Paul Le Wol

NRG Member-

Posts

1,060 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paul Le Wol

-

Eric, this is going to be a great project to follow. Three of my favorite things; boats, trains, and boats with trains! You know it’s funny that I’ve heard that old Taj Mahal song about the Katy hundreds of times but never realized what it was about until after reading your introduction. Looking forward to this.

-

Bryan, congratulations on finishing Le Martegaou. Excellent boat and top notch crew!

- 55 replies

-

- Le Martegaou

- billing boats

-

(and 1 more)

Tagged with:

-

Jacques, I’ll miss your extensive research but I look forward to this interesting build. Good luck!

- 139 replies

-

- ancre

- Bateau de Lanveoc

-

(and 2 more)

Tagged with:

-

J, congratulations on completing your Pram. It is beautiful!

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Wolle, welcome to MSW. I am looking forward to your project!

-

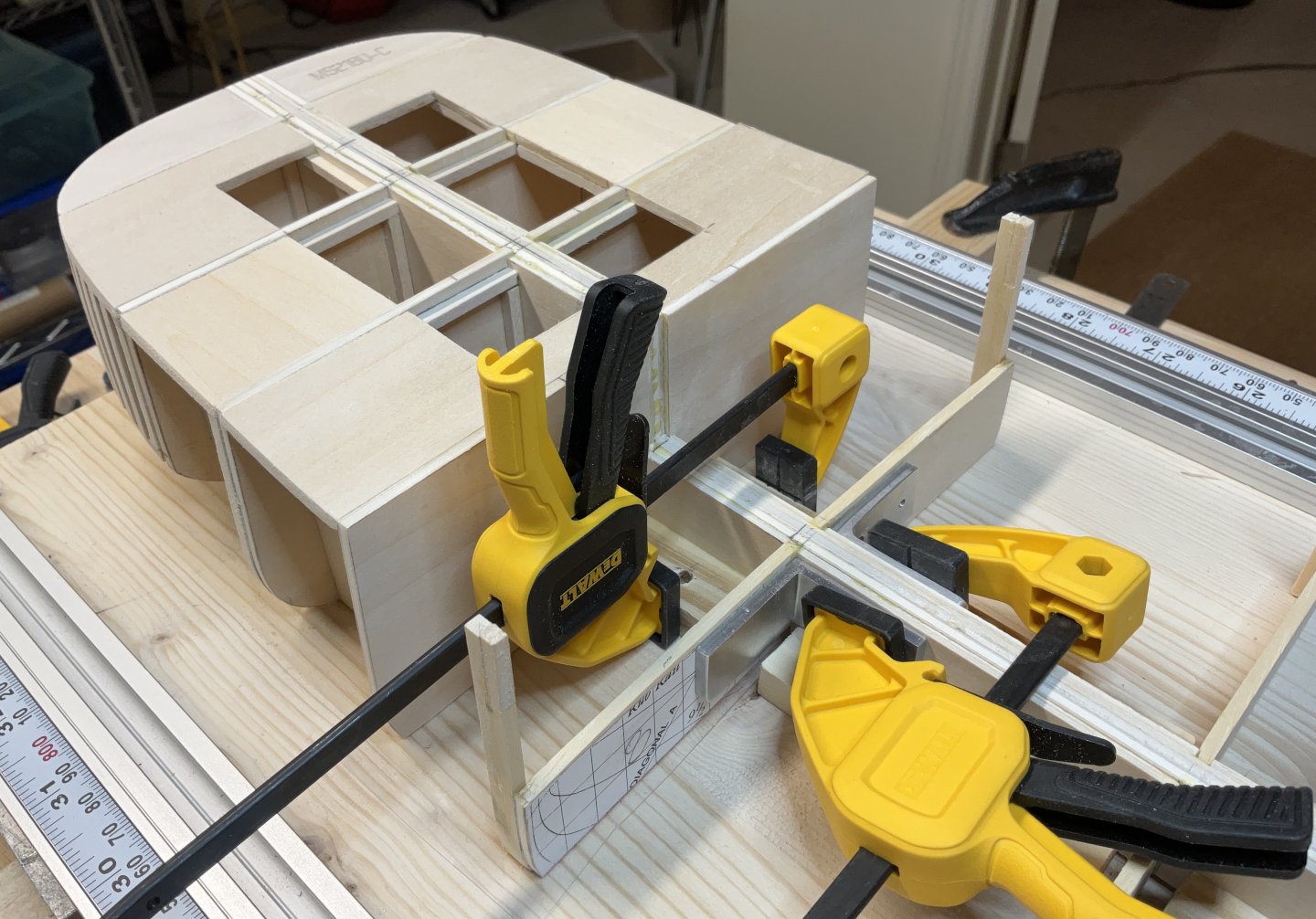

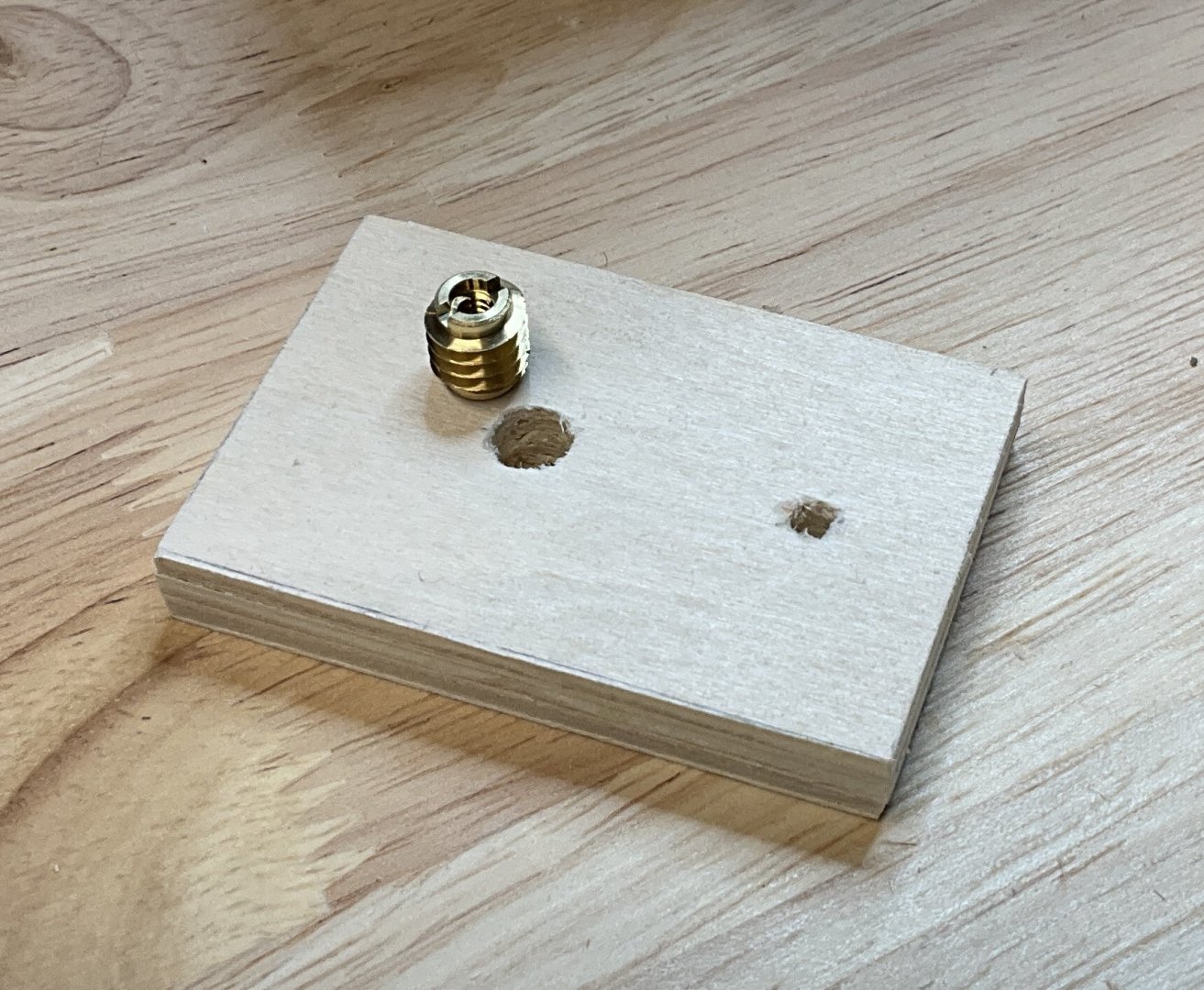

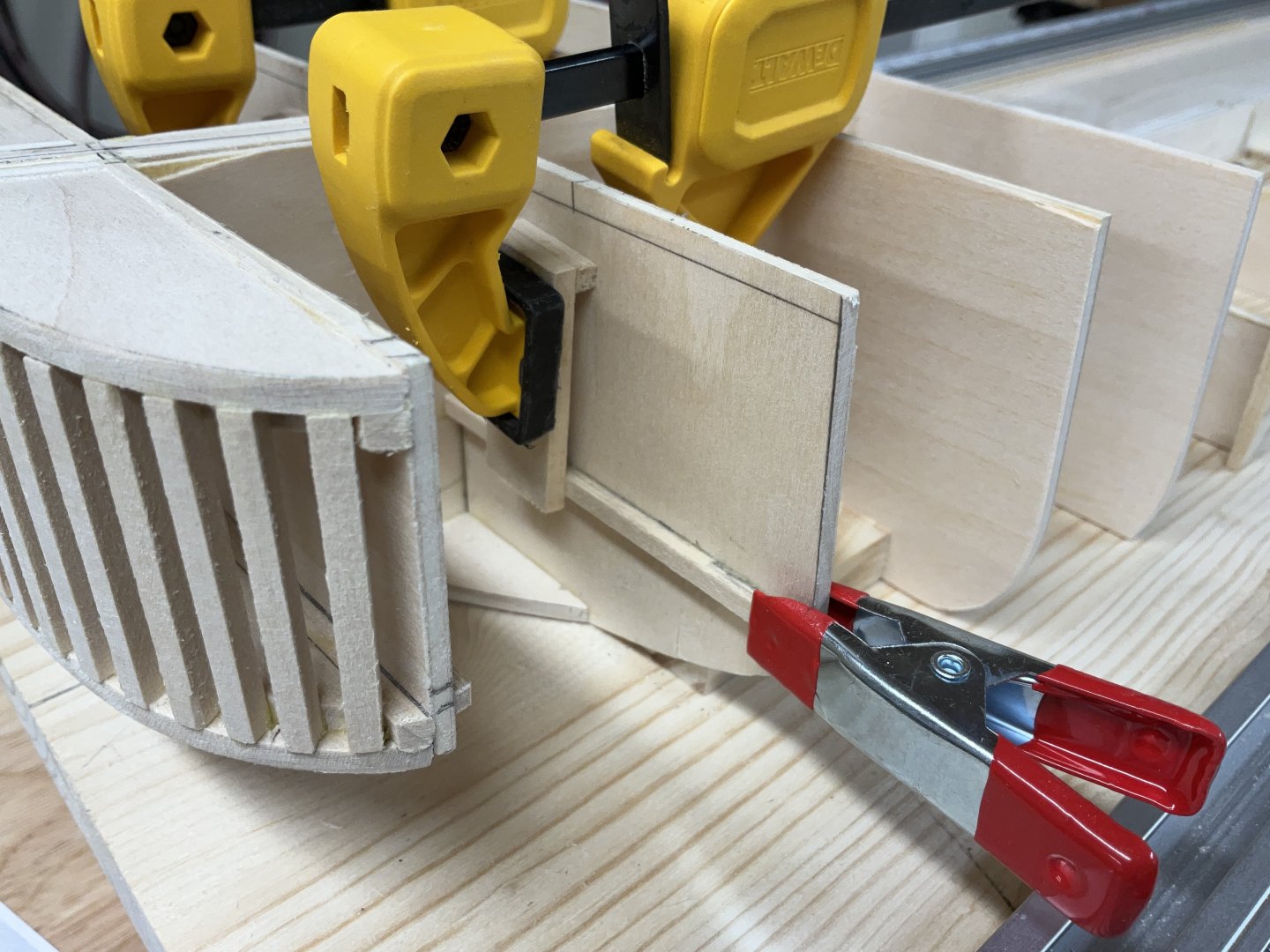

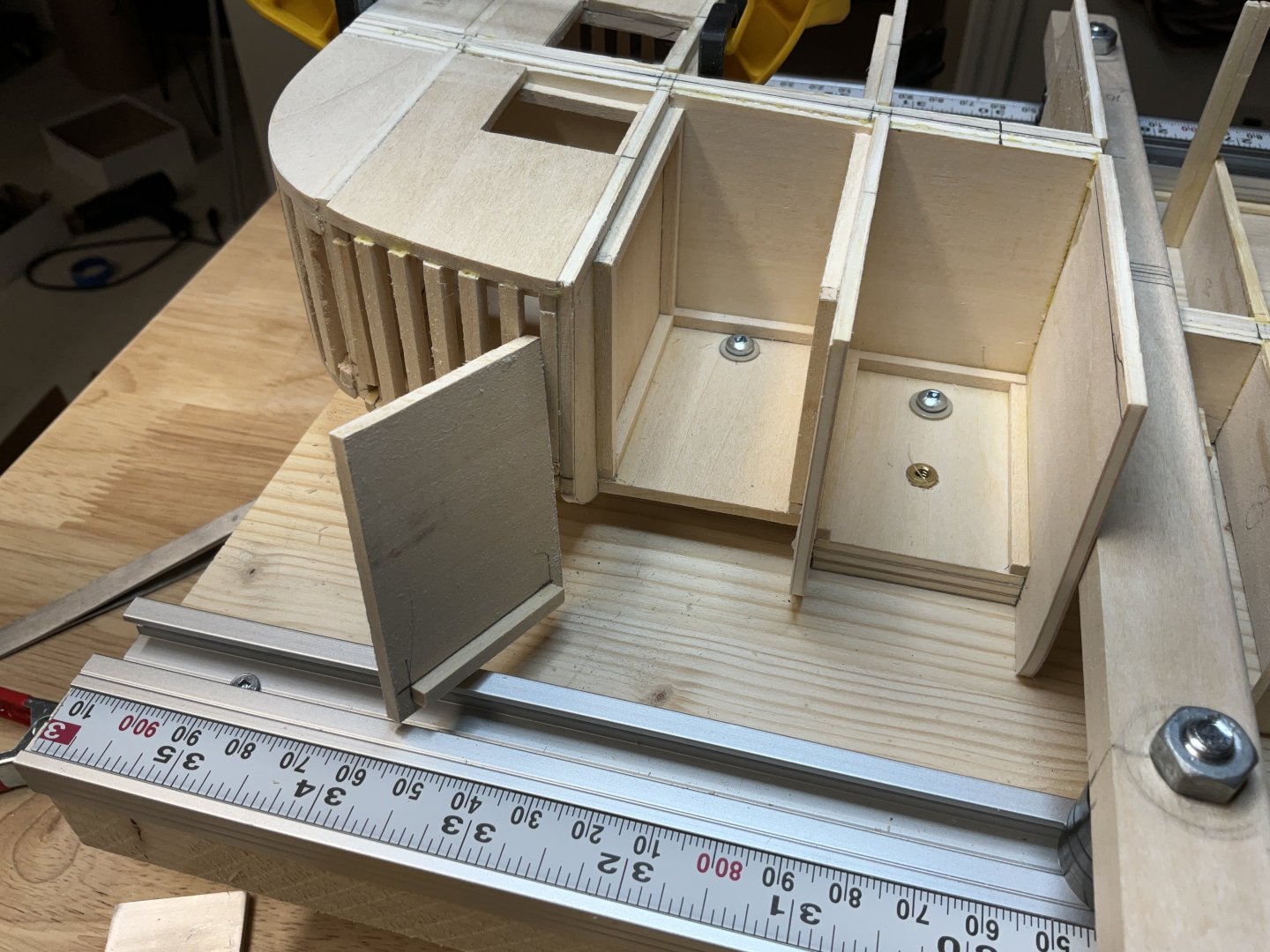

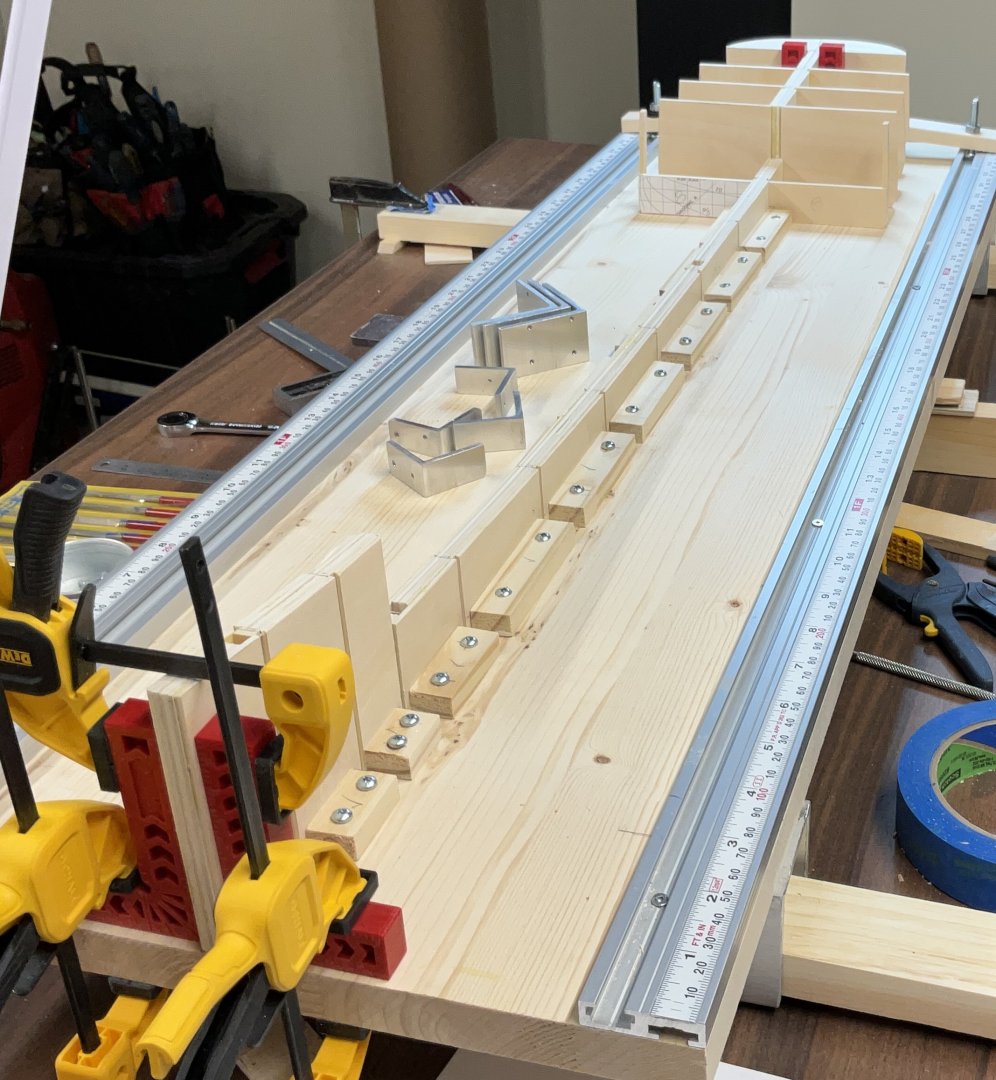

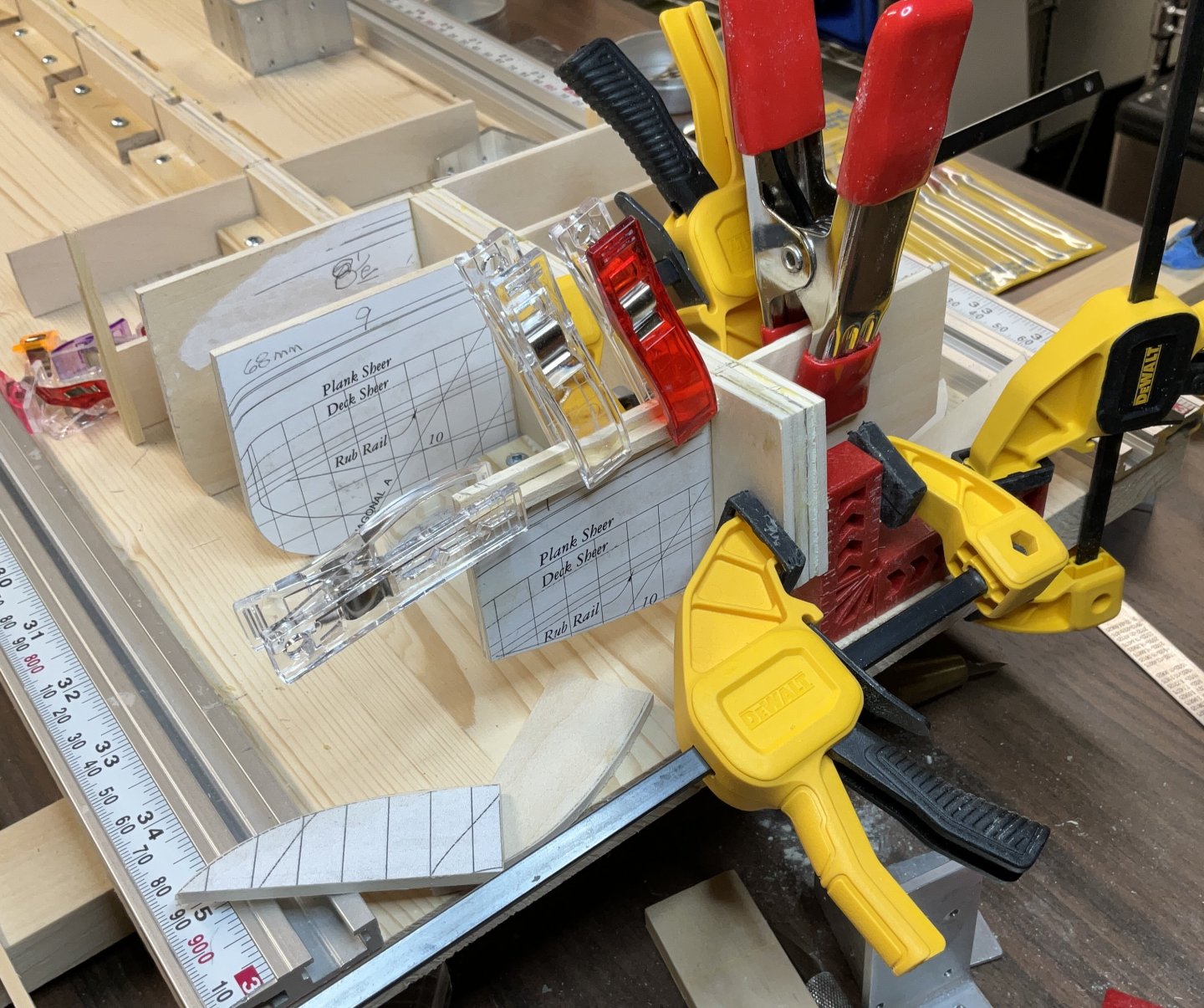

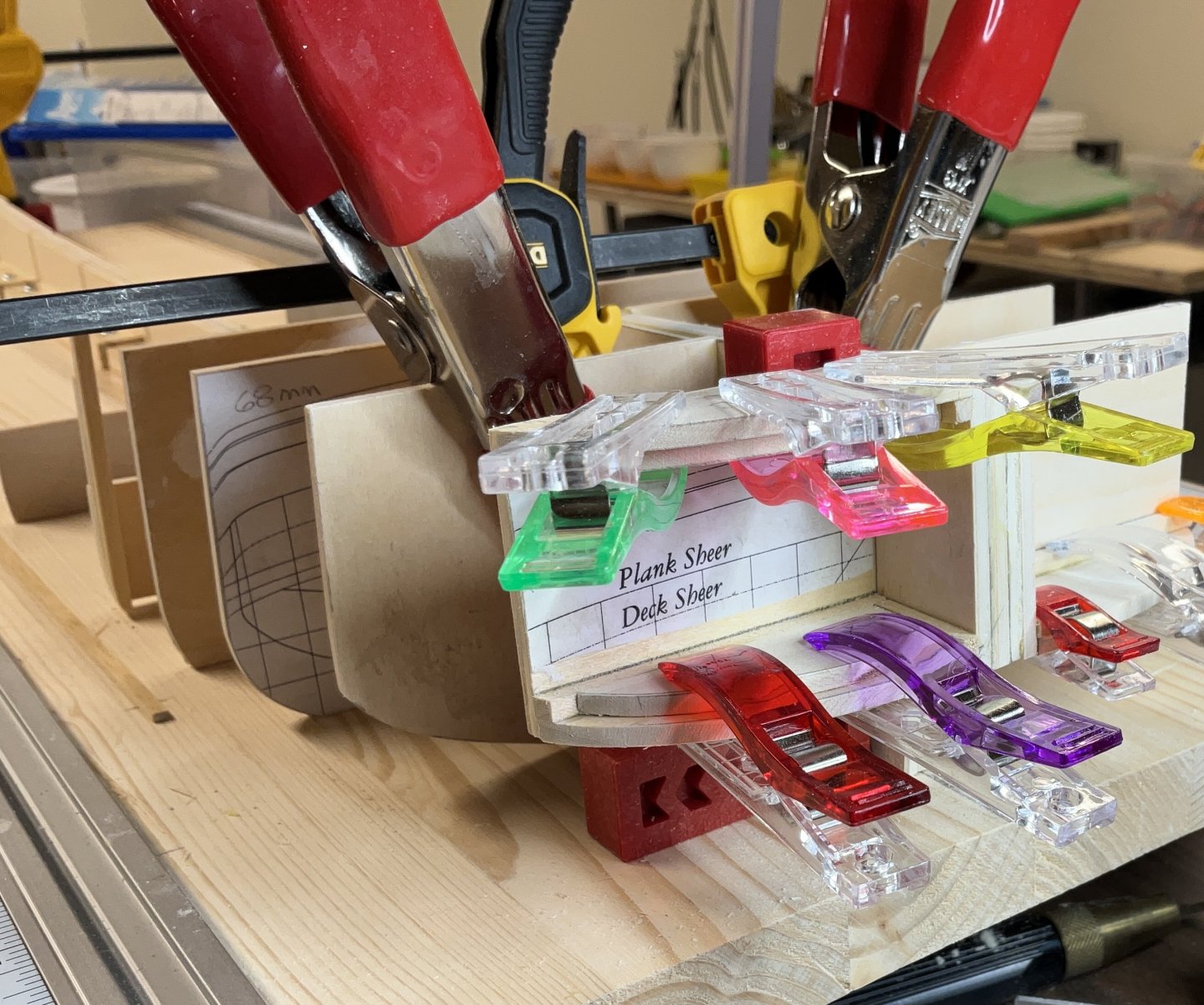

Hi Everyone, hope everyone that got big snow is all dug out. Thank you all for your Comments and Likes. I appreciate them very much. Slowly inching towards the bow with the bulkhead supports. The