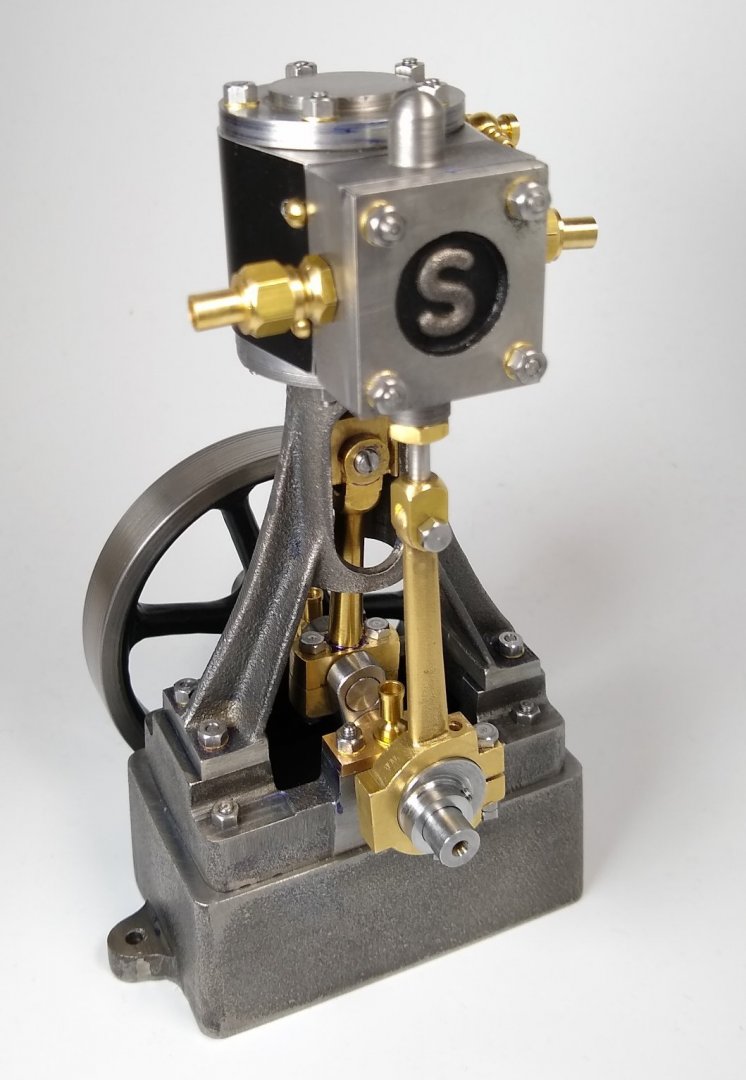

Hi all, So here is my final post (for the moment*) on this build of the Stuart 10V completely assembled and with a minimalist paint job. I know most industrial and model versions of the engine generally have a predominately Green paint finish with touches of Red, but I really like the way it looks at the moment - leaving most of the metalwork bare let's one see how the parts were machined. The kit came with a Black anodised Cylinder surround and I used that as my colour cue - I added Satin Black to the Flywheel spokes and inner rim, and also to the backdrop for the letter 'S'. Well, that's it ...a short Build Log and thanks to all for popping in and the Comments and Likes. Richard * The Reversing Gear will be added to the Build over the next 12 months, but now back to HMS Alert....oops, HMS Flirt, it's been a long time.

-

'More tape?' Bruce, there was more tape used than you could shake a stick at 😉 ....and it was actual Duck tape....no expense spared! I think that having proven the engine moves properly, when connected to my hand drill, I should consider doing a thorough investigation in to compressors and air tanks. I will be adding the Reversing Gear kit to it sometime in the next 12 months so the engine will deserve a decent power source to prove it's functionality., even if it's not an actual boiler...yet. Richard

-

'vacuum' ... I tried it using my Panasonic upright, but the air exit port is a large grill that isn't easily turned in to a funnel. I also tried using the the vacuum's suction port and connected that to the engine's exhaust port ie sucking the piston down rather than pushing it down...the Flywheel actually moved about 1/4 turn but was struggling. Also the vacuum's motor was beginning to slow down and get a bit warm ;-( The vacuum's suction tube has an ID of about 30mm and the engine's ports are about 3mm ID. So that's about a 100:1 reduction in CSA. Probably too much. Still thinking though.

