-

Posts

1,002 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wintergreen

-

For someone without artistic ability... I would say that that carving is p-r-e-t-t-y d-a-n-g g-o-o-d! I think you should reconsider your abilities Toni ;-)

- 1,449 replies

-

Nice looking vessel. Count me in as a bystander :-)

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

As all your work, stunning. But, rinsed under running water... then you are very sure the yard wont bend when in water. Straight grained should not be a problem though, but there could be surprises. I guess one should consider which wood, and how it was milled before opting to soak tiny long structures in water. Oh, and btw, Santa brought your first Naiad vol. A very nice piece I must say!

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

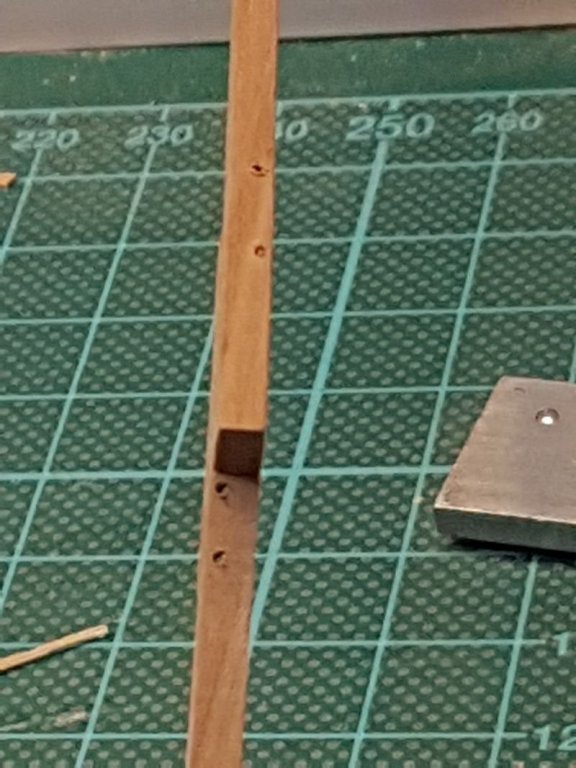

As per requested, the day was spent in the small ship yard ;-) What did master accomplish? Some much needed clean up of some rubbish in the corners of the shop. Assembled the keel, stem and stern. Managed a decent tapering of the structure. And also something to be not so overly proud of, though I thing it happens to all of us... For the assembly I started with the fore knee and glued it to the keel. Then I faired the surface that faced the stem. My template was faired alongside this to get angles of stem and stern fairly close to spec. The aft part then, sternpost and knee glued together. Some minor adjustments and it was glued to the keel. Drilling for bolts were done on freehand (which can clearly be seen in pic 1) with my bulky Dremel. Note to self: Save up for a Proxxon multitool and drilling station. Tapering of the structure was accomplished with another annealed mat knife blade. Sometime during the day I recognized that my floor was a mess so I wiped. In hindsight I would have benefited from looking if any of the pieces had gone astray before I wiped the floor. Find the anomaly... Note to self 2: Keep small parts contained in something (anything!) Apart from that minor setback I'm fairly satisfied with the day. Til next time, ta!

-

Vaddoc, thanks for the comment. I plan to compare the sapwood of apple to birch. I've read that birch is a good wood for planking models. Will do tests later of steaming and bending, as well as to see how they keep their edges sharp (basically wood density). Stay tuned.

-

I will lay my vote for the Chewbacca.. sorry the Chebacco. Mostly because, as some stated, there are numerous kits of those with cannons. Then I'm not overly fond of the Dutch lines, they don't appeal to me (Note, very personal opinon!) Therefore the other work boat. Nice lines, fair amount of detail, manageable size. But that's only my to cents.

-

Haha John, no it sits steady on terra firma. At the moment I'm refurbishing the galley. The old owner /builder merely gave the interior one slush of varnish...

