-

Posts

1,985 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glen McGuire

-

I think you are fixing to be an expert at coppering hulls! Great job so far!

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

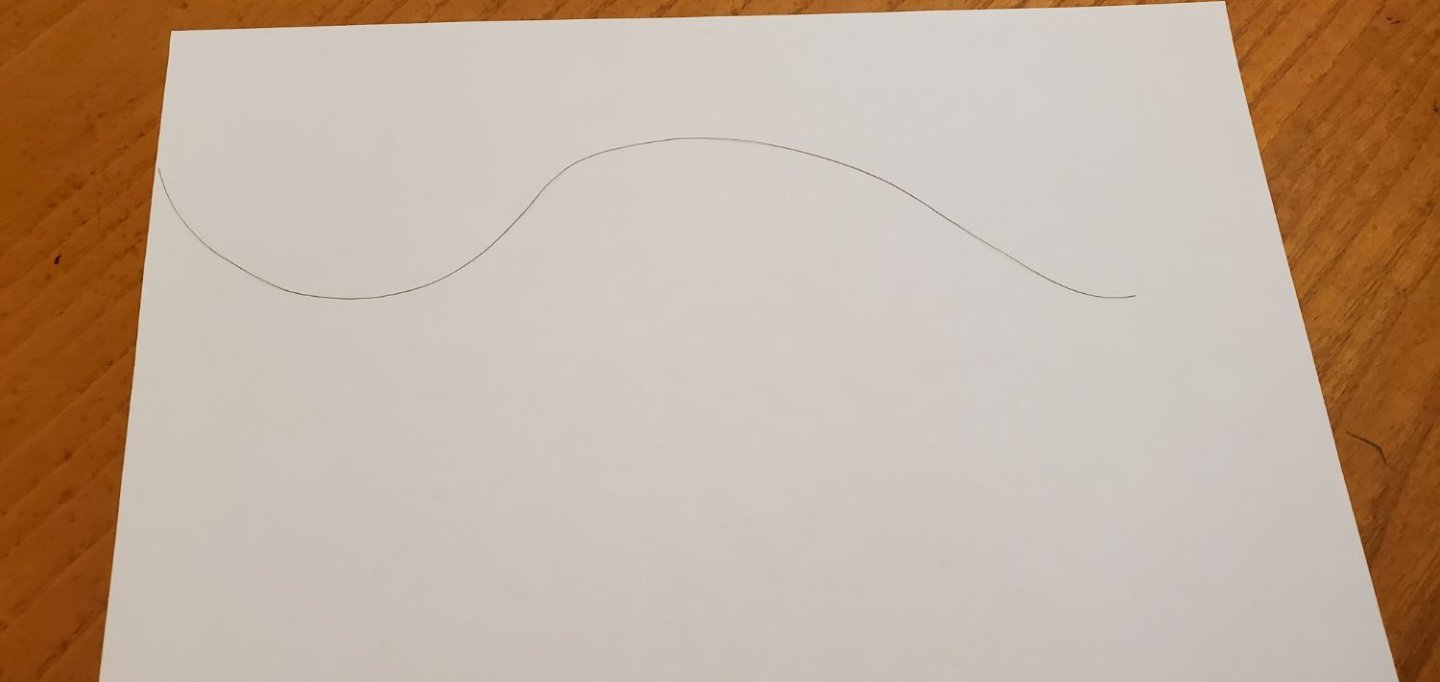

Thanks for the diagram and explanation of all the wiring. That really helps to understand what I'm looking at in your model. Back to your original question about keeping that thin thread in the shape you want, rather than wrapping around itself. The thinnest thread I use is Uni fly-tying thread 72D, 8/0. To eliminate the natural curves and loops it has from being wound around the spool, I will cut a piece, drag it thru Aleene's Fusion Fabric Glue, pull it taut, and let it dry (the glue dries flexible so the thread is still workable). See pic below where I did all of that and then lay the thread on a piece of paper with a couple of smooth curves. It is just resting on the paper, not glued to it.

-

Totally agree with Chris. The carving skills on display with the small parts are particularly impressive. Well done, John.

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Beautiful work, Ian. I love the look of the X pattern.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

Glen McGuire replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Third time's the charm? I would say those booms are way more than acceptable. They look great and the uniformity of all three is superb.- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Fantastic job, Bryan. A real work of art!

- 134 replies

-

- sea of galilee boat

- SE Miller

-

(and 1 more)

Tagged with:

-

Nice work on that helicopter, Bob! And your priorities are in good order - kiddos first!! Keep that ticker in good order too! If he ever changes his mind, the longhorns here will welcome him to the herd.

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

That is a beautiful model, Jason. Congratulations on your fine work.

- 75 replies

-

- Oseberg

- Billing Boats

-

(and 1 more)

Tagged with:

-

Amazing work, Ian!!! This has been fascinating to follow!

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

... and the hits just keep on coming!! "You fancy a bite?" 🤣🤣🤣

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Blue-footed boobies doing a mating dance?!?! OMG! Not sure how anyone will ever top that!

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Welcome, Giuseppe!!

-

That planking looks really good, Bob. I can't believe how fast you got that done. As for this comment, however... Capt Marvin is welcome as long as he doesn't say those B words around my cows! They are very sensitive!

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

Thanks to each of you for all the kind words! That made me laugh!! And it will probably be the last time. Unless maybe @Keith Black or @Knocklouder or someone else gets a penguin in their pen. Whoa! 1400 done. Now THAT is cool! Thanks for sharing that info, Chris. What an amazing place this is! Thank you so much, Pat. I keep working on it, trying different things (most are suggestions from y'all), and trying to get better. Thank you, John. I have learned a lot (ok, stolen/borrowed 😃) from looking at your work!! Thank you, Thukydides. You had some really good suggestions along the way. Now if I could just figure out how to say your name! Thank you, Keith and Grant. And thanks for your helpful ideas during the build. Not sure what the next project will be. I don't have anything in mind yet, so I'll probably just sit back for a while and enjoy everyone else's work.

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Your Albatross is a beautiful ship, Paul! I hope you will reconsider doing build logs for your future efforts. I'm sure some of us could learn some things from you!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.