Pirate adam

NRG Member-

Posts

240 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Pirate adam

-

The myrtle wood looks very nice. That should make for a really sharp looking model. Adam

- 92 replies

-

That figurehead is looking really good. Interesting choice of olive wood. I'm a little bit surprised we don't see more use of that on the site, as I have seen some amazing carvings in olive wood. Adam

-

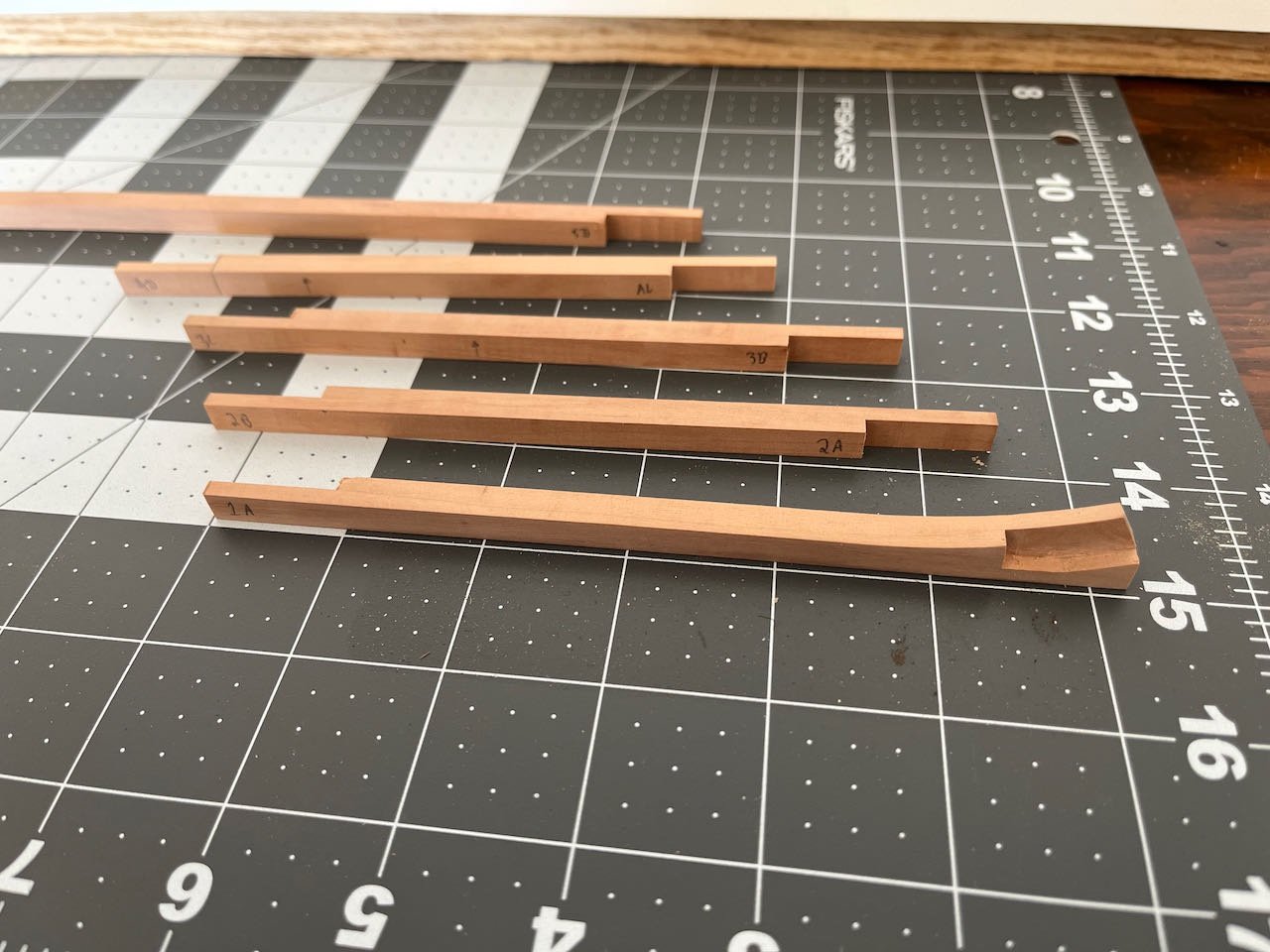

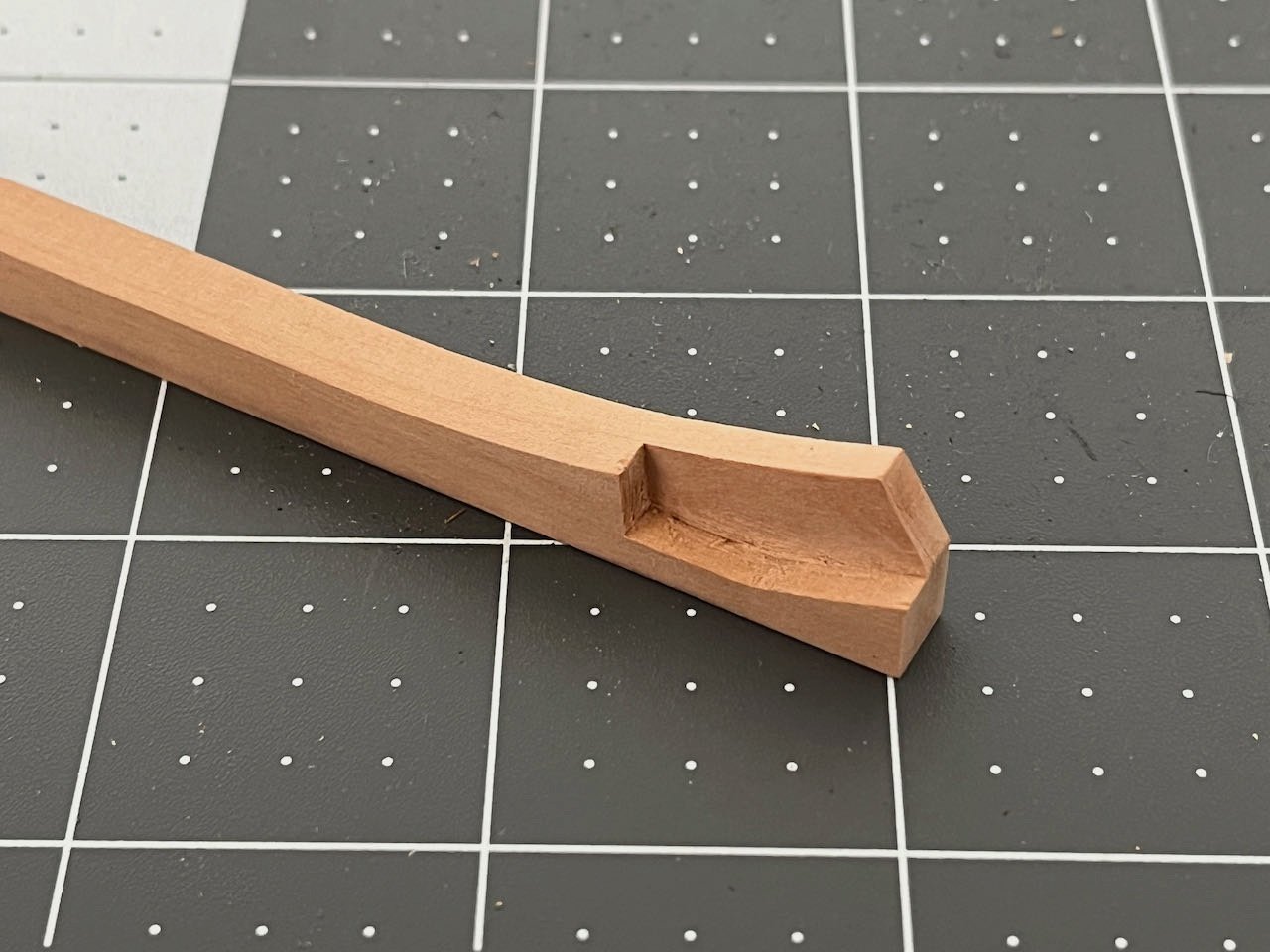

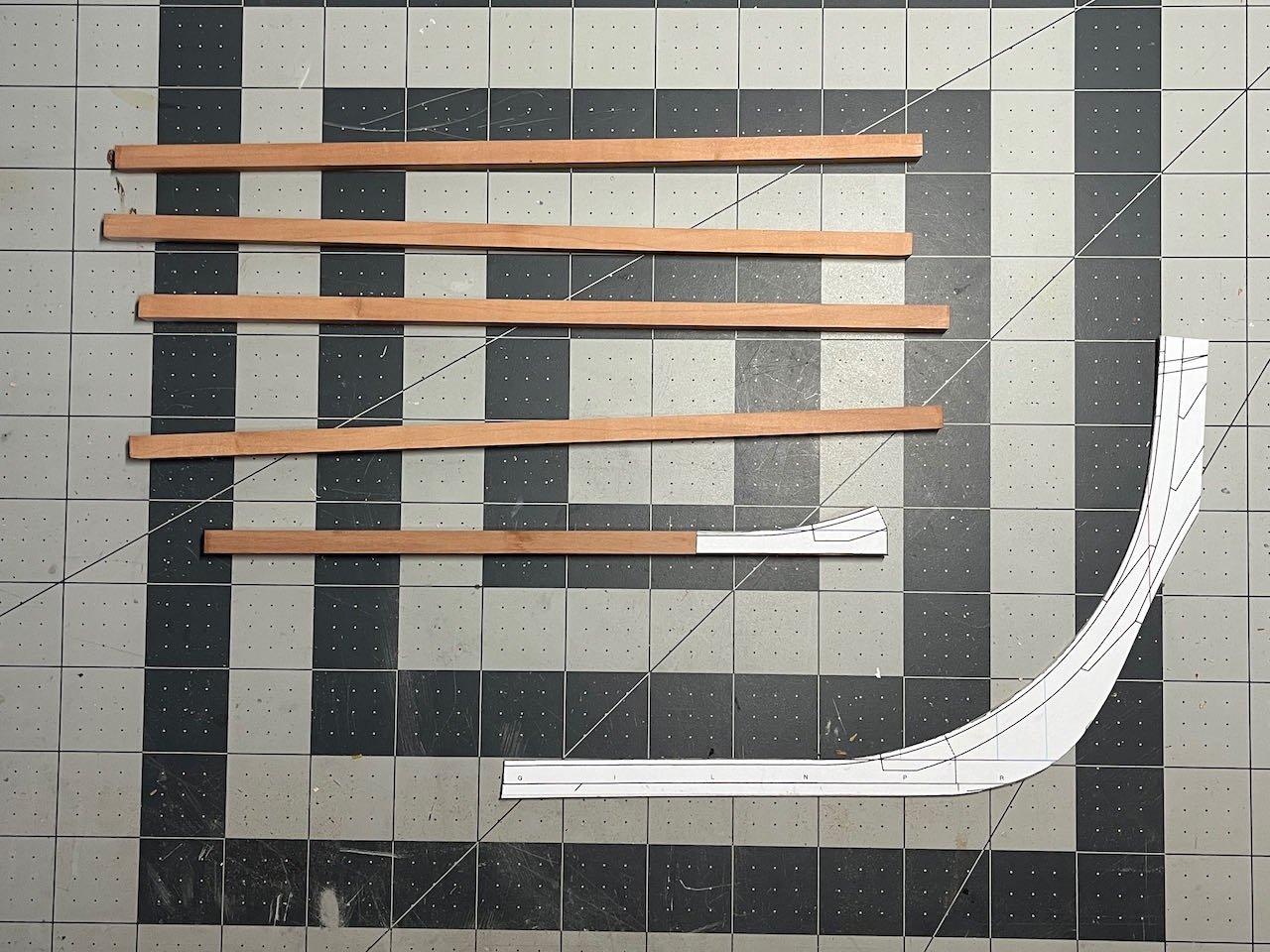

