-

Posts

3,607 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yvesvidal

-

None of the above :-) The Discovery pictures are from my Android phone. Everything about the submarine is from an old Sony camera, unable to focus at short distance. Yves

-

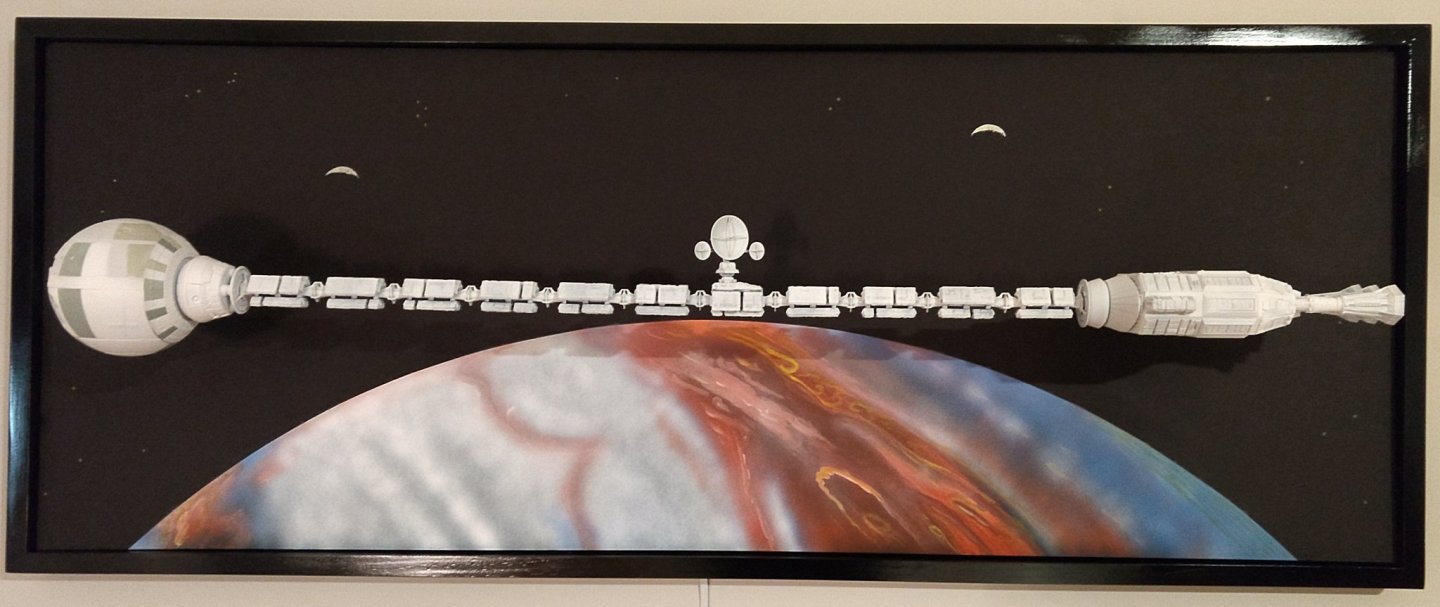

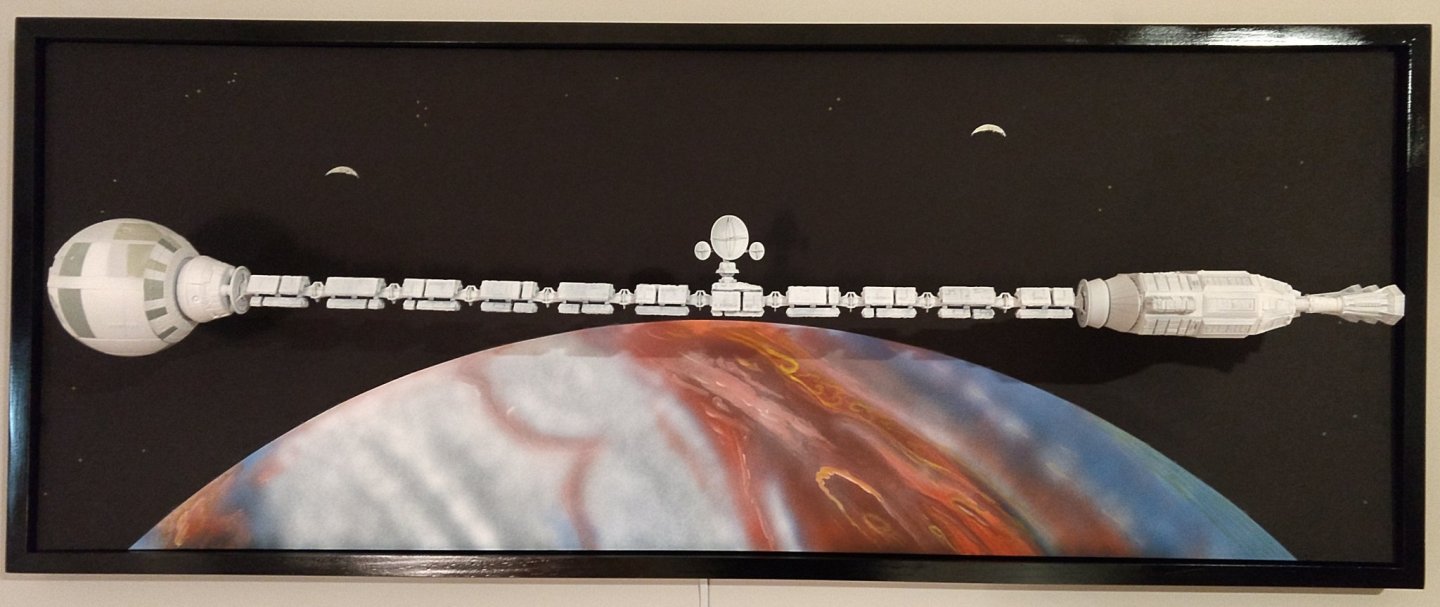

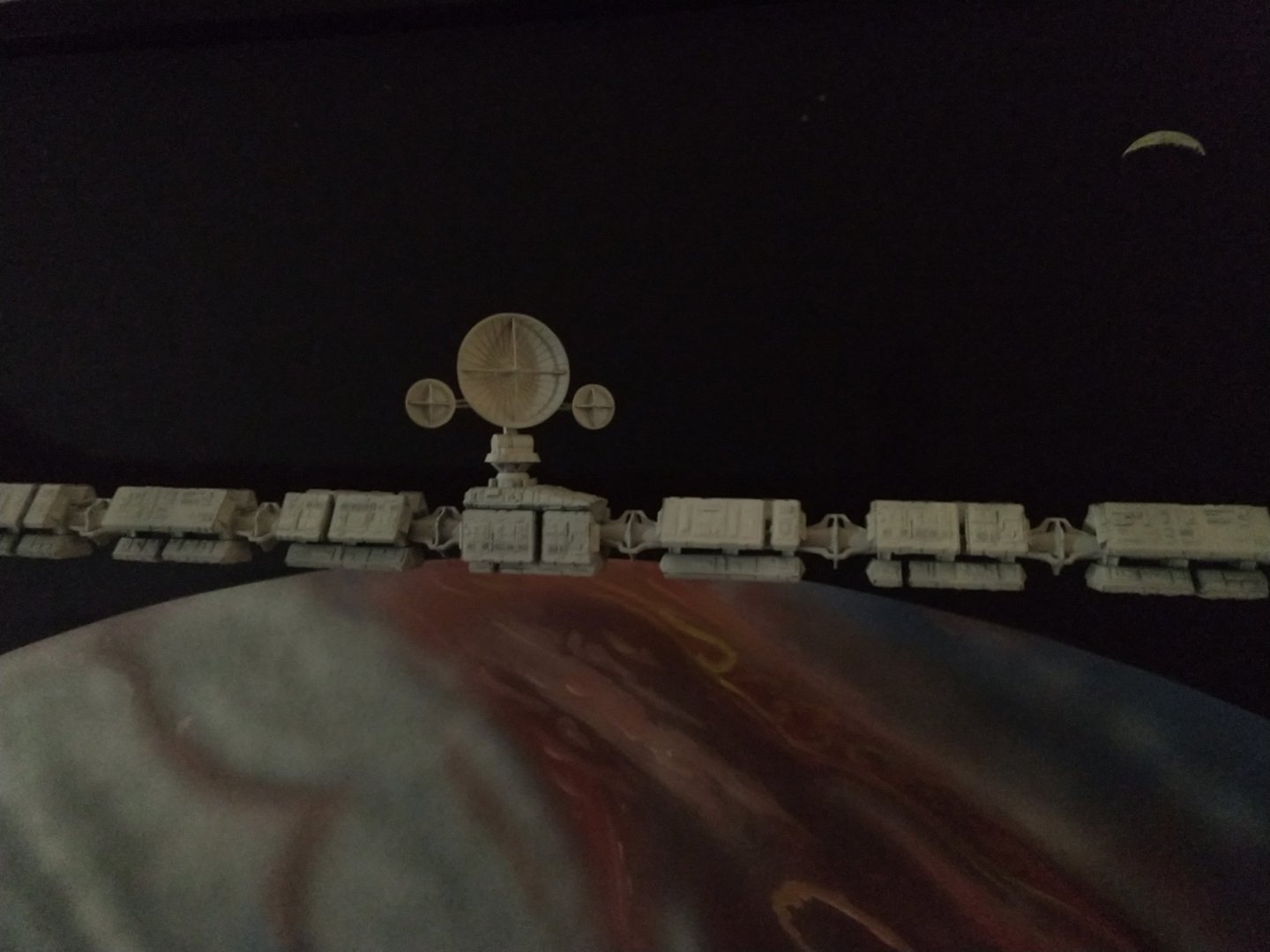

Well, the deep space "submarine" Discovery XD-1 is now completed: It will be a little while before I go back to the U-Boot but who knows..... the urge may come back, quickly. Yves

-

Superb work of patience and Love. Yves

- 171 replies

-

- artesania latina

- bounty

-

(and 1 more)

Tagged with:

-

