-

Posts

857 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jond

-

Rich thanks for the encouragement. I will continue to follow you and it won't be 30 years before I come back. I am completing an old model of Bowdoin right now and experimenting on diorama. I started a log for it. When I come back I hope to make a diorama here too. I actually bought line drawings to create whales and I plan to try that with Sculpy….. cheers

-

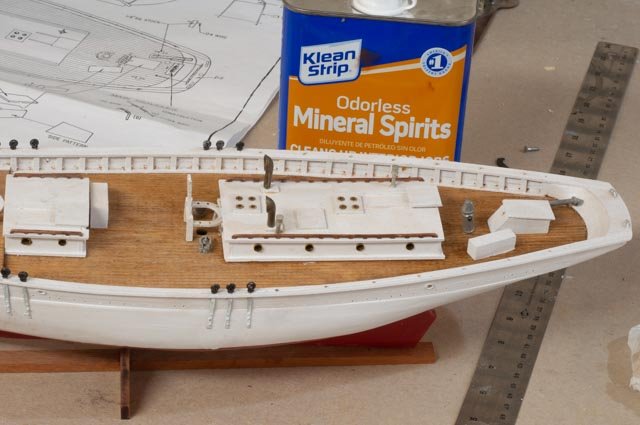

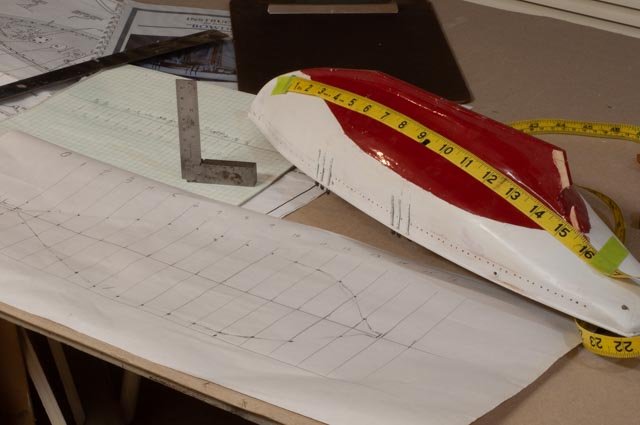

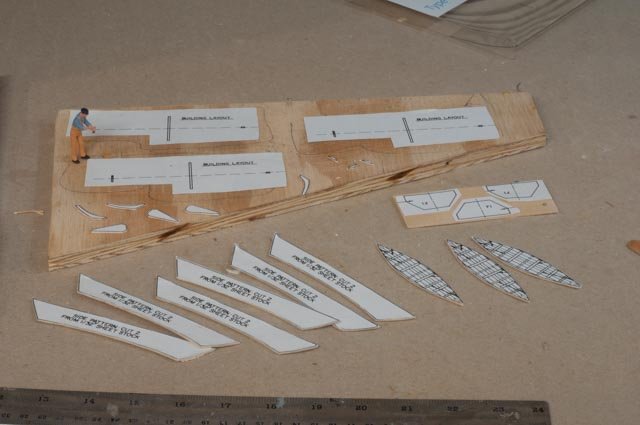

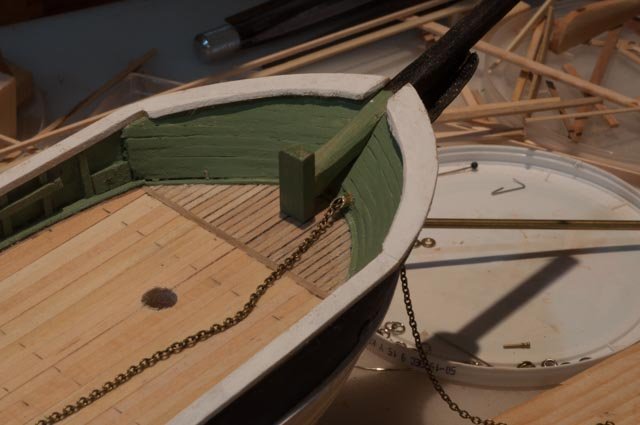

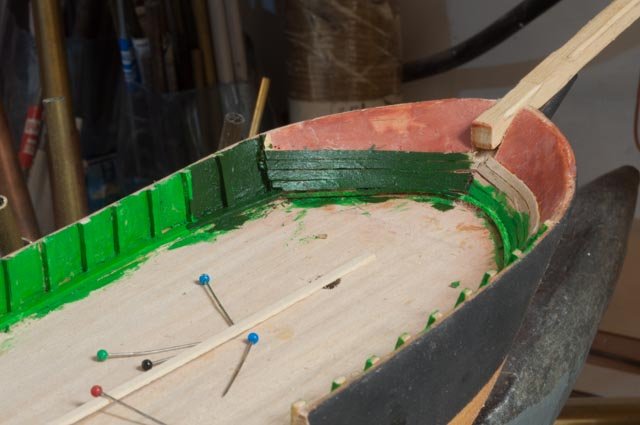

start to rebuild the kit post 2 I need to first get started with the rework on the model. It has sat on a shelf for years and though an occasional once over with a light vacuum, it is shall we say dusty. · First up is cleaning of the deck. I believe I used a satin poly on this. In my preliminary research I am finding a beat-up deck followed by painted decks. I need to think more about the final decision as to what era I shall try to replicate. I think this might be water base poly, very hard to remove for staining. My guess is the first voyage was just oiled deck as was practice of the day. In some reading they advised that good old Charlie Hodgdon... [ his history well known around here as the family still operates one of Maine's great Boat building facility]... took over the line drawings from William Hand and completed the planning of the build that was specific to the needs of the arctic. I doubt in 1921 a painted deck was on the original launched boat, though by the end of the 1920’s it was clearly gray and white paint. More on this later in the build. · Next up are the spars. They were not finished; just roughly shaped and varnished. First step is to remove all finish to allow staining for the lower masts and shaping for rings etc. · Now to the bottom and the shape needed to install the rudder and propeller. Lines check out to be ok, but more shaping is needed to get the rudder installed. also i think the bottom paint is a little loud.....will do again I am sure. · Now my first attempt to build three small dories. I plan to follow the kit instructions and see how I do. I know from Bluenose these little guys are very hard to do. base wood just does not like to bend and I have never been able to get fast glue to dry fast. I have yet to make a dory I like, but must solve that issue. I first experimented with scan and print and found I got copies the same size, and for production printed out three sets to make shaping parts easy, especially with eh spindle sander, my new favorite tool. There are clearly 3 dories on the early trips. They were stacked to port side. more on e that later. Ok off to the diorama stuff. · I had some scrap 1/8 plywood with teak veneer for my pond yachts that I will never use. I have no line drawings, so to trace a drawing of the waterline in plan is not available for a starting point. I used trial and error and the first hole was too big by up to 3/8 in the middle to ok at the ends. So, I measured the offsets as best as possible and cut out the second one. If I were going to set the hull in and make wake water or something for a model under sail, or ice for hull in ice, this is OK. I shall experiment with this version being a sheet of ice. At the same time, I continue to search out the translucent acrylic product. Next up is to collate several visuals I found at the Boothbay Region Historical society. They are extremely helpful to see how the Bowdoin was rigged in the early days.....stay tuned. many changes coming......tweaks that is . All for now

-

Jeff thanks for the tip on the supplier. I will definitely check it out. I have some templates too that I made in 1/8 plywood so I can play with other options like clear resin over paint and more likely ice. that would be resin over white paint, maybe some salt...??? I will look into your log too...see you there regards

-

Gary and Jim thanks for feedback I read a recent article about the resin pour. That is a great solution for waterline display, and I need to keep that as a possibility. I was blown away a few years back with the technique of taking translucent acrylic and displaying it either flat or heat bent for a rolling sea, then setting the model so you see both below and above the water. For a whaler one could have fun trying to place a whale next to the boat. Here I will try an arctic scene, and at this stage am open to experimenting. It seems that the vendors want to sell either textured clear or colored sheets. I have four little sample pieces coming of clear textured and a few colors to experiment with making layers. I will then try some amateur coatings. There may be a peel and stick film that could go on the bottom of the textured sheets too. These two experiments might be like the clear resin over painted back ground. I also found a site that offers a 16 inch by 24 inch piece of sea blue textured that might work. I am just ready to plunge. I want more practice. I have already cut two attempts of holes through scrap 1/8" plywood. A little trial and error as I stated there are no line drawings included in the kit. I will share in future post when I get more progress on making the right size hole. cheers

