-

Posts

2,535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

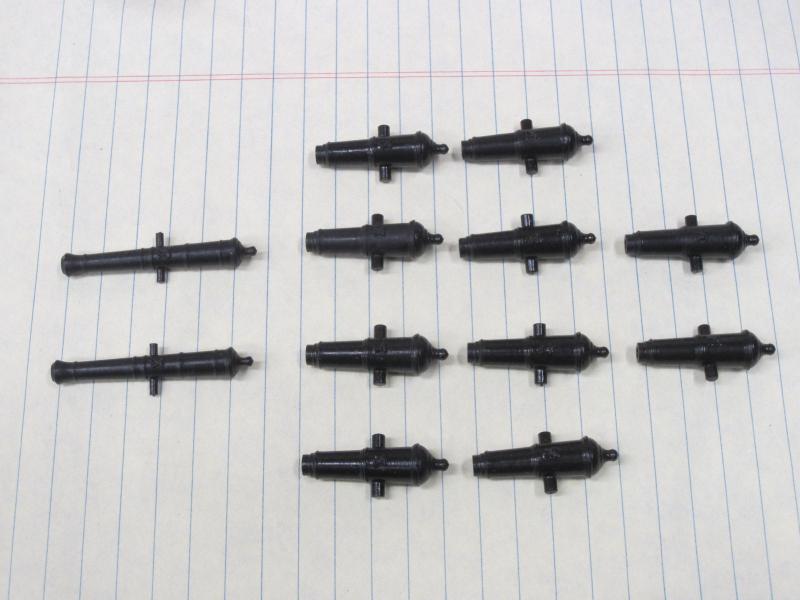

Red trucks won out and here are the finished cannon. I've set them aside and have to finish some outboard and inboard work before I can place them.

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks all for the input. I like the idea of the black band but if that’s not accurate I’ve scrapped that idea. Chuck I could have put money on your answer because I remember when you had to make the same decision. I’m leaning hard towards red so I’ll do up some that way and place them on deck alongside some black ones and see what slaps me upside the head! Thanks again.

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

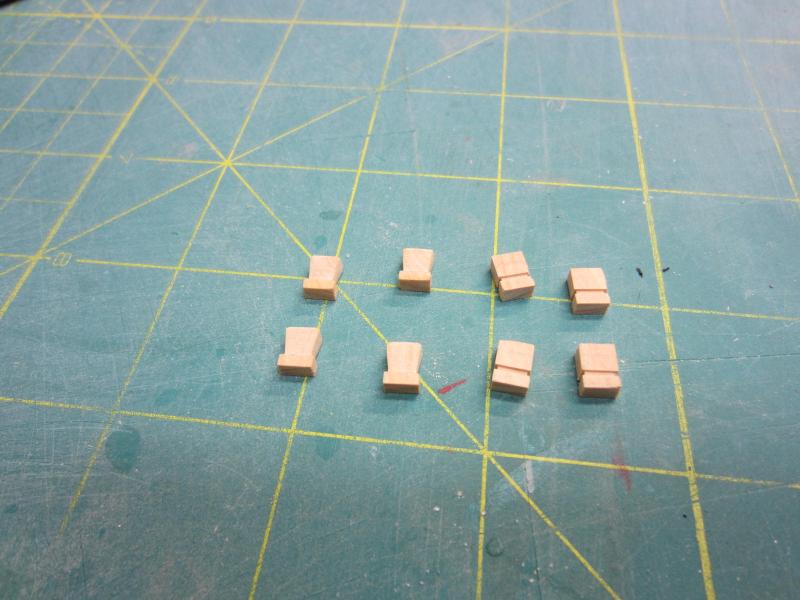

Ok it's time to paint the trucks. Now we've seen Chuck painting them red but I also wanted to look at them in black. Here you see the two test samples. Now that I've seen them both ways I'm perplexed as to which way to do them. Any thoughts?

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Brian. Pat I'm not sure why you don't see the pictures they show up on my PC and tablet. Also thanks for all the likes too!

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

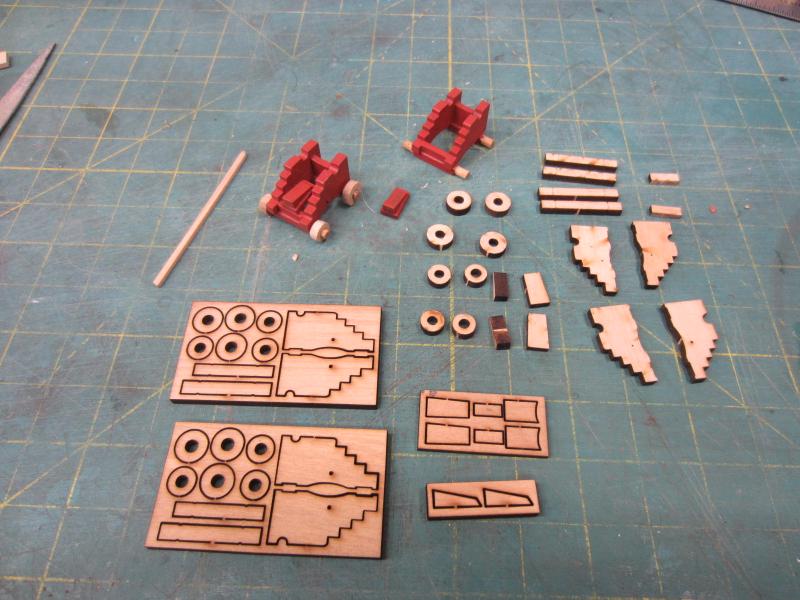

Hi All, Progressing slow but sure here. As you can see all the gun carriages have been assembled and I’m adding the eye bolts. Then I have to sand the trucks and put them on. Also the carronades and cannon barrels have the first couple coats of paint. You also see the pile of rings and eye bolts I’ve made for the carriages. Now that all the festivities are over I hope to have everything assembled by the weekend.