This Spanish Economic Web site seems to imply that AL is "In liquidacion", meaning Chapter 11 in the USA, or "toasted" for the rest of the world: https://empresite.eleconomista.es/ARTESANIA-LATINA.html Yves

-

Re.... Hmmmmmm Why would a Spanish company go to HongKong? So unstable and so far away from their normal territories. Maybe the wife convinced him.... That could be a disastrous situation. Maybe the "Son" does not care.... Yves

-

YTL-45 Taiwanese Navy tugboat by Erik W - FINISHED - 1/350 scale

yvesvidal replied to Erik W's topic in Plastic model kits

Absolutely superb. You should move that thread to the Build Log area. Yves -

oh oh somebody is smuggling liquors in the bilge.... Yves

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

I think it looks perfect and very realistic. Yves

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

Coming along nicely. You are making great strides with this diorama. Yves

- 69 replies

-

- diorama

- Glad Tidings

-

(and 2 more)

Tagged with:

-

Great project Nils. When I was a kid, I was drooling on the Hjejlen kit in the Toulouse Hobby Shop (Ideal Models). I never got it but I always kept it dear in my heart. I am so glad you managed to find such a beautiful model and give it a second life. Yves

- 38 replies

-

- billing boats

- hjejlen

-

(and 2 more)

Tagged with:

-

Amazing. Thank you for the very detailed explanations on how you proceed to build the deck. Yves

