-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

Hey Pete, Looks like we were logging at the same time. It's hard for me to wait also. Maybe I should mount the main before I start the fore mast. I’ll have to consider that. David Thanks. MSW seems to be a place to spread knowledge. Just trying to do my share. Bob

- 420 replies

-

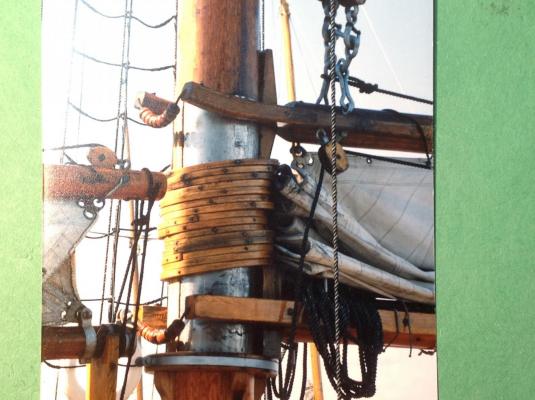

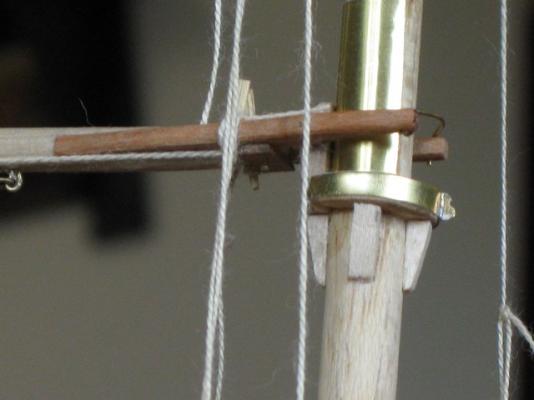

Michael, I just found this picture on Keith’s, “Swift by themadchemist”. At the top you can just see the bottom of the two blocks and how one is higher than the other. They are hooked onto the spectacle iron which is also higher on one side than the other. The links, alowed to move on the round part of spectacle iron, straighten everything out so the jaws pull up square. Bob

- 420 replies

-

Michael, According to Chapelle’s book multiple blocks were needed to lift the heavy gaff and sails. Because the pull was all from one side that side would be pulled up and the jaws would cock sideways and jam against the mast. The spectacle iron and links helped the jaws to stay square. Thanks Popeye, I keep telling myself, “I will put it on the boat.” “I will put it on the boat.” “I will put it on the boat.” Bob

- 420 replies

-

Dee Dee, I really don’t know. I never tried with PVA. But in my experience when PVA dries it is still flexible like hard rubber. (This probably depends on the brand.) Epoxy resin, on the other hand, even without the glass will set up hard. If all you are doing is to glue the planks together PVA is fine but if you want to give the planks body to resist the pressure of sanding, I would use epoxy. One more thing. If you sand through the wood planks epoxy will still be hard enough to paint. Bob

-

I don’t know how anyone turns masts in a lathe. The main top mast I just made is .156 (4mm) dia and 9” (223mm) long. If I put that in the lathe the center would vibrate off center so much I would not be able the put a tool against it. I use my lathe for parts under 4” (100mm) long. Bob