-

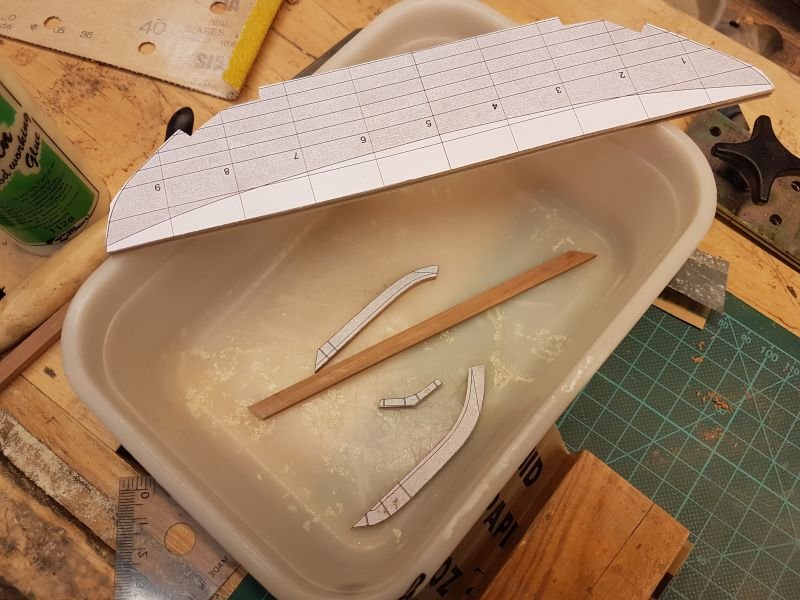

Hi again all, another update. The days I don't have to commute to work I save three ours of my life. Today I spent those hours at the yard :-) Work continued with forming the pieces. First by file in my vice and then at the disc sander. Yes, it's the same lathe that doubles (or triples) as thickness sander also, except being a lathe... Vaddoc, I now know what you mean with the glue. It took a thorough wipe with methylated spirits to get the glue off. The glue can come in handy in other applications perhaps. When all parts were ready, the rabbet was next. I've seen from other logs how the builder has shaped a mat knife blade or similar to scrape mouldings and stuff. The rabbet here is quite straight forward, just some different angles, that's it. As a first attempt the blade was squeezed in one of my clamps. If examined closely it can be seen that the rabbet takes a shortcut over the most acute bend on the stern. It was due to the clamps being too clumsy. Also, the tip of the blade broke off leaving an uneven rabbet as well. (funny, what are my shoes doing in that picture...) Option two. Two mount plates held together with wing nuts. Fairly easy I'd say. To fix the blade the torch came out to anneal it. After sharpening to an angle of ca 30 degrees the torch came to work again. This time the blade was quenched in water to be hardened again. It is a bit fiddly to set the cut up, but then it is just to scrape away. Now I appreciated my two sets of boat pieces because I fiddled a bit too much with the blade on the first set and had to go over the rabbets a second time. With the other set I will be meticulous in setting the blade and then do all the rabbets at once. For the weekend I might take a trip to my real boat or I might choose to stay at home in the yard. What do you reckon?

-

Thanks for the comments and likes :-) Denis, glad you remember the Regina project. She sits nicely in her display case. And re the drum, there was never an issue with the drum going into an orbit. It was held in place by the dubbs (? maybe they are called something else ?). But a coned shaft is of course a better option. Vaddoc, the apple is two colored. Outer wood is much paler. I will take a picture to show you. Also, thanks for the heads up on the glue. Guess now that I've bought that expensive bottle I need to use it... And the boat (or type) does not have a centerboard. I cant think of any traditional Swedish boat that has that. Instead lead or iron ingots as ballast. Approx 500 kg for this 22 footer. Edit: Picture of the apple wood.

-

Hi Mark, thanks for the comment. No, the bowsprit is unsupported, so yes, bends under pressure from the rig. But, easy rigging, easy taking down. I guess it sails like most boats with sprit sails, slightly better than a square rigger.. no, really, I don't know, only that with this kind of rig going upwind is not the favorable direction. That is why there will be oars also.

