-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

Russ, Michael, John, Walt, David, Keith, Nils, Thanks to all of you, and thanks to the likes. Long ago I was told by another modeler, “If your scrap bin doesn’t outweigh the boat you’re not trying hard enough”. As for the silver solder I used to enjoy it and I’m glad I was forced to use it again. Bob

- 420 replies

-

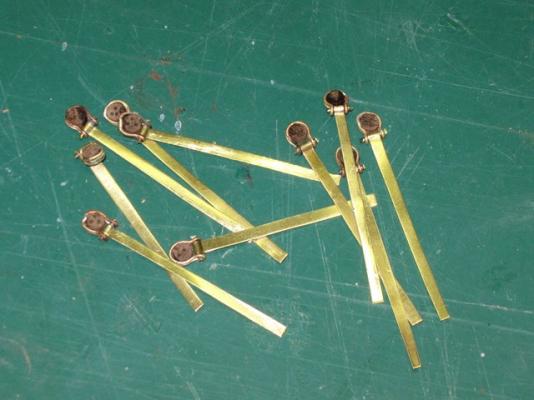

Ah, the problems we create for ourselves in this joyous game we call ship modeling. Now I needed to make the chain plates and deadeye straps to go with the deadeyes I made last week. That was the problem. I tried to soft solder the wires for the deadeye straps, but as I bent the wire around the deadeye the solder joint broke. I needed to silver solder. I had not silver soldered since I was a teenager. So I dug out a torch, some silver solder and some flux and melted a few inches of wire. Finally, like riding a bicycle, the memories returned and I soldered the rings. I bent the wire with the solder spot in the wrong place. Placed the wire around the deadeyes and fastened them to the chain plates. The more I looked at them the more I didn’t like them. The solder spots were harder than the wire and did not bend the same and as I forced them around the deadeyes the deadeyes started to fall apart. What a mess! So, as I had told so many others, it was time to start over. I went back to the start and made a new jig to drill the deadeye holes. Rather than evenly spaced I placed the holes, two on the diameter and one at right angle to them. I also made them out of harder wood. This time when I soldered the wire I used less solder. And when I bent the wires I was more careful as to where the solder spot was. These were much better. These I can use. So I did. I mounted them with only one pin at this time so they can pivit to the correct angle when I do the rigging. Then I will put in the second pin. The first two pictures are of the bad parts. Bob Solder spots in the wrong place. You can see the flats on the wires crushing into the deadeyes. Good parts Jig for shaping straps Good assemblies Mounted

- 420 replies

-

I’ve never built in plastic but I’m enjoying watching your Arethusa go together. Well done. Bob

-

What nice curves she has. Please show us some more pictures from different angles. Bob

- 86 replies

-

- muscongus bay lobster smack

- Midwest Products

-

(and 1 more)

Tagged with:

-

Xebec by mij - FINISHED - 1:60 scale

captainbob replied to mij's topic in - Build logs for subjects built 1751 - 1800

Looks like the eagle is about to catch the rabbit. Poor rabbit. Bob -

Walt, Thanks for letting me know about the pictures. I think I have them fixed now. Bob

- 420 replies

-

Congratulations on another beautiful ship. Bob

- 70 replies

-

She's looking good. Can't wait to see her in the bottle. Bob

- 36 replies

-

- black pearl

- bottle

-

(and 1 more)

Tagged with:

-

Nils, I'm glad after 10 years you remembered and finished her. You did a super job. Bob

- 70 replies

-

Nils, Ah yes, why? I could have bought them off the web for a lot less than the time I spent making them. I guess there are two reasons. First I didn’t have any the right size and didn’t want to wait to receive them in the mail. And secondly it was just to see if I could. Paul, glad I can be of help. Bob

- 420 replies

-

I found this plastic syringe at a drugstore in the baby supply area and have used it for years. I fill it with Titebond II. I had to cut a little off the tip to get the size I wanted. The orange cap is a protector from the end of a wire. Bob

-

That's a lot of sail for such a small boat. When finished, how long will your nmodel be? Bob

- 144 replies

-

- corsair

- bermuda boat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.