-

Posts

2,666 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glenn-UK

-

-

I have continued on with steady progress. I have assembled 12 small machine guns, which was quite time consuming given how small the parts were and that I also had to manufacture 24 gun barrels, each 5mm long.

I also fitted the bow and stern photo etched plates.

Following on from that I added the rolling chocks, propellers and rudders to the hull assembly. Again there was quoite a bit of work involved with these tasks.

-

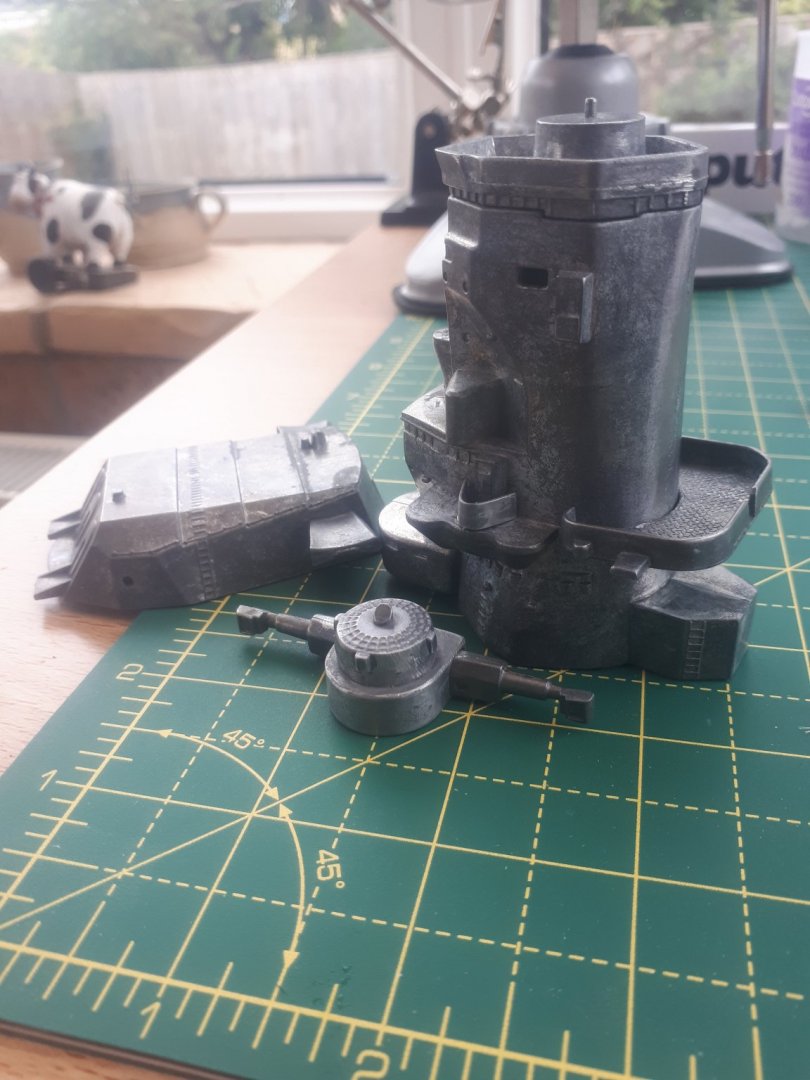

I have continued to work on the main superstructure assembly. It takes quite a bit of work due to the poor quality of some of the die cast parts, requires plenty of filing and putty to correct. I have added primer to some parts to help highlight some of the defects

The main bridge and funnel assemblies have not been glued as yet, as there is still some more bits to add.

-

-

I have spent quite a bit of time on sanding (and filling) the hull to get a nice smooth finish. It is still very much work in progress as I continue to apply more coats of primer and to then sand smooth. It is a task I prefer to do outdoors and the weather is not playing ball today (windy with a few drops of rain).

To make the attached photo a bit more interesting I decided to add some of the superstructure parts, noting these have not been assembled or positioned correctly on the deck. They have just been added for a bit of fun, but I think they do add menace to the model. The two photo etched deck parts are also only positioned for effect. There will need to be painted prior to actual fitting.

