-

Posts

1,729 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

HMS Euryalus 1803 by rlb - 1:48 scale

scrubbyj427 replied to rlb's topic in - Build logs for subjects built 1801 - 1850

That looks great Ron, stellar chisel work!- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

-

Thank you Matt, slightly scientific but still relying on the old eye test. Thank you Fred, very much looking forward to you resuming work on your Winnie, your cheerful looks very good. Thank you Waldemar, much appreciated. Thank you Rusty, my cleaning frequency has slightly regressed to bi-weekly lol. Thank you Glenn, you’ll be there sooner than you think by the looks of it. I’ve been using your build as a “you should go back and re-do that part” or “why didn’t I do it that way” kind of guide. 😆

-

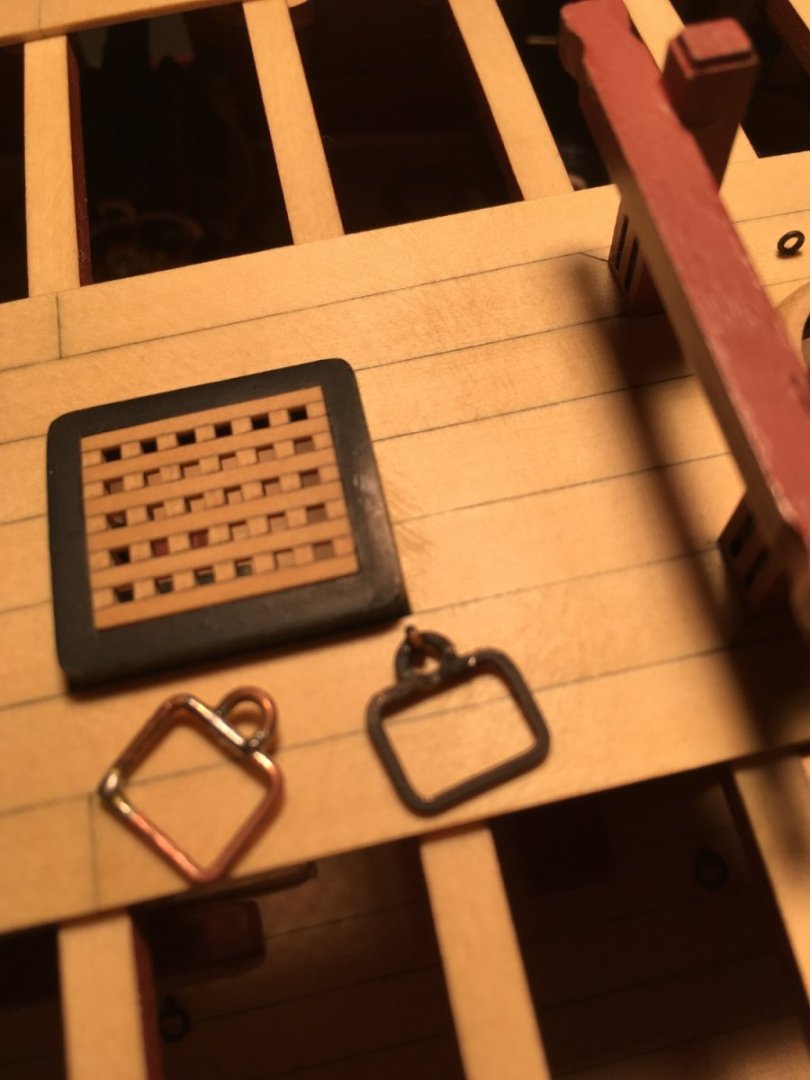

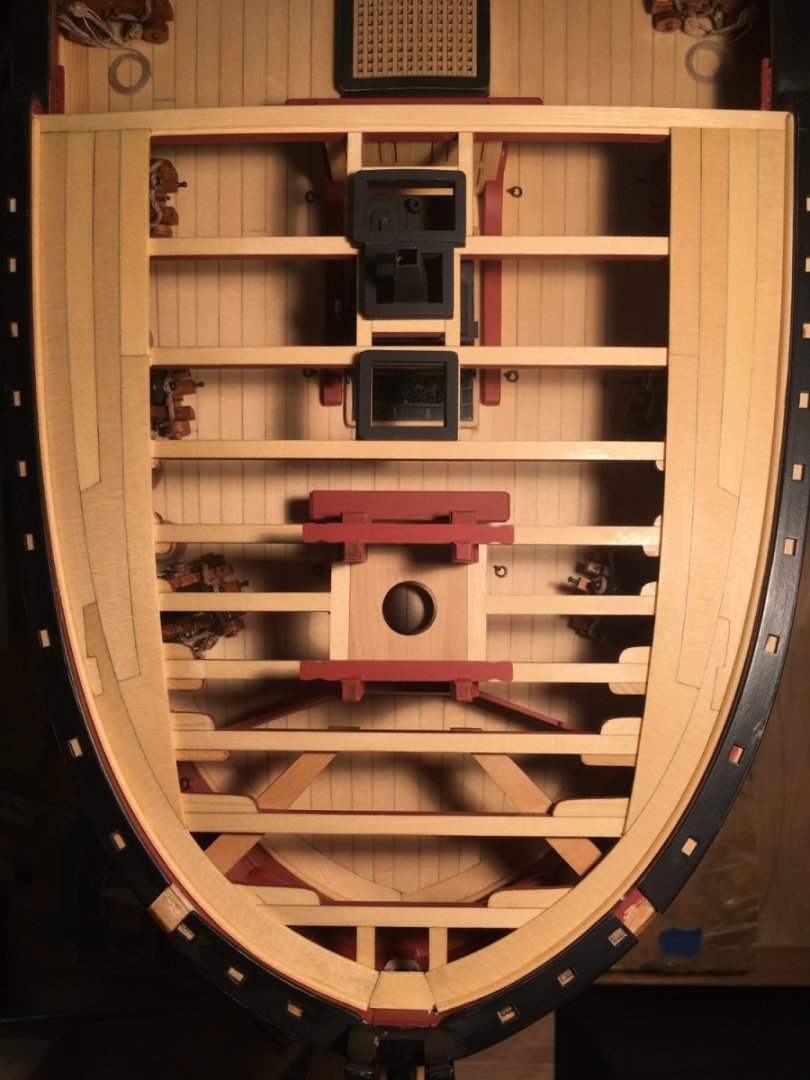

Completed chapter 9 a few days ago and already onto 10. Spent a lot of time on fitting things, lots or test/sand/repeat, until it fits right . The railing was kinda tricky due to the fact that my bow is slightly out of shape from not checking/correcting this very early on but I made it work and am happy with the results. I spent a lot of time of the cat heads and trying my best to make them look identical, I even laid a batten down across them to make sure they were at the same angle, this being off would drive me nuts. the spanshackles were made from round copper wire and soldered, filed and then filed/sanded to look flat. Took a lot of care to make sure the belfry fit right, so I actually took adhesive backed sandpaper and stuck it to the part of the deck at which it would be glued down and gently sanded the deck camber into the bottom, I think it worked well. I pinned it down, it’s a certainty I will probably knock it off otherwise. Thanks for checking in. JJ ps. Please excuse my filthy model, it is an absolute sanding dust ball!

-

Looks great Rusty! You’re almost there.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wonderful work Fred! Your cheerful has turned out just excellent. I think your rigging looks very nice and clean, it brings the model to life very well.

- 113 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Fred, practice makes perfect…. Or lots of imperfect leftovers… Thank you JP! Thanks Jim, I absolutely went crazy with it and just started ripping planks that I didn’t even need, just because it was fun and they looked so good. I can’t believe I didn’t get this sooner. I’m going to order a couple more so I never run out of them! Ha! Thank you Ron, your Euryalus is quite the build and is motivating me to jump into full POF.

