-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Ditto congrats and 'well done' with those crows feet and the euphroe blocks - very nicely balance with fine detail. cheers Pat

-

Great start to the installation Glen; looks great! cheers Pat

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Very nice work Keith (as usual). I am very impressed with the leather (like) covers/wraps to the splices etc - looks very realistic. cheers Pat

-

Looks like you're having an absolute horrid time Rob ;); only thing missing was a 'mai tai' - Enjoy cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Lovely work Glen; wishing you good luck in getting them into the bottle without 'drama'. cheers Pat

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

That decoration/gingerbread is looking great Glen; a great left-of-field solution. cheers Pat

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

WWII Sunken German Warships Exposed by Drought

BANYAN replied to mtaylor's topic in Nautical/Naval History

Thanks Mark Interesting, I wonder if the opportunity will be taken to remove them? The costs would be very high though I would assume - I wonder if being submerged they have been protected from radioactive contamination, thus making their steel much more valuable. cheers Pat -

Persistence has won out (hopefully); I admire that you stuck (no pun intended) with it. The repairs are looking good. cheers Pat

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

AKRYPTO, try the RAAF Museum at Point Cook, I think they have a Walrus. An email may elicit a response or some answers? cheers Pat

- 88 replies

-

- Australia II

- Finished

-

(and 2 more)

Tagged with:

-

Absolutely stunning detail Brian; looks great! Don't worry about the desk, there is plenty of eye candy to distract from that cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Eberhard, with this machine it is even more important to get it set-up right. It works really well to make LH lay, but to do RH, the feed spools need to be wound differently, and if you do not use the correct initial lay of the stock thread, it twists and kinks madly as it is made up. It can be done, but it takes a LOT of patience and a lot of fussing about (in my experience, and also experienced by a couple of others in earlier discussions in this forum). The machine is beautifully made and a credit to Jim (as with his other machine tools), it is just a lot more complicated to set-up and use to make RH laid rope which sort of detracts from it other primary features (being able to produce long lengths of rope) in a minimal foot print (only a couple hundred mm). I will report back after I have experimented further with it as I think I have found some LH laid stock BUIT much too big for my purposes - unfortunately everything in the Victoria is RH laid (as she has wirerope instead of cable laid shrouds and other standing rigging). cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Both Keith I have one of Jim Byrne's Universal ropewalks which is very good at left hand lay but not so easy to make RH lay - need to source LH thread stock and a bit of mucking around. This may be due to the fact I do not use it that often and have not yet developed the technique adequately for RH. For RH I have been using the club's walking rope maker which, with a bit of techniques allows some very fine small scale (down to .25 so far) ropes to be made. I am confident I can get 0.2mm but not sure about 0.1mm - If I can find suitably coloured fly tying thread/line as suggested by Eberhard, I will have a go with that. The stuff I have used though is easily frayed so will have to experiment with make as well. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi Keith, thanks for the suggestion. I have tried polyester, and still experimenting with Rayon, but I found the poly has just too much stretch in it - even PR stretching hasn't helped much, especially here with the wide range of humidity we experience. I agree with you re shine though, especially if you use the 'glace' types. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Bruce, sorry for my tardiness; had not realised you had started a log. A very interesting discussion of your progress, trials and tribulations and it seems you have conquered all. Looking forward to your updates. cheers Pat

- 43 replies

-

- mediator

- first build

-

(and 1 more)

Tagged with:

-

Very nice work Steven, your persistence to get it right is 'Admir'able - sorry couldn't resist. Seriously, though, your GH is looking great and I really love those sails. cheers Pat

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Love the detail you are adding Glen, quite the diorama! cheers Pat

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Stunning detail and very well executed Greg; some great eye candy. cheers Pat

- 203 replies

-

- Roma

- Micromaster

- (and 4 more)

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for the feedback and comments Eberhard and Mark, and for all the 'likes'. Eberhard, yep, hopefully I will be able to make all of it, but may resort to suitable thread if I have no luck with the smaller stuff. I'll have a close look at that fly tying thread, but my concern here would be a colour match with the thread I have found for the silver/grey to simulate wire - this latter is a Gutterman cotton (long staple). cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Ditto Looking really good Rob, the furled sails really add to the look, and I am seriously considering this for the Victoria. cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

