-

Posts

360 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Alex M

-

Hi Toni, absolutely precise workmanship! Amazing model! Alex

- 1,449 replies

-

Hi Joss, that are really nice plans! According to tapering of keel, it tapers only fore and aft part, as described in Euryalus book. The fore piece of false keel looks really short. It may be, that the false keel has one piece less than main keel (5 in your case), so the fore piece may be longer Alexander

-

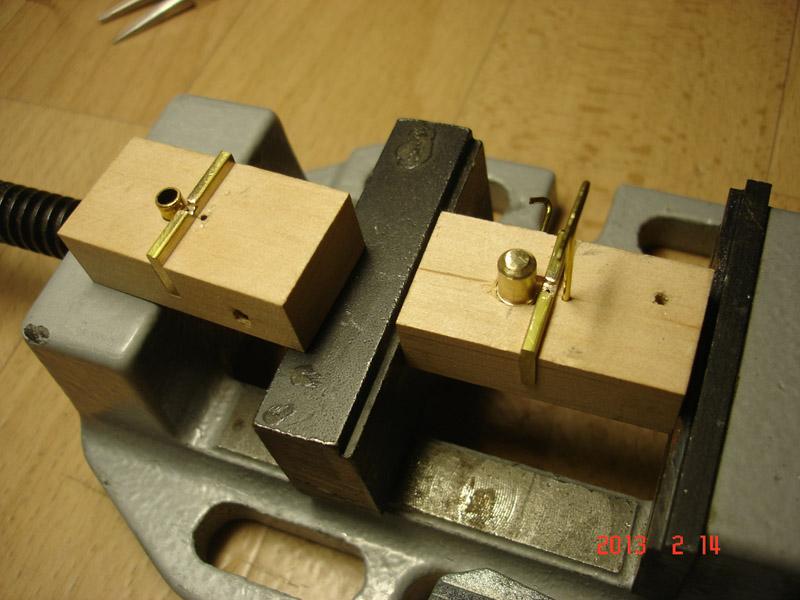

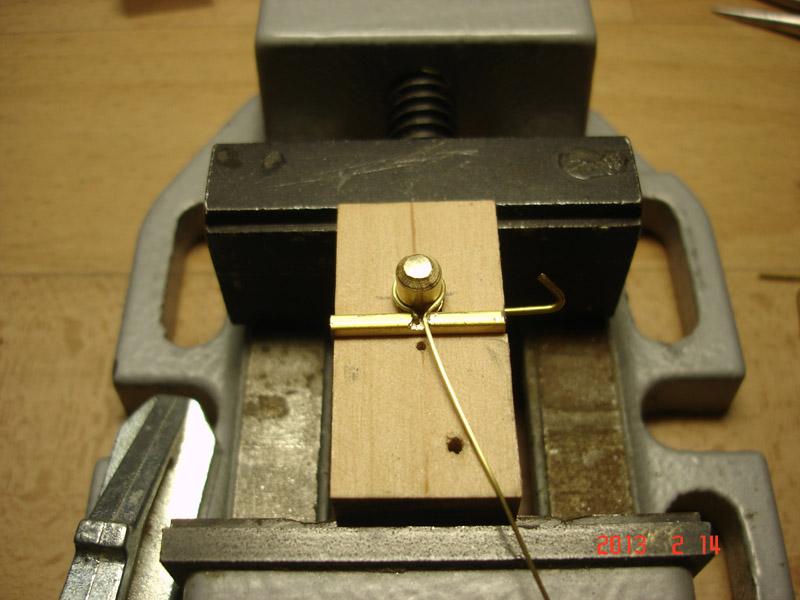

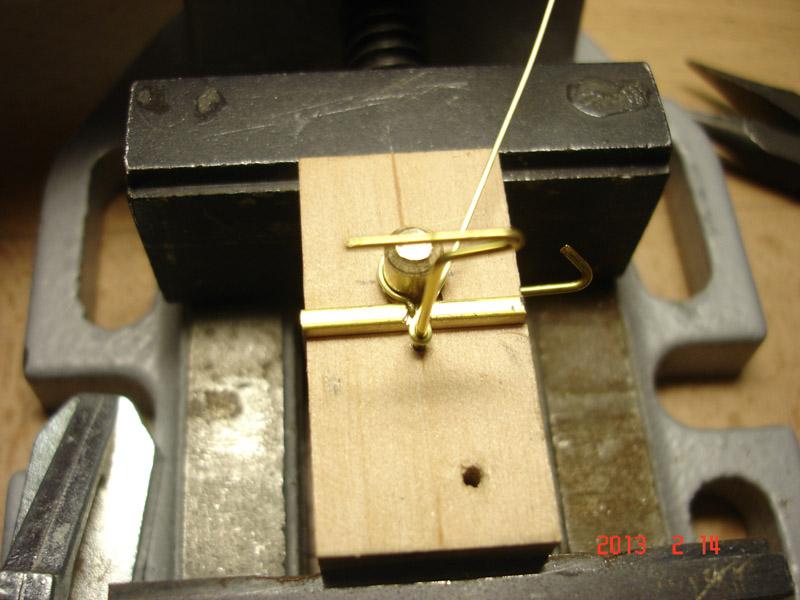

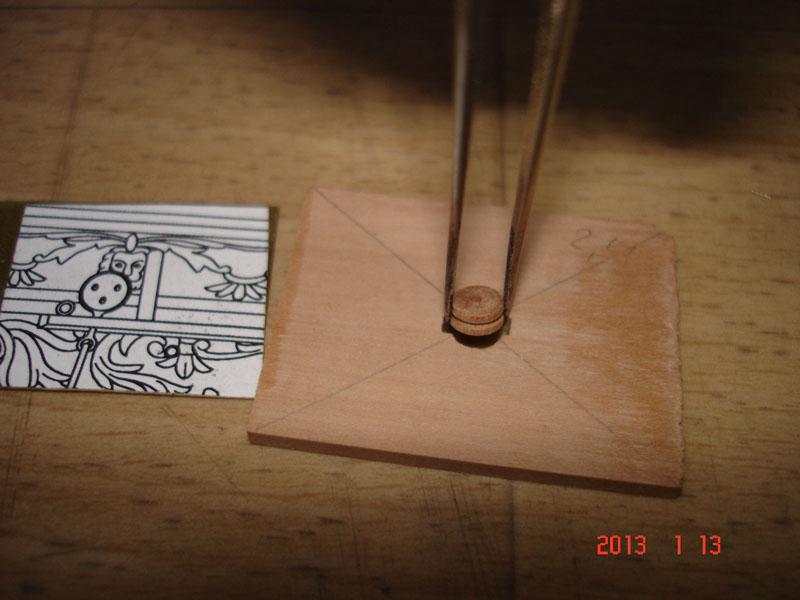

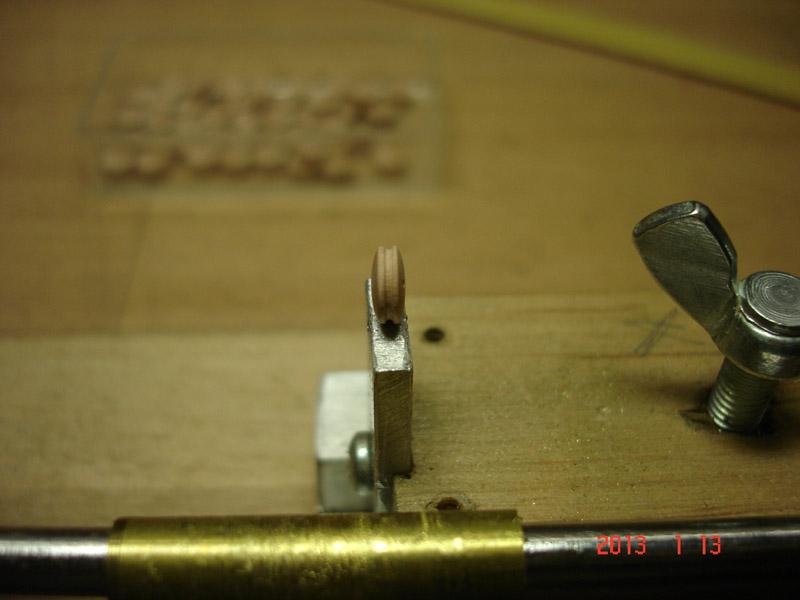

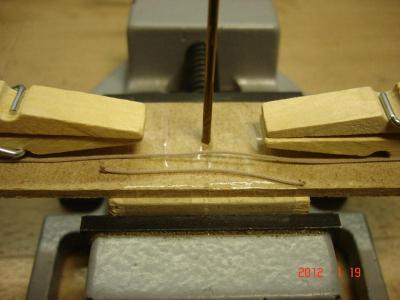

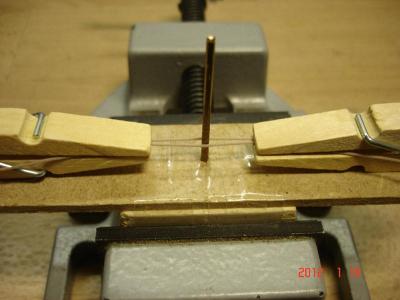

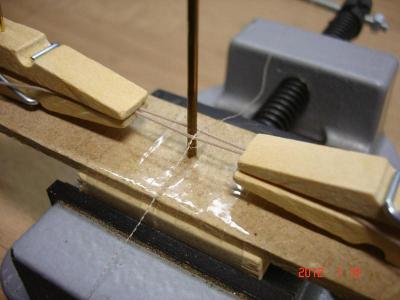

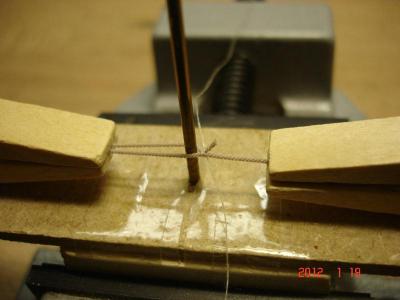

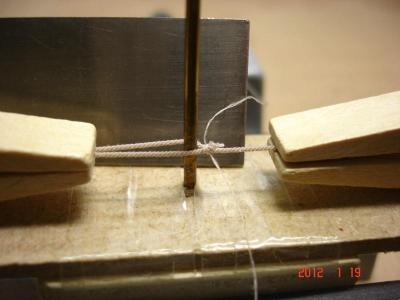

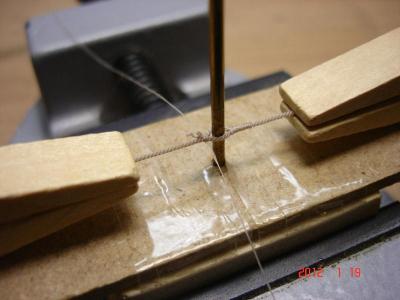

Hello, the next task is to make deadeyes. I have tried to photograph each step, and hope the images are self explainable. One end rounded with "truck tool" Turned and cutted Holding tool for drilling Truning of the holder The first deadeye One side done, shaped witn fine grind paper Ready deadeye And here are these This was the last post from me before crash, so the re-building of the log is now done. To be continued Alexander

