-

Posts

1,002 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wintergreen

-

What allanyed said on previous page, and that schooner looks FAST 😉 Great build this far, keep it up!

- 140 replies

-

- benjamin w latham

- model shipways

-

(and 1 more)

Tagged with:

-

On a positive note for us bystanders, this log will hopefully continue for a long time still 😉 And on a more serious note, we really hope all your trials will end and that life will be sorted for you Remco. Take care!

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Those are some crazy (in a good sense) detailed yards you've lined up there. Always impressive work Ed, always.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Sweden is a great place to live in 😉 But then I might be a little biased of course 😄

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Mark, about the bleeding issue... I've read, not tried, that after the masking tape is applied one can apply a layer of varnish over the edge of the tape. If the varnish bleeds it will be close to invisible and it will also seal any opportunity for the black to bleed. The varnish needs to be matte or satin (i.e. non glossy) so that it blends with the natural finish of underlying wood, but that I think, comes without saying. Still a lovely model you're building.

-

Thanks Siggi. Actually, I didn't expect that. Alder, I associate with clogs or matches, now I know better.

-

Dave, that is exactly what he does. Go to seawatchbooks.com and you will find three volumes from EdT. (maybe you knew this already, and then, maybe you didn't.) Excellent books by the way. I have one of them on my shelf (Naiad vol I).

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I'm with druxey on this one... it is just crazy many lines and blocks... pristine work Ed.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Nice chisels also. I'm sure they are a joy to use. Knee surgery you say. Been climbing too many towers, maybe? Let's hope for a swift recovery whence its done. And on the subject of learning... with all issues you learn a lot. As a colleague said at work, "if it was easy, they wouldn't pay us.." Take a break when stuck and as you do, ask the intelligentsia out here for advice. Keep it up, mate!

-

Mario? You're back! Cant give any technical advice here just cheer you on. 😁 Boy, my chair was dusty... where's the popcorn btw?

-

Vaddoc, you are quite right. I did try both with battens and lines, but the hull is so small and it all was too fiddly at the time. Maybe I give it another go later. Will see.

