-

Posts

13,288 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Swan class 3D model in progress

druxey replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

Those images make me smile. Well done!- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

This is well worth looking forward to, Dan. Thanks for sharing your process. I note the difference in mortices for the lashings between the battens on the ship itself and the cross sectional model. the lashings just appear and disappear again.

- 22 replies

-

Thresher & stable engine by RGL - FINISHED - Plus Model - 1/35

druxey replied to RGL's topic in Non-ship/categorised builds

Very convincing rust and grime! -

'Shivers' are sheaves: live ones are rotating ones in the fixed blocks in the sides of the ship. So, in modern language: fixed blocks opposite the mizen mast.

-

Just stumbled across this log. Lovely work!

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

Nautical archaeology internship programs

druxey replied to Ferrus Manus's topic in Nautical/Naval History

I believe that Texas A & M is still one premier place for marine archaeology. -

Ah, the joys and frustrations of rigging! Hopefully you can install the cleats before permanently securing the masts with shrouds.

-

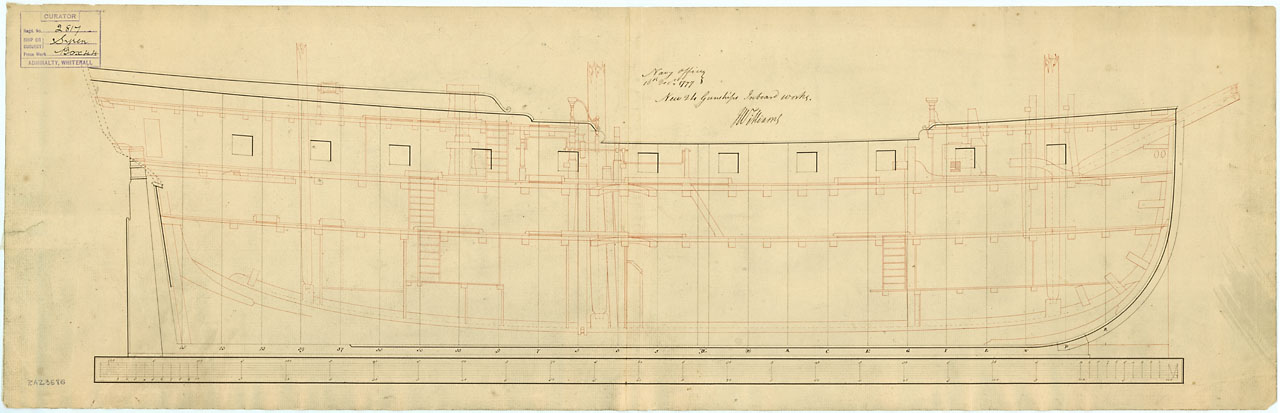

This is a problem with modern re-drafted plans - unless it's stated one doesn't know! Contemporary plans show both the line of beams at the side and centreline. In this case you don't even have a line of ports to give you a clue. The Royal Museums Greenwich hold a sheer and profile of the Pandora class: https://www.rmg.co.uk/collections/objects/rmgc-object-83477?_gl=1*1l5sqqk*_up*MQ..*_ga*NTU5MTEyMTE3LjE3MzE2NzU5NTI.*_ga_7JJ3J5DBF6*MTczMTY3NTk1MS4xLjEuMTczMTY3NTk3NS4wLjAuMA..*_ga_4MH5VEZTEK*MTczMTY3NTk1MS4xLjEuMTczMTY3NTk3NS4wLjAuMA.. This would be a more reliable starting point for you.

-

L'Amarante by marsalv - 1:36 - POF

druxey replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

Beautiful and clean work, marsalv. I usually delay attaching the knee of the head until after planking and work on the external hull is complete, to prevent it breaking off. Also, it is not in the way when planking the bow. -

Excellent advice for those with sufficient patience!

-

Congratulations on completing your model, Greg. Lovely looking case. But might I suggest a couple of ventilation holes in the base covered with fine mesh to prevent insect entry? A sealed case is not good for a model.

- 123 replies

-

- Le Pourquoi-Pas

- Constructo

-

(and 1 more)

Tagged with:

-

Examples of wooden pin in the Royal Museums Greenwich collection range from 43 to 49 cm (17" to 19") in length and 4 to 5 cm (1 1/2" to 2") in maximum diameter.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.