-

Posts

3,639 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yvesvidal

-

Clare, you are absolutely correct. Of course, it is not the module that triggered the neurosis crisis within HAL9000, but the prospect of loosing its individuality and intelligence, after reading the lips of the two astronauts. The second replacement of the module was just an excuse to terminate one of the crew, after taking care of the three scientist in hibernation. Thank you for your enthusiasm and please show us what you will be building on the subject of 2001. Yves

-

I hear you Hubert, and of course, there is no way my poor painting skills can compete with a picture from NASA. However, the seams between the sheets are not giving me complete satisfaction and I have tried to improve on my painting a little bit. Jupiter is not an easy planet to depict due to the variety of colors and the tumultuous atmosphere. Here is where we stand right now. I have also included a couple of moons partially hidden from the sun by the enormous planet in front of them: Yves

-

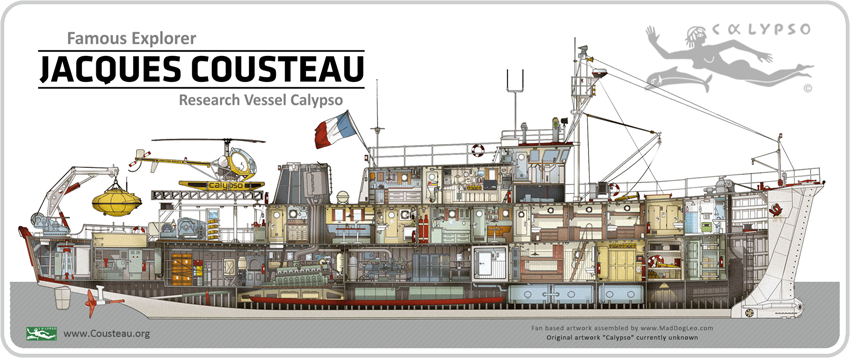

Sorry Luekutus, I am not trying to hijack your thread but found these interesting pictures of our beloved boat on the French sites. Arrival in the Harbor of Concarneau in France: Calypso in her way out of Concarneau, after the beginning of the restoration. En route to Turkey..... Arrival in Turkey: Renovation in Turkey: More details in French: https://www.bateaux.com/article/25424/renovation-de-calypso-un-chantier-avance YvesLa Calypso arrive en Turquie _ Mer et Marine.html

-

I remember the Hjejlen Kit from when I was a kid..... Long time ago. What a beautiful model that you realized. Yves

-

It is not easy to see, but the planks were actually nailed with metal rivets: Those rivets may have been made of aluminum to cancel all magnetic properties. Difficult to say. Interestingly enough, Calypso was supposed to be restored in Concarneau (France) and the picture above shows the very slow work that took place. The French government and the Cousteau Foundation started arguing and the ship has been basically rotting almost untouched until 2016. At that point, Calypso was moved to Turkey where the Foundation found a shipyard willing to restore the vessel. Apparently, the French Government refused to sponsor the reconstruction of Calypso, even though the ship has been attributed the title of Monument du Patrimoine National as is the Cathedral of Notre Dame and the Eiffel Tower. Recently, the Turkish naval shipyard was making good progress when a fire caught up and destroyed all the newly restored section..... Tough luck for that poor vessel. The Cousteau Foundation is not giving up and has decided to continue the restoration. You can read more details in the French Trade press. Yves