-

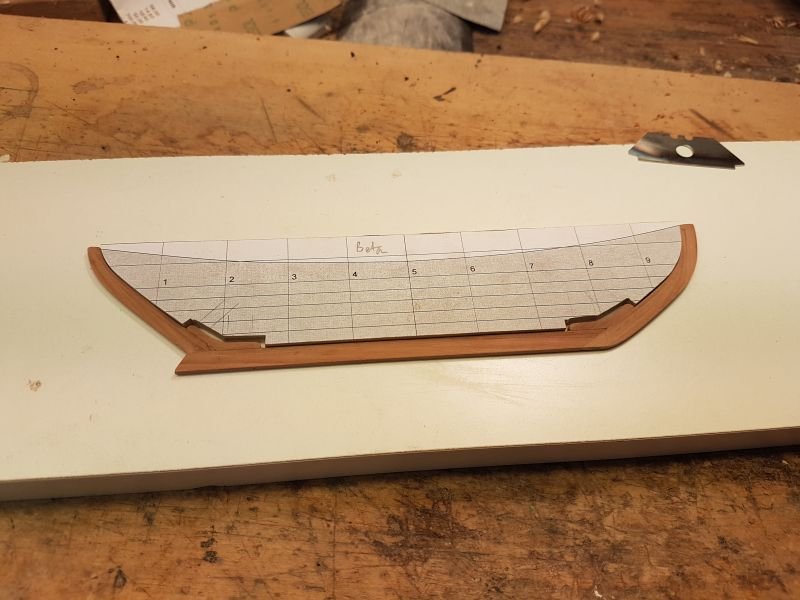

Ahh...sawdust, finally! Yes, John, I use the shop vacuum also. It's just that it is so noisy. Guys, thank you for the likes also. After building the thickness sander, which by the way, works really well. Note to self.: I do need to countersink the machine screws a bit. The ones that hold the wedge. They scarred the wood, not too bad, but still ugly. I went down to the hardware store and bought a ridiculously expensive spray glue. Well, it worked like a charm, so maybe, just maybe, it was worth the expense. This glue is intended for gluing the printouts to the wood. As can be seen in the first picture. With them glued, I spent the better part of 30 min rummaging about to find a tool holder for the scroll saw. I knew it was in a bad place... finally found it. Next 15 minutes was spent trying to remember how to set the darn thing up. Google told me in the end. While letting the scroll saw eat wood I pondered about how to file and sand those tiny little pieces and stopped myself right there. Like you eat an elephant of course. One at a time. See next picture. Ed wrote: "when fatigue sets in... stop!" which what I did next. Before the halt, I had managed to release all parts from the slab of apple. Picture three. One might wonder why there are two of everything. Well, to my knowledge, practice makes perfect. So, one set is for practice, and then I can do it right the second time on the other set of parts. Clever, huh? Finally, I find it interesting how many tools you bring forth in time at all... don't you?