-

Bowdoin in ice display build post 1 This build will be my first attempt at a diorama I wanted to start this log to record both the research and the effort to replicate an expedition scene. It is going to more about studying the ship from 1924-to say 1930, its expeditions and the making of the overall display rather than only the model itself. I know I am going to need help. More than 15 years ago, I either bought or was given the Bluejacket model of the Bowdoin. When I stared modeling schooners in about 2012, my first thought was to use the 1:48 kit information as a study and then to build a 1:24 sailing model. [ that is the scale of my Bluenose and it is fun!] I still may do that, I just have too many possible projects. I want to use this opportunity to explore more of a diorama display of a type of ship to better learn how it was used. The Kate Cory build that is now on hold will come back, and I will try to have a whale on the side being treated. For the Bowdoin I am not sure, but think I want to show her in the ice or afloat next to the ice set up for winter in the arctic. I hope to have this display ready for next summer as a local family store owner wants to make Boothbay Built schooners a feature of their new venue. I have offered this model up as a backup, as other Bowdoin models may come available. My thought is an icy diorama with the model in it. As I have tried on my other models, I am more about trying to find out how things worked and what they were like in old photos and then try to adjust the model in that direction. I hope I can carry that off. This log is also for the purpose of documenting those items. The local historical society has tons of visuals to review, and the Donald Macmillan material is all available at Bowdoin College that is only 45 minutes away. [ in the winter light traffic anyway]. My love of this boat started in 1962. I was a junior sailing instructor in a summer program in Massachusetts and Donald Macmillan came to talk to us and sell his book. I fortuitously bought an autographed copy that is still in my library. I have read it both years ago and then again more recently as part of my extensive reading about the arctic. So many items will fill in as we go, but to start off …where are we with the actual build? There are just a few old photos that show that in 2012 ish, as I was starting to play with 1:48 scale builds, so I could down size my scale experience to be able build the four masted Schooner Charles Notman. All I did at that time was to rough out the hull and set up the deck. I noted that the kit did not require nor include any line drawings. A few years later as I was researching the Boothbay Harbor One Design at the Boothbay Region Historical society, I found they have a copy of the William Hand design of Bowdoin….I got a copy of the section lines so in the future I could rough out a scaled hull in RC friendly larger scale . I am told the original drawings of all of Hand’s work is in the Hart Museum at MIT. In a casual search of their site, I was unable to find them in their data base. If anyone seriously wants them that is a place to go. So to the build…these photos are about about 5 years ago... . · Here I was using the famous bondo glazing putty to smooth out the hull. Looking at the results 6 years later, I would likely send it back for another few coats. Three days more maybe then would have been great…..oh well. · Here we got some base coats painted and deck stained. · Here we added the bulkhead strips · Here we have the cap rails on and I notice more putty fixing the sides. It seems that for some of us, we can only see those defects after the first base coats of paint. That is why I stared the filler prime process. …. just spilled milk as they say · Finally, here is furniture partially built or as supplied in the kit in place and we are resting waiting for any action. This roughly represents the amount of deck detail I would include for an RC model. I have taken what I can find of the unused kit material. Obviously after this much time, it is scattered, so I am sure I will make or reorder what I need. The bell by example is nowhere to be found. What big new thing do I want to learn? ……The most urgent modeling method study for this build is to find out where to buy and how to work with textured and tinted Acrylic sheets. I want to cut out a hole for the boat and maybe a dory. Then one looks from the side and sees the underwater hull, maybe a fish or two, or even the anchor. There are several of these in Lunenburg museum and they are stunning. So far, I only found one source and they need about $50 for one sheet about the right size. That’s fine if it is right, but I need to practice. I looked all over MSW and was unsuccessful finding any articles or logs that jumped out at me. Anyway that study and experiments will be part of this build…..also how to make ice? then if i get brave or find some help make people and dogs. all in time. Cheers jon