-

Hi all, A few more picture and notes below, to later be followed with a final post of pics of the 'paint job' and thoughts. Below, the Eccentric Strap having it's 5/8" dia hole bored out. Towards the end of the build I came to realise that boring and then reaming a hole was probably overkill ....boring seemed good enough. Reaming was suitable for smaller holes that my 8mm square section boring bar wouldn't fit in. Even then I do have an old 1/8" dia hand made boring bar from back in the day, so I could probably bore out quite small holes with it. I'm saying it is the Strap being machined on the lathe below, but it might be the Conrod....it's moving too fast to be sure, but my money is on it being the Strap. Back to the mill with the Eccentric Strap to drill a 7BA clearance hole through on one side. The Strap is then cut on that side (using a Dremel cutter that happened to fit the mill's 3mm collet). The 7BA screw can then 'close' the hole around the Eccentric Sheave that revolves in the hole till it is a nice sliding/rotating fit. Seen above is the miniature Faithful set square that I bought shortly after getting the mill. As it turned out this was an excellent purchase and has become one of my favourite multi-purpose tools. It's quite well made nestling accurately into my larger Moore & Wright set square. Below, tapping one of many holes in the engine. using my trusty Eclipse No 245 tap wrench (1/8"-1/4", 3mm-6mm). This is the best tap wrench I have ever used since the dimples on the end encourage finger tip gripping only and the flat shape aids visual horizontal alignment. I also owned it's little brother, the No 244 but it disappeared years ago....however....it miraculously turned up at a friend's house the other day....so I'm very happy about that 😉 However I was saddened to see it described on eBay as 'Vintage'...gulp. Below - Starting to finally fit parts together , checking alignment etc. I lost count of the number of times I fitted/removed the fixing screws and nuts. I ended up buying a set of BA box spanners to speed that up and to complement my BA spanner set. Finally, test fitting the gaskets and adjusting the valve setting. Towards the bottom of the picture is the oft mentioned but never spotted Eccentric Sheave (circular, silver coloured part) which is locked by grub screw on to the Crankshaft. The Sheave's purpose is to drive the valve up and down as the Crankshaft rotates and in synchronisation with the piston movement. I've tested the finished engine using a power hand drill clamped on to the Crankshaft - it seemed to work fine. But really, it should be the piston powering the crankshaft - not the other way around. I'd like to at least 'properly' test the engine with compressed air which leads me to thinking about purchasing a model airbrush + compressor + tank for painting, with the compressor + tank part also being suitable to drive the steam engine. I did some rough calcs the other week about air flow rates -v- engine consumption etc but if anyone has any thoughts/advice/experience on a suitable UK item please feel free to fire away. Catch you soon, Richard Edit: Air compressor now ordered, so a more life like test will be possible. And the compressor will one day drive an airbrush also 😉

-

Mark, The grooves are actually flush and even running my finger over them can't tell they are there. I'm quite happy to leave them there as they add a bit of 'character', or so I'm telling mself. And yes, the wheel has had P1000 Emery run over it. My lathe doesn't have Compound or Cross slide power feeds, sadly. Well, it does have a lead screw that I can engage but I don't trust the slop in it at the moment. Also, the slop in the saddle was ridiculous when I first got the lathe so I fitted a lock and that really tightened things up. Bangs for bucks the lathe is very good but it's still at the low end of the market. But for my purposes I'm very happy with it. Richard

-

Thanks Roger, I suspect that if you can machine small brass parts then you can pick up general workshop practice pretty quickly. Shadowing someone (an Elmer with a home workshop?) for a few weeks whilst they use their workshop tools is a great learning method. Then they can start gently letting you have a go on the various tools. And I'm sure you know this, but ALWAYS wear safety glasses, and avoid having any dangly clothing that can get caught up in things. With new machines I do a good 5 mins of dry rehearsals using the Emergency Stop buttons, to train memory muscle. Sorry, if I sound like 'teacher' 😉 Richard

