-

Posts

139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by SimonV

-

-

Royal George ... Can I already pay an advance 🙂. This one is defenitely on my shopping list (price does not matter).

- Canute, Gord-Canada, chris watton and 2 others

-

5

5

-

-

-

-

Hello,

I have to sell some of my books because of the move. Please Contact me for shipping costs or if you need more information.

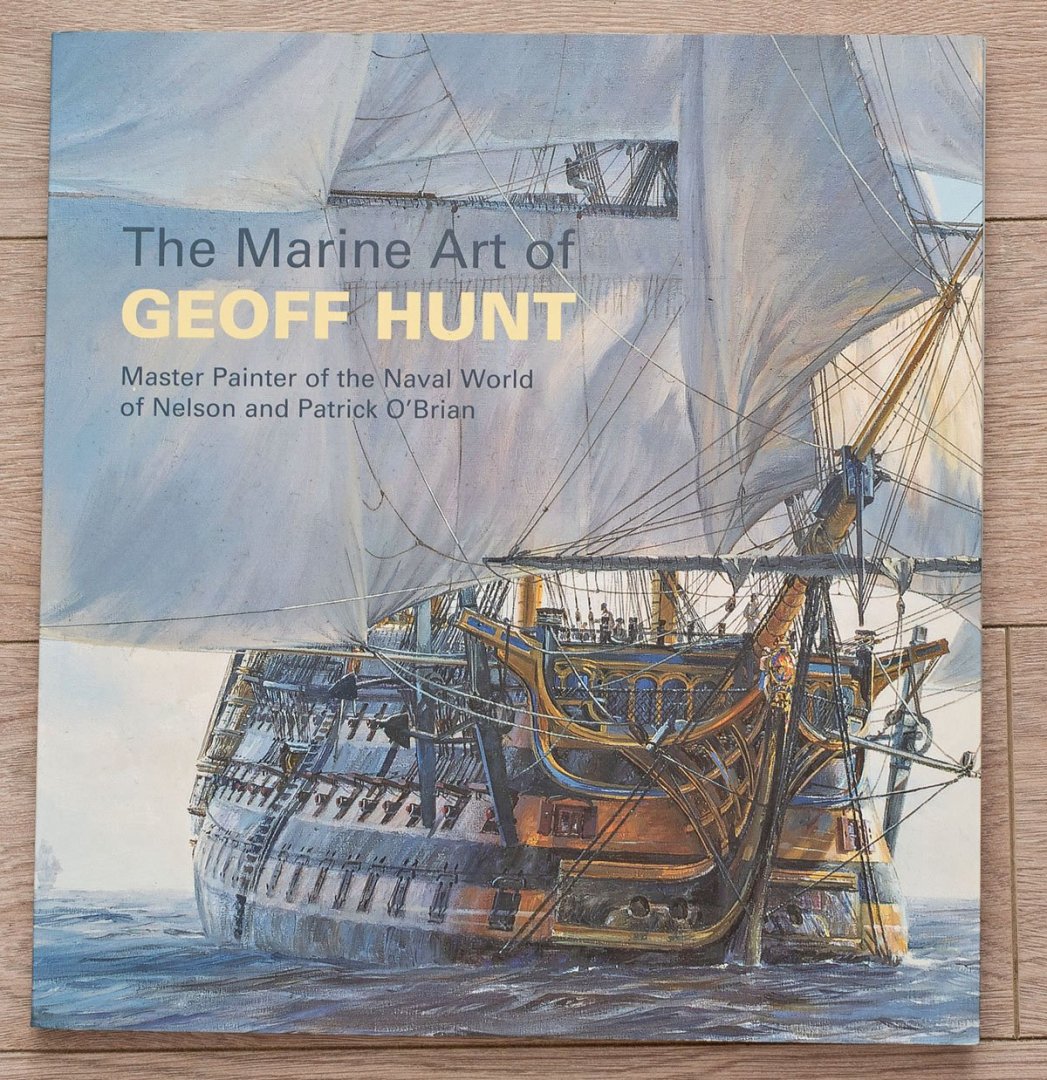

The Marine Art of Geoff Hunt (NEW) - 20 EUR

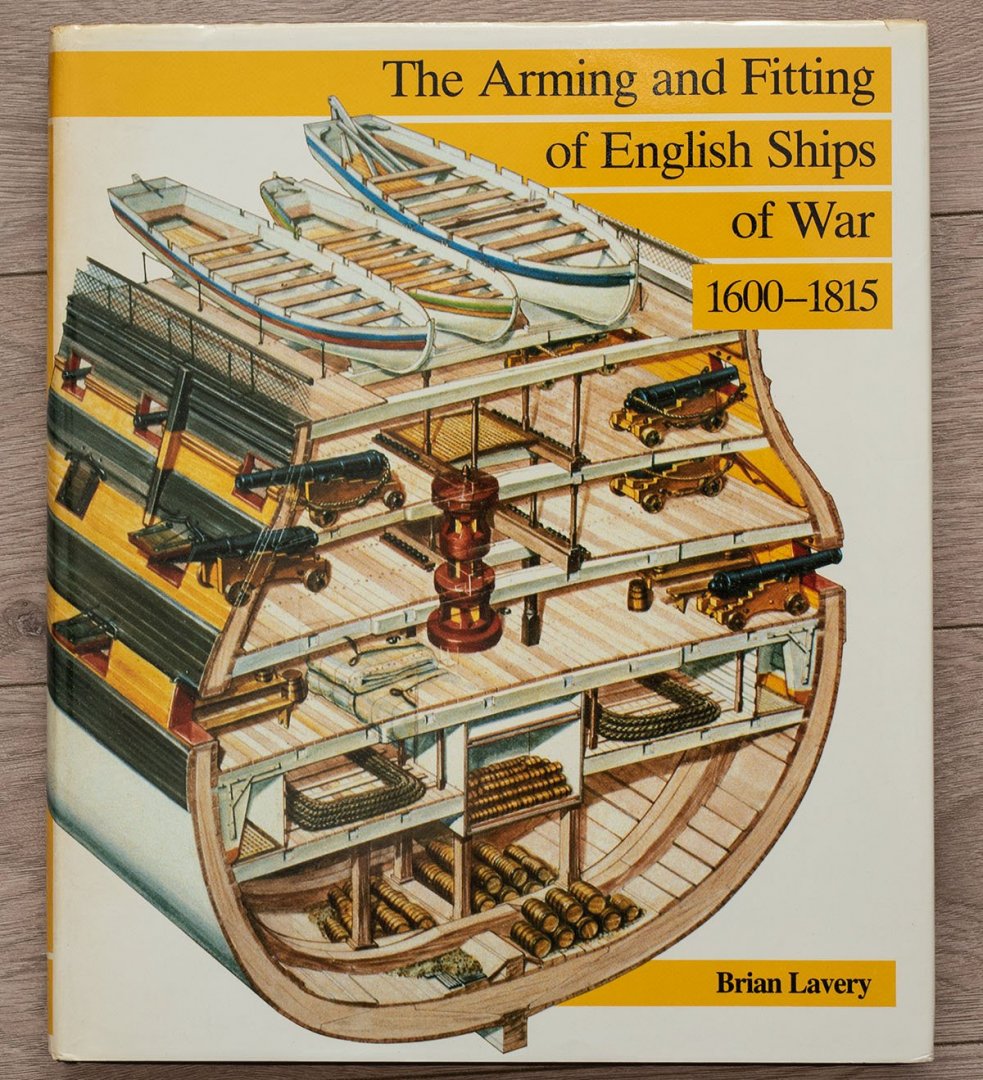

Arming and Fitting of English Ships of War, 1600-1815 - 65 EUR

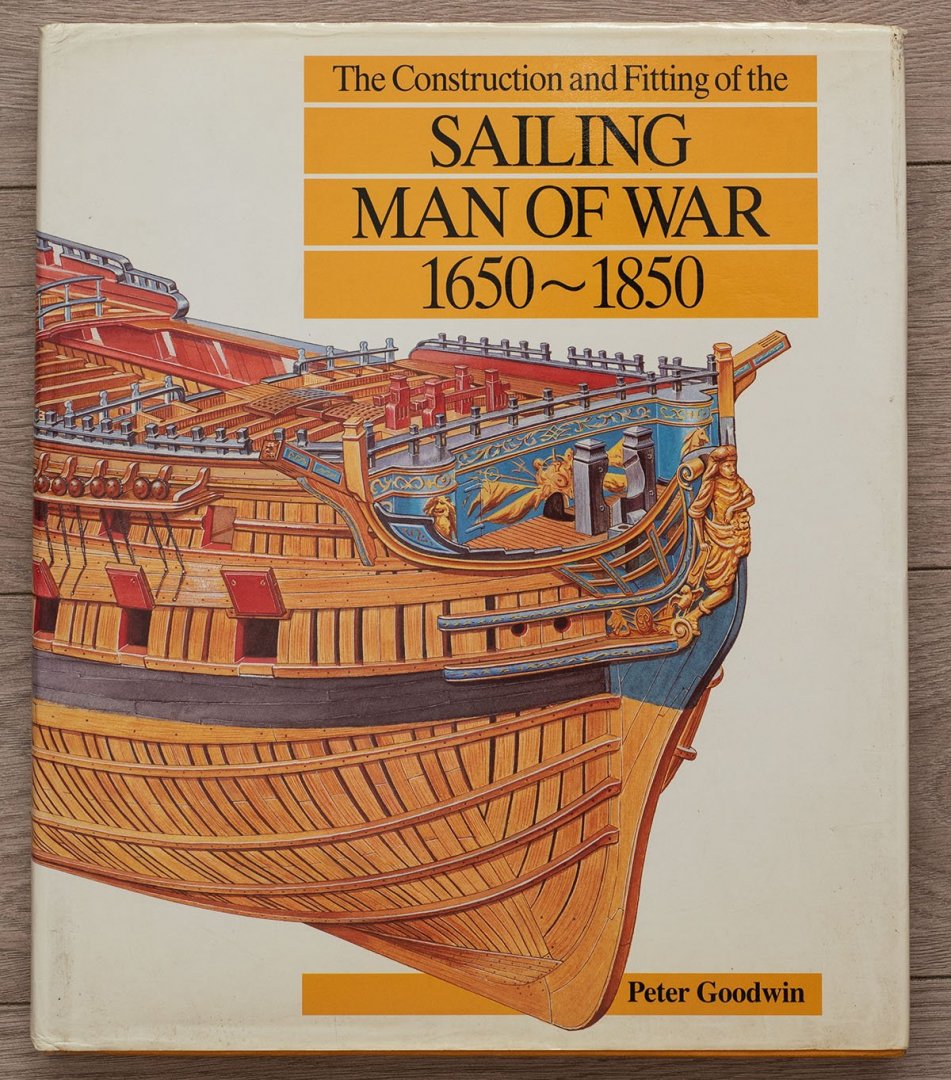

The Construction and Fitting of the Sailing Man of War 1650-1850 - 65 EUR