-

This post is to record an unplanned but wonderful delay in this build. A local vendor in town has decided to celebrate Boothbay schooners in his new maritime focused store. The focus shall aim at those Schooners built in Boothbay. As stated multiple times in my previous builds, both studying and modeling these locally built boats has been my desire for years. Charles Notman was built as a prototype for building some of the 12 big 4 masted schooners built here [ 20 in the county] near the end of the schooner development in 1921. The Maine Ice industry use of schooners and wintertime labor was also a big part of our local history including a 500-foot-long dock feeding up to 4 schooners at a time in the harbor. The great sardine fleets, locally built packet brigs and barks etc. So what does that mean……. These whalers will be on the shelf for some time. Similar sized packet brigs were built here at the same time as the whalers, so who knows what will happen. I will return to spruce up Charles Notman as I am scheduled to talk about the big schooners next summer, and there are several items to be completed and fixed. I shall rebuild and complete Bowdoin hopefully in my first diorama, build a Pinky in 1:24 scale etc. etc. Anyway my other logs will get updates and I will switch to a new one on Bowdoin as that was a first item to get done, so as we pick up this project… Here we see I partially completed my first attempt at copper tape on a bottom. My approach when I got to this stage was to order another roll. I must say the challenge of using this tape is real. It just does not like to easily stick. I will likely remove it all, sand and smooth up the finish with several more coats of buffed varnish. A lesson to learned it needs to be very smooth to hold. Here we see a supply of mock up barrels I bought. I plan to figure out how to make them, as a dock side or even at sea rendering scene would need many, and in that case they should be home made. Also I want to learn to make some hollow ones on the lathe. So much to do! Finally, here we are resting on the shelf. All loose materials, plans and notes back in the box. Not to be forgotten so Bowdoin is next up All for now...we shall return

-

Rich good to see you making progress. The dories look great. I have been hit by a great opportunity to get back into schooners, so my kate cory will be on hold for a few months...… I'll post about it later this week. It's a funny thing however, I immediately have to build three dories for the Bowdoin …...oh well . I believe a guide to measuring an amount of added detail is the comfort of getting ones thumbs stuck trying to get that next little part attached. If they , the thumbs that is, can get in and out, it's fun to keep going. example...I love your cleats. cheers

- 109 replies

-

- model shipways

- kate cory

-

(and 1 more)

Tagged with:

-

i wanted to get to a stopping point as diversions have come up including a trip west. I am reasonably happy with the rough paint job. It is not the last however. I assume working the bottom and getting the bow sprit done will get me to a point to focus on redoing and finishing that process. I got advice on using foam sanding sponges after the first painting on small surfaces like the whale boats. This small scale is giving me hair like fibers of the wood, dust and roughness and I need to learn to deal with it. Using a scalpel for cutting has helped a lot. Good by x-acto knives. I have also read in a recent blog that working with bass wood at this scale it is necessary to get one coat on and then final sanding. I look forward to trying it. The small whalers all need that on there outer planking. I went outside and took four pictures with normal lens and four with wide angle to suck in more color and add perspective. These photos show me so many defects that I know I have a way to go, but also the wonderful early fall season. As photography is part of learning how to do these logs, I find it interesting as I go back and forth with a 60 MM macro that on FD nikon that is really 90 MM and a 24 MM I keep on the FX body, so it stays at 24 MM... I really see differences. My photos have a long way to go though, and it's fun to try things out. here are 4 with normal lens.. at 90 MM the images seem flat. I set the aperture on max to improve the field but outside i would be better to reduce it and loose the background. and here 4 views with the 24 MM shot on auto. the exaggerated perspective and deep field in focus is interesting. anyway I am off to cowboy-land for a bit. I just tried the copper bottom tape and wow I have a lot to learn when I get back cheers