-

I am almost done with the vessel. There will be some pictures and some comments I would like to do about the kit and how I approached it. Hopefully, my mistakes can help other modelers to not fall in the same pitfalls. Before closing the sphere, it is recommended to paint the inside black or some opaque color. Let's remember that the sphere itself is used as a light chamber and as such, the white LEDs are blasting totally uncontrolled: First mistake (now too late to correct it: I painted using a brush, as I did not want to spray black all over the white external paint. That is not good enough. You need to spray (air brush) to really get something opaque and to prevent the light from seeping out. I have the black coat, the white plastic, the German grey coat and multiple coats of mat white. You will not believe it, but the light managed to seep through in a couple of tiny places. It can only be seen in complete darkness and not in moderate low light. The brush stroke are not as thorough as the airbrush and in retrospect, spraying inside with German Gray would have been better than brushing black mat paint. Below are a few pictures taken in full obscurity. On the right seam joining the two halves, you can distinguish a small light leak.... Some leaks also above the windshield. I probably will end up reducing the voltage of the LEDs, to tone them down a little. The entire vessel is now completed. It is quite difficult to picture it, due to its length. Doors are hand painted with a white background airbrushed. Second big mistake I did (and this because of the light circuitry in the sphere) is to close the two halves of the sphere AFTER painting. Big mistake. The reason is the two halves are not matching exactly and because of the rear bulkhead already glued, the lower half was protruding a little bit, forward. So, I sanded a little bit the rear part of the lower half to make it fit better in the front. In addition and that is the big problem, when gluing the two halves, I ended up damaging the white paint on the seams. I had to delicately sand (without butchering the painted panels), mask again and do some touch-ups with my airbrush. Not a pleasant job and rather nerve wracking. So, if you decide to build that model, follow the instructions, glue the two halves together, spray the inside opaque, do all the interior details that you want to add, glue the rear bulkhead and paint the whole sphere separately from the rest of the vessel (white plus panels masking). Think how you are going to connect your electrical wires ahead of times..... There is not much room and the steel rod does not give you a lot of latitude to play. Anyway, you can see on the next two pictures, the coupling of the two halves and the rear bulkhead. It is not too bad, but it could have been better. I am working at filing up the triangular gap and paint it carefully. Overall, it is a great kit with parts joining neatly and cleanly. The two halves are a little bit delicate to glue together and a few modelers have been complaining about them in other forums. In retrospect I did not have much of a choice but I should have handled the painting of the sphere as one block. What remains is to finish the background painting, and install the power supply on the frame. Stay tuned... Yves Yves

-

You should negotiate a contract with Model Shipways to provide them with high-quality parts for some of their kits. Yves

- 222 replies

-

- sultana

- model shipways

-

(and 1 more)

Tagged with:

-

There was one at the past 2019 Oshkosh air show. A real monster when you stand next to it. Unfortunately, I did not take any picture. I also had the chance to work while in France (IBM France) with one of the 12 French pilots that were trained on these machines by the US Air Force. The lad had some salty stories about the Avenger.... Yves

-

Interesting to see that modern technology on such an old vessel. What a contrast. Yves

- 222 replies

-

- sultana

- model shipways

-

(and 1 more)

Tagged with:

-

Try E-Bay (European sites ebay.fr, ebay.gr, ebay.it where these kits were sold) and Facebook Marketplace. With Patience, you may get the missing issues. At worst, you will have to fabricate the missing parts. Good luck. Yves

-

Echo by davec - FINISHED - cross-section

yvesvidal replied to davec's topic in - Build logs for subjects built 1751 - 1800

Chuck, I hope it will motivate you to resurrect the Cross-Section kit that you had in the back of your mind, at one time. Yves- 127 replies

-

I wish I could hire you to weather my Submarine.... Fantastic job on the Essex and what a collection. Yves

-

I am very happy that you are starting (actually resurrecting) this build, of such an iconic ship. I built the Billing Boat kit quite a few years ago, with my first paycheck from IBM, when I was still on the French Riviera. I built it for RC and my model has sailed on the sea (Cagnes Sur Mer harbor) and many lakes, including Boston, MA and Raleigh, NC. I have been thinking about renovating it, but have been derailed by many other projects. I never thought about planking the ABS hull, but you have a fantastic idea, there. Below is the presentation of my model, not a Build log as you will (hopefully) present us: Looking forward to seeing your progress. Yves

-

You are doing a very fine job. It is superb and very clean. I love the meshing.... Yves

- 171 replies

-

- artesania latina

- bounty

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.