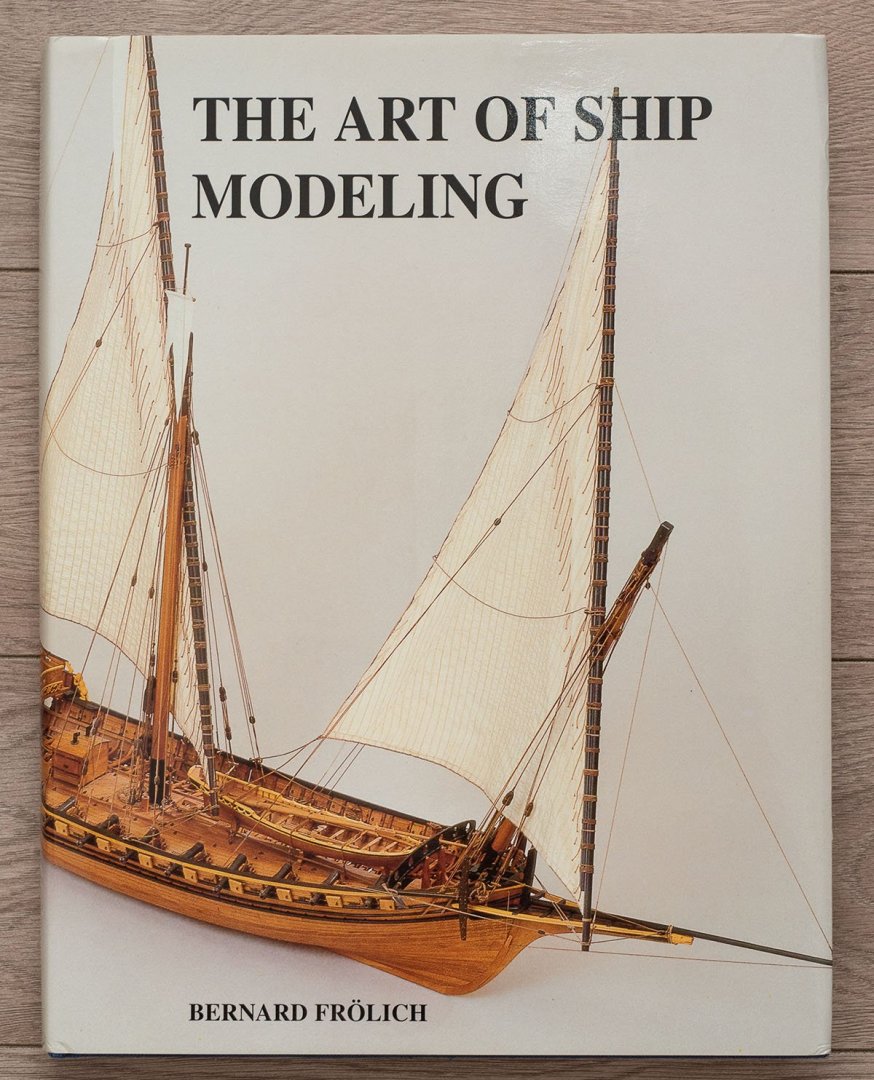

The Art of Shipmodeling - Bernard Frolich (NEW) - 70 EUR

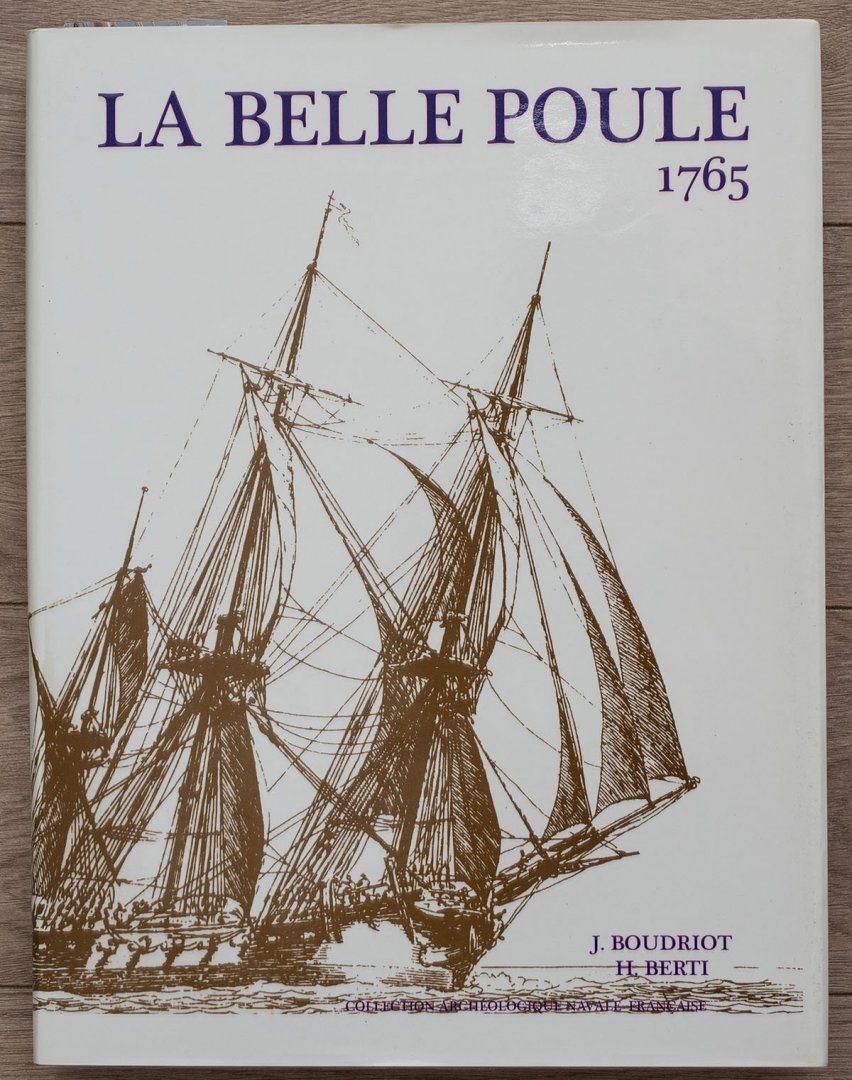

LA BELLE-POULE - Frégate - 1765 (NEW)- 85 EUR

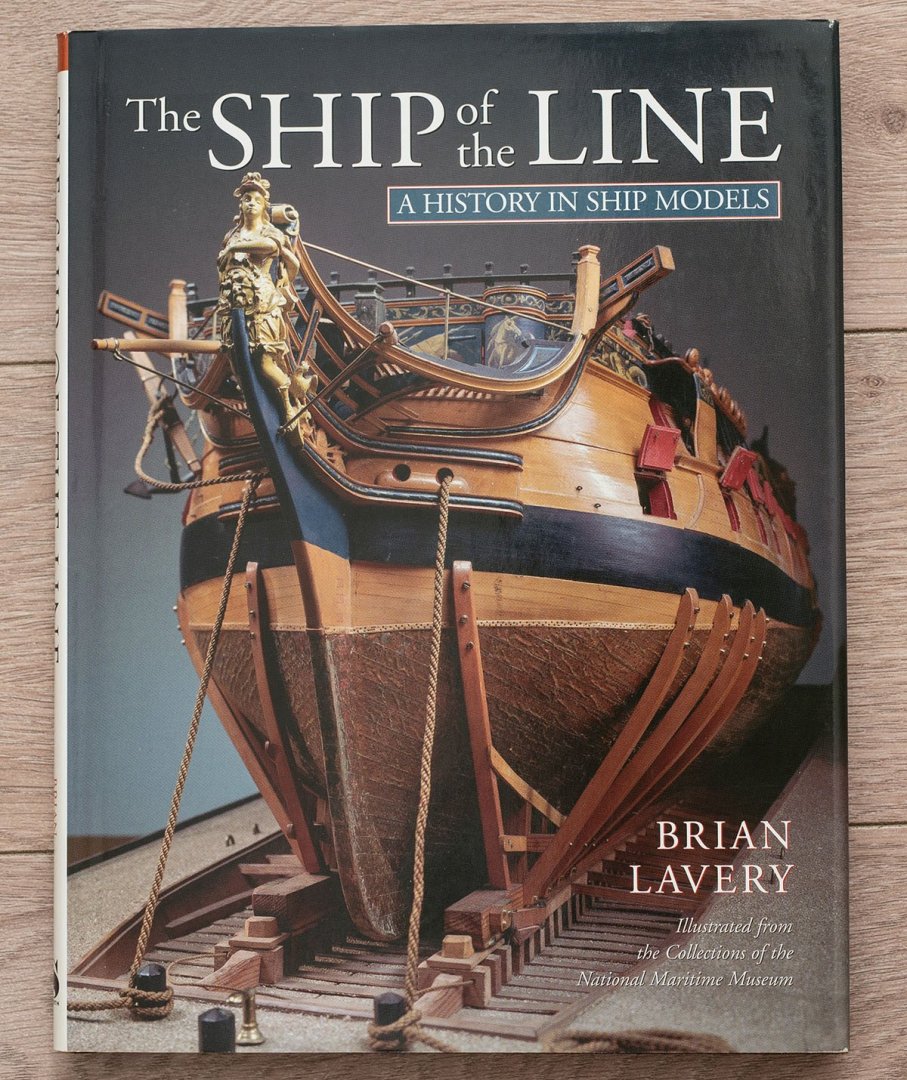

The Ship of the Line (History in Ship Models) by Brian Lavery - 25 EUR