-

Mike I am slow right now as our actual sailing season ends, boat just out of the water, and we will take a trip west for a few weeks. When back I plan to move along and the boats will become different. I want one boat to be working at sea. I found a site that sells plans for keel and bulkhead lines of whales. I think if I make the mold and fill it with sculpy I might make a whale. I have a sheet of lexan and may cut it out at waterline for Kc and a whale by her side and a small boat in the water. If bad I can just trash it. I have many visuals in books showing the process. I believe in the brig they may have rigged a storm staysail in place of the furled Main. I say that because the fishing schooners did that. There maybe a main staysail and a jib set.. Not sure but lots of fun studying Boat two......pavilion has fore sail like a schooner. I will likely have it sailing with bulkhead closed, or do a dockside showing unloading of barrels. lots to think about . This will be first attempt of diorama l keep looking for build logs on making thin waterline so you above and below water. There are some incredible examples in lunenberg museum …..I consider the opportunity here low risk practice and learning before I try charles morgan next year. Cheers

-

I have some more work to get done before starting the copper bottom …I think. I am not sure what is right. The top gallant rail is not too strong and they include all of this in the books as the first phase. They are not too clear about when and how to do the bottom. · My favorite adventure so far is getting these cheek knees installed. We are slowly getting there…maybe. each time I look I want to make them smaller. · The top gallant rail and “rooster tails”. I already knocked them off once, so maybe this is out of sequence. I decided so far not to so the knight heads and buffalo rail until after the bottom is on, as I like removing the bowsprit. I made a little cut out piece that goes in after the knight heads that I will cut through the cap rail for strength. · The cutaway bulkhead is the first fun piece. · Second boat cheeks · Top gallant on stern · Hawser pipe surrounds · Sanding of wales and cheeks ready for trial painting · Bulkhead installed for sailing · Bulkhead from inside boat two. One of these brigs will have it open and stored….not sure where but that’s a plan at least. it would clearly block access to the pin rails if just to one side. I am going to do a first paint out to see what we have. I expect damage during copper so I will save touch of then. All for know

-

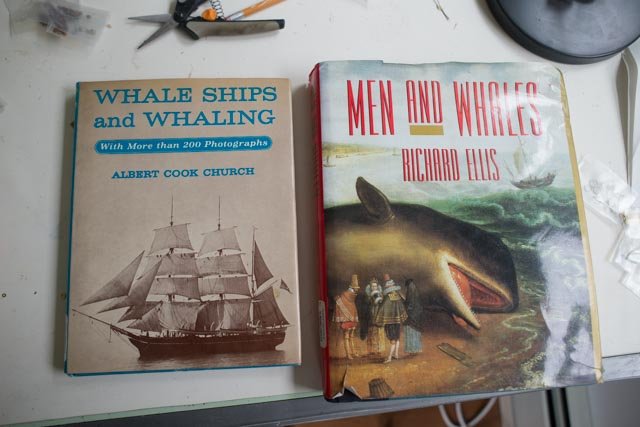

Off to the Downeast Shipmodelers Guild Both models cleaned up ok but are still very rough and have a whaler on board in first the planned color schemes. · Here we are after lunch sitting around the table · I shared three of the 12 books I have for this build and a few tales of the amazing travels of little 75-80 foot brigs. · …Whales Ships and Whaling by Church is listed in several build logs as a great collection of visuals for anyone taking this venture. Men and Whales by Ellis is simply amazing. I plan on it being s great winter read. it is encyclopedic in its approach and scope. I also took the Pavilion book I mentioned in an earlier post. I will list all the books in my research as we go along. After we got over the banter about how I was going to sail such small models [ my recent previous builds all were sailable] we got into painting skills for these static models and how to display in water. I learned to keep working in artist acrylic paint but when ready, and before rigging, spray on clear coat to fill in and get a much smoother finish. We talked about water display, but I’ll hold that for future discussion. Back in the shop I needed to finish the basic work to get above becks done to be beyond any rough handling. Then I can begin my first attempt at a copper bottom. · First up is to get hawser pipes done. I went around a bit trying to select a chain size for this new scale to me of 1:64. A settled on 15 per inch but want to know more. This is not a three masted bark, but a under 80-foot brig. That choice gave me the pipe size. I have also started my third attempt to build the cheek knees. They may be ugly, but we’ll get there I hope. · I decided to put on the wales. I had hesitated because I am not sure how it works with ending the copper about 1/16th inch below. I feel comfortable pinning to the solid hull, as I can fill the pin holes before painting. · I am guessing that the pads around the masts were the same oiled material as the normal deck and not the light pine sheathing. · I temporarily strung some chain to check it out. Also, I notice others have modeled with chains on both sides. Considering the primitive windless I can not image sending out hundreds of feet of chain. The choice of rope however would have lightened the load involved with hand cranking. Anyway, I will continue with what is shown on plans and study to see if lines were used for deeper waters. perhaps they simply did not plan to anchor in anything very deep. All for now Cheers