- 168 replies

-

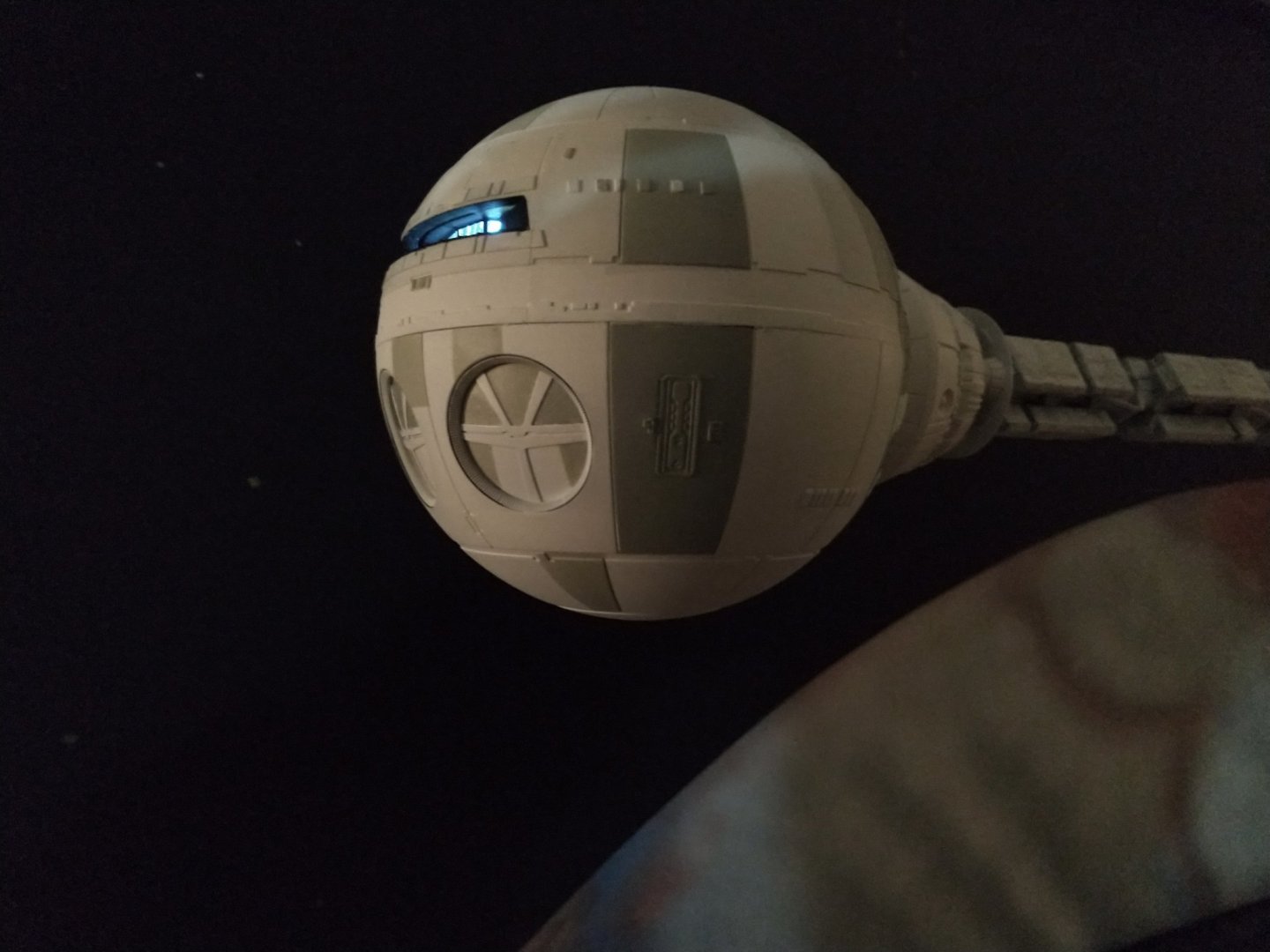

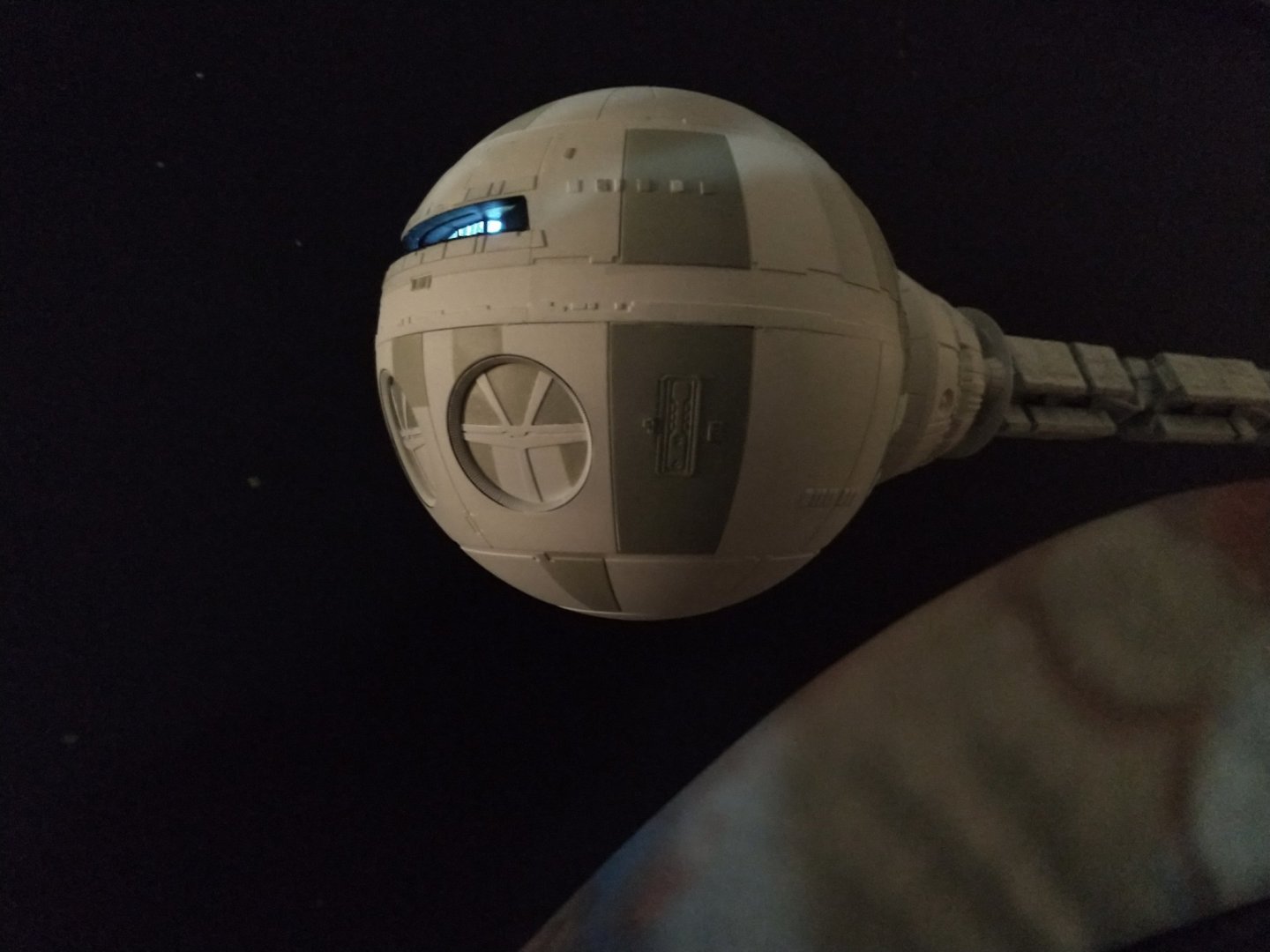

Clare, you are absolutely correct. Of course, it is not the module that triggered the neurosis crisis within HAL9000, but the prospect of loosing its individuality and intelligence, after reading the lips of the two astronauts. The second replacement of the module was just an excuse to terminate one of the crew, after taking care of the three scientist in hibernation. Thank you for your enthusiasm and please show us what you will be building on the subject of 2001. Yves