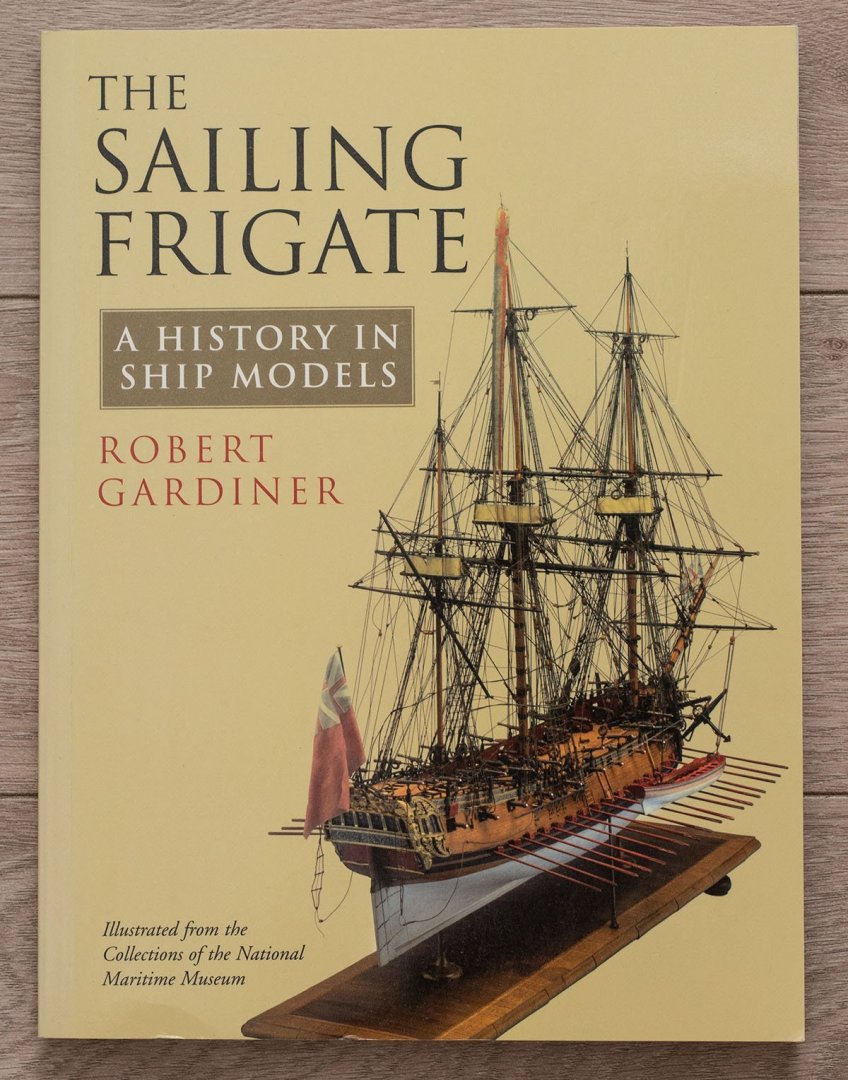

The Sailing Frigate: A History in Ship Models - 25 EUR

Ship Models (The Thomson Collection at the Art Gallery of Ontario) - 10 EUR

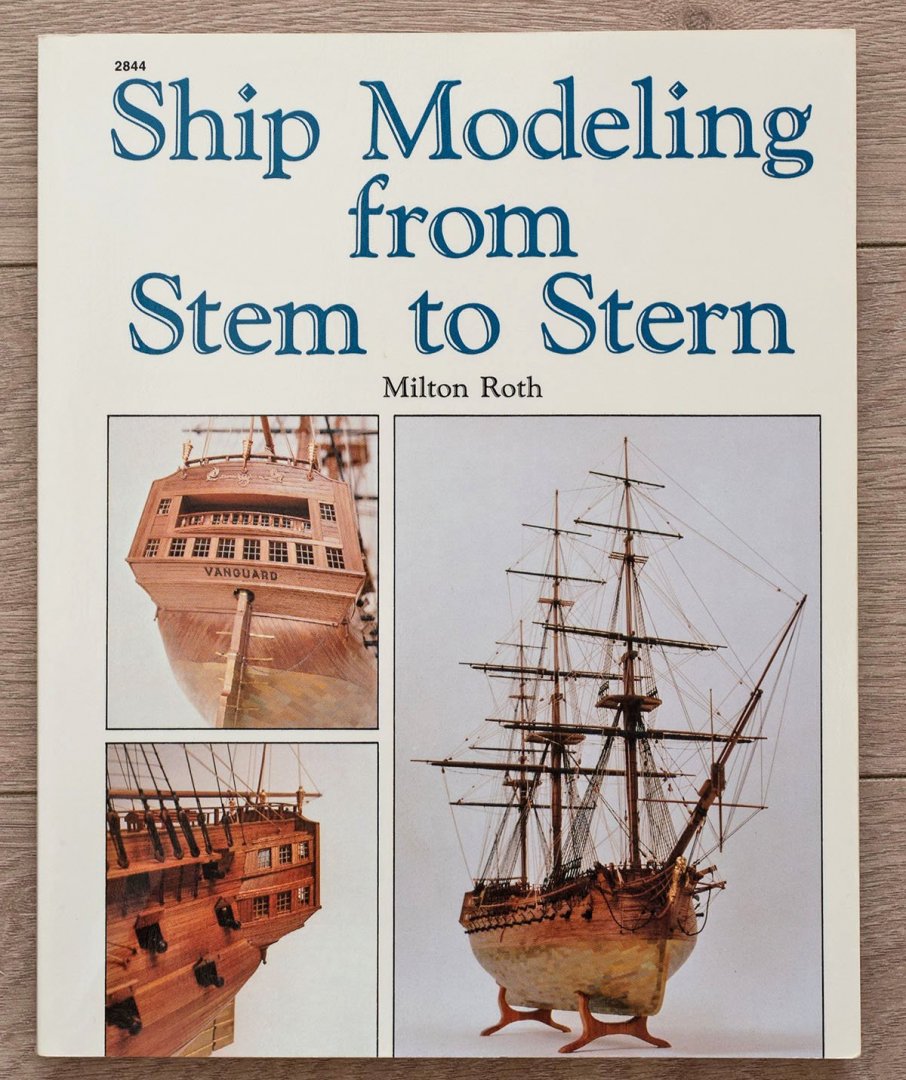

Ship Modeling from Stem to Stern - 8 EUR

Ship Modeling Simplified - 8 EUR

Naval Warfare : An Illustrated History - 12 EUR

