-

Posts

13,405 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

That broadside view is now particularly impressive, Marc! That is a lot of breeching rings to close up. I hope you have a pair of very small-nosed parallel pliers for the job....

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

If sanding, use sandpaper glued to a flat stick to keep the bevel flat at a constant angle.

- 33 replies

-

- Model Shipways

- Norwegian Sailing Pram

-

(and 1 more)

Tagged with:

-

Animation of Newport 'mediaeval' (15th century) carrack/nao

druxey replied to Louie da fly's topic in Nautical/Naval History

I was amused by the sailor climbing by every other invisible ratline. That's picky, Steven! Nicely done, though. -

1876 Parcel van by michael mott

druxey replied to michael mott's topic in Non-ship/categorised builds

Terrific, Michael! Your metalwork is equal to that of the late, great Gerald Wingrove. -

Your trials and tribulations are familiar to all of us. Persevere, and you will find that your skill at cutting joints will keep improving.

- 92 replies

-

Well done indeed, Matt. A very nice first model. Now you can build on your experience and skills.

- 69 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

1876 Parcel van by michael mott

druxey replied to michael mott's topic in Non-ship/categorised builds

Nice (re)start, Michael. -

You have a lot going on, haven't you? Hopefully you'll keep the kitties away from the model now!

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hope that you are doing OK now, MB. And no, it was not particularly cooler near the lake last week! Thanks for asking.

- 69 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

Good save on the transom!

- 33 replies

-

- Model Shipways

- Norwegian Sailing Pram

-

(and 1 more)

Tagged with:

-

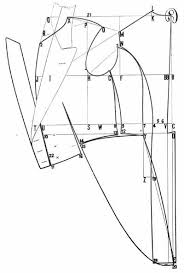

I agree with Martes; the coat is fitted using a drop shoulder seam to the back of the shoulder and separate pieces along a curved seam from the rear shoulder down: It give a very elegant line. You can just see the curved seams in the uniform coat photo. Darts in clothes were used once wider bolts of machine-made material became available.

-

You should be OK painting the filler. It may need sanding and repainting a few times to get a really smooth finish, though. For larger gaps a tube of wood filler (such as LePage's 'natural') is easier to handle and sand. It also dries faster! Looks like a nice job that you've done. You commented on the variation in wood. As it is a natural not synthetic material, any wood piece has its own peculiarities that you have to adjust your techniques to. We all experience this, whether kit or scratch builders.

- 69 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.