temporary blocks that align the bulkhead former are being replaced with permanent blocks that are glued in place and once dry are screwed to the build board again. I picked up some 6-32 brass insert nut from Lee Valley. They are mounted in a block which is made from 3 layers of 1/8” basswood plywood. All together there will be six of these blocks to hold the model to its base. These blocks are also used to temporarily hold the model to the build board again. The last bulkhead that extends up to the cabin deck was squared up and braced. Now it’s on to the main deck Fairing has started but still lots to go. Thanks for dropping by and I hope to see you soon.

-

Hi Ross, I haven’t used their cotton for this application so here are three Ropes of Scale .25mm beige cotton clove hitches tied to a length of..9mm dark brown polyester. The beige on brown was for clarity. The one on the left is dry and holds well . The center one has been treated with diluted pva and the right one has been treated with Vallejo Matt Polyurethane Varnish

-

Great photos Jacques. I think that even a seasoned weathering expert would have a tough time emulating the deck in the last photo!

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

I guess I should have said extend the upper platform to the front of the building.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Hi Keith, really enjoying your planning and decision making. Would it be an option if you mounted the steps as in the photo of Lula but extended the upper platform forward a couple of feet so that you are able to walk under them?

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

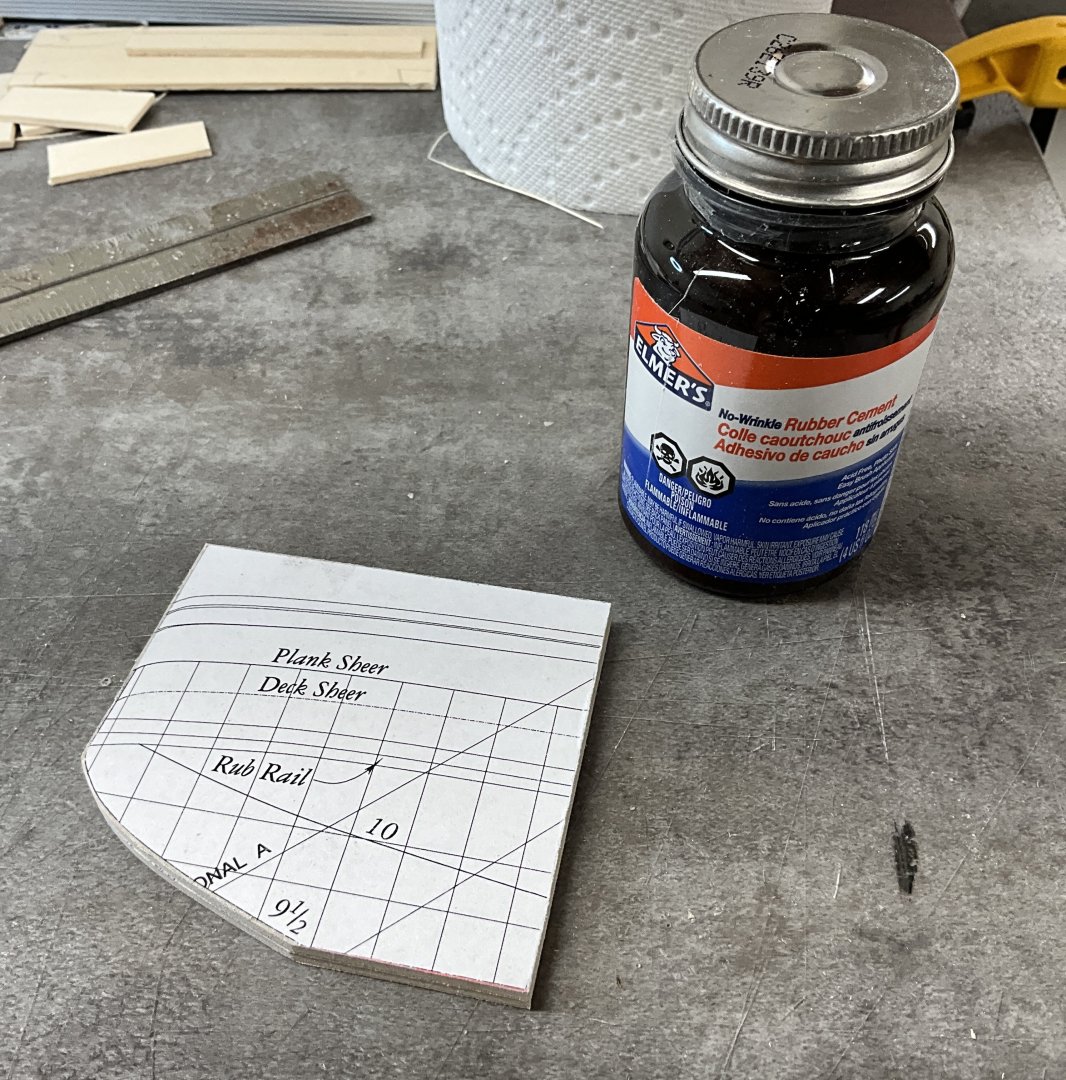

Hi Phil, thank you for the advice. I’ve been using the Elmer’s rubber cement for temporarily sticking the paper to the wood. I’ve only been removing the paper and rubber cement where there wood needs to be glued. As you say it is easy to remove. Been using yellow PVA for gluing the wood. Once the hidden work is finished I’m going to switch to white PVA and/or CA. One drawback to the Elmer’s rubber cement is its odor although that goes away fairly quickly.

