Pirate adam

NRG Member-

Posts

240 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Pirate adam

-

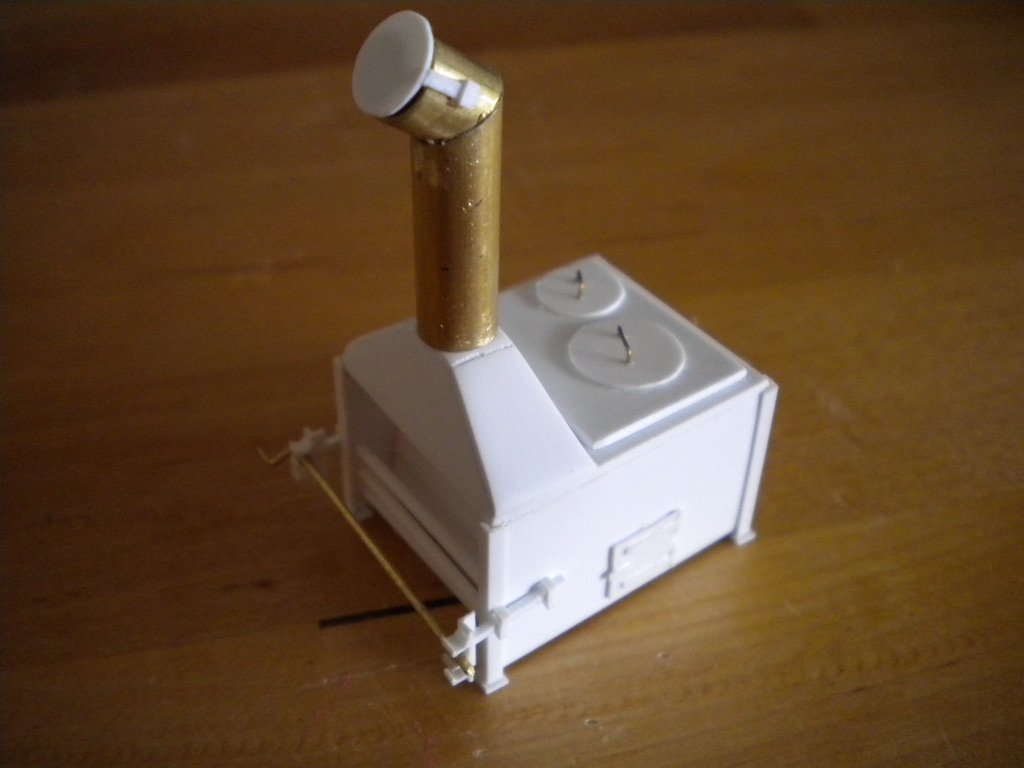

I have also spent the last several months learning some new skills. I turned all of the cannons and swivel guns on a Sherline lathe. There is a whole bag of practice cannons before I got to these. Next I need to learn silver soldering to finish these guys up as well as the various other metal working on the ship.

-

MONTAÑES by Amalio

Pirate adam replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

There are many amazing models on this site, but this is one of my role models for precision wood working. Incredible! Adam -

The curved grating is amazing. Very inspirational high standard of work. Adam

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

NAIAD 1797 by Bitao - 1:60

Pirate adam replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Bitao, This is amazing work. Your craftsmanship is beyond most of us on the site, but I love seeing the limits of what is possible. It gives a lot of inspiration and ideas for techniques even for those of us not quite as skilled. This is one of the few models I have seen with the pump dales actually in place. Adam -

Glen, That is a really cool display. One of the most unique displays of a ship in bottle I have seen. Adam

- 177 replies

-

- Independence

- bottle

-

(and 1 more)

Tagged with:

-

Chuck, Sorry if this has been asked before, but I can't find anything in the various logs. Do you have a sense of how much the Winchelsea's hull weighs at this point? Adam

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You make it look so easy Marsalv! I have learned so much from reading through this log and your Pandora log. It makes me want to practice, practice, practice. Great work. Adam

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Rope making attempts - Feedback requested

Pirate adam replied to Moonbug's topic in Masting, rigging and sails

It looks great to me. I also recently bought a Rope Rocket, and I have been really happy with it so far. I agree with Chuck that making the rope is weirdly satisfying, and my wife even found it interesting. -

I have been a bit of the passenger on the site as late, but work on the Washington has continued in fits and starts over the last couple of years. Construction has picked up nicely as of late, and I think we may just end up with a finished galley at some point Here is the latest look at work to date. I have treated a lot of the pear wood as well as the decking with a layer of tung oil. Decking is holly. I'm super happy with the look especially on the areas that were coated a year+ ago. I am planning to leave the gun deck more or less as-is with half of the beams exposed. I'm still deciding whether or not to add another row or two of planks below the wales. I have seen models either way, and both look fine. Next up I will start with the internal planking. Adam

-

HMS VICTORY 1765 by albert - 1/48

Pirate adam replied to albert's topic in - Build logs for subjects built 1751 - 1800

Looking forward to seeing this one develop Albert.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.