-

Small update. So I received my lumber supply from @Joe V at modelers sawmill, wonderful job on milling and sending me just what I needed, thank you Joe! i was able to finish the port QD as well as the bow planking. The Bow was quite a project and required a lot of patience as each plank is a mini project of its own but it was well worth the effort. One thing I noticed after applying WOP, depending on the grain direction, the plank appears to change its tone at different light angles as you can see below, some of my planks are obviously facing different directions but it’s not nearly as dramatic to the eye and not even possible to tell until poly is added… also note I just added WOP to the stbd side so it’s even more dramatic but it will settle down in 24hrs. But I’m happy with the results overall and the quality of the wood. I will begin planking the center of the foredeck today and hopefully finish in a few days. Oh I finally got a new slitting blade from Byrnes model machines, can you believe I’ve been cutting all my wood with a 36 tooth and sanding both sides smooth for all this time! Lol. Excited to bolt this thing on. JJ

-

I would disagree. I think you're doing a great job. I’m considering a CAF purchase after seeing your build progress.

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

Very nice comparison Ben! Both models look excellent! You’re moving along faster on two models than I am on one haha!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Kevin, Any plans to continue on Enterprize? Your progress to this point is great, the development of the lower decks is very nice.

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

Wow she looks excellent! Glad to see you back at it again! The stand you are building is very nice as well.

- 60 replies

-

- enterprize

- caf

-

(and 1 more)

Tagged with:

-

Looking good Edward! You are moving along indeed, you’ll be past me next! Haha. Gun ports are fun, I spent a lot of time trying to get them right. Next time I build gun ports I decided that I will do them during the planking process and use the same planks as I'm using on the hull so they match better. It looks like you’re off to a good start on your ports.

-

HMS Euryalus 1803 by rlb - 1:48 scale

scrubbyj427 replied to rlb's topic in - Build logs for subjects built 1801 - 1850

Very nice work!- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.