-

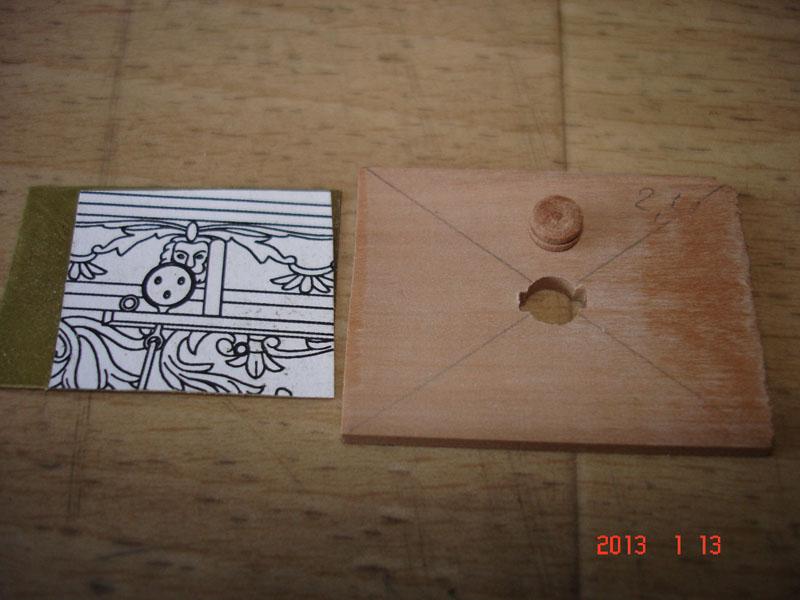

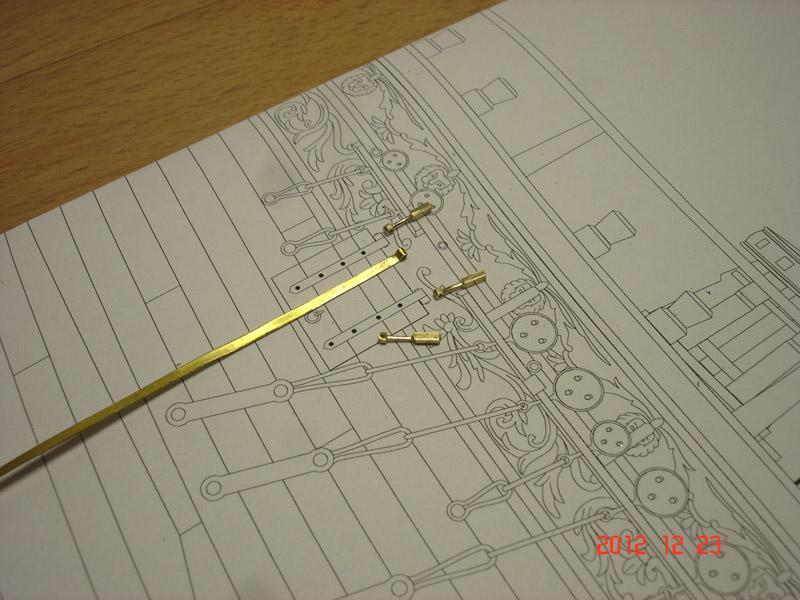

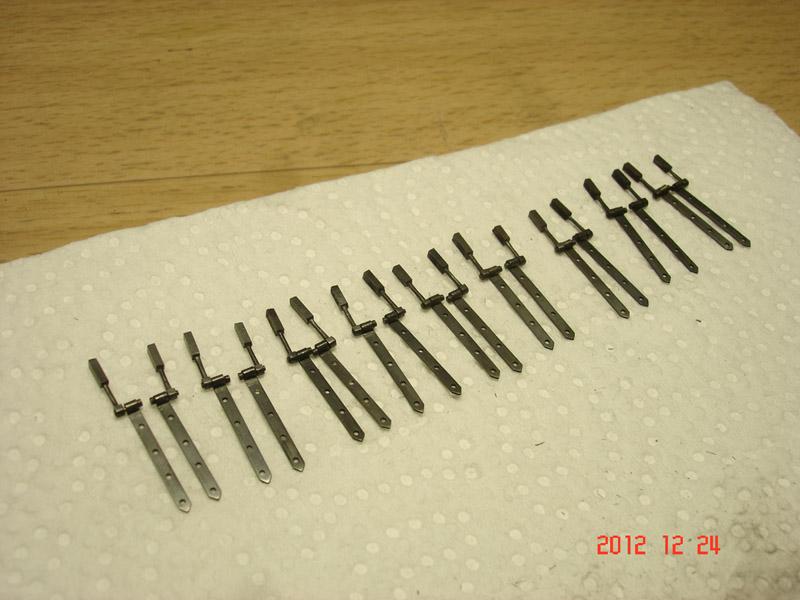

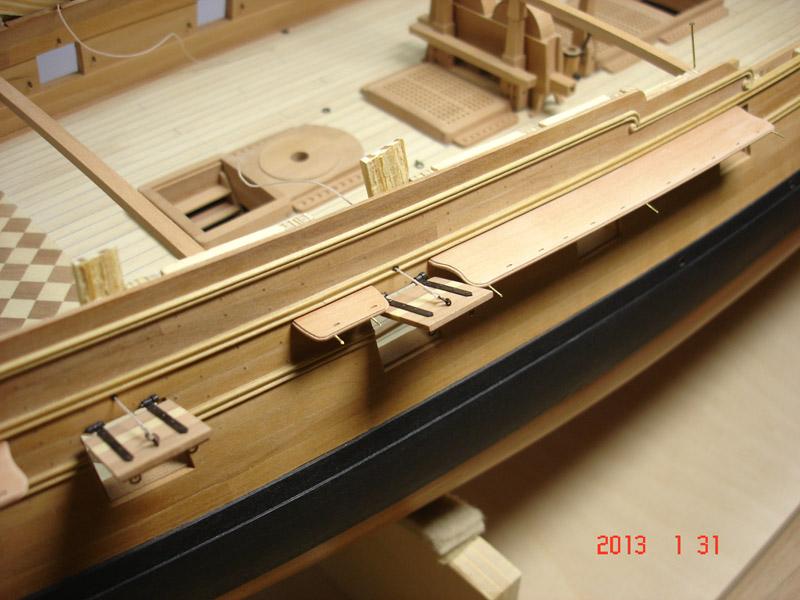

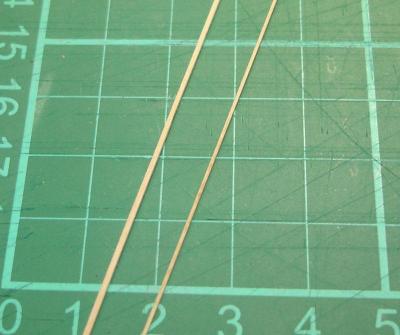

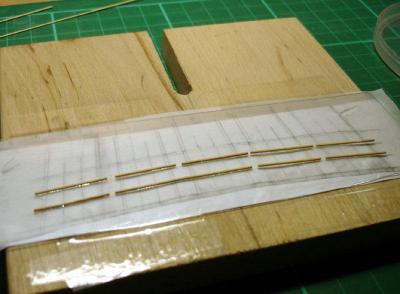

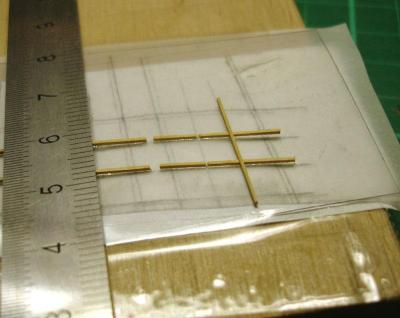

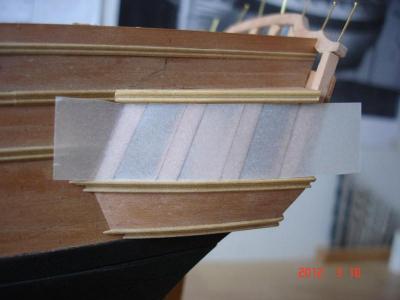

Hello, Before I begin to install all guns, and work further with beams and knees for quarter deck, gun port lids must here. So the production of hinges, the lids itself are made earlier. I hope, the images are self explainable. The installation of hinges and lid tackles. After I have installed all lids, I have made blanks for channels, shaped them to right size and thickness, and installed them (only dry now). To be continued Alexander

-

Thank you Harry, Gregg, Peter, Joe and Toni! I very appreciate your comments! Hi Harry, warm welcome and hope to see your build log soon here, It's Kit or Scratch? Hi Peter, the monograms are glued with CA glue to barrels, I have describet this here: http://modelshipworld.com/index.php?/topic/410-hms-sphynx-by-alex-m-scale-148-english-20-gun-frigate-as-build-1775/page-2#entry5559, pictures from 13 to 16. Alexander

-

ancre LE BONHOMME RICHARD by Jeronimo - FINISHED

Alex M replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

Hello Karl, it is a pleasure to watch you finest workmanship, I'm really impressed! Alexander- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Hi Karl, the model is a piece of Art, absolutely wonderful! Alexander

