-

Posts

1,280 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dave_E

-

Hi Mike, welcome to the forum! 👍😀

-

Hey Chuck, Welcome to the forum. Bump everything these guys have already said. 👍😀

-

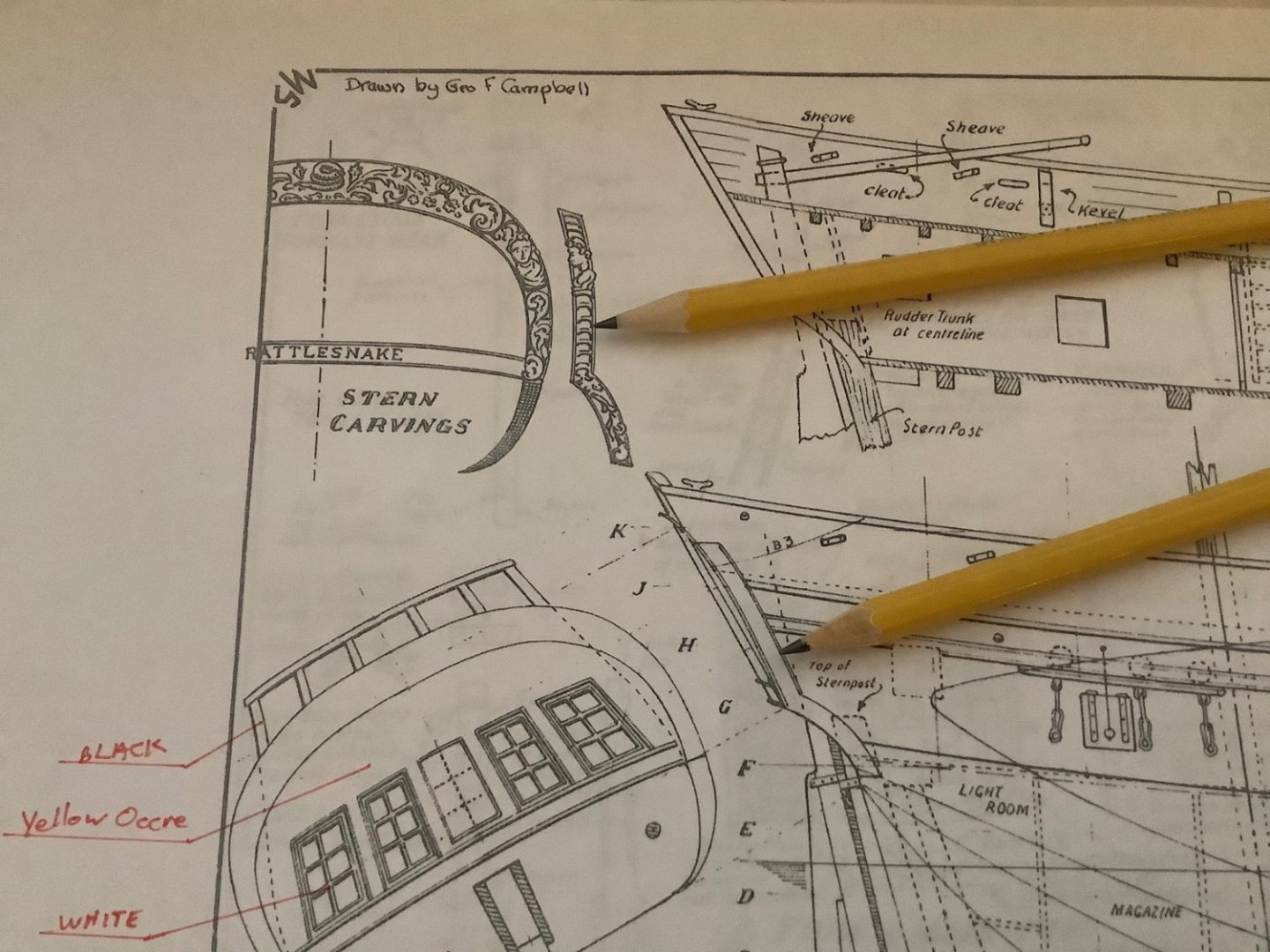

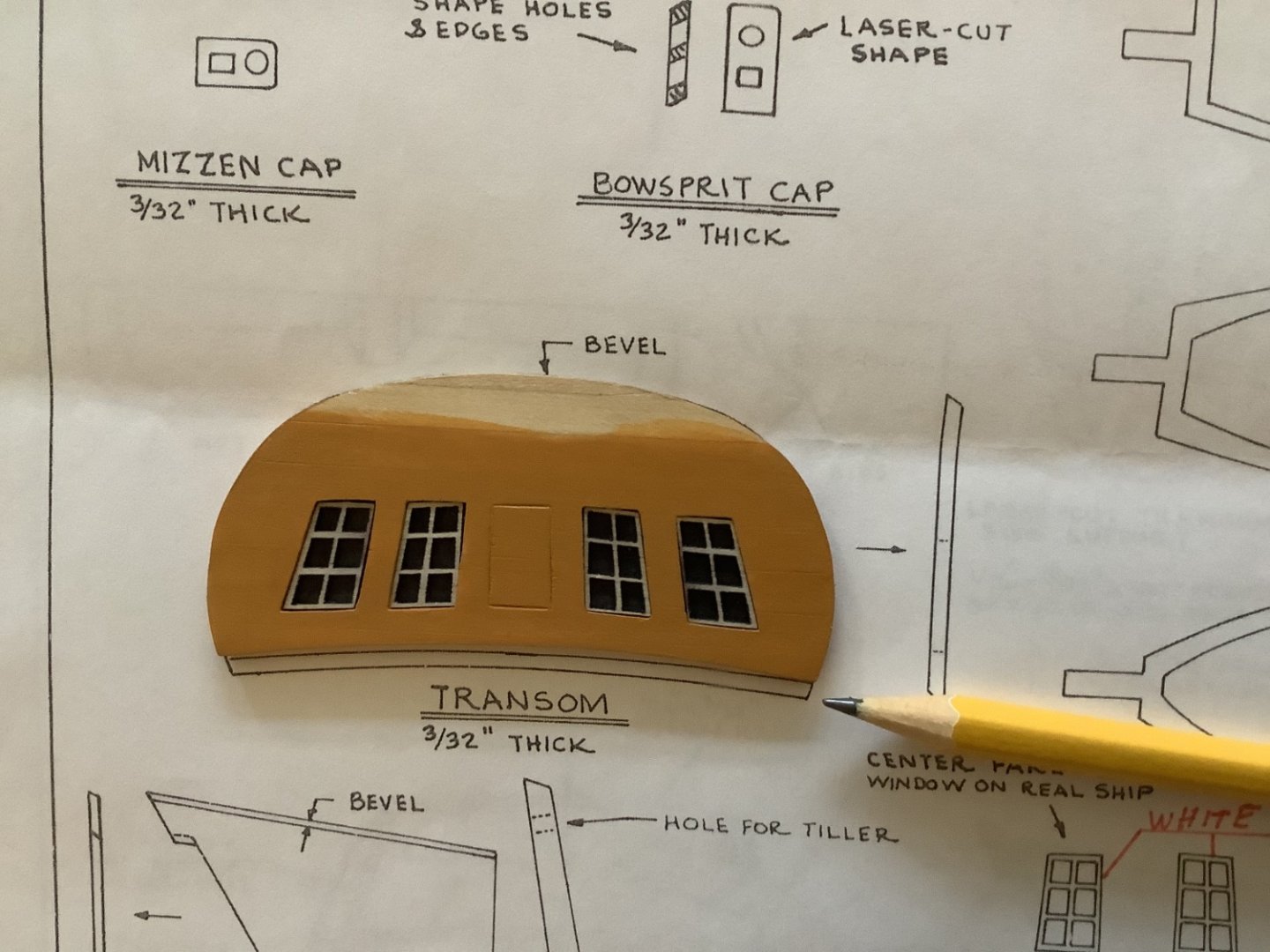

Hey Ed, Check out my post #93. After completing the bulkheads and making the transom carvings… that stern piece did not fit. I studied the drawings and came to the conclusion if I just put it in position, it would be way to low on the bottom. I goofed something or the drawings aren’t 100%. More than a couple of views on the drawings are “view” only and not to scale and that didn’t help me with the fitting problems. So I downsized the stern piece to fit, that’s why my Britannia seems to “fit”. So… when I get into one of these predicaments (it happened on my lady Nelson also), I do some engineering. When the ship is launched, only a fellow builder of this ship might notice a minute deviation from the drawing. If your stern wood fits per drawing, Jim’s suggestion is good. 👍

-

Mayflower by tj456 - 1/19 scale

Dave_E replied to tj456's topic in - Build logs for subjects built 1501 - 1750

Does your wife know your using the dining room table? 😳 -

how do I sharpen my craft knives?

Dave_E replied to Benjamin S's topic in Modeling tools and Workshop Equipment

If your refering to things like exacto type blades... I don't, I purchase new ones. 👍 -