The fun begins. My references indicate the keel should be built up in 5 segments 13" square. I am using swiss pear for the keel and frames. My plan is to cut the scarphs for the keel on the mill and cut the boxing joint with chisels. We'll see how that goes . I glued a copy of the stem to a piece of plastic to use as a template for shaping both the boxing joint and the stem later.

-

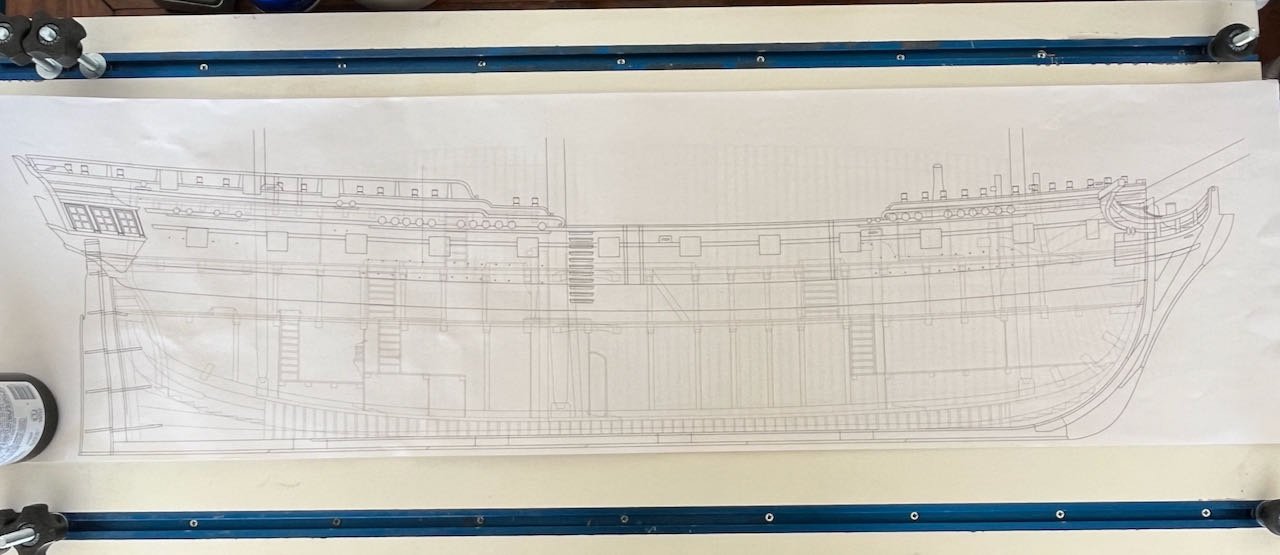

I have collected a number of references for building this ship. I started with a printed copy of the lines plans from the National Maritime Museum. I have also made a lot of use of "The Elements and Practice of Naval Architecture 1812" which is available as an electronic download from Google books. I have also taken a lot of dimensions from "Scantlings of Royal Navy Ships 1719-1805" by Allan Yedlinsky. That book contains information from "The Shipbuilders Repository" of 1788. Both "The Elements and Practice of Naval Architecture" and "The Shipbuilders Repository" are believed to have used the Porcupine class in the tables of scantlings for 24 gun ships. I have found the dimensions from "The Shipbuilders Repository" seem to more closely match the dimensions from the Admiralty Draught in many cases vs. dimensions from "The Elements and Practice of Naval Architecture." I also have the "Anatomy of the Ship The 24-Gun Frigate Pandora" book by John McKay and Ron Coleman. This book is a treasure trove of information for a very similar ship. I have finished all the basic drawings that I need to get started building, but still have work to go to have a "full set" of working drawings. I have little concern that it will be easy enough to keep ahead of construction with the drawing development. I am far enough along that I have confidence that I can start building without any regrettable mistakes to have to deal with later.