-

Hello again, Some more snippets from my Stuart 10V build follow. As I mentioned earlier, the build order may seem it is a bit haphazard but was influenced by such things as turning all the 10mm dia parts in the lathe's 10 mm collet since that was already set up, leaving a part half finished whilst I awaited the delivery of a tool (eg (3/4" reamer), having to go back to an earlier part since I had not appreciated how well it needed to fit a later part etc etc. First, facing off the Standard's top surface in the 3 jaw chuck. I used the same Ikea 'mandrel' from earlier, this time showing the anti-rotation peg/screw I had fitted. Below - I then mounted the Standard on the Faceplate to bore out the 5/8" dia hole. That went quite well and resulted in a smooth enough finish. There was a little spring on the boring bar but repeated in-outs at the same setting shaved off a few tenths of a thou" each time. Just to make it super smooth and to size all the way down the bore I used a 5/8" reamer driven by hand power - that worked fine. On to the cast Crankshaft Bearings, which arrived as one piece to be later cut in two. The top surface of the casting was filed smooth as much as I dared since there was little extra material on that face. The Sole Plate 'U' channel was also hand filed out to accept the bearing. After cleaning up the bearing surfaces with a file and cutting it in to two pieces (one bearing each side) I had read that the bearing would actually fit centrally in a 3 jaw chuck with a little bit of packing, which it did. The hole for the Crankshaft was then roughed out and circular bosses added. Below- Next was to clamp the two bearings in the Sole Plate and pass a 9/32" reamer though. At that time I hadn't appreciated the underside of the bearings that sat on the Sole Plate mounting faces should have been machined flat (and together) rather than gently hand filed. Centre pops marked what bearing went on what side of the Sole Plate. As mentioned, the undersides of the bearing should have been machined flat....the toolmaker's clamp highlights how out of line they actually are ...it's actually quite subtle, but when it came to tighteneing up the nuts on the bearings, the Crankshaft went from free running to locking up with the last half turn or the fourth nut...darn! I later machined the offending faces. The Crankshaft assembly was fabricated from two 9/32" rods, two Crankwebs and a Crankpin. This was a sligtly tricky process but turned out OK - all parts were pinned and Loctited together. Earlier Stuart kits supplied the Crankshaft as a one piece casting. Below are the two Crankwebs (for the Crankshaft) being drilled out to size to accept the rods. I had to use my bench drill since it had a deeper reach and could take the large drill. The micro mill only goes up to 3mm dia. Yes, a larger mill is on the 5yr wishlist. Below- marking out the Conrod. Brass is a lovely material to work with but it doesn't half produce tiny little spears that home in on my finger tips. The Conrod connects the Piston Rod/Crosshead and the Crankshaft at the lower half of the engine.. Above - the hole centres need to be reasonably accurate, but there is adjustment in other parts that can compensate for a 0.5mm error, say. Sorry about switching back and forth between Metric and Imperial ....that's how I was trained and I can generally keep track on these values in my head. Below- The Eccentric Strap, which works the Slide Valve assembly, which in turn allows steam to enter the Cylinder. I think the pic shows me fixing a mistake....I had centre popped the hole for the Eccentric Sheave hole, cut the Strap end in half and then realised the centre was in the wrong place. So I'm about to face off extra material to bring things back in line. Below - The Bottom part of the Sheave that was sawn off...it will be faced, clamped to it's mating half and then two fixing holes drilled in both to hold the two halves together whilst the 5/8" dia Eccentric Sheave hole is drilled/reamed. Below - the Cylinder's bottom end cover being drilled on the MF70s Dividing Head....that worked fine. And now using that Cover as a template to spot the fixing holes through on to the cylinder. My small toolmaker's clamps hadn't yet arrived so I improvised 😉 The Cylinder is peppered with drilled holes. Here we are drilling through at an angle from the cylinder chamber (on both ends) to one of the three apertures on the cylinder Valve Chest face. The little vice was more than strong enough to hold the Cylinder in place during this operation, thankfully. And... a Cylinder with a Coke bottle cap finish at one end of it's 3/4" bore. This was the result of not leaving well enough alone. I had bored the hole out to a good finish, but it was time for another reamer (3/4") delivery so I used it, badly. It's not pretty but lets just say the lighting make it look waorse than it really is and leave it at that...cough. Below - Starting to see the home straight now. Here is the flywheel being turned to almost finished dimesions on the 4 jaw. Once the centre was drilled out it was fitted on a mandrel and finish machined. I had read that the dominant visual feature of a flywheel when it is rotating is usually the part you can't machine ie the inside of the cast rim....hence the 4 jaw for centering on that feature. I did file the inside rim reasonably smooth but not to a turned quality. Below- It's starting to look a bit more like a vertical steam engine. Still loads of fixing holes to be drilled and tapped though. Above - Interesting to note the narrow bands on the Flywheel perimeter....I think this is due to the lathe's Compound slide lead screw having a slight bend in it....each of the bands is 1mm apart which matches how far one complete rotation on the Compound slide's handle moves the tool point. This was another reason for building the Stuart 10V ...to unearth any lathe/mill parts that weren't quite right and needed fixing. Below - The Valve Chest, the brains of the operation. The little hollowed-out brass cube slides up and down over the three openings on the Cylinder only ever connecting two openings at once. More thoughts on the above may come to me over the following days/months so I will tweak the posts as necessary. I think that's it for today then. Hopefully tomorrow I'll be able to show the finished engine. Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.ace64b651831e5c68a6fd9a76d181014.jpg)