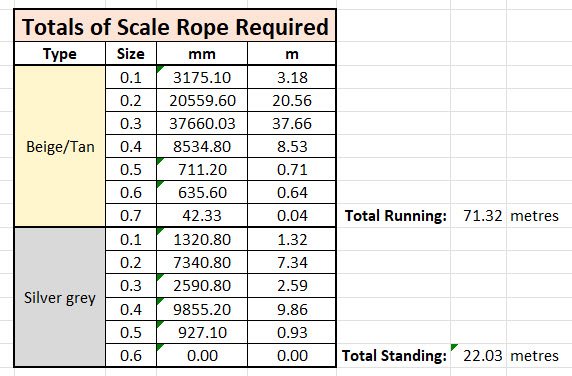

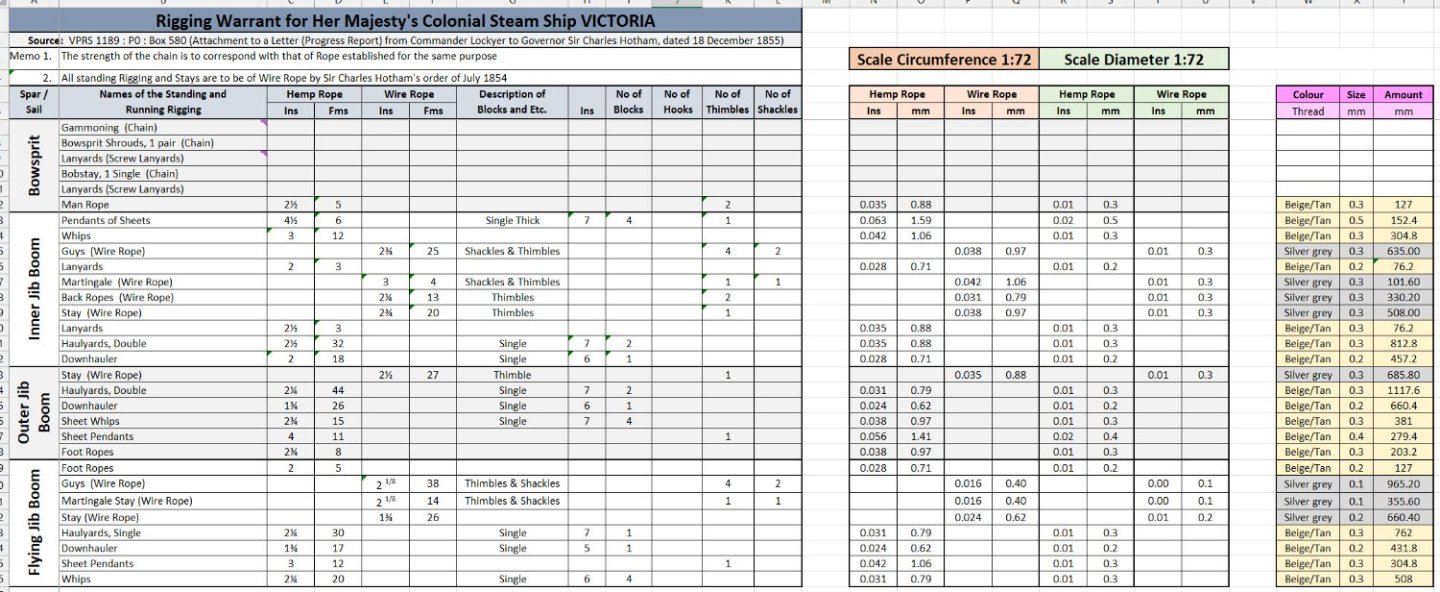

Hi folks, this post is one for those interested in just how much scale rope would be required to fully rig a vessel in the mid-19th century (steam/sail). HMCSS Victoria was rigged as a three masted Barque with a full outfit of fore-and-aft sails). After transcribing a copy of her Rigging Warrant into an Excel Spreadsheet, I used some background formulas and pivot tables to calculate the various sizes of thread I would need and was very surprised with the result. This may not surprise the more experienced modellers, but needing over 71 metres of running rigging scale rope was somewhat enlightening for me (and that doesn't include some of the extraneous stuff like lacings, some rigging tackles, gun tackles, boat rigging (5 x boats) etc. Please note that I am using silver grey thread to simulate the wirerope rigging - using wire would simply destroy the rigging fittings at this scale. I am posting an example of one of the worksheets (that for the Bowsprit and combined Jib Boom) the spreadsheet. The scary bit - how do I make 0.1mm rope I think I will just have to find some suitable sized thread, or simply round these out a bit and use say only 3 or 4 sizes but stick to the principle of lighter ropes to the upper rigging etc. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Keith, can you get heat shrink of this small a diameter (and right colour)? Might make life a little easier for simulating the wire coverings. I love that photo of your helper (dockyard assistant) - looks like she is well on her way to lofting plans Hopefully I can encourage both my granddaughters to help cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks everyone for the comments and encouragement; and welcome aboard French Mr Bean - appreciate your kind comment. Good ideas Eberhard and Druxey, I will experiment with those techniques but I must admit I have never had much luck with concentricity when boring out cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.