-

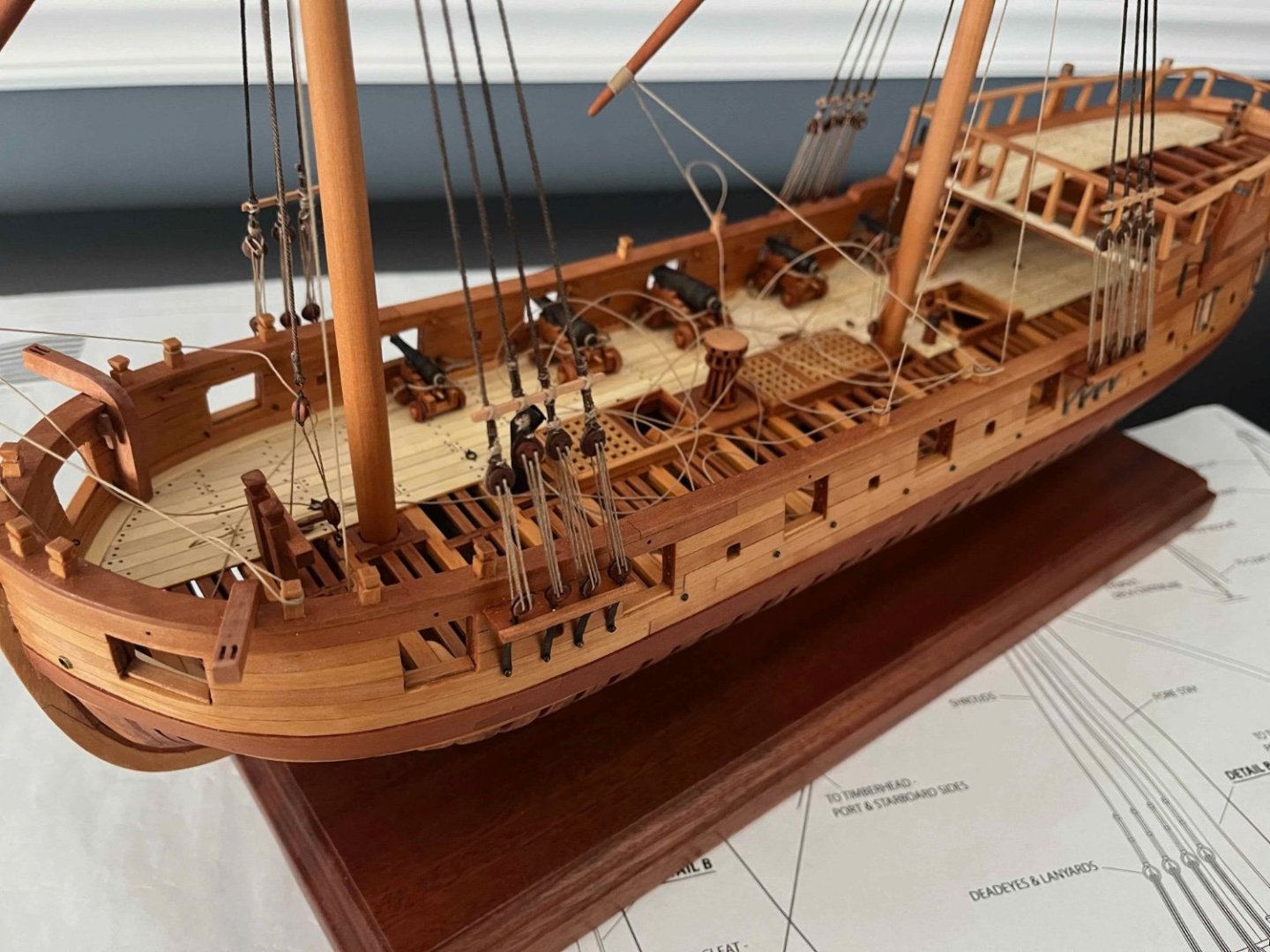

After completing my Washington Galley, I am ready to start a new project. I will start on the HMS Crocodile of 1781. The Crocodile was a 24 gun Porcupine class post ship. It is a sister ship of the famous HMS Pandora of 1779. It was a ship of no particular significance and was wrecked off Prawle Point, England in 1784. I chose the Crocodile for several reasons. Firstly, I was looking to do a small frigate that would be a "reasonable size" at 1:48 scale. Secondly, I wanted to do a ship that I have never seen anyone build before. Thirdly, I really like the look of the ship in the drawings that are available from the NMM. I purchased the plans of the ship from the National Maritime Museum. The plans include the figurehead and stern carvings. I am blown away by the beauty of the original drafting and that the plans are still in good shape after over 240 years. I have been working for several months drafting working drawings in TurboCad. I am hoping to finish the model over the next 8+ years. I would like to thank a number of people before I even get started. I followed Wayne Kempson's article Drafting Ship Plans in CAD from the NRG homepage almost from start to finish to draft the lines plans for Crocodile. I also have worn out the drafting section of Ed Tosti's Naiad book and David Antscherl's Fully Framed Model series. I do not think it would have been possible for me to draft a set of plans for a fully framed model without all of their work. Allan Yedlinsky's book Scantlings of Royal Navy Ships 1719-1805 has also been immensely helpful. Finally thank you to all the members of MSW going back to the original MSW for all the inspiration and for answering questions over the years. I don't think I would ever have even dreamed of starting a model of this complexity without seeing all the great work done by so many amazing modelers over the years. Adam

-

The split in the planking below the gun ports in the stern view opened up during the dry weather related to our recent arctic blast. Fingers crossed that it closes back up when the weather warms up. I need to take this into account for my next build, because I normally work in the garage where it is cooler and RH is higher. I brought it inside the house to work on the rigging at pretty much the most inopportune time from a climate perspective.