-

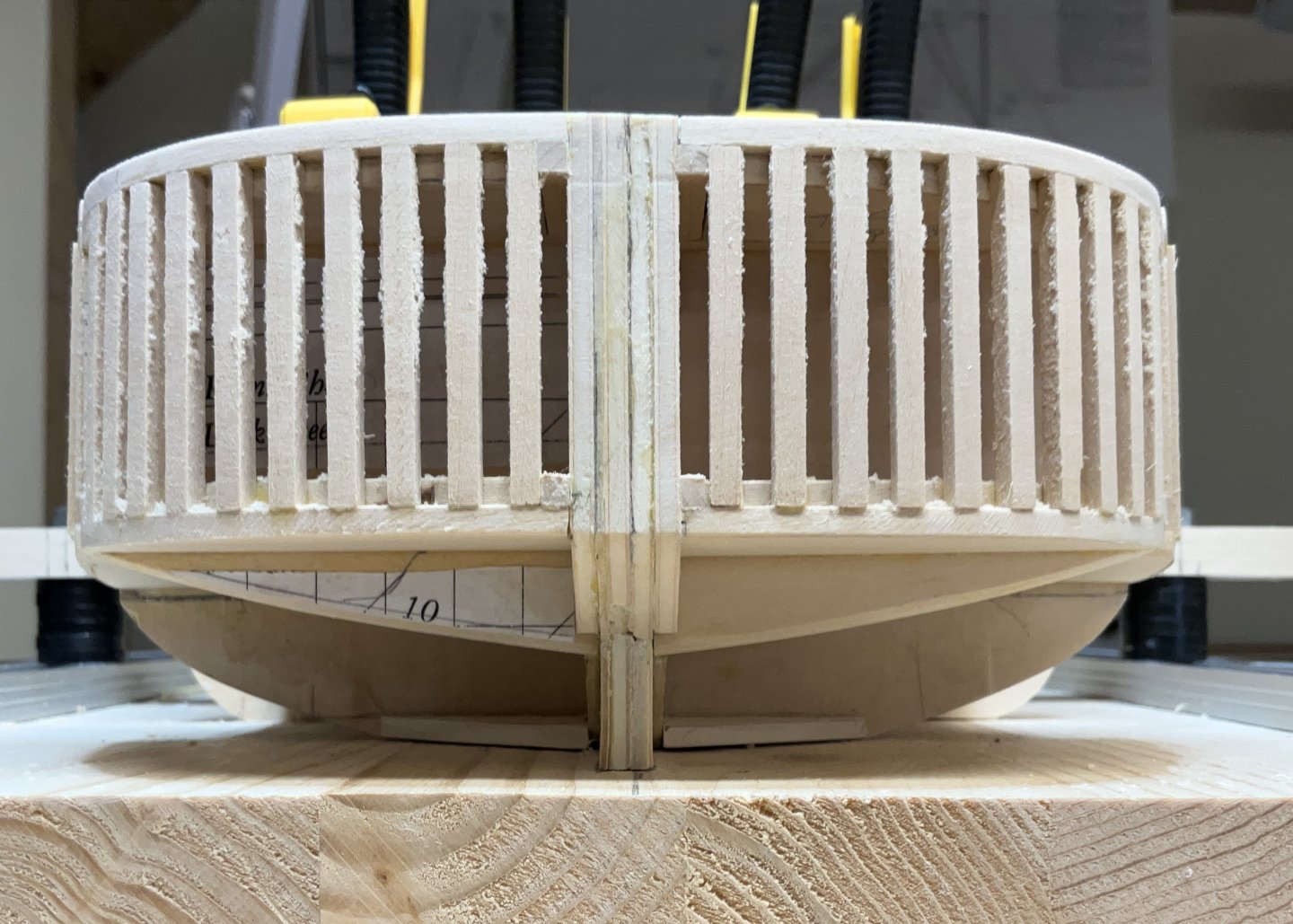

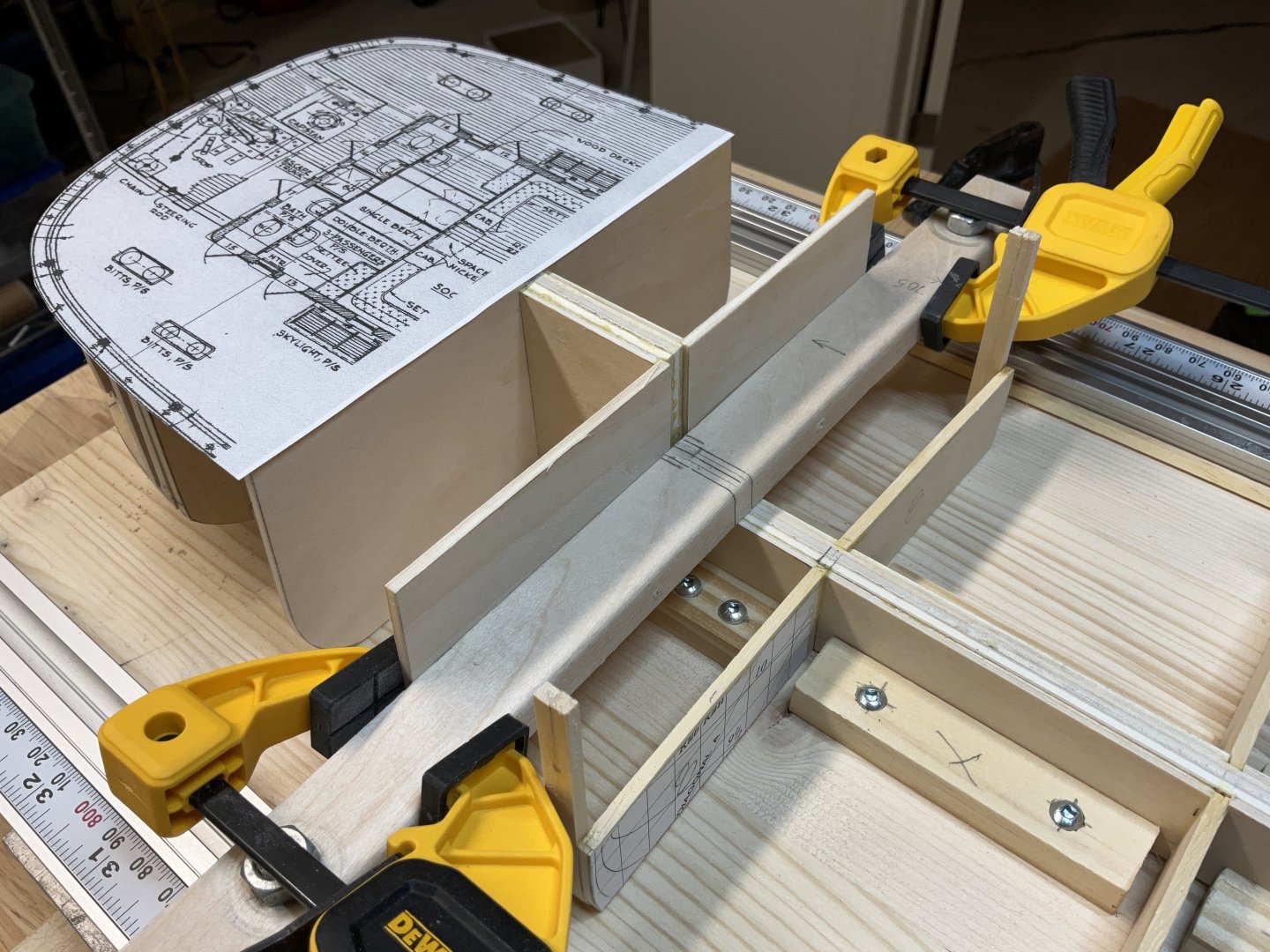

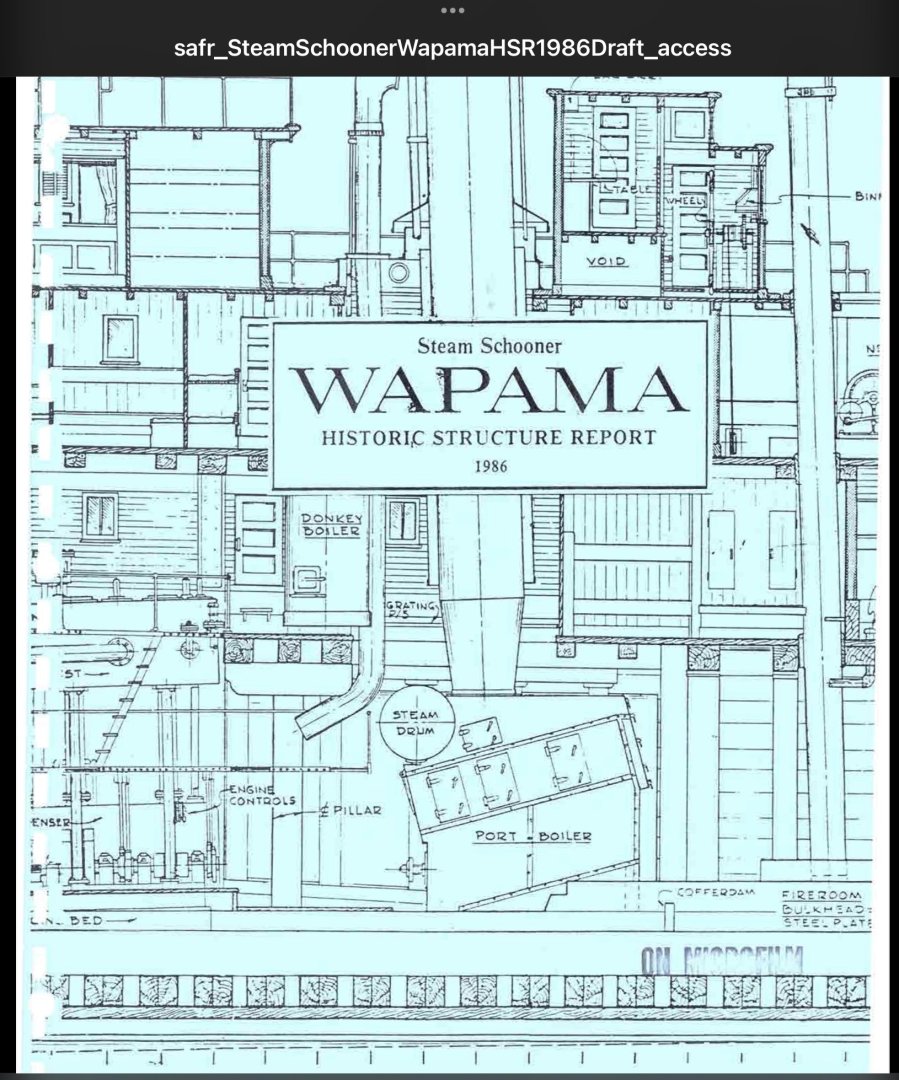

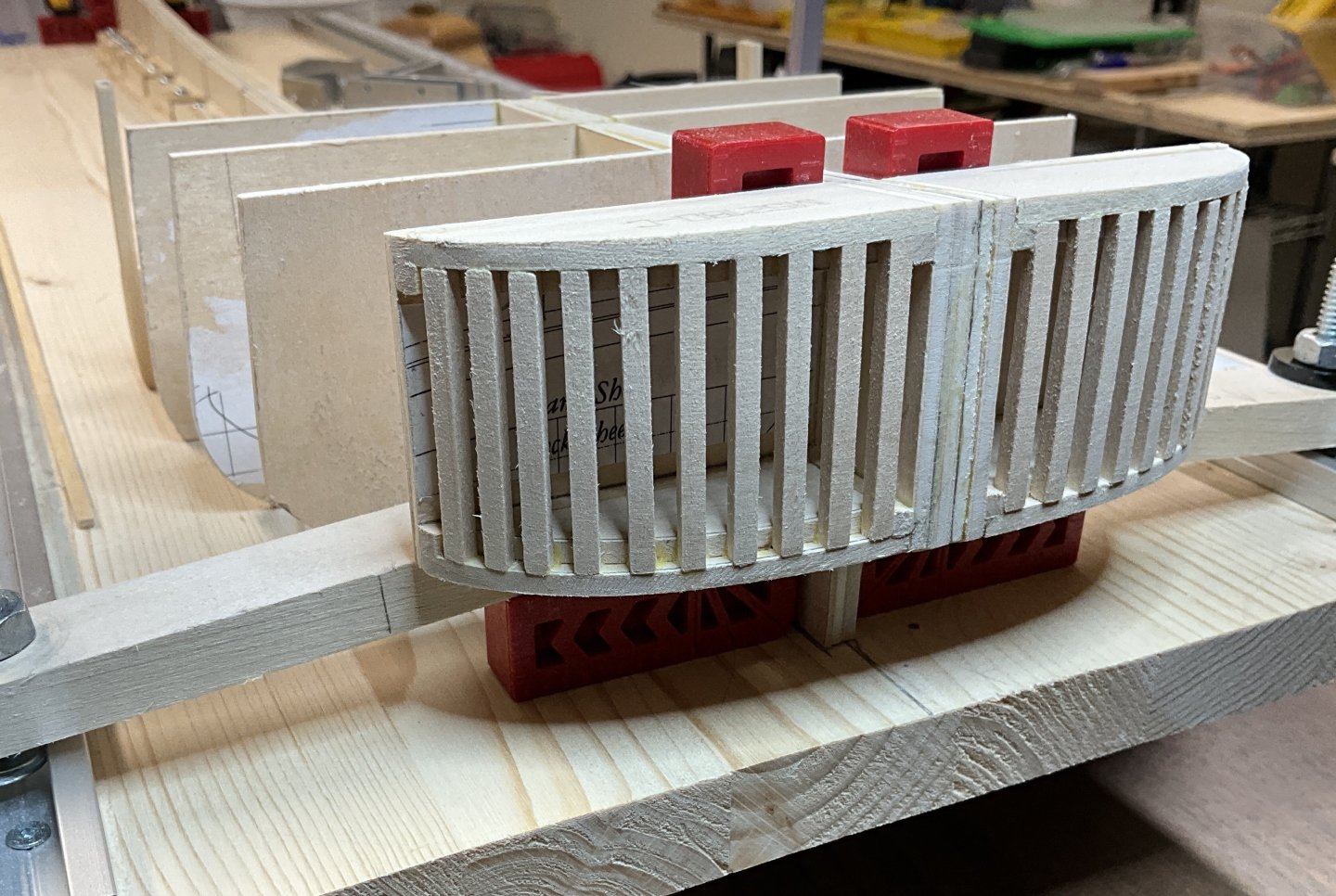

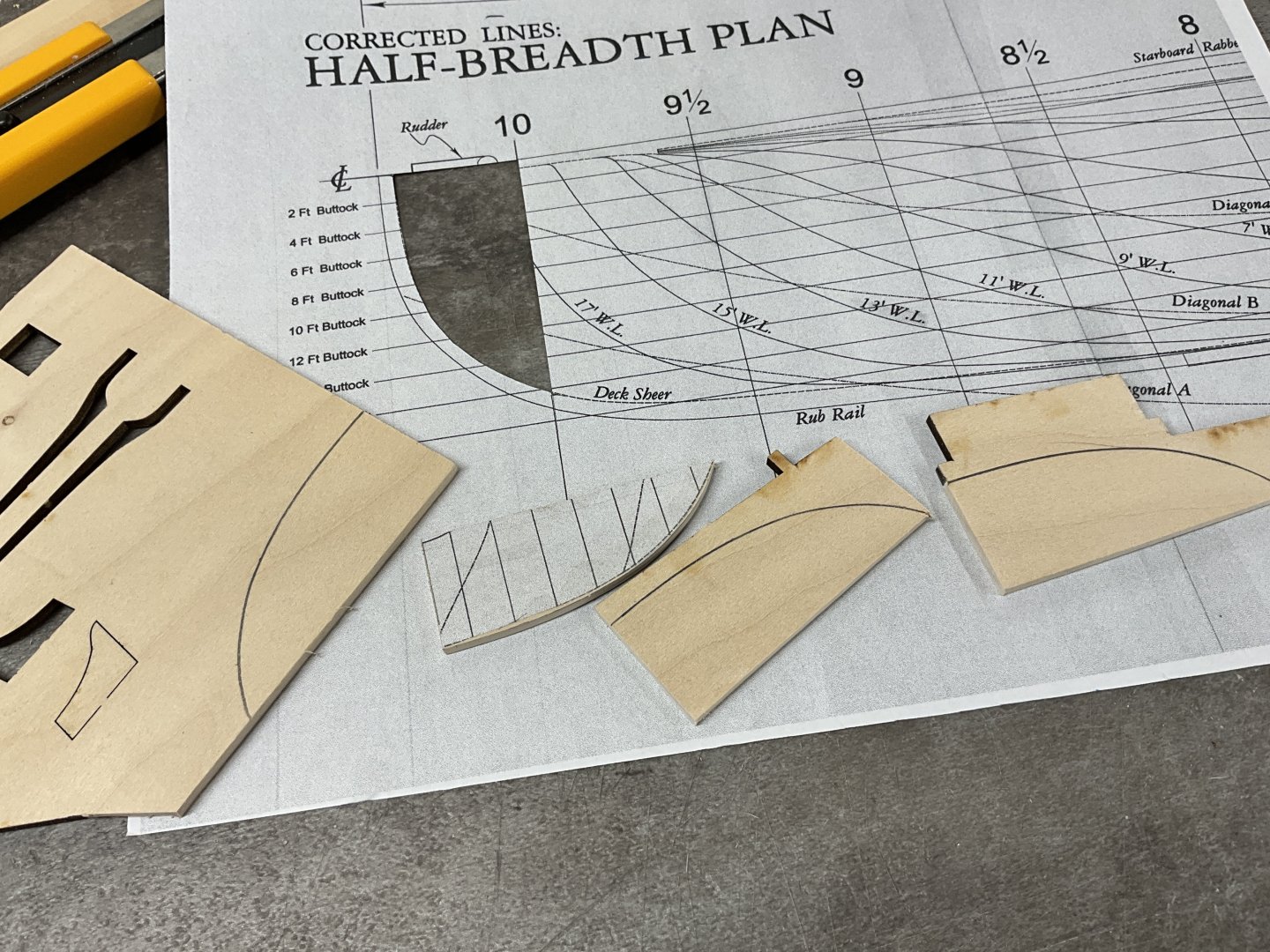

Hi Everyone, I hope you are all well. Thank you for all of your Comments, Likes, and support. I have been reading this report that @bruce d posted a link to in his topic “ 1915 steam schooner Wapama - detailed tech book and plans “. Thank you Bruce. Tons of details! In my opening post it should have been mentioned that the hull of Wapama was built by St Helens Shipbuilding Company in St Helens Oregon and towed by Steam Schooner Multnomah to San Francisco for completion. Work on the bulkheads has begun. They are made from the 1/8” plywood. They will be beefed up with 1/8” basswood later on to give the hull planking more gluing area. I started at the stern because it is the most complex part of the hull and didn’t want to get too far in case it needed some revisions. Left over 1/8” carrier sheets from Model Shipways are being used wherever possible. It is of nice quality. The area aft of the last bulkhead was “caged” with 1/8” x 1/8” basswood strips. The bulkheads that extend up to the cabin deck are all glued in place. The next bulkheads will just go up to the main deck. Thanks for dropping by. Hope to see you soon.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.