-

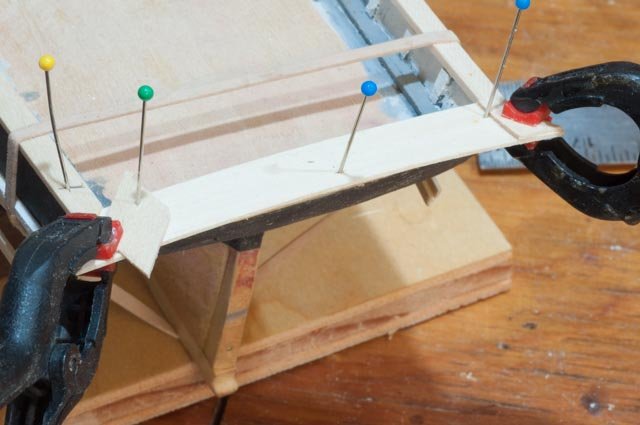

It is time to get ready for the first sharing of this project with our local Modeling group. The Downeast Shipmodeler’s Guild meets monthly at or near the Maine Maritime Museum. We have some good builders in a very diverse spectrum, and I always learn something new. · I have added ceilings and seats in some of the whalers and needed to get paint in them before it was too late. I was experimenting with yellow and tan and light gray at this point · So a few days before the meeting I put my things together getting ready for the meeting I decided that I needed to get more done so I could better discuss the color issues on the main hulls and I think I should get more paint on the whalers so let’s go · Here is second attempt on the cheek knees. Following the book, I am working on building them 1/16 thick through lamination. I had to put this on hold since not enough time. · I wanted to put on the cap rails and get a white coat on them. For the transom I laminated two sheets to get the arch. · Here the second sheet fills in · For the bow I made split pieces and just love this new tool. Switching to a spindle I made four of these pieces in about ten minutes · Here we are one evening with cap rail on….note another oops. Here on KN I ran the starboard cap rail all the way forward, so it would take the small bend after wetting in ammonia water solution. On Pav I wanted to use a scrap piece, so I cut it at the side opening. It was then impossible for the forward piece · Overnight I had to bend a soaked piece to complete the rail Now we are ready to go see how we are doing. Off to the guild cheers

-

I just made a successful trip to Michaels I hope to get some new paints… · The tube on the right shows a color I liked. It came from the local store and produced the very dark green. I guess you cannot tell paint form the cover. the oily mess is rthe bottle that came in one of theold kits....ugly. the next sea green is too gray and the xmas green just awful. · I painted all the greens I bought at Michaels and settled on this one….some kind of mossy meadow. Also we're getting near the top on the bow planking. several repairs in the near future I see in the photo · Here I am on the outside of Pavilion adding the anchor hawser holes. I need to find them and the wales line up so I can design the cheek knees. · This is my first unsuccessful attempt to build cheek knees for the bow stem. I must say the plans to do not show them and the instructions show nice diagram but no dimensions. It’s time to figure out the decks on Pavilion. · Here I am showing the colored deck from KC. The KC build as of now is to be 'newish'...the brig only lasted a few years. I want Pavilion to be old because she was converted to whaling after 8 years and whaled for nearly 25 years. Let’s experiment and come back to this one. · I believe I am showing 'newish' deck here in the bow area and very new sheathing · Now it’s time to add the exterior wales · Here we have the first deck in place all for now

-

it is a nice way to end the summer.....or should I say it's a nice way to begin the fall. She looks great and I look forward to your copper bottom job. I have never done that and look forward to the lesson. cheers

- 145 replies

-

- model shipways

- charles w. morgan

-

(and 1 more)

Tagged with:

-

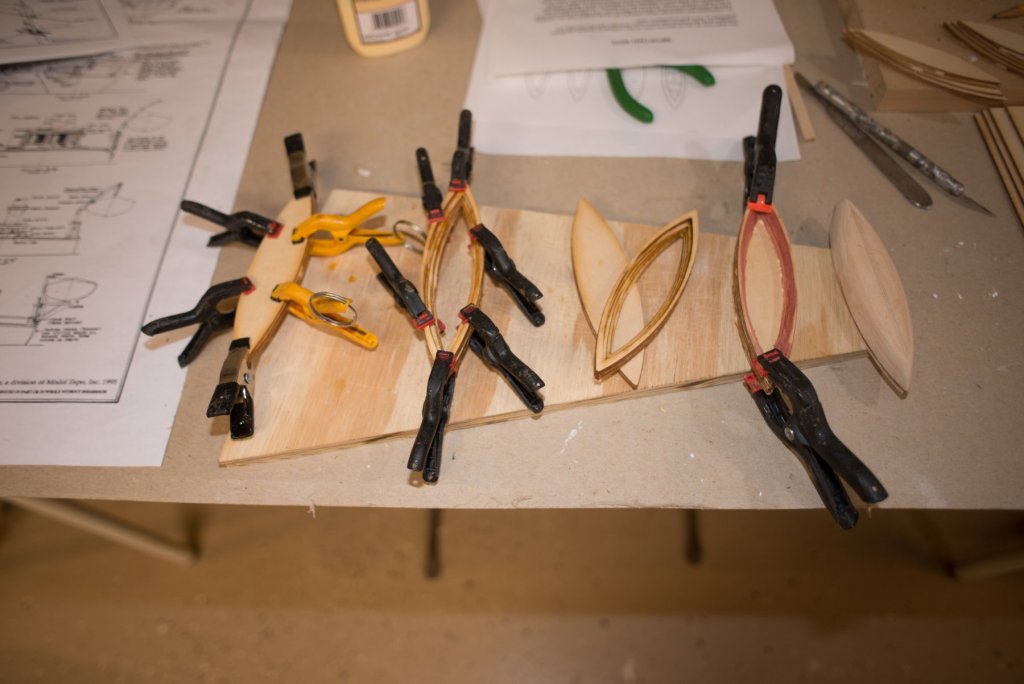

I want to share some more progress on the eight whalers and two main hull topsides. I am starting on the slippery slope of finding the level of detail for the whalers. As this is my first attempt, I am holding back my expectation. I also need to make decision on the coloring for Pavilion. The older photos I see in books, and the more paintings I see also in the whaling books, I find the boats to often be white on the outside. So, this is something easy to change but as I start, they will be white. · The beauty of doing many of these little boats is that by the third one in, I begin to get the hang of it. Here on the early boat I cut the wet keel to the right size and fitted it into the stem and pinched it with the clamp to dry before gluing. By boat three I learned to keep the wet keel about .5-inch-long at each end and bend it down past the stem and tape it to dry. Faster and better fit after drying out. · Here we have the assembly line. ceilings on the left, keels in the center and the last stems and gunnels are on the right · Now we need the bow chocks. Here they are being shaped. Also, the sole and ribs are in and we are awaiting the ceiling planks here we see the first painting experiment on the the whalers Back to our hulls. I have been to the local arts store and found a paint that on the cover looked good……but · The KC will carry on with the green theme and Pavilion will be older and in the black and white theme. Now for the decks.....I have taken the two deck materials and tried to get the color right. I learned the hard way that if decking is veneer or even 1/32 inch, it is better to stain and/or to add one coat of hand rubbed poly before introducing any glue. Even with water rinse I have failed in the past to keep all glue away from the surface and there is not enough wood to deep sand for stain. It is I and not the process on this one…So here is color scheme for KC decking. · It’s time to get the anchor holes roughed in, so we can work around them. Also, one hole was off and easier to patch up and re-drill now than later. · I have cut through for the bow sprit started the inside planking of the bow. · Here on KC we see some bow planking in place and the first local shop artist paint……too dark for me so off to Michael's…a 50-mile trip · Working our way up the inside of the bow gets very tricky for the ceiling planking. Fortunately, with a painted finish, I can use pins and then patch and paint. here i tried gray but have voted it down since I saw white in old photos. · The transom is much easier to do. You can see all the experimental painting on the bulkheads. This will be solved soon. All for now cheers

-

I am enjoying this build as I start my first whalers. I have eight little whalers and having this same kit on my shelf gives an incredible amount of information through the plans. I hope to build this next year. I look forward to seeing you work through the issues Cheers Jon

- 21 replies

-

- whaleboat

- model shipways

-

(and 1 more)

Tagged with:

-

Now the first big oops…. · back in the shop looking at the results it does not take long to see the affects of the swinging line. The water line crept up. I have sanded and re-masked for painting · Proving it was the string we find the same problem at the other end · And yes, both ships needed the rework…. back to the garage Now it is time to start finding the color scheme of the decks of the two brigs. I have now read the book on pavilion. Great story and amazing travel log. She made it to the pacific and ultimate found her demise in the North Arctic sea. This was pre GPS and only a 79 foot ship….wow Just before this primer, I started to add the interior planking to the transom. · Before planking the bow area, I tried an experiment. I had some scrap poly styrene and it bent with some convincing to make a replication of the water way. · The documentation all lead Kate to have a green theme so to speak. The only green in my shop was meant for Christmas decorations so I used it for a primer. As to Pavilion I am comfortable that the bulkhead of the packet ships often had white. I am collecting photo samples to rationalize that from the whaling books. The water ways and other hatch beams were likely dark and for now gray is an easy option. More on this to come in my search. · Back to the whalers · The final 4 whale boats were able to get through the shaping stage efficiently. · Here I put in place the seat lift as provided in one of the kits to take a look. I choose not to use these seats and cut them all out. · Here I took the smaller lift and marked the bottom to help guiding the rough sanding · Now we need to get stems in place. I cut grooves bow and stern and cut out the pieces to glue in. Once the fit is right [ it took several ties] , I just made 14 more so I could get them on easily. · Here boat #1 is glued up and boat t#2 has the groove. working away cheers

-

Mike thanks for sharing a liking for whalers. I am having so much fun reading about them and the people and the historical impact on our new England maritime life. I look forward to seeing your Charles Morgan. My coming up build could be the Morgan, I couldn't resist the recent sail and I have it on the shelf. I will do an update tomorrow as I have made some more progress cheers

-

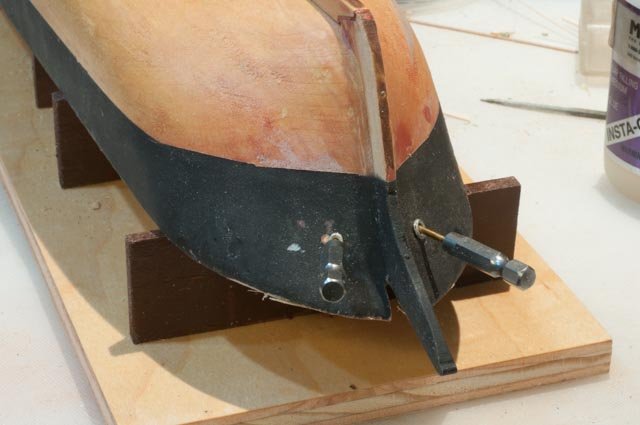

Some more progress, a few more issues and yes more fun. · I worked more to get the rough sanding of the outside of the first whale boat done. Now for the production. My newest shop tool is a great addition. This is a combination spindle and belt oscillating sander. One can order several grits and I did get finer for more critical future work as I am determined to enter the world of building frames. · Here we see the set up using the belt · For these little boats in just a few minutes of figure tip control I can roughly shape them · We then turn them over to the wireless Dremel small diameter sander for better control. Back to the two ships. We need to identify the water line and get a coat of black above and light poly below to support the eventual copper tape · I thought I was ingenious as I rigged up a POF frame from a schooner project of the past. A few calcs off the drawings and we are ready to go · Here we are where eventually we found a problem. On all past models I set them upside down and rigid. Here they are loose and swing on the string……let's see what happens · We have learned over the years that it’s all about the prep. Here we have used the glazing putty to fill in all the scratches and dimples inherent in the carved hull. After sanding with about 600 grit we are ready to prime · He we use the body filler primer from a local auto parts store. I love the flat gray.My friend uses it on his WWI navy boats with just clear coat Back to the whalers....It is time to start boats 5-8 while we read more about the full whaler in Ronnberg's book · Yes, the first steps go faster on boats 5-8 because it is only a few days ago that we learned how and not last year. I have learned the hard way that forgetfulness is a trait of our generation. cheers