.thumb.jpg.6dc639cfb4d854eb91d13595802588ff.jpg)

.thumb.jpg.6db0ed55b3f5c124a73f5c9557f1171c.jpg)

.thumb.jpg.be00a69e8d32734bc602c0e6a44597df.jpg)

.thumb.jpg.8e50e4c7969e1552a10036ab0695e480.jpg)

.thumb.jpg.9aab1b204f27355dbb38209768d19ed6.jpg)

.thumb.jpg.8ab59ce4ad39579f3afe43f66325f94a.jpg)

.thumb.jpg.879cf214ec7e8d39526cf14f9f7d4fa7.jpg)

.thumb.jpg.f0950e7bacb1bddc5e3a1e2c246833d7.jpg)

.thumb.jpg.c3f18ffd021f8191d287786fc33c1fc1.jpg)

.thumb.jpg.0a5ced1979d619a57a3f82b7e1436074.jpg)

.thumb.jpg.b1d0d7531bf78afe08b5ad9fc97ba33a.jpg)

.thumb.jpg.a1aa9119f55ef34fd99b36b8b5b3d166.jpg)

.thumb.jpg.bc57430f5ce40665349f36fa1a4a8b89.jpg)

.thumb.jpg.af805eb31e255914221bde191fd1615d.jpg)

.thumb.jpg.2e437bfe561d0a4cfd4a449bb1a66561.jpg)

.thumb.jpg.a42ad71f343bba4b3fd89874bc7b97e7.jpg)

.thumb.jpg.3ea8d92090e2e8b6b72057a9c51b2987.jpg)

.thumb.jpg.6b4033b633a187a256e914be2ea6cbd0.jpg)

.thumb.jpg.3c0dba312f2512d192dba803c0723254.jpg)

.thumb.jpg.678d2c38bed03f79fe651c1f2acc82bd.jpg)

.thumb.jpg.7e0cf465fc551f5aa88a857a4456d623.jpg)

.thumb.jpg.176d4df40d2050f70c2b09e2fb046b4a.jpg)

.thumb.jpg.90fb47216f23501e647a53da576da903.jpg)

.thumb.jpg.660c00c1edbb2be8d334d46595083eee.jpg)

.thumb.jpg.a78aa464efe4ef1c1de0229aac709ef1.jpg)

.thumb.jpg.8d273be12ba8dfd6ad73481a1846bfe6.jpg)