-

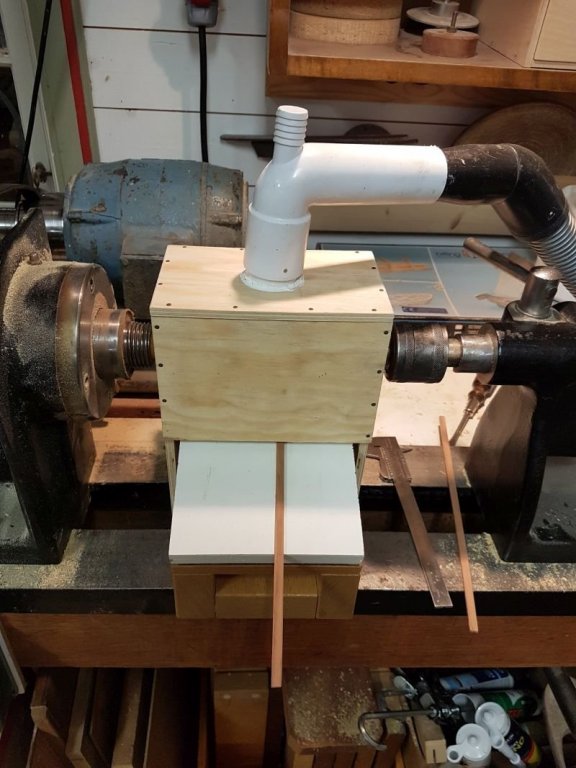

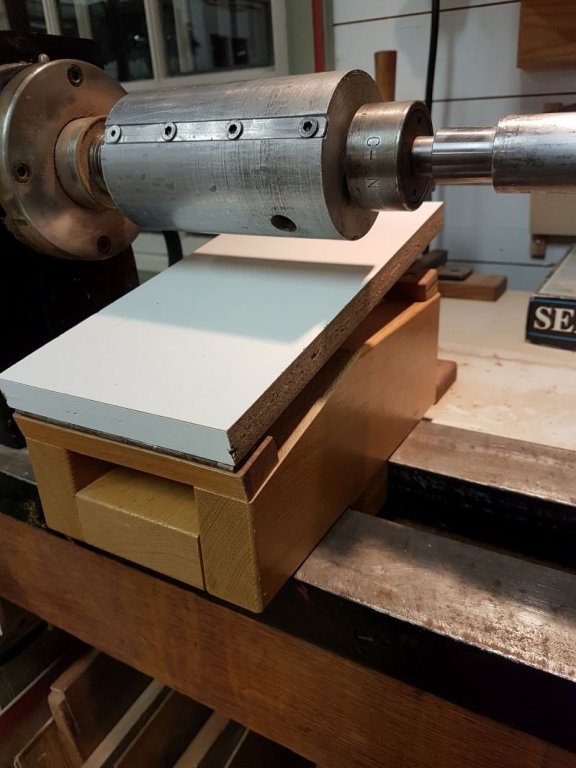

Hi all, John, I took your word for it so I turned a shaft instead. One side coned like all other lathe tools and the other with a small dent for the support. Also managed to finish a dust cover with a tube to attach shop vac or similar. My long time plan is to extend the shop dust extraction system with a hose for smaller tools, like this one. I attached 150 grit paper to the drum and the first tests were satisfactory. It will however take some time to learn about at what pace the material should go through. Also, it seems that a speed of ca 1400 rpm is quite enough. Well, with that taken care of, it is back to the boatyard to see if there will be some progress...

-

Hi EnT, just took the time to read through the great planking of 2017 and realized what a recognition to have ones model on display at a national maritime museum, let alone The National Maritime Museum. Hats off for that! Excellent build so far. About bending oak. One often think it is very hard to bend such a sturdy lumber. Quite the opposite, oak, if not squishy, it is at least very bend-able when coming out of the steam boiler. But then again, of course it will take a lot of manpower to squeeze an 8x10"x20'(?) in place...

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

-

Ouch! Practice makes perfect is not much of comfort. Just keep focused and it will turn out even better than before as Mark says.

-

I think you have made some correct desicions. Deck beames, if you go back to the ships of the line, deck beames were indeed a segment of a circle. And also, in my opinion they should sit vertical. Great job so far.

-

Hi all, Re the book; it covers a replica build of the original boat from 1900. Since these boats always were build without plans, the book contains no blueprints. The original boat was measured and from this they made a couple of plans, which are part of the book. Will show you later. Now for todays update. In my earlier post I headed out to my shop in order to create some kind of thickness sander. So far, so good. I have yet to try it out with sanding paper, but I think it might work. In the future there will probably be room for updates on some of the details of it. The aluminium drum is held in place by squeezing only. Might need another way, but the friction seems good enough. As you can se the height of the table is adjusted by a knurled knob attached to a M6 threaded rod. One full turn raises the table 1mm at the aft end. The drum is approximately 2/3 up the table. One full turn would then approximately lessen the space drum-table with 2/3 of a mm. (I guess). The table is hinged at the front end. I also need to build some dust extraction for it. But that will be quite easy, just some cover to stand over the whole unit with an outlet to attach a hose to. We will see. To be continued...

-

You are right Steven, it was Treebeard that said it the first time. M&P just repeated it a couple more times. Re the project, yes, I'm in for a challenge here...

-

Thank you guys for your likes, comments and interest. This build will take a while. When I started to mill the blanks for the keel it became obvious that I need a way to sand to dimensions. The easy and expensive would be to just order a thickness sander. But after some thought I realised that my lathe could be turned into such a device. So, at the moment, still no sawdust. As Merry and Pippin says in LOTR... lets not be hasty...

-

Lovely piece of modelling going on here! I second what everyone else said about your metalwork. Also, the model resembles the very smallest boat in Rolex Sydney Hobart, is that by chance?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.