-

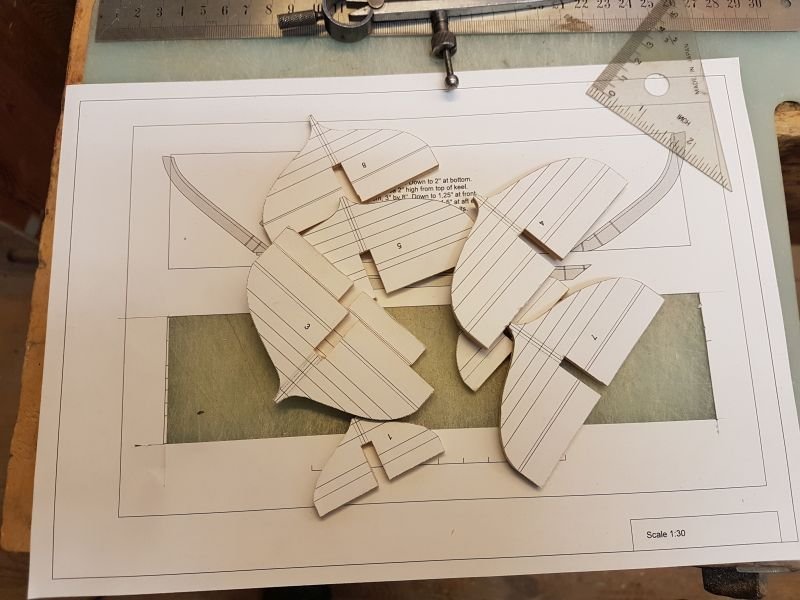

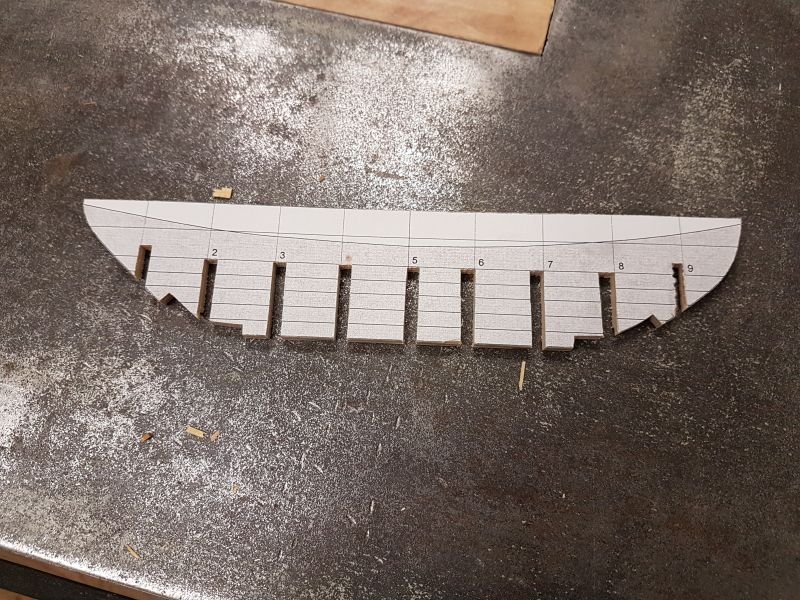

So, there he was, peacefully cutting pieces for a new mould. Everything was in order and the "flow" was with him. Sanding bulkheads, cutting slots and all. Dry fitted every bulkhead on the backbone to see it was a reasonably tight fit. When all slots were cut (nice fit all over) and a closer inspection was carried out it dawn on the builder that, somehow, someone, had cut slots in the backbone to the wrong side of the station line. Leaving no option to sand a bevel on any bulkhead, bar no 5, which is the deadflat one. Well, it was time for coffee anyway... Returning to the shop the builder carefully cut a new backbone. Carefully cut new slots to receive bulkheads, this time slots were cut on correct side of station lines. Nice fit all together. Dry-fitting. Needed a square block for gluing parts together. Finding clamps and on went Titebond. One in place, square and all. No 5 it was. Looked for 4 or 6 as next option only to realize that no 5 still was resting on the tabletop... quickly eased pieces apart and decided it was time to call it a day... To be continued...

-

Doris, Regarding the Riksäpplet study, if there is something I know, that would be Swedish... pm me if there is something you want translated.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

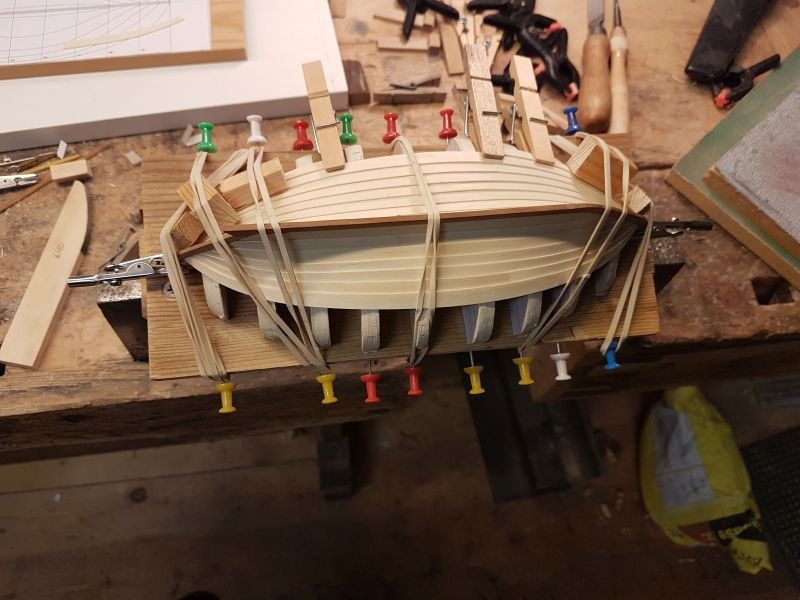

Again, thanks for likes and comments! Just a quick status update here. Paul - I dislike cleaning just as much as my teenagers. It's done on a need to-basis. Not before. John - that is also my conclusion. Not that the planks are cut down, but the curve too wide. Tapering needs to start from the 2nd station going forward and dito aft. Otherwise there will be this build-up that my hull shows. 8th row in place and I think it is time to do the restart. At the stern it is clearly visible that the planks don't meet in height. Otherwise I am surprised over my accomplishment in this build. I never thought it would come this far without a mental break-down somewhere along the way. The weather forecast looks promising for shop time and not so much for varnishing on the 1:1. A fair bit below zero coming week. Lets see where that takes me in this. To be continued...

-

Work continues, first one of those rare grossly close-ups to show the rabbet at the stem. And then, more planks convinced to stay in place. Hm... why does Gulliver and the land of Lilliput come to mind, I wonder...

-

Hi guys, I'm glad for likes and questions. Mark - yes, it is very much "by the eye". From the dead flat the builder can approximate the number of strakes needed, but the run... that's where I failed. That has to be done by eye. At stem and stern almost no plank has the same width. Try, and try again... Druxey - I thought someone would eventually ask that question. No, they have an overlap all the way. From the book I learned that the last 6" get a bevel to half the thickness. And the coming plank is treated so as well, a bevel on the lower inside, closest to the stem/stern. That way the planks fit nicely and flush in the rabbet. (well, not SO nicely on my work, but nothing some sanding can't hide). Now, it is back to the shop for some more planks...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.