-

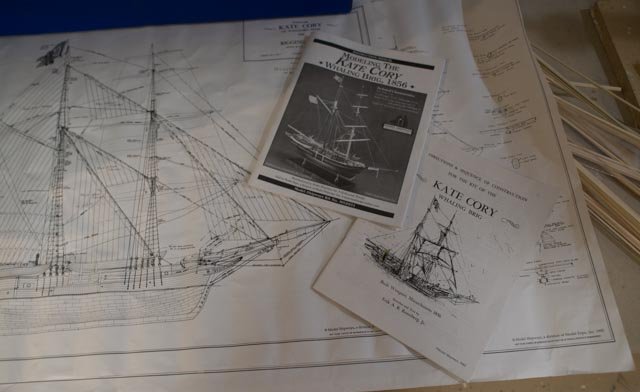

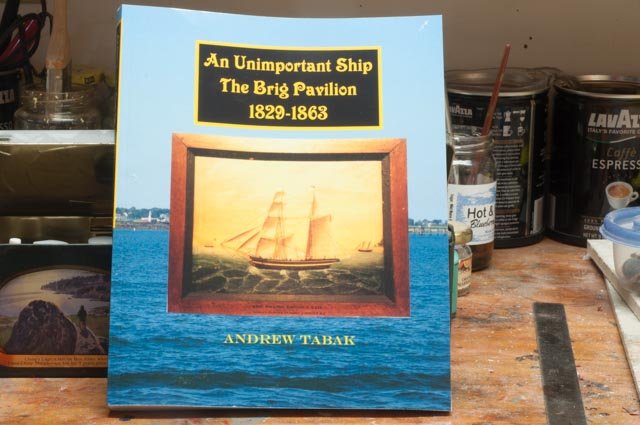

June 2022 edit Well it is time to sort this build out and make progress not noise. The ultimate plan has shifted further into the Boothbay, Maine vessel category. A few things to consider as I rationalize this change. I will do all that in the 18th posting below where I pick up the story. The short version is this build started as two sister whalers based on the kit Kate Cory. It will now be two Schooners bridging 1829 to 1902, both built in East Boothbay. please jump to post 18 below. if there is importance to the location of this log it might be moved based on the now 1829 selected date for the schooner version to best match the hull design. I will remove one of the hulls [ pavillion] from this log and add a second old schooner model in need of repair and retasking. This will make one old style schooner of 1830 February 2022. edit This edit including the change in name and update is to celebrate a final decision on what to do with this started project. Since working on general maritime history where whaling is clearly a big part, I have refocused my limited ability to the shipbuilding in our own Boothbay region of Maine. It is true that many Maine built vessels and seamen went to the whaling industry. In fairness I leave that to all the folks in that region. In my ongoing studies that will be parallel to the restart of this build will be study of the 32 brigs in Boothbay. This build will be planned to make the two brigs representative to two built here. I will identify the two later and plan to have them in a sailing pose. Parallel to that completion next winter, I will be planning a version of a brig on a scratch build. We shall either expand this log to cover all three or start another.....thoughts for another day. started project through 16 posts was to be . the new work will begin on planning over the summer as I complete another project, Dancing Feather. original log Two Whaling Brigs, Kate Cory and Pavilion KC Built: 1856 in Westport Point, MA Pav built in Ct and converted to a whaler in 1841 Length on Deck: KC 75 feet and Pav79 feet [ close enough at this scale] Models are model Shipway kits at 1:64 It has taken me a while to figure out what to do with two, yes, I have two, Kate Cory kits. During the last several years before I retired I would play each Christmas season on eBay and bid on Kits. Two times I won two bids for different versions of the same boat….oops I’ll share the other one in a few years when I move in that direction. What I got with those bids was one old 1994 version and one newer version with the 2007 instructions of Kate Cory. They have different parts provided and so far, and I found some missing wood. No big deal to me, as I have a good supply. The old paint kit came in one box. It was kind of sad, I’ll show it one day. One reason I got these kits is I have always had a plan to take a tangent into the world of whaling. That means considerable reading, some travel and yes building a few models. I am fascinated with the arctic and whaling is a big part of our New England experience up there. I plan to ultimately build a large cross section of one focusing on the process of rendering the oil. We’ll see where it goes. Now what to do with boat number two. I thought about rigging one as a schooner and the second as a brig, but the story seems to be that the schooner was not a successful rig for ocean whaling. In my early research I have found a book that tells the complete history of a 79-foot brig that first built as a merchant and then refit as a whaler. I bought the book and for now plan to see if yes that is hull two. I will start off as much of what is to build is affectively identical. Then other than the white strip and fake cannon ports see what could be different. I also have my other builds that all need work before next summer, so this is truly a squeezed in adventure. So let’s start out. I shall add in some of my research results as we carry on. This also my first down scale to 1:64 so I have some new skills to learn here too. · Here we see two books. As stated one was written in 1993 by Erik A R Ronnberg and the second 2007 by model shipways. The plans are the same. They seem fine for modeling at this stage though lack many details. I have read in other blogs that until recently the New Bedford Whaling Museum would sell the Erik Ronnberg multi sheet detailed plans and booklet that would be needed for anything larger or more detailed. I want to pursue them but so far, no success. I hope to visit the museum over the next few months. · Here is the book I bought giving a full life study into the 79-foot brig Pavilion. For now, I shall plan to try match up some colors from other brigs of the time [ though guessing at this point]. The picture on the cover shows the fake cannon deck and that is easy to include. This model is the first solid hull kit that I have built. For these early whaling kits I am focused more on what makes them whalers and how to work at smaller scale. I have so much to learn and it would take so long to build two hulls, that is why at this point I am happy to try it out. I was very impressed that after cutting out the patterns [ only available in one of the kits] I was to find that both hulls were pretty good. They advertise correctly that the bow and stern need work and that is true. They also advertise that cutting the bulkhead was to be the most difficult work. To be honest, now that I have done it [sort of], and now I see we are planking both plank shear and whales on the upper topsides, I would recommend cutting off the bulkheads and building them up in proper thickness. I will show you my compromise for this build in a bit. · Here the aft end is shaped up and one of the stern posts is set. I also drilled the hole through for the rudder post. · Here I completed one of the fit ups and added the rough masts and rudders to take a look see. Now to get going on those little whale boats. My Bluenose dories did not come out well and someday I need to rebuild them. First, I plan to go through whaling boats. With two KC’s and Charles Morgan followed by the big ¾ whale boat I should get there. As in previous builds, making one hundred turnbuckles, multiple spars etc I try to set up some form of production line. I do it not just to get through, but I assume by the last part I get the hang of the task. Here I have eight boats to make. I would think the 8th boat to be easier than the 1st. let’s see · Starting off both kits use the buildup lift method. My plan is to move through four boats one step at a time. Then as I get it figured out expand to all eight before I forget it. · Here we are making progress getting them set up; the insides are shaped using a wireless Dremel, file and sandpaper. I added some glazing putty as the fit up of the lifts inside was not great. I sanded again and put the bottoms on. I just started to rough sand the outside on the first boat. More on that process next time Cheers

-

Rich I am entering whaling as a whole new area. I plan to build a few kits to get the hang of it. Kate and a sister brig....you'll see what I mean... then the Charles Morgan and a large whale boat...3/4 scale I believe. I love the process of studying a real ship and Mystic is so much fun to visit. During these builds, at 1:64 scale, I hope to learn new skills...….. and following others advice I'll be working on more sailable boats like the BHOD one designs, my existing marbleheads etc. and a 3/4 scale schooner I never finished. The open question is what to scratch build …...a sailing whale ship model or a large cutaway showing the insides. As to making a sailing model, Kate Cory as a schooner would be easier at 1:24 but the more I am reading the Schooners were not really good for the process of whaling. I would love to figure out how best to rotate a foremast, so that is on the table. Also holding me back with KC is the better plans that used to be sold by Bedford museum are not easy to find. As to ship insides, I would love to build a POF version of something and then open it up. anyway it's all fun. I started to gather photos today and plan to get posting in a week or so. I also have the Halifax model on hold and more to do other models. cheers jon

- 109 replies

-

- model shipways

- kate cory

-

(and 1 more)

Tagged with:

-

I am envious of your trip to New Bedford museum. I went to Lunenburg twice while building Bluenose. I am in research mode now as I start my build of Kate Cory. I enjoy you log too. It is so important to see how others have interpreted the details. The plans are limited in details. I'll start my log soon Cheers Jon

- 109 replies

-

- model shipways

- kate cory

-

(and 1 more)

Tagged with:

-

David I want to watch too. I have a few projects ahead of this one and then want to build Kate Cory [ as a schooner] and then Charles Morgan. I loved visiting Mystic a few years back; there is so much information there to help figure out how everything works. cheers

- 145 replies

-

- model shipways

- charles w. morgan

-

(and 1 more)

Tagged with:

-

I want to update with the logistics I encountered in trying to be able to move this big model. I must say it was a bit of help from my skipper that solved the problem of movement. First up was to lay her down and add 2x2 over the sailing keel bolts. Looking at her I felt I could not show her half dressed. My daughter was here for a racing weekend , but we were fogged in. We took a rain day and she helped me complete rouging out the three top sails. We pinned them on and said "yes"... she goes with all sails in place even if they are pinned. My Skipper's son just happens to have a truck....it takes a village someone said With flashers going we drove one mile down to the Yacht club at 15-20 mph and made it.. The mainsail was flapping and flapping but held up. We got her inside where she stayed for a week. We gave a lecture one night on the racing history and modeling of Bluenose. lots of fun. We got her home and only one jib topsail sheet ripped. Last week we took her 2 miles further down to a boat yard on Southport Island to be displayed as part of the summer art festival. Again we had lots of fun. Now as we look in these views it is easy to see the need to replace the main and jumbo. winter is coming. Just like the Ironsides in Boston, she went out for a few trips in the harbor and when returned to the dockyard is reversed. the winter sun will shine to the starboard side this year. More importantly the port side is now exposed and ready for its ratlines and other work. cheers

-

Michael thanks for dropping in. my next post shows her as close the water as I fear she will get. I have gone too far both in construction and detail to sail this one. Moving her is also a challenge. cheers

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.