-

Posts

360 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Alex M

-

HMS Alert 1777 by Jaekon Lee - 1/64

Alex M replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Very good planking, Lee! How many clinked hulls you have build? Can you show us fotos? Alex -

Perfect mast partner, very fine work, Remco! Alex

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

I'm sorry if this make you less happy, but the whole is more complicate, as far as I know... The garboard plank was beveled in mostly cases to match the rabbet. As clearly shown in those drawings: http://collections.rmg.co.uk/collections/objects/85449.html http://collections.rmg.co.uk/collections/objects/80965.html http://collections.rmg.co.uk/collections/objects/80745.html here the later practice: http://collections.rmg.co.uk/collections/objects/80704.html and here a couple of frame drawings that show tre rabbet and garboard planks: http://collections.rmg.co.uk/collections.html#!csearch;searchTerm=Telavera_1818;start=10

-

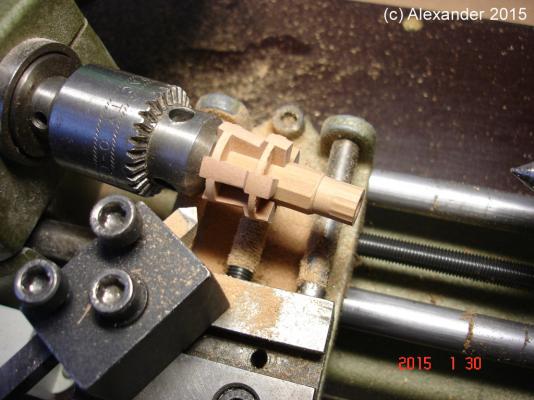

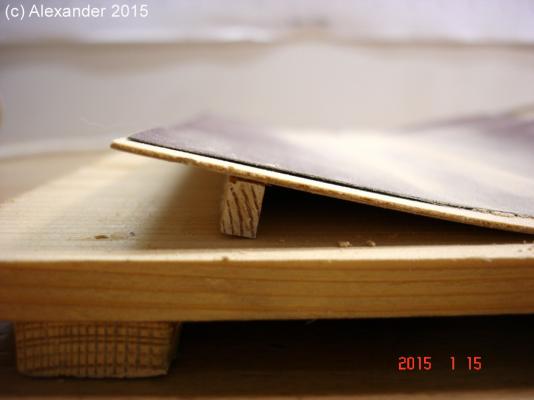

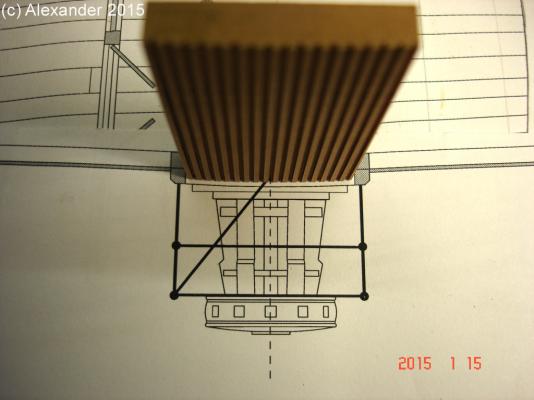

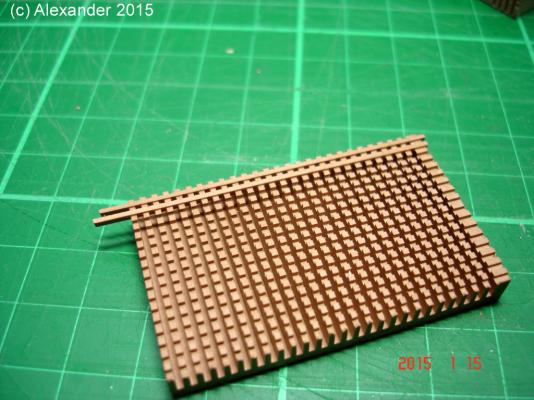

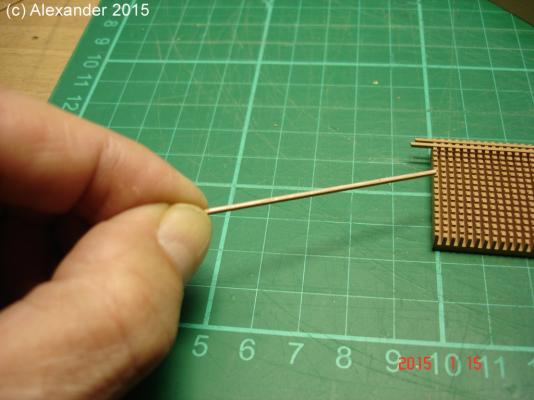

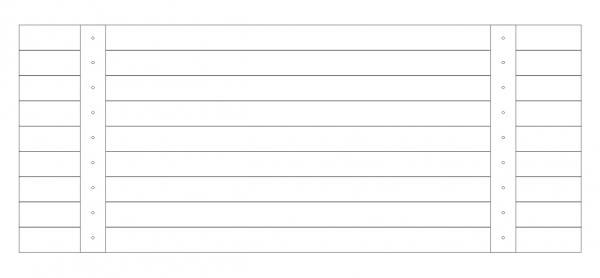

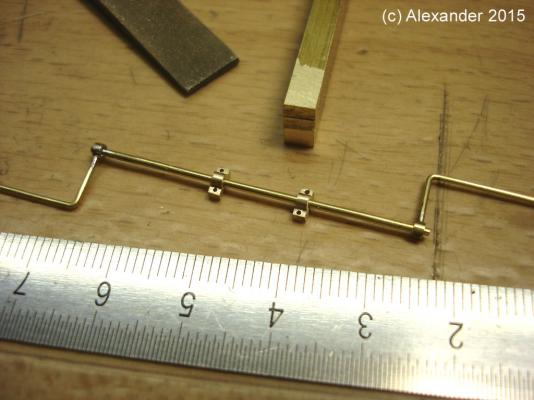

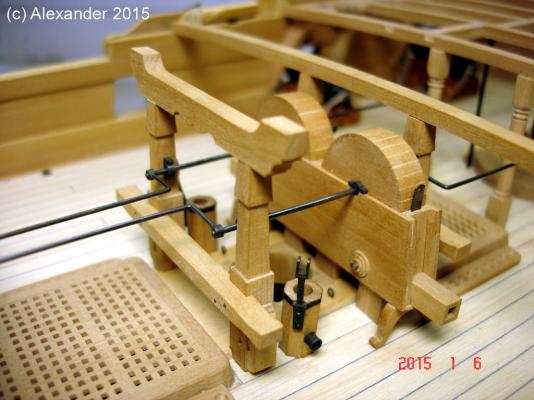

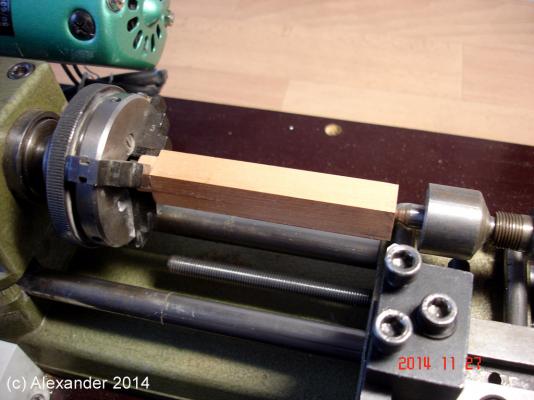

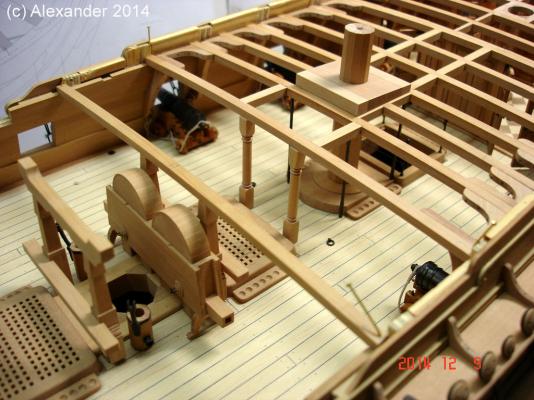

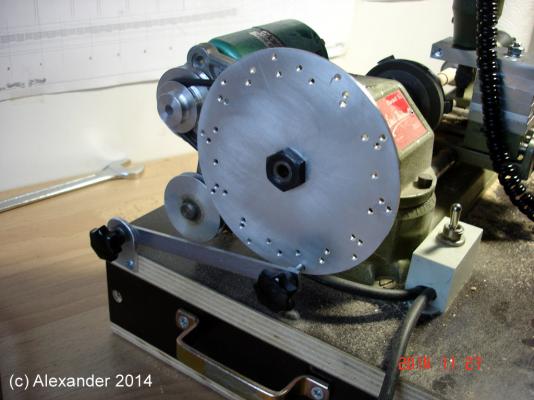

Hello, the work continues with the gratings and coamings of the quarter deck, and ladder way to gun deck. In this case the gratings should look like "real" and have proper thickness and shape. Follow images show the process. First the upper edge of the block was shaped on this jig: then cuts are done on tablesaw: then strips are glued and the whole was sanded again in the jig: Coamings are build around gratings, ladder way and coaming added: All is dry fitted now. Alex

-

Chopping block work table

Alex M replied to qwerty2008's topic in Modeling tools and Workshop Equipment

Hi Lextin, I would screw two or three 2x2 inch boards of hard wood (oak as example) to the underside of table. You can also glue them all together before them. Important: bound boards tight all together with ratchet straps before screwing. I have one very similar to yours in my basement as workbench, is very solid and stable. Alex -

HMS Alert 1777 by Jaekon Lee - 1/64

Alex M replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Hi Lee, looks very good! It's a lovely little and fine model! According to beams: I would highly recommend to cut them instead of bending. It's not soo much more work. Otherwise this can end with bad surprises later... Now it's a state where you can avoid some problems. Alex -

HMS Sphynx by TBlack - 1:64

Alex M replied to TBlack's topic in - Build logs for subjects built 1751 - 1800

Hello Tom, thanks for warm words about my plans! I have folowed your build of Vinal Haven and should say, that you model looks very realistic. So please do'nt stop! I will follow your build! Alex -

HMS Sphynx by TBlack - 1:64

Alex M replied to TBlack's topic in - Build logs for subjects built 1751 - 1800

Hello TBlack, nice start! looks like my Sphynx at beginning Alex -

Hi Chuck, excellent planking job! Very clear and smooth! Christian, I'm not Chuck, sorry, but if you look at the image with red painted counter in Chuck's previous post, you will notice a small step between them and tuck. The tuck will be planked later, and all will follow the plan. Very smart solution, Chuck! Alex

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.