- yvesvidal, Canute, Ryland Craze and 5 others

-

8

8

-

-

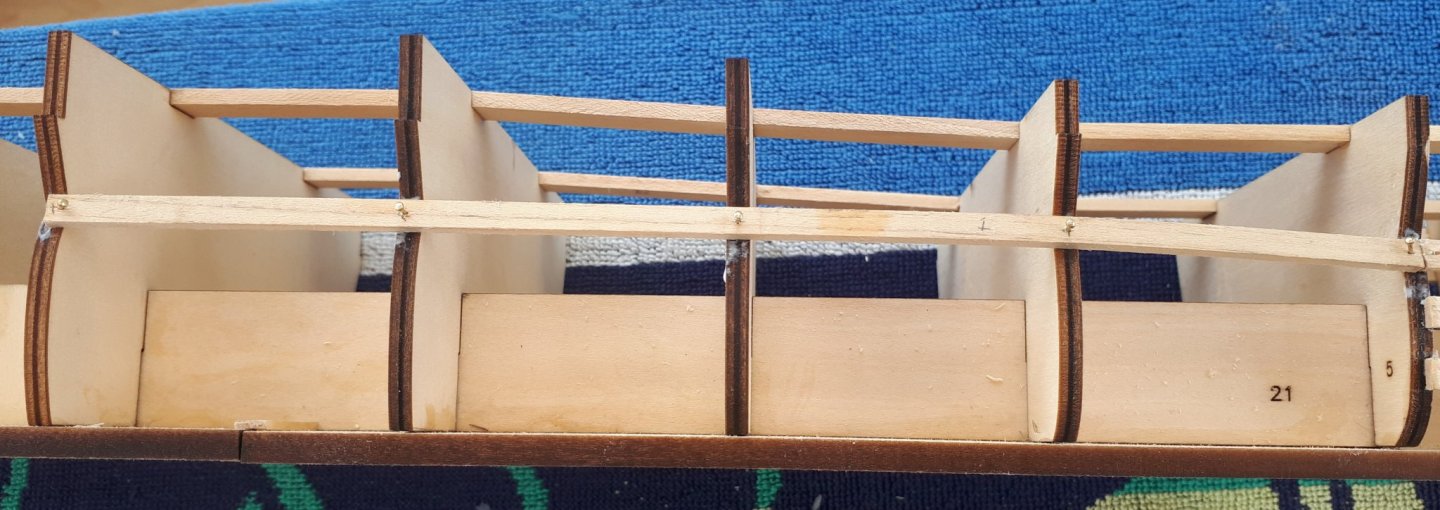

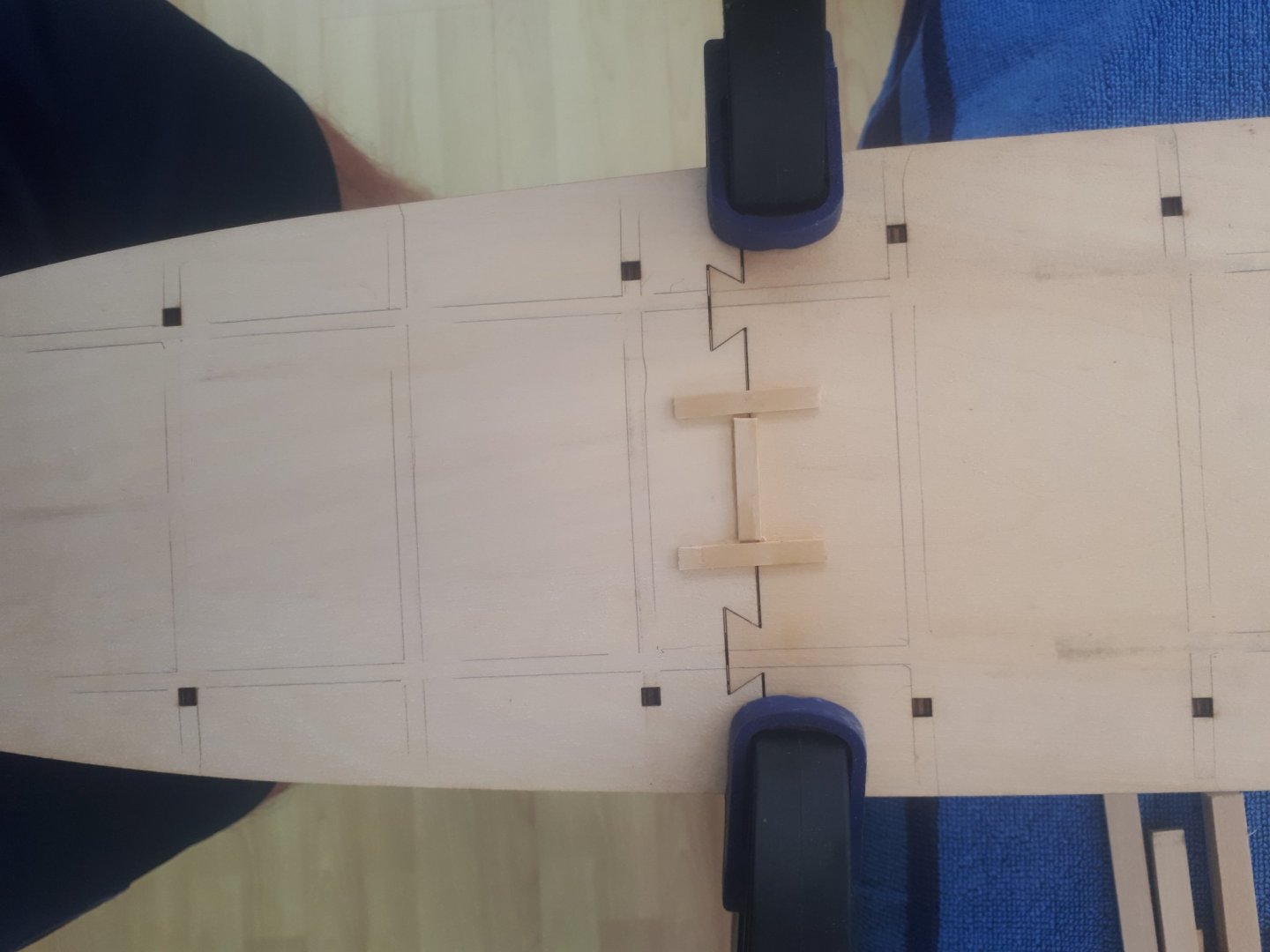

I decided to deviate from the instructions, which requires each deck part to be planked separately and installed at a much later stage. I think it is better to fit all the deck panels first and to then fit the deck planks later on. The photo etched parts are only dry fitted at the moment as is the final deck part, as the hanger deck will require painting prior to the fitting.

I found this method was much better for getting the hull profile to fit the sanding templates.

Decks fitted.

-

Having completed the hull planking I decided to dry fit the hull deck parts. The seemed to fit OK and will not require too much tweaking.

I took the hull sanding profiles provided (a great kit idea) and spent a nice couple of hours in the sun this afternoon sanding and smoothing. The hull profile is now more or less in line with the all the different profiles templates. The hull requires a couple of minor tweaks. I think I will spray the hull with a primer to highlight any defects. This can then be filled as necessary and sanded smooth.

-

I have now completed adding the strakes to the starboard side of Yamato's hull framework. It looks rough and uneven at the moment which is to be expected. I should be able to complete adding the remaining strakes to the port side in the next couple of days (or so).

Once I have added all the strakes the hull can then be marked out and sanded (and filled) smooth, using the various templates provided to ensure the correct profile along the length is achieved.

I think the sanding and filling process will take some time to get right.

I have noted the problem strake toward the keel on the following picture, which I have now sorted out due to a bad glue joint.

-

-

-

I have continued to make good progress on both the superstructure and hull planking.