-

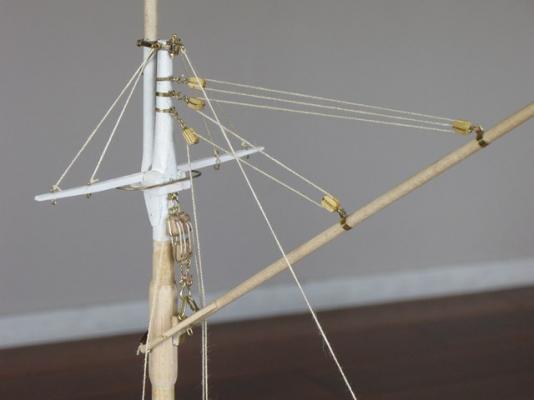

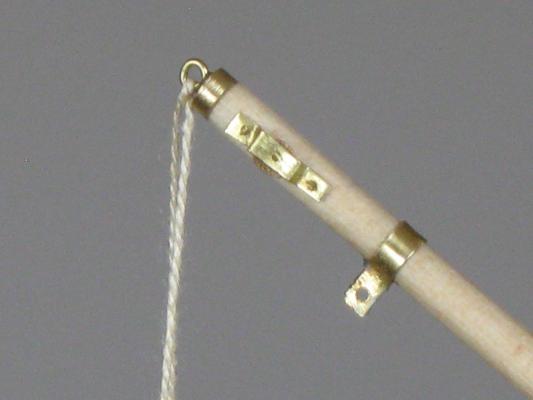

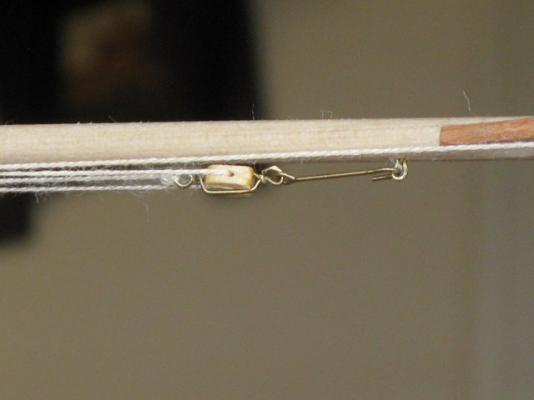

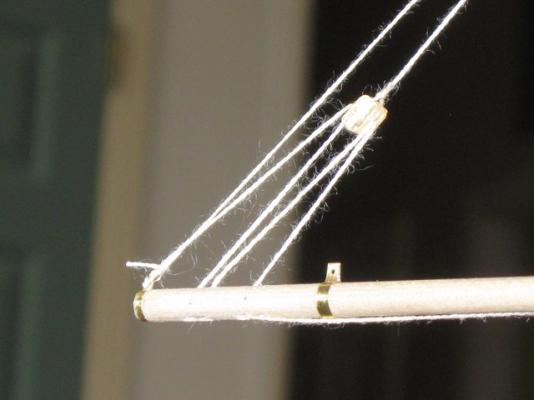

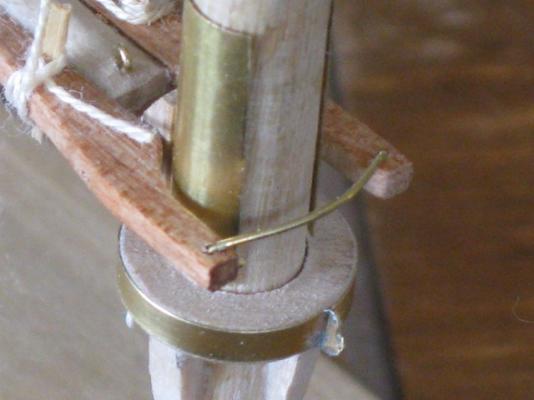

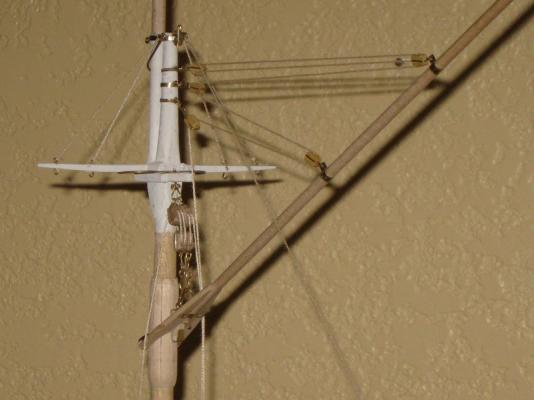

So many are following this log and saying such nice things about my work that I would have a hard time naming you all, so let me just say thanks to all entries and likes. And to you new viewers, welcome aboard. Just a word about the brass, all blocks are stropped with .020” (1” scale) as well as hooks and most eyes. The crosstree support is .030” wire, annealed and flattened in the middle and ends. All sheet brass is .005” and cut with scissors. Now I’m off to do the same with the fore mast. Bob

- 420 replies

-

Part three: Crosstree area. Metal work. Gaff halyard blocks are mounted with open hooks. Throat Halyard. Shackled at the top with a heart iron and at the bottom hooks into the spectacle iron. Bottom of boom showing the eye for the sail throat, also a good view of the spectacle iron. At present the parrals are just tiny beads. The end of the gaff fitting for peak of main sail, side block for the top sail clew halyard and an eye for the gaff vang. That’s it for now. If anyone wants more, just ask. Bob

- 420 replies

-

Part two: Front block of the boom guy. When going down wind this would be fastened forward on the rail to prevent jibing. Aft boom guy block and upper sheet block. End of boom showing band for sail clew and topping lift rigging. I'm trying to break this up so it makes sense. More to follow. Bob

- 420 replies

-

Keith, this one’s for you. First, thanks for your appreciative words and wanting to know more. For the size of the blocks, the sheet blocks are 18”, the throat halyard blocks are 15” and all others are 10”. Now on to the pictures. The admiral wanted lots of gold color on the boat, so the hoops are slices of tubing. Since the boom does not travel up and down so it is captured with a simple bail. There should be a plate on top of the shelf for the boom to ride on. Pins are just splinters for now. More to follow. Bob

- 420 replies

-

Thanks to all of you who thought the rigging of the main mast separately was a good idea. To me it was a necessity. Looking at rigging the whole boat became too overwhelming. This was a way to break it down into smaller parts that I was able to handle. Nils, you’re right there were parts that were changed as I built. For one thing, on the peak halyard, I wanted to have a jig halyard coming from the top mast block but it pulled the block down too low and crossed the lines. So I left it with a single halyard. Bob

- 420 replies

-

Here I am looking at the exquisite interior of a fine yacht when all of a sudden a giant puts his thumb right in the middle of it. Beautiful modeling. Bob

-

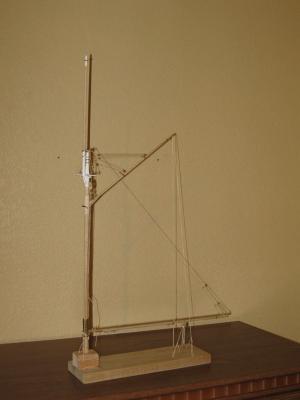

After many hours of research, mostly in reading and re-reading the last half of Chapelle’s book on fishing schooners and many hours on the web. I finally think I know the rigging of a fishing schooner, at least the way the Lettie G. Howard will be rigged. I also decided that the saying, ‘Each part is a model’ is true. So I made a holder for the main mast. I mounted the fittings and pulled thread through the blocks to check everything. When the mast is on the boat, the thread will be replaced with rope. I will also add the shrouds at that time. So here are pictures of the main mast, boom and gaff. Relooking at the pictures I just realized I need to add fairleads, one or two on the boom and a couple at the crosstree. I have new respect for you who build the square rigged ships with all their rigging. Bob

- 420 replies

-

With a closed bulwark the capstan bars were laid in up turned hooks mounted on the inside of the bulwark. Mainly they have to be out of the way of being snagged by lines swinging past. Bob

-

Thanks for letting us know about this. It's great. Bob

- 36 replies

-

- bermuda sloop

- sloop

-

(and 2 more)

Tagged with:

-

Nice looking transport cart. Now you're just having fun. Good for you. Bob

- 2,214 replies

-

Nils, Just to let you know, I'm still watching and dreaming that someday I will be able to do half as well. Bob

-

If the deck is not on yet, epoxy the inside to stiffen the planks. Bob

- 80 replies

-

- Americas Cup

- Endeavour

-

(and 1 more)

Tagged with:

-

Ah. She’s a lovely boat and looks great in the water. Now that I see her I agree that black was the way to go. With all that weight as ballast make sure to cradle her well when you lift her from the water. Boat hulls are designed to take pressure from the outside not the inside. I have seen weights open seams. Bob

- 2,214 replies

-

You should be proud of a boat well built. Congratulations !

- 296 replies

-

- herreshoff

- buzzards bay

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.