Architectura Navalis Mercatoria - 10 EUR

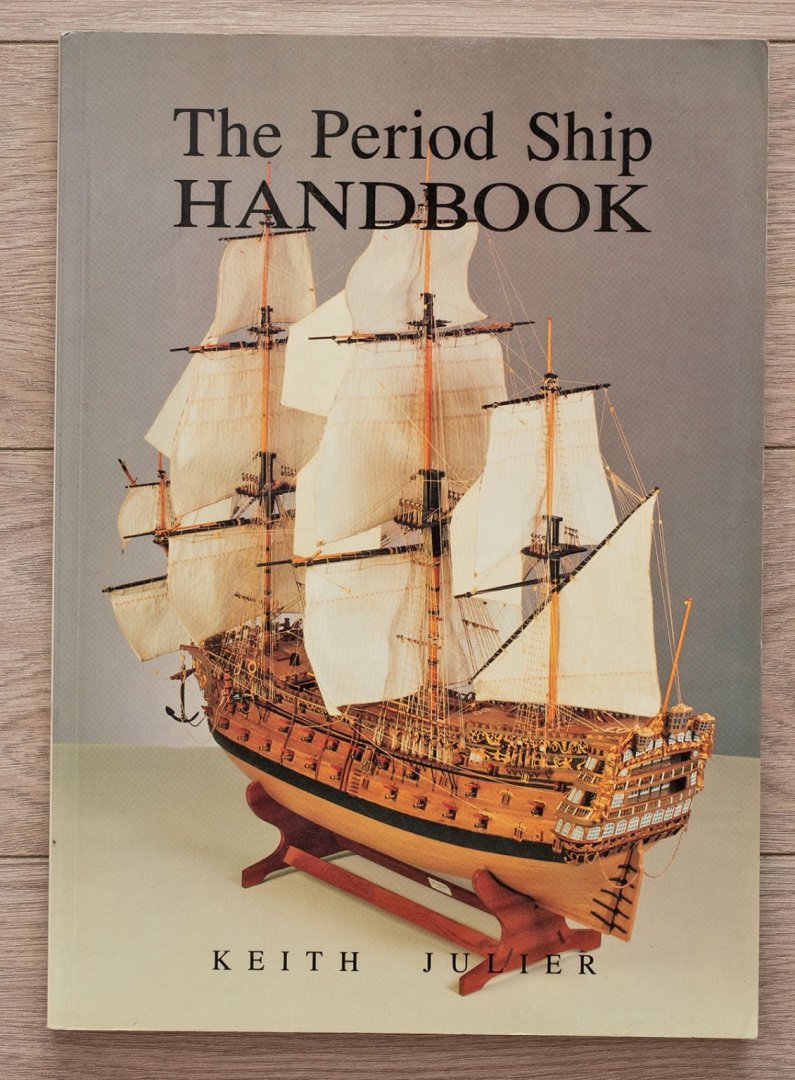

The Period Ship Handbook - 8 EUR

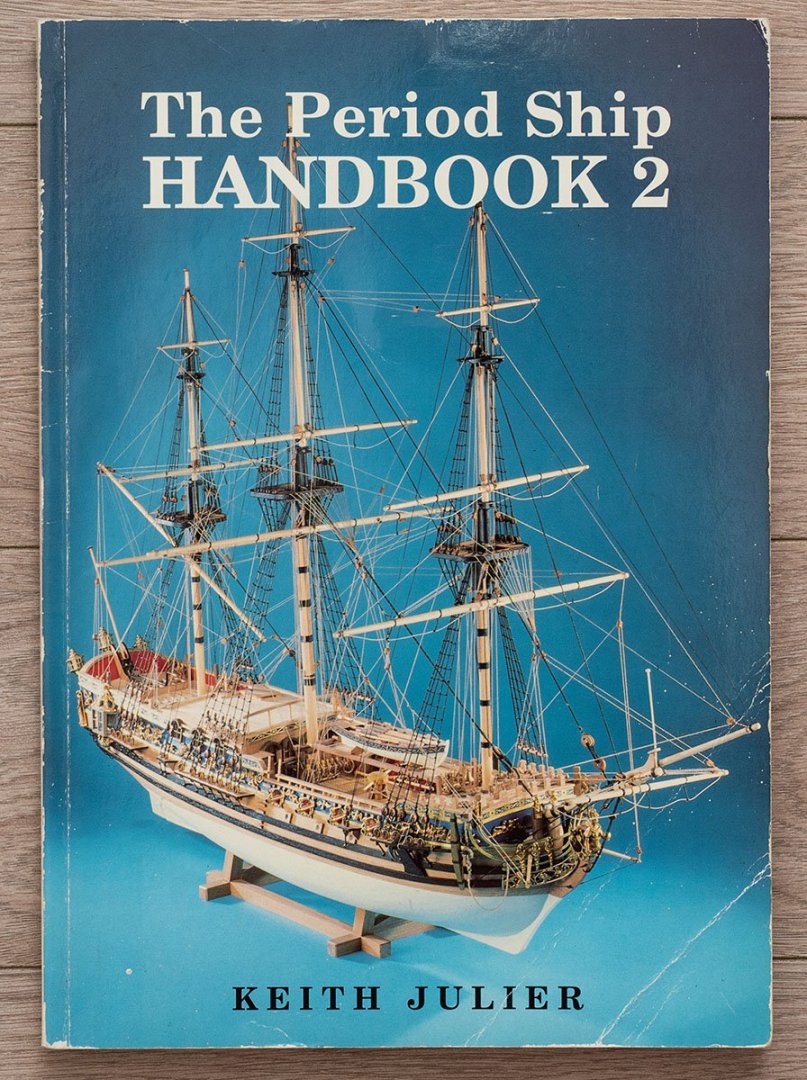

The Period Ship Handbook 2 - 8 EUR

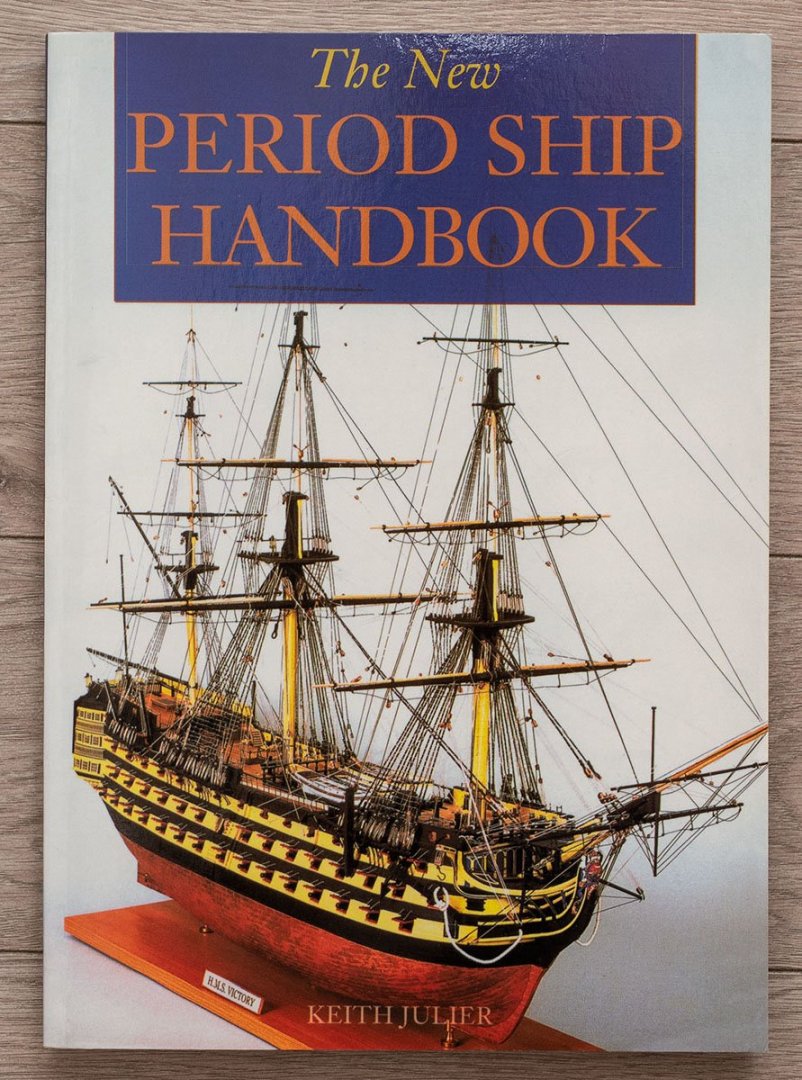

The New Period Ship Handbook - 15 EUR

Le gréement des navires anciens (1700-1850)- 15 EUR -

15 hours ago, VTHokiEE said:

That's a wonderful video, please tell me you need a very expensive machine so that I don't start window shopping 😉. I've used a friend's CNC before but for very basic stuff. I'd quickly go off topic if I start asking questions, but I can't not ask one. How do you maintain perfect accuracy when flipping the stock over?