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Same to you Ben. I'll be waiting impatiently for updates.

- 889 replies

-

Thank you all for the welcome back and kind words. It's great to be working again. Nothing major to show but I have started building the gun carriages. It is a repetitive task but not bad as there are only ten carronades and two 6 pounder long guns. Here’s my progress so far. After the carriages are complete I’ll start painting the barrels.

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you for stopping by for all the likes too. I found out that you not only have to dust off the cobwebs on the tools and model but from the brain too.

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well now the fun begins again. I’ve dusted off the plans and instructions and have started “working” again. It really feels good to start cutting wood and making saw dust….hack, cough sneeze. Hmmm a bit out of condition I guess. I cut some boxwood and shaped the timberheads, added the boom crutches, outboard ladders, transom knees, cleats and working on adding the channels. Yippie

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Chuck, It's was great getting caught up on all you've done while I was gone. Wonderful workmanship and can't wait to get back to it myself!

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Bob. Getting caught up on what I'd missed and it was fun to look in on your great progress. As always you're doing a fine job.

-

Hi Grant. Just got back and enjoyed getting caught up on your build. She looks fantastic! Well done.

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

The best part is it was her idea that I take up a hobby!

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Dave, It was a pleasure to sit back and catch up on your build. Very nice.

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Thanks to everyone for stopping by and all the likes. Chris, It's nice to hear that you'll be getting a work space. Look forward to more updates. Michael, Thanks so much. Druxey, Much appreciated and I can't wait to start back up. Bob, Thanks and checking on you from time to time helped with the withdrawal. Ben, I'm glad to hear you're close to sarting to build again. Pat, When I started stripping it I was pleasently surprised at the quality of the wood. Grant, "Play" is what the Admiral calls it everytime I say I'm going to the shop to "work".

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hello Everyone, Getting real close to opening the shop up and thought I'd give you all an update. Plus this proves I'm still kickin'. As you might recall we purchased a different home this past spring. We did a LOT of renovating to the interior. Replaced 16 interior doors, all the trim molding, took out the old carpet, new floors put in, two bathrooms redone and on and on and on! I never want to see a can of paint again. Then I got one enjoyable moment and that was the creation of a new work space. Again I'm relegated to the basement but now I'm not sharing my space with the furnace and hot water heater. A reminder of the old work space. Here is the space I have to work with. The finished interior dimensions are 10' x 18'. Long and narrow but I think I got it to work. An electric subpanel was run to power just the shop. No worries now of lack of power or of popping a breaker that would shut down part of the main house. After framing the walls I decided to use plywood for the walls in place of sheetrock. This way anytime I wanted to hang something i didn't have to find a stud. Also I prone to "bumping" into the walls with stuff and this should cut down on the collateral damage. The cabinets were either from the old shop or ones removed from the renovation. Countertops are either plywood or a butcher block the admiral didn't put back in the kitchen. Very sturdy! The counters then received numerous coats of heavy duty poly. The dust deputy and shop vac are out of the way under a cabinet with the hose coming through the back to be attached to whatever tool needs it. I also hung the JET air filter at the end of the shop where most of the power tools will be cutting os sanding wood. For lighting, and we all know you can never have enough, I used new LED fixtures. There are a total of four 4’ double tube LED fixture and one 2’ single tube fixture. They are switched so I can light it up like daytime or if I don’t need to blind myself I can turn fewer on. So the renovations and my normal hectic August/September work schedule kept me real busy. Then throw in the unpleasant surprise of an inguinal hernia surgery in late September that backed things up even more. But all is mended and doing fine so I’m back to unpacking the shop, sorting , throwing away, putting away, not liking where I put it and moving it three more times! Repeat for the next box and on and on. One other thing that ate at my time was the refinishing of my grandfathers 1930’s office desk. At some time in its life my mother thought it would be nice to paint it white. I always remember it being white so it’s been that way for more than 50 years. As you can imagine it has seen better days. With the cold weather coming I needed to focus on this or it would have to wait until spring. So lots of stripper, rebuilding drawers, sanding and staining it is almost done. As far as transporting the models go there seems to be no damage to most and minimal damage to a couple. So far that is. I am happy to say the Cheerful was unscathed in the move and is waiting impatiently. After a 40th Anniversary trip coming up in two weeks I’m hoping to have the shop open for business by the last weekend in November or the first weekend of December. Whew that’s the longest ramble I ever put together. Hope to be back in full swing soon.

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Oh I love looking at her! Well done Chris.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Hi Grant, That is a first rate job on the deck and hatch planking. Well done.

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

Hi Karl, Thank you very much for the kind words.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Very nice work Grant. The hull planking was a real bugger. As you said the deck is much easier the hatch behind the cockpit was also a little difficult for me to get those seams to line up with the deck seams. Keep up the good work!

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.