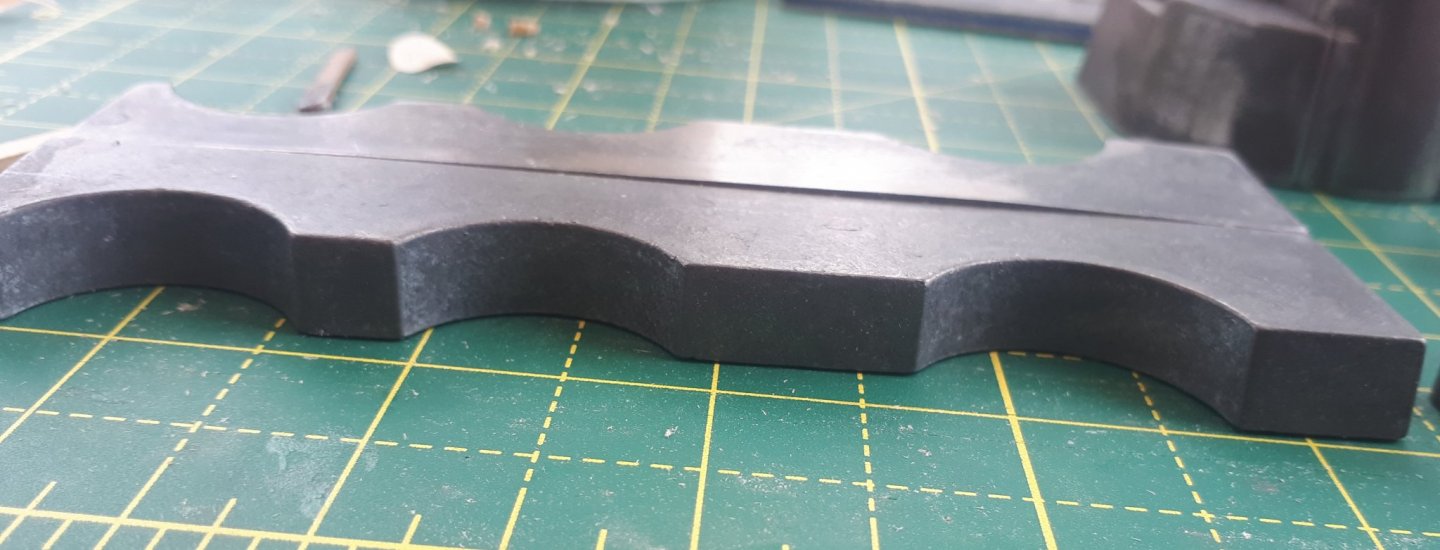

The quality of some of the die cast parts is a concern, one part arrived badly warped, it has an approx. 3mm displacement. I could use the part but it would require a lot of filing and filling with epoxy resin. I have been in contact with the supplier and they have ordered a new part.

Photo of warp part

WIP Superstructures

I am finding the detailed planking instructions very odd and goes against what I would normally do. I should be able to completed the hull planking in the next few days all being well.

Planking progress photos

- Canute, gieb8688, chris watton and 4 others

-

7

7

-

Better quality every time, my experience with poor quality materials from Model Space confirms that in my opinion