Hey Ed, Looks good Brother. The bulkhead fairing in my mind is such an important part of planking. I didn’t spend a lot of time on mine, because when it’s time… every single plank is a new project and that will include bulkhead fairing to get it as perfect as possible to receive a plank. We’re just about at the exact same place on our builds. Monday I take off for Hawaii for the whole month, so won’t be any progress on mine until January. I’ll be watching you though. 👍😀

-

Slipping in from Massachusetts and Minnesota

Dave_E replied to Janelle's topic in New member Introductions

Hi Janelle, welcome to the forum! 👍😀 -

Welcome to the forum! What may we call you? 👍😀

-

Hi Lyle, welcome to the forum! 👍😀

-

Thanks Dave. The reason I did not do the center window was because as mentioned it appears the real ship, according to the Admiralty drawings (after capture and subsequent renaming to Cormorant) didn’t have one. Dave, your paint scheme for the Britannia is exactly the colors I have chosen. Thanks for the painting link! 👍😀

-

Royal navy - stern colours?

Dave_E replied to Vane's topic in Painting, finishing and weathering products and techniques

Thanks for the resource! Good for lots of detail, not just color. 👍😀 -

Looking good! That NHL rug brings back childhood memories from 1971 living in Sault Ste Marie watching Hockey Night in Canada every Saturday. Bruins, Maple Leafs, Canadiens, Blackhawks, Flyers, Redwings… what an era! 👍😀

-

From out of the shadows ...my first post!

Dave_E replied to RobTBay's topic in New member Introductions

Hi Rob, welcome! 👍😀 -

They do indeed! I have personally watched sailors at the marina hand waxing their J boats before weekly race day.

- 31 replies

-

- Shamrock V

- Amati

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.