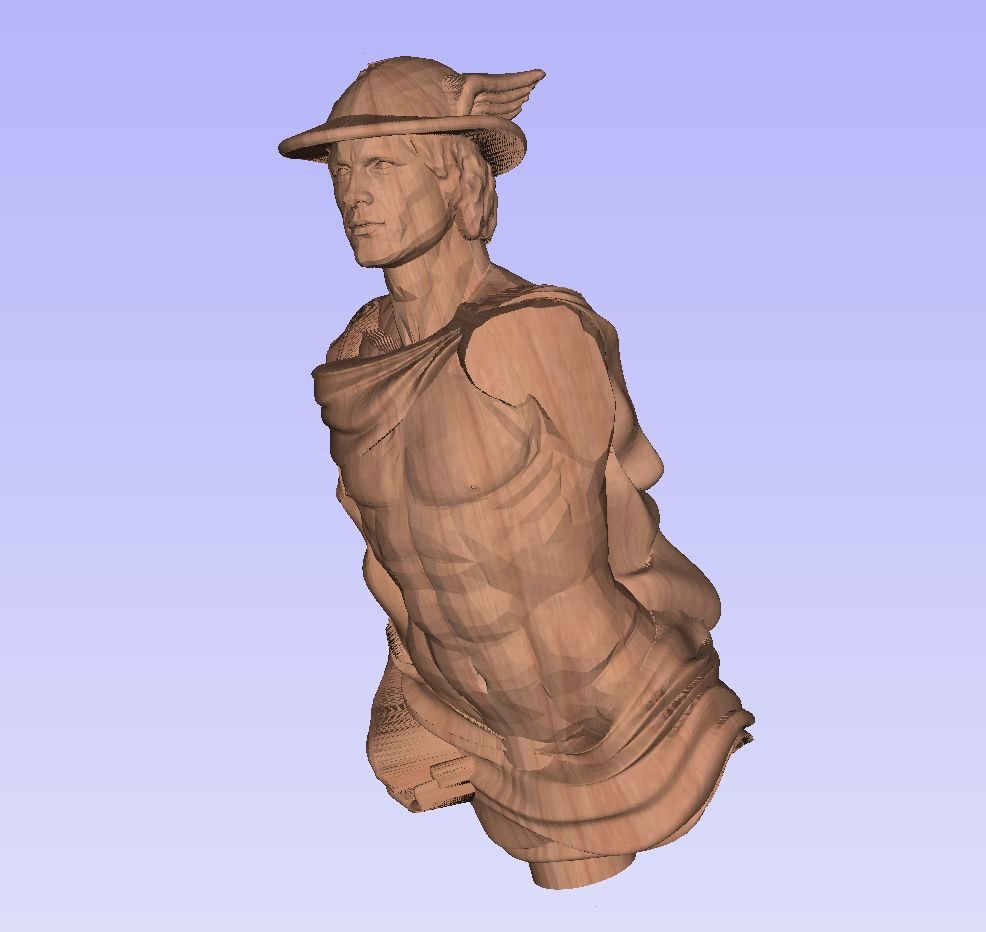

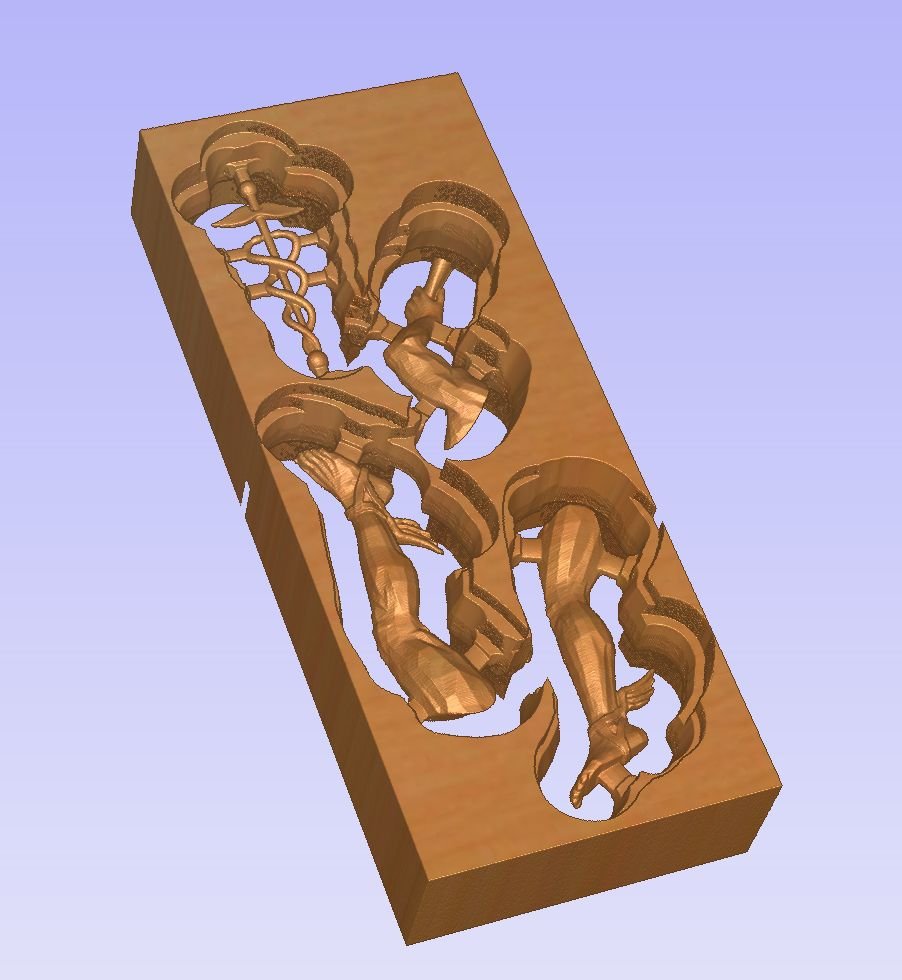

Thank you. Regarding perfect accuracy when flipping the stock over. Base material is milled to accurate block and XYZ datum is same for both sides of milling. Before flipping stock over small pocket was milled to machine table (wooden part) which assure perfect alignment.

Machine is better version of 3020 model with some modifications for higher accuracy, but still bellow 1000 EUR. If you have any questions I will try to answer you, no problems.

8 hours ago, Heinz746 said:Simon, this is amazing.

I would not hesitate and order from you.

Maybe for my next model.... 🙂

Best

-Heinz-

Thank you Heinz for nice words. Still learning but I am confident enough to do some work for others.

-

-

4 hours ago, mugje said:

That's amazing! I myself have a background in CNC but never worked with a 4 axis mill. The result is really beautiful! Especially at that scale. Maybe make a business out of it

Thank you. Will think about business , but need customers first

4 hours ago, VTHokiEE said:

4 hours ago, VTHokiEE said:That’s amazing, I’d love to try to learn how to CNC something like this (but the design along may stop me and having no experience with 4-axis either). It looks beautiful!

Thank you. If you look at my first post there was no planning for CNC...a Few years later 4 axis is no problem. I started with simple 2D stuff and slowly progress to 3D.... If you have any questions or need help, please feel free to ask.