- chris watton and DelF

-

2

2

-

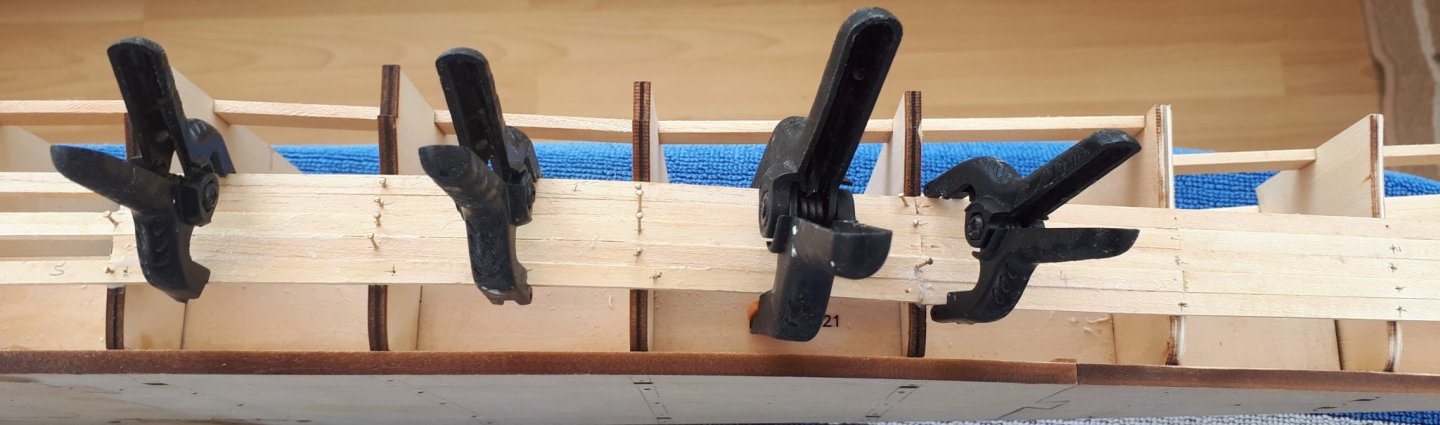

I have added a few more hull planks today. I thought I would share my method for doing this.

The instruction manual requires 5 planks are fitted at a time. I started by measuring and cutting the 5 planks to the correct length.

I then added a chamber to the top edge of the planks to ensure the edges line up when fitted to the hull.

The next task was to make the pin holes and then to add the pins. I made a small hand made tool to make the holes.

The first plank was then glued and pinned in place, ensuring it was correctly positioned on the hull frame.

I then repeated this process for the 4 remaining planks, using clamps to close the gaps between the planks and where necessary using the pins to help secure the planks.

- JeffT, gieb8688, Landlubber Mike and 4 others

-

7

7

-

- yvesvidal, Landlubber Mike, mtaylor and 4 others

-

7

7

-

I do have a commission build for a local bistro so I'm looking for a nice model for them. Flirt is on my radar as is Alert.