-

Richard, This is what I would try. Wait for the varnish to be fully cured. Then give the hull a light sanding with around 600 grit (or maybe slightly coarser) sand paper. Then mask and spray the areas you want white with Tamiya or Mr Hobby primer (they have a white primer). You should be able to paint with just about any paint you want with the primer on and dried. Adam

-

Ken, I used the Gutermann thread recommended by Chuck. I haven't had much trouble with gluing with white glue, but it does darken the color a bit. I have used a drop of CA in a couple spots that I really wanted to make sure stayed glued. Next time I am going to be more careful with the heating and stretching step to make sure I don't end up with lines that want to twist when stretched. I had some issues with that on the shrouds. Adam

-

Closing in on wrapping up the galley. I am underway with the rigging. Nothing is glued yet, so lots of loose ends of rope. I had a lot of mental debate about mounting the yards inside or outside of the shrouds. I ended up going with the instructions and mounting outside the shrouds. I'll admit I'm not sure I see how this would work in practice, but not sure how it would work the other way either. Next I will move on to making the anchor and the swivel gun mounts.

-

That's a cool little project. Thank you for sharing!

-

Allan, I am not an expert in this area, but I have encountered the same line on my Crocodile draft. I have interpreted it as the top of the moulding that is even with the bottom of the midship rail. Once the moulding diverges from the rail at the waist it continues aft to the quarter galleries and forward to a point above the stem. I'm not sure if that moulding is called the "drift rail?" Adam

-

This is great. I think one of the coolest aspects of this hobby is the number of skills you can try to master along the way. I haven't gotten to the carvings phase, but it definitely will allow you to take your already beautiful model to the next level. Adam

- 1,126 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.