- 40 replies

-

- ancre

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

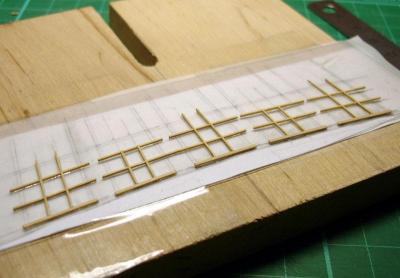

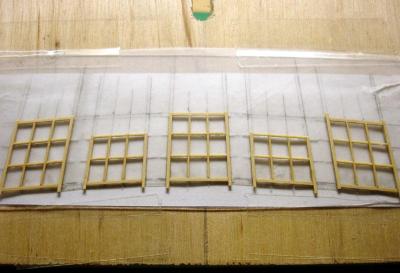

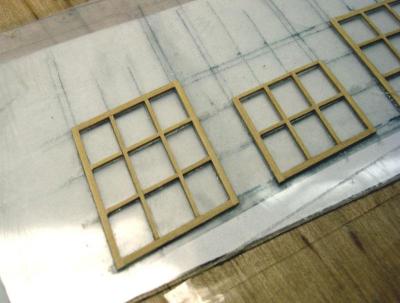

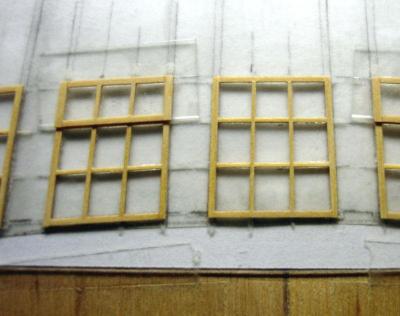

Hello, before I put the guns on their positions, I have decided to work around hull, especially the stern area und the bow. Here are few pictures of making the windows. The wood is Castello, the strips are 0,5x0,5mm and 0,5x0,8mm. For glazing I have used 0,3mm thick plastic from package, then glued framing with CA. The framing of stern windows was transfered to transparent paper, then the windows mullions are drafted on this transparent paper according to plan. Then I have glued white paper sheet to wood plate, and glued transparent paper over the first. So I have correct windows outline and right angles. Then placed clear plastic sheet over paper, and fixed them with tape. Now the mullions. Horizontal mullions (0,5mm x 0,5 mm) are glued directly to plastic with CA glue. Then slots for vertical mullions are cut out with chisel, they are not halflapped, they go through horizontal down to plastic. This is showed in third picture. Then vertical mullions are glued on. then all was cut to right length according to drawing. Then outer frames (0,5mm x 0,8 mm) are glued, again directly to plastic. Then the windows are sand flush, the plastic was then cut out, and the window is ready. The horizontal strips are glued first, then gaps for vertical strips are cut. Vertical strips glued on, cut to right height, and outer framing gluing overall view with outer frames. Also the sliding windows. Close view after sanding The frame for permanent window glued over additional sheet of plastic Check how they fit. The windows need some cleaning, then coat of varnish will be added to simulate old glazing. Preparing framing for galleries beginns The shape of windows traced to transparent paper. The windows for galleries are done in the same manner as before. The glazing is imitated by adding a coat of varnish, this give the irregular transparence like old glass. The battens between windows added separately. They will recieve mouldings later, and are hold at now by a little spot of glue. All windows are dry fitted at now. Here is how the wooden shindles are made, and ready cover for gallery The planking of stern is completed. The arches are made from two strips of 0,6mm boxwood glued together. Internal view with few beams of QD installed To be continued Alexander

-

Hi Pat, I showed my set up here: http://modelshipworld.com/index.php?/topic/410-hms-sphynx-by-alex-m-scale-148-english-20-gun-frigate-as-build-1775/?p=5559 I have turned them on an old Unimat SL machine. To turn taper surfaces you should set the head stock to the angle of taper, so I do it as showed in the picture from above. Then I have tuned each gun at one time using brass template as guide. Here is my Unimat: Alexander

-

Hi Dan, I was impressed by you build log and by you Vulture in old MSW, now I'm impressed by you re-build! Marvelous work you do here, Hats off! Alexander

-

ancre Le Commerce de Marseille by Zbigniew

Alex M replied to Zbigniew's topic in - Build logs for subjects built 1751 - 1800

Hello, really awesome build and very fine woodworking! Lovely images! Alexander -

ancre LE BONHOMME RICHARD by Jeronimo - FINISHED

Alex M replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

Hello Karl, great to see you back! It was awesome build log, and I'm happy to follow it here! Alexander- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

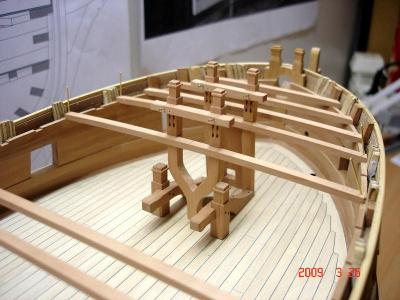

Thanks you Greg, Wacko and Pat! Posted: Tue Feb 17, 2009 9:47 am I have worked on pumps, they are not completed at the moment. The brakes of hand pumps are not installed now. I'm not sure, if I do to cower the pumps heads with cooper plate, as show on the model of Amazon by NMM. Probably not. So the pictures follows. Quarter deck and fore castle beams cutted and sanded, and main and fore bitts in process: Knees for fore castle beams: To be continued. Alexander

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.