3 hours ago, Vane said:Thats insane! That coin must be at least 10 times as large as a normal one…. 😉

Thanks Vene, I am glad you like it .

-

- mugje, captain_hook, JpR62 and 6 others

-

9

9

-

- BETAQDAVE, GrandpaPhil, JpR62 and 2 others

-

5

5

-

I must say that it is a true pleasure to follow your work Chris. Really high standards.

All of the kits looks beautiful, but will wait for a frigate (my dream is still Bellona), because I still have a lot of work to do with the brig Mercury.

Keep up good work!

- Murphy, chris watton, mugje and 3 others

-

6

6

-

Thank you etubino. I am glad you like it .

-

Hello everyone.

I didn' abandoded this build... there are just other things in life (kids, other hobbies, buying a new appartment,...)

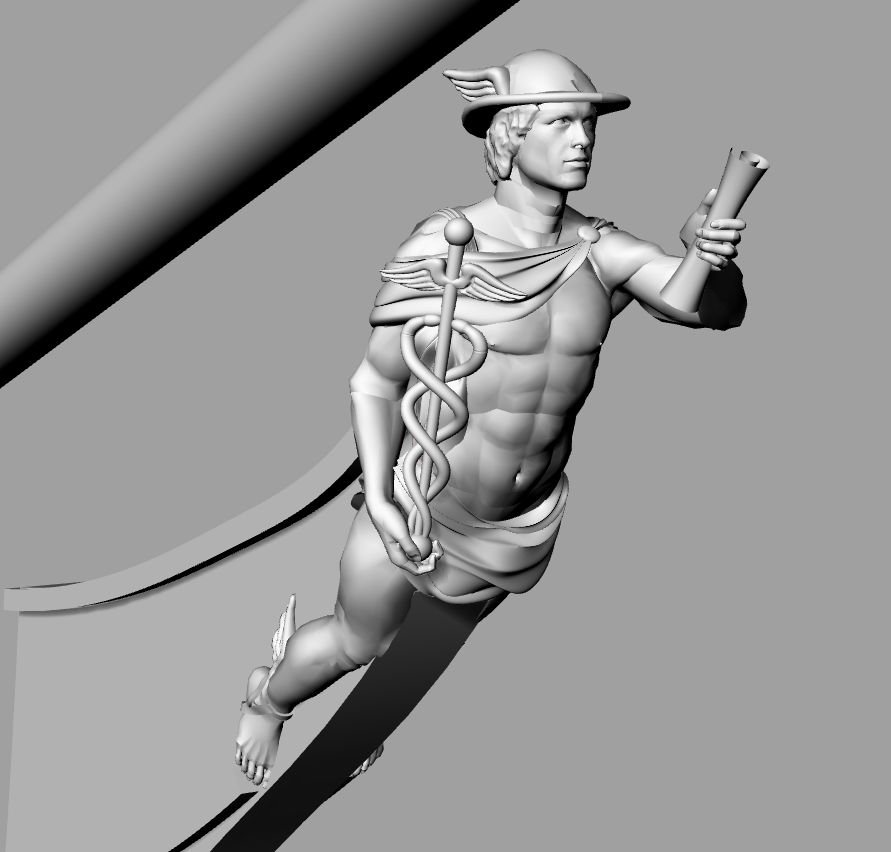

Because I work in automotive industry as qulity controller and CNC in part of my work (coordinate measuring machine) I could not resist to most challenging part of this build- 4 axis milling of head figure.

Currently I am still experimenting with different approaches , parameters, tools and will post progress...

-

Thank you all for your kind words. I am glad you like it .

-

Bellona is my favourite ship. I saw your model here on MSW a long time ago.

I would buy it, regardless of price. Count me for pre- order.

-

-

What about buying lumber and then resaw it at local woodworker? I do all this by myself and do not have big industrial equipment like most woodworker shops (only small Proxxon tools and bigger table saw)?

For example I bought 2 pcs. of Castello boxwood (approx. 250 x 80 mm and 1200mm in length). Before buying I saw pictures of exact lumber (not just some generic pictures). It is my lifetime stock and much cheaper then buying already sawn wood.

I know, maybe it is not an option, but just my thought. I highly appreciate your project(s) Chris and following with great interest.

Regarding Arkowood. I also buy from them and Boxwood which I received was some strange soft brittle wood, not boxwood at all. Pearwood was o.k.

-

14 hours ago, Thunder said:

Simon, where do you get boxwood from in the uk?

Castello boxwood from Timberline UK - http://shop.exotichardwoods.co.uk/ (I also buy Ebony from them )

English boxwood (for carvings) from Workshopheaven UK- https://www.workshopheaven.com

I buy lumber and then resaw it by myself.

Chris, on my build of brig Mercury I used pear and castello boxwood for planking and Castello boxwood for decks ( Brig MERCURY ).

This style is used by Russian modellers as Michael Bezverhny and Alexey Baranov. I prefer pear over cherry for planking, but that is only me.

-

As Dave, I also bought wood from Frank Horschig, good quality and consistent dimensions. Only "drawback" ( if it is?) is that he only speaks German (I called him, English is no-go), but in this times with translators I don't see that as a huge problem. Also he doesn't stock boxwood which I get from UK.

-

- ccoyle, chris watton, GrandpaPhil and 23 others

-

26

26

-

I heard for this a year ago and immediately know I need to build it when available (Titanic fan from childhood) . Release date is planned for June 2019.

For detailed photos please look here: https://www.world-in-scale.de/gallery/ships/1-200-rms-titanic-by-trumpeter/

- CDW, popeye the sailor, mtaylor and 1 other

-

4

4

-

- KARAVOKIRIS, Tigersteve, bruce d and 9 others

-

12

12

-

Great progress on beautiful ship Max. I followed all your previous builds with great interest, following this one with pleasure :).

Keep up good work!

-

- KARAVOKIRIS, egkb, Beef Wellington and 5 others

-

8

8

Mercury by SimonV - Amati/Victory Models - Scale 1:64 - 99% scratchbuild

in - Kit build logs for subjects built from 1801 - 1850

Posted

Hi,

due to other commitments, I have very little time for the hobby at the moment.

But I can give you a contact that could make it. If you are interested please contact me via "Message".