-

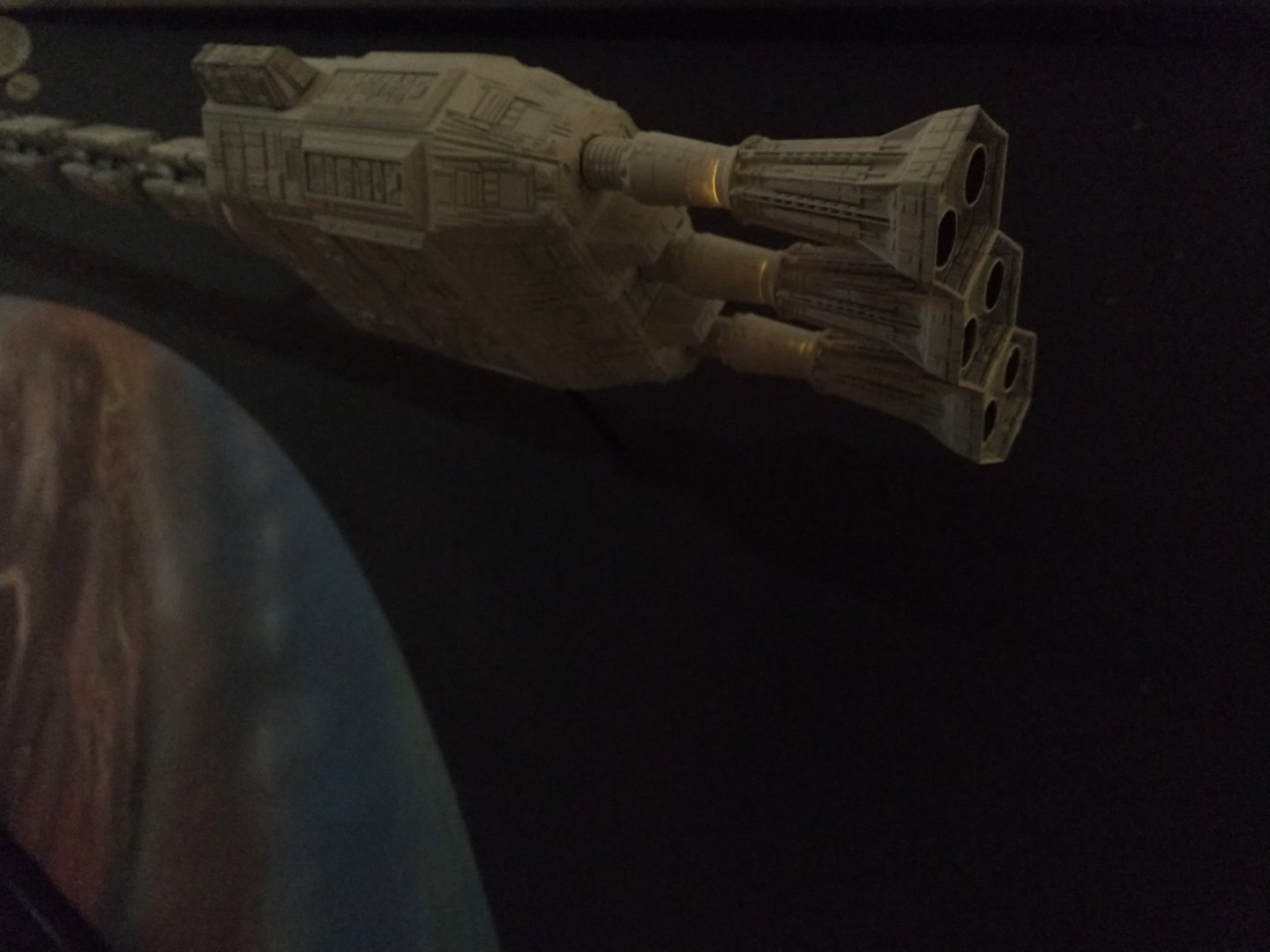

I hear you Hubert, and of course, there is no way my poor painting skills can compete with a picture from NASA. However, the seams between the sheets are not giving me complete satisfaction and I have tried to improve on my painting a little bit. Jupiter is not an easy planet to depict due to the variety of colors and the tumultuous atmosphere. Here is where we stand right now. I have also included a couple of moons partially hidden from the sun by the enormous planet in front of them: Yves

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.