- chris watton, mtaylor and BobG

-

3

3

-

- chris watton, Canute, VTHokiEE and 6 others

-

9

9

-

More work undertaken today on the bridge and hull

Bridge Work

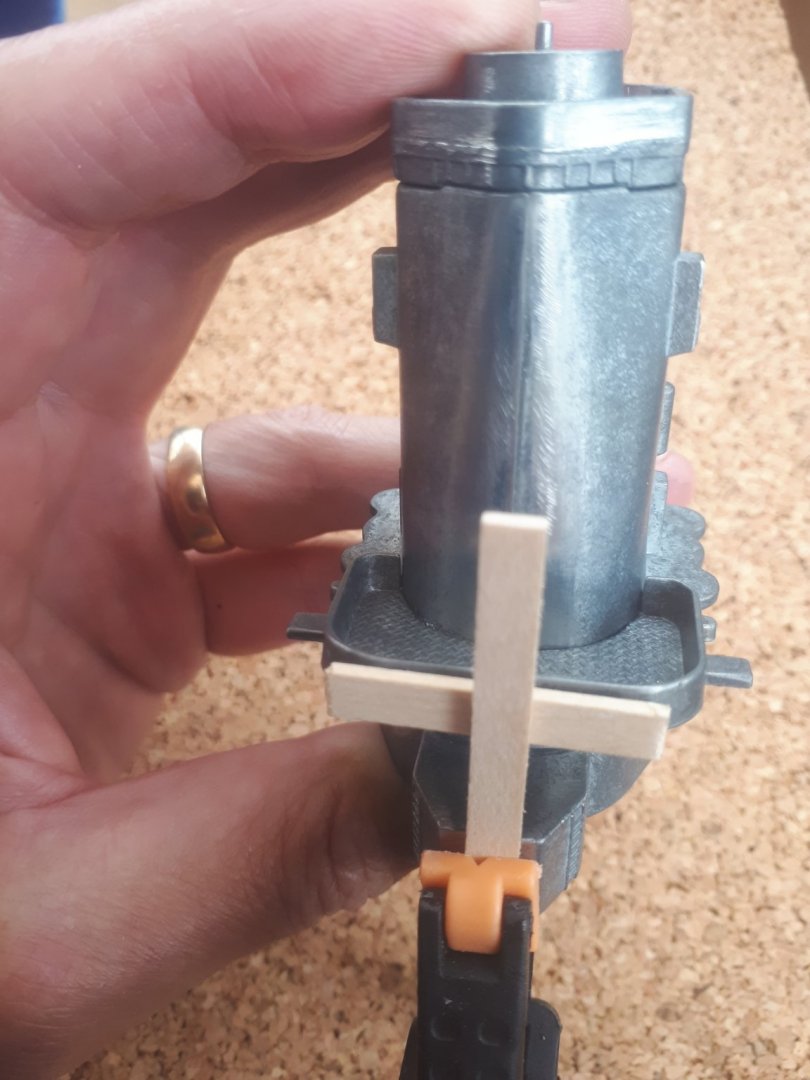

I have added some more bridge parts. I made another small wooden jig (10mm one edge and 11mm the other edge) to support one piece as the epoxy resin sets.

