-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

Thanks Popeye. We all need help now and then. Bob

- 420 replies

-

WOW! I thought I was the only one that had more trash than boat. Bob

- 89 replies

-

- scottish maid

- clipper

-

(and 2 more)

Tagged with:

-

Well done. You make it seem so simple. Bob

- 89 replies

-

- scottish maid

- clipper

-

(and 2 more)

Tagged with:

-

Wow, it’s a three dimensional jigsaw puzzle of a boat. Oh, what fun. Bob

- 36 replies

-

- black pearl

- bottle

-

(and 1 more)

Tagged with:

-

Every part of this boat is so well done it would be nice to have that “I shrunk the kids” machine to become small enough to sail her yourself. As for sail winch I saw a 5 foot boat, with big sails, where the owner used a reversing screwdriver/drill with a torque control for the winch. I'm sure you'll work something out. Bob

- 2,215 replies

-

Russ, Michael, David B, S.os, John, Elia, Thank you all for the kind words. And thanks to those who click on “like”. I know how it is to not know what to say. Michael, Thanks for showing us how to make the flare on the pipe. I rounded the point of a nail and used that as the chasing tool. Not as nice as your tools, but it worked. S.os, Yes, I like working boats. Even when I sailed I always bought older boats. I don’t know if that’s because I feel they should look lived in or if I’m just not careful enough to make them look new. Bob

- 420 replies

-

The centerboard suould go down until the upper back corner is almost to the keel. Bob

- 86 replies

-

- muscongus bay lobster smack

- Midwest Products

-

(and 1 more)

Tagged with:

-

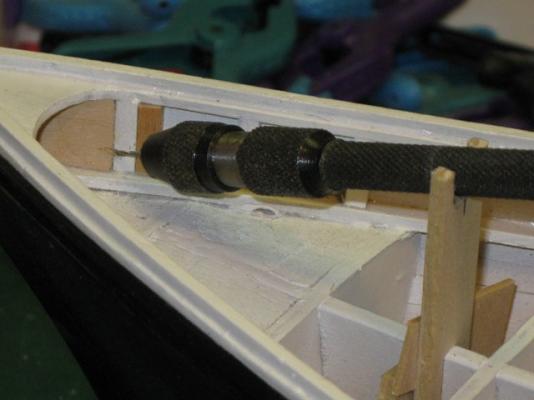

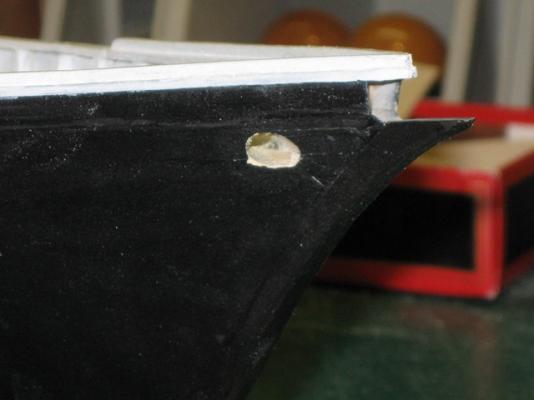

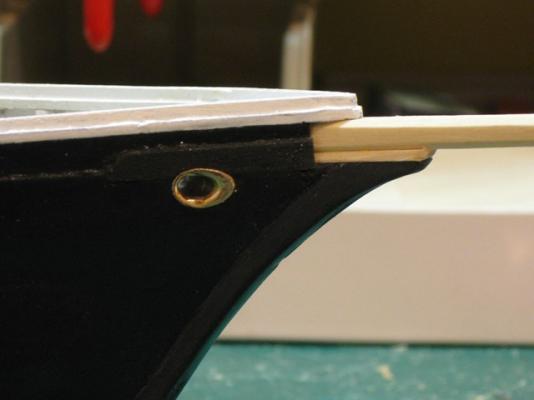

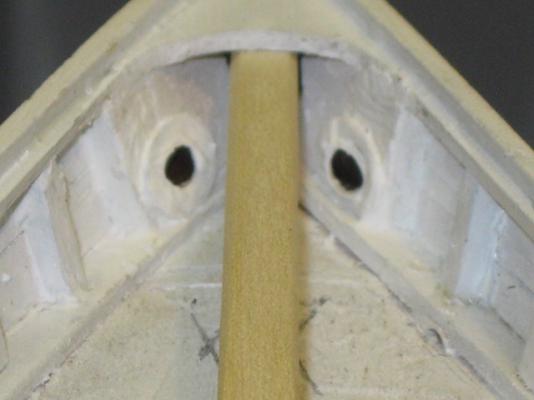

So now it’s time for the hawse holes and hawse pipes. One of the old pictures is looking straight down the hawse holes and it is taken from the top of the sampson post. I placed a yolk at the sampson post location and used it to guide the drill. I enlarged the holes to accept a brass tube 9” scale diameter. After flaring the outside, the tube was cut to length and an oval washer soldered to the inside. The last two photos show the bow sprit temporarily in place. I have to admit there was a problem the old picture was of the Lettie after the fore deck was raised. But my model has the fore deck lowered. So I drilled the hole in the wrong place and had to raise it to put it into the correct location. All good now. Next the chain plates. Bob

- 420 replies

-

Nils, Congratulations on a fine build. It has been enjoyable watching you build the Gorch Fock 2. Thank you also for all the information and help you have shared with us during the build. Bob

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Michael, I agree the curved grain piece is the way to go. It will blend in better than the laminate. Bob

- 2,215 replies

-

If the centerboard is down raise the sail. If you furl the sails raise the centerboard. Bob

- 60 replies

-

- muscongus bay lobster smack

- first build

-

(and 2 more)

Tagged with:

-

Ah that hawsehole lining looks just right. Last night as I lay in bed I came up with the same method, but thanks for showing how first, now I know it will work. What metal is the pipe it looks too silver to be brass? I will be using 1/4” brass. Bob

- 2,215 replies

-

Tom, I remember how you did that on the Vinal Haven and it turned out looking very good. Michael, sounds like John did it first but he didn’t tell us which boat he did it on, and anyway I was hoping to follow your lead. Bob

- 420 replies

-

Drafsight v's Autocad LY2002

captainbob replied to michael mott's topic in CAD and 3D Modelling/Drafting Plans with Software

If you are having that kind of trouble you should contact Dassault Systems, the same people that make SolidWorks. They are the ones the put out Draft Sight. Or talk to your IT person at work you use it there with out problems. I make all my model drawings in Draft Sight and have never had any problems. Bob -

SS Vinal Haven by TBlack - FINISHED

captainbob replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

It took you a lot of thought and work but you built a boat to be proud of. Well done. Bob- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

Popeye, I wish that would work. The hawsehole goes through the bulwarks almost parallel to the keel, so the outside shape will have to be an oval. You can also see the wood that will have to be added above the hawsehole. Bob

- 420 replies

-

S.os, I agree with you about the clock, but at present . . . Mark, thanks for the kind words. Lawrence, I know about one boat at a time. That’s the way I build also. I’m sure the Annie will wait for you. Thanks, Popeye the black paint help to mask the bad places. David B, I agree. It was the lines that grabbed my attention. Now that I’ve said all that, I need to mess things up. I just realized that I forgot the hawseholes. There is extra wood above them and the drawings say they are bronze hawseholes. Now let’s see, first I'll have to . . . Bob

- 420 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.