Hull Assembly

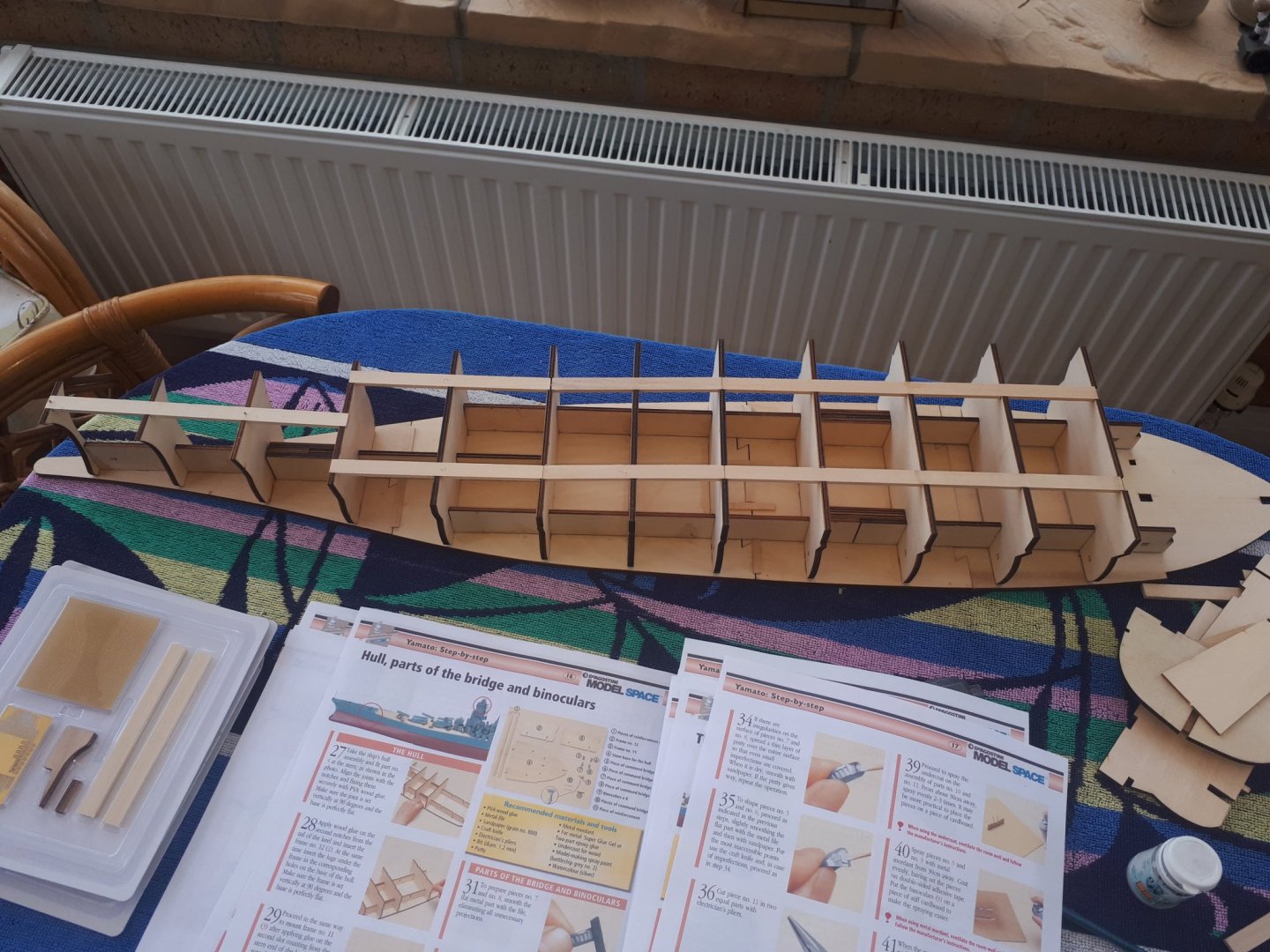

I have now glued the majority of the hull bulkheads in place. I still have a slight issue with the warped keel support piece but it is almost straight. I'm just giving it one more clamping (after soaking in water).

- Landlubber Mike, JeffT, yvesvidal and 4 others

-

7

7

-

I have sorted out the issue with the gun range finder and using epoxy resin, fitted both parts to the main gun assembly.

I also fitted the flag signalling deck to the bridge assembly. This took a bit of time to get correctly positioned. I made a small wooden jig to aid the clamping of the deck as the epoxy resin cured.

I tested fitted the range finders to the command post, they required a bit of filing before the could be located in the fixing holes.

I added a some small wooden strips to help fix the warping issue with the base plate and also applied some wood glue and clamped the two edges. I also marked the position of the bulkheads and support frames to assist me to correctly pin the bulkhead.

Finally I clamped the warped keel support, after I had soaked it in water. This seems to have sorted the problem.

-

6 hours ago, yvesvidal said:

Very interesting kit. I will be following your efforts with interest.

Obviously, this model will be top-heavy, due to the amount of white metal on the superstructure.

Yves

There is quite a bit of wood required for the hull assembly, especially when the hull and deck planking has been added which I think will balance the weight between the hull and the die cast super structures.

- CDW, mtaylor, Landlubber Mike and 3 others

-

6

6

-

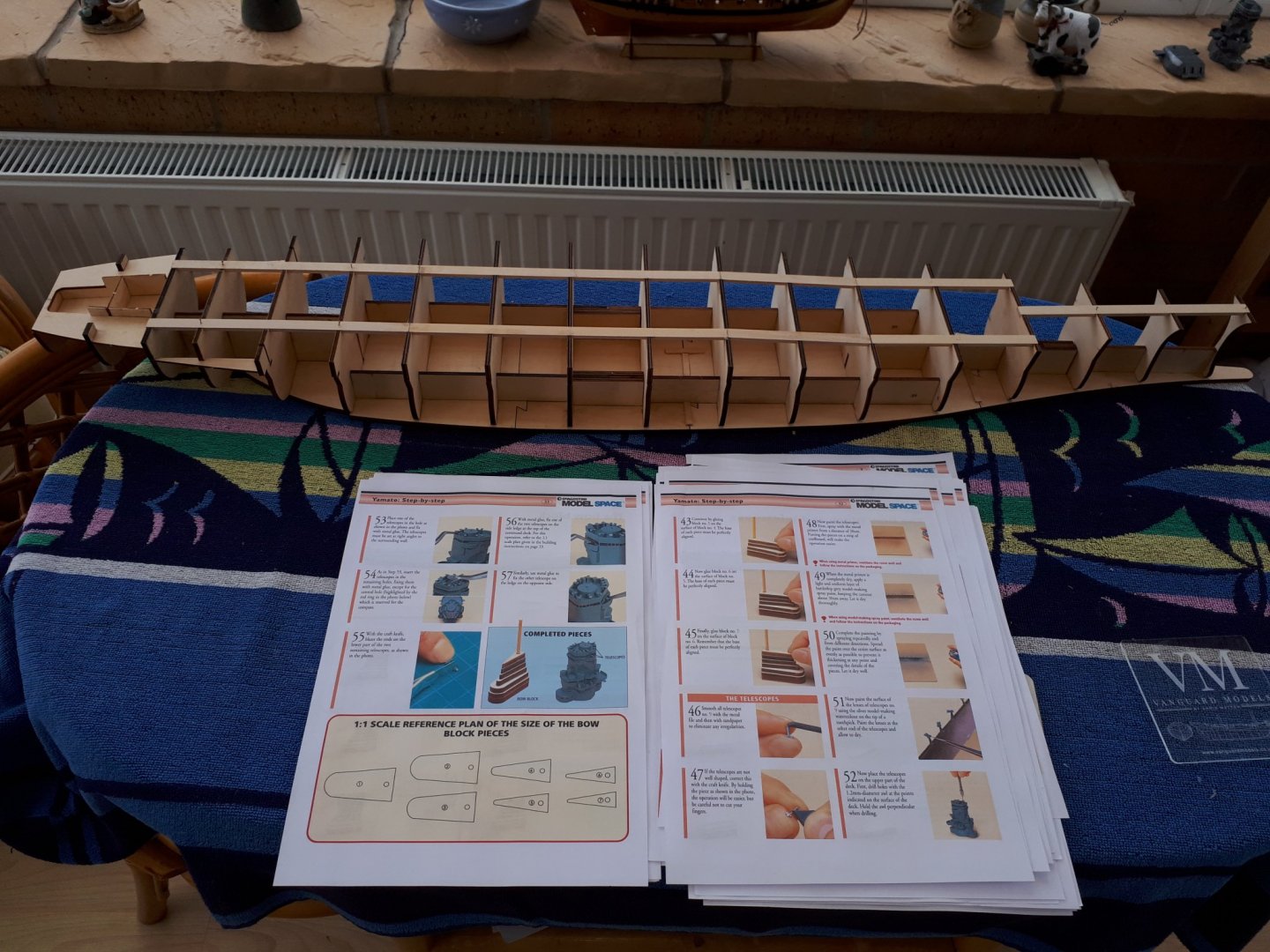

Today I have started the build in earnest.

First task was to dry fit the hull parts. Everything went together without any issues and the Yamato is going to be a big model.

There are two parts which are warped however. One is one of the base plates which can be rectified when the bulkheads are glued and pinned in place.

The other part is keel of stern part. I will probably have have to straighten this piece before it is fitted in place.

I fixed the bridge misalignment issue. This turned out to be an easy task as I was able to file a little bit off the locating pins.

I also looked at the first big gun. There are a couple of minor issues that needs to be addressed. The first one is the wooden based plate is a tad to big and a couple of the edges need to be trimmed.

The second issue is one of the two range finders does not fit in the slot provided so will require a bit of filing to sort that out.

-

51 minutes ago, maaaslo said:

this is weird way of building superstructures. i know its cheap, but seeing your example, i would tend to think that probably more common than one would welcome in such expensive toy...

well, you certainly took some challenge head on.

It is not a cheap kit to buy, looking at other examples of this build, there are not too many build issues to contend with. There is a lot more detail to add to the bridge and the slight misalignment would not be noticeable when complete. However better to correct it, if possible, in my opinion.

-

First problem encountered. There is a slight alignment issue with the bridge assembly due to position of the locator pins. It is only a fraction out but it does not look right as the right side is lower than the left. I have a few different options in mind to sort this out which I will experiment with.

-

Starting a new project which is bit of a departure from my previous projects. I have bought (and received) the full kit for the 1/250 scale model of the IJN Yamato.

This is mixture of standard wooden hull construction, photo etched parts and die cast metal parts for the superstructures and guns, etc.

I have had to sort through the delivery and I believe I have received all the parts, there were 90 different packs. The kit does not include a build manual but this is available on line in pdf format as 22 separate files. I have printed out the first 12 files.

I have been following the progress made by John Builds Iconic Military Models on his YouTube channel, who is currently building this model. This is going to be a great help. There is also an official build log on the Model Space forum which will also be checked from time to time.

The first picture is the first 16 packs, 4 packs required per build file document.

The next picture shows my workstation which is ready for me to start work.

- Landlubber Mike, mtaylor, yvesvidal and 2 others

-

5

5

-

I have the proxon lathe and it has been an invaluable tool for production of masts, yards, booms, etc.

IJN Yamato by Glenn-UK - FINISHED - DeAgostini & Model Space - 1/250 Scale

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Thanks Mike

It is an interesting build, difficult at times due